A109E Window Loss Highlights Maintenance Lessons

During a post-maintenance flight over Cornwall on 27 June 2019, of Leonardo A109E, G-ETPI, as the helicopter was accelerated towards 140 kt, there was a loud bang and a sudden increase in wind noise. The window transparency from the left cockpit door had separated.

The pilot was able to land the aircraft safely.

According to the Air Accidents Investigation Branch (AAIB) in their safety investigation report:

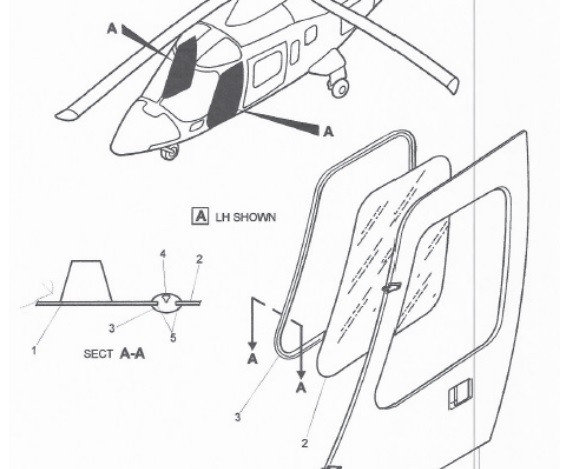

The A109E cockpit doors are of a composite construction and include a non-opening single acrylic window transparency…attached to the door by an extruded rubber seal channel.

The rubber seal has three separate grooves to accommodate the window, the door frame and a seal filler strip which locks the seal and window in place.

The Maintenance Manual requires that a thin layer of adhesive is applied to the seal channel during installation. During the previous maintenance the aircraft had been repainted…

…which necessitated the removal and disassembly of all cockpit and cabin doors and windows. These tasks were documented as a single item on a maintenance worksheet, which was signed-off by the certifying engineer on 21 March 2019.

Following completion of the helicopter base maintenance and repaint, the doors and windows were reassembled and refitted by an engineer. The worksheet did not record the date on which the task had been completed but indicated that it had been inspected and certified by the certifying engineer on 9 April 2019.

During examination of the window aperture afterwards it was not possible to confirm that adhesive had been used. The window and seal were never recovered so could not be examined.

The right cockpit door window was removed for inspection and this revealed the correct presence of adhesive in the grooves of the seal.

Inspection of the cabin windows confirmed adhesive had been used but “minimal squeeze-out”and so extra adhesive was applied. However:

The post-incident inspection and reinstallation of the cockpit door windows was undertaken by the same engineer and certifying engineer who had done the original window installation in April 2019.

The maintenance organisation carried out their own investigation, which only started after the post-incident inspection:

It identified that the engineer who installed the left cockpit door window had experienced some difficulty fitting the seal filler strip to the seal channel. The engineer had used a soapy solution to insert the filler strip but acknowledged during the investigation that the solution was applied liberally, such that it covered the window and the concentration of soap had been stronger than might normally be used.

The C537 adhesive specified in the A109E maintenance manual is a multi-purpose silicone adhesive/sealant which adheres to most surfaces and cures to form a tough flexible rubber.

A single 310 ml tube of adhesive was issued to G-ETPI during its original maintenance input. …a similar tube of adhesive with approximately 1 inch of adhesive remaining was found in the hangar. It was determined that this was the originally-issued tube of adhesive and that it had been used during the original and post-incident window installations on G-ETPI.

The maintenance organisation considered that, applied in correct quantity, the original and post-incident installation of all the cabin, cockpit and cockpit door windows would have required more adhesive than that which appeared to have been used. It would also have expected to see residual adhesive on the door frame.

The maintenance organisation’s investigators concluded that…

…little or no adhesive had been applied to the door side of the left cockpit door seal and that excessive use of an overly soapy solution to fit the seal filler strip had reduced the ability of the seal to retain the window due to friction alone.

[As] the helicopter’s ventilation system was set to maximum during the incident flight would have created a cabin pressure differential as the helicopter accelerated and this may have been a contributory factor. It believed the ram air effect of the ventilation system may have pushed the window outwards and caused the seal to roll off the door aperture, assisted by the lubricating effect of the soapy residue.

[They] also determined that the certifying engineer did not perform a staged inspection during the task to confirm the presence of adhesive prior to installation of the window and seal. This was based on a perception that the task was relatively simple and that the engineer performing the task was fully competent to perform it correctly.

[They] also identified that its procedures did not make it clear that maintenance tasks involving steps which cannot be visually inspected or otherwise verified upon final completion, should be subject to a staged inspection.

AAIB comment that:

The A109E maintenance manual indicates that a small brush should be used to apply a soapy solution within the grooves of the seal filler channel. This suggests the need for precise application…

While the maintenance manual does not specify the concentration of soap to be used, other engineers in the maintenance organisation, indicated that one would normally use water with a light concentration of soap.

In the 11 weeks had elapsed between installation of the window and the incident, the water would likely have evaporated leaving a soapy residue. This may have acted as a lubricant, which in combination with the absence of adhesive allowed the window to separate from the cockpit door.

AAIB also state that:

Reduced supervisory oversight by the certifying engineer, based on their evaluation of both the task and staff competence, meant that stage checks were not conducted throughout the window installation task. Such checks may have identified and addressed the difficulties that the engineer experienced while installing the windows and/or the absence of adhesive on some of the window seals.

The fact that the same engineers undertook the same task, on the same aircraft could have adversely affected their recollections of the original installation, when interviewed during the subsequent safety investigation. This may have affected the quality of information available to the investigation.

Safety Actions

The maintenance organisation has added window replacement to their list of Critical Maintenance Tasks. They are changing their Emergency Response Plan so that maintenance personnel involved in maintaining an aircraft are not involved in the response to an associated incident with that aircraft and they have…

…introduced a new production planning tool across all its maintenance bases to control and monitor to allocation of manpower, including supervisory staff, to aircraft undergoing base maintenance.

Safety Resources

Aerossurance has previously written on these associated topics:

- Airworthiness Matters: Next Generation Maintenance Human Factors Over the last 10-15 years, much attention has been focused on maintenance human factors training and reporting & investigating errors. While we could concentrate on simply doing more of these and certainly can find ways to do these things better, perhaps the next generation approach needs to include a much wider range of activities.

- Aircraft Maintenance: Going for Gold? Should we start treating maintenance personnel more like athletes who need to achieve peak performance every day?

- Safety Performance Listening and Learning – AEROSPACE March 2017

- James Reason’s 12 Principles of Error Management

- Back to the Future: Error Management

- Critical Maintenance Tasks: EASA Part-M & -145 Change

- B1900D Emergency Landing: Maintenance Standards & Practices

- B747 Landing Gear Failure Due to Omission of Rig Pin During Maintenance

- When Down Is Up: 747 Actuator Installation Incident

- Lost in Translation: Misrigged Main Landing Gear

- Maintenance Human Factors in Finnish F406 Landing Gear Collapse

- Hoist Assembly Errors: SAR Personnel Dropped Into Sea

- Fire After O-Ring Nipped on Installation

- Crossed Cables: Colgan Air B1900D N240CJ Maintenance Error

- A Lufthansa MD-11F Nose Wheel Detached after Maintenance Error

- Inadequate Maintenance, An Engine Failure and Mishandling: Crash of a USAF WC-130H

- USAF Engine Shop in “Disarray” with a “Method of the Madness”: F-16CM Engine Fire

- Inadequate Maintenance at a USAF Depot Featured in Fatal USMC KC-130T Accident

- Meeting Your Waterloo: Competence Assessment and Remembering the Lessons of Past Accidents

- AS350B2 Accident After Vibration from Unrecorded Maintenance

- Maintenance Misdiagnosis Precursor to Tail Rotor Control Failure

- Contaminated Oxygen on ‘Air Force One’

- Tree Top Autorotation for B206L1 After Loose Fuel Line B-Nut Leaks

- FAA Rules Applied: So Misrigged Flying Controls Undetected

- Loose Engine B-Nut Triggers Fatal Forced Landing

- Glider Controls Fail After Non Compliant Maintenance Embodying an AD

- ATR72 VH-FVR Missed Damage: Maintenance Lessons

- ‘Crazy’ KC-10 Boom Loss: Informal Maintenance Shift Handovers and Skipped Tasks

- Dash 8 Q400 Return to Base After Pitot System Contaminated By Unapproved Test Kit Lubricant

- Luftwaffe VVIP Global 5000 Written Off After Flying Control Assembly Error

- UPDATE 7 February 2020: S-61N Damaged During Take Off When Swashplate Seized Due to Corrosion

Aerossurance worked with the Flight Safety Foundation (FSF) to create a Maintenance Observation Program (MOP) requirement for their contractible BARSOHO offshore helicopter Safety Performance Requirements to help learning about routine maintenance and then to initiate safety improvements:

Aerossurance can provide practice guidance and specialist support to successfully implement a MOP.

Recent Comments