AW169 Update

Launched at Farnborough International 2010, the 4.5t AgustaWestland AW169 is progressing towards certification and entry-into-service which AW describes as being “in a few months’ time”. Currently orders for nearly 150 AW169’s have been placed by customers for a range of applications including corporate transport, air ambulance and law enforcement.

Flight Test

The four AW169 prototypes performed their maiden flights in May 2012, July 2012, November 2012 and January 2013 respectively.

Certification had been expected in late 2014. As inevitable with new designs changes have been made during development flying. According to Flight International in October 2013:

…modifications to the flight-test aircraft include the addition of a pair of fairings atop the engine cover aft of the main rotor mast. One of them – dubbed the “horse’s collar” – runs along the edge of the cover, while the second, a comb-shaped component, sits immediately aft of the mast. The fairings are designed to prevent tail shake through changing the path of the rotor wash. The exhaust ports have additionally been turned outboard by 10˚ to prevent overheating of a section of the AW169’s composite tail boom. This temperature anomaly manifested itself on the port side of the tail during lateral flights or with crosswinds in hot conditions, says the manufacturer.

The third prototype, I-AWCG, was on show at the HAI Heli-Expo in Orlando in March 2015. It had arrived from Alaska where it had been undergoing cold weather trials.

I-AWCG was put on show still with extensive flight test instrumentation (FTI). For example the tail boom was heavily strain gauged.

Family

AW are marketing the AW169, powered by two Pratt & Whitney Canada PW210A 1100shp turboshafts, as the smallest of a ‘family’ of similar designs, alongside the popular AW139 (now certified at 7t and with over 700 in service) and the 8.6t AW189, certified in 2014. AW claim the trio “share the same common cockpit concept and design philosophy”. https://www.youtube.com/watch?feature=player_detailpage&v=Jmdq7Pvf_CE The AW169 features three 10×8 inch Rockwell Collins displays with touchscreen controls. AW selected Rockwell Collins’ Helisure system in 2013 for a number of their product lines.

Production

AW169s will be produced both at Vergiate, Italy and at Philadelphia, Pennsylvania. The company’s Yeovil, UK plant is manufacturing a number of critical sub-assemblies for the AW169.

Training

On 31 March 2015, AgustaWestland announced the first AW169 Flight Training Device (FTD) had been certified. The certification, by a joint European Aviation Safety Agency (EASA) and Italian Civil Aviation Authority (ENAC) team, is to FTD Level 2 as per CS-FSTD(H), the EASA certification specification for Helicopter Flight Simulation Training Devices. This AW169 FTD at AW’s Marchetti Training Academy in Sesto Calende, Italy, has been designed and built by AW and operated by Rotorsim, a joint venture between CAE and AW.  AW say that:

AW say that:

The AW169 FTD features an AgustaWestland developed flight dynamic model, avionics and aircraft software modelling, and a high performance visual system with 150 degree by 60 degree field-of-view 12 ft (3.66 m) dome display system. The FTD will provide effective training for pilots in the use of automated flight data systems and various flight procedures including situational awareness and decision making under normal, abnormal and emergency conditions. This device will allow for credits for IFR Training and for the majority of malfunctions and emergency scenarios.

Roles

In the offshore role the aircraft has a D-value of 14.7m, which puts it between the AS365/EC155 and the S-76. The most likely offshore seating fit is an 8 seat cabin, with a large, accessible push-out window for every 2 passengers. A more constrained forward facing configuration of 4 + 4 +2 layout is also offered. The cabin volume is larger than an S-76D (6.5 m3 vs 5.8 m3) with a larger baggage bay too (1.4 m3 vs 1.1 m3).

In the VIP and EMS role, the Mecaer Aviation Group, who have facilities alongside the Italian and US production lines, is offering a number of AW169 cabin options.

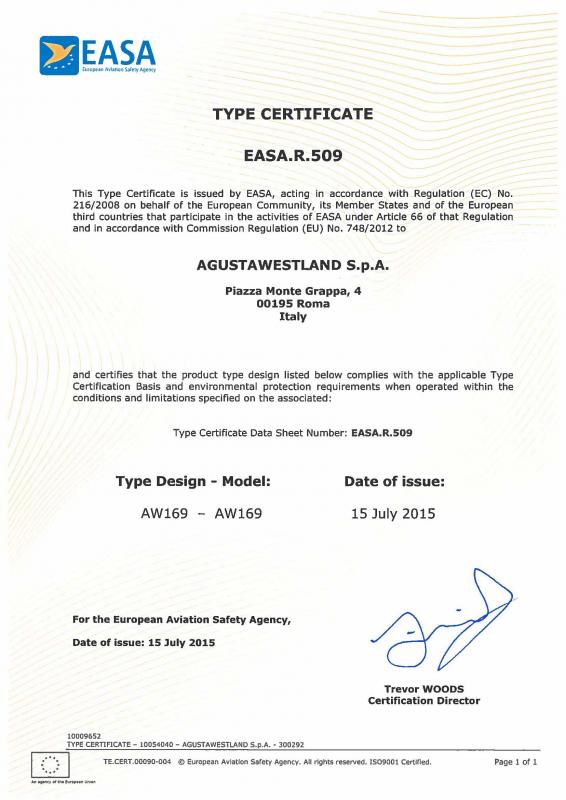

UPDATE 15 July 2015: EASA has issued the Type Certificate for the AW169:

Aerossurance has previously looked at other members of the AW ‘family’:

- AW139 Global Fleet Passes 1 Million Hour Milestone

- The Rise of the ‘Super Mediums’: EC175 & AW189

- AW189 Progress

- Heli-Expo 2015 Photo Report

- Heli-Expo 2015 ‘Super Medium’ Photo Report

UPDATE 26 August 2016: The first AW169 for use supporting wind farms has been delivered to Emden based HeliService International GmbH. The aircraft, ordered in October 2015 and leased from LCI, will be used to support the giant Siemens Gemini wind energy project, winching maintenance personnel onto the wind turbines.

https://youtu.be/RYgq739wVD8

UPDATE 26 September 2016: Airlift AS, an NHV company, has been awarded a contract to three AW169s for transporting Norwegian marine pilots for the Norwegian Coastal Administration (NCA). The 6 year contract commences on 1 July 2017, with an option for a two year extension.

UPDATE 12 October 2016: Helitech Orders Underscore AW169 EMS Credentials

UPDATE 22 November 2016: EASA certified a MTOW extension to 4.8t on 31 October 2016.

The manufacturer says the additional 200kg is “extra payload” and translates to a range extension of 100nm (185km) if used for extra fuel.

A retrofit kit is available for existing aircraft.

UPDATE 23 May 2018: Pilot Review: Leonardo AW169

First AW169 air accident: G-VSKP, Leicester, 27 October 2018

UPDATE 27 October 2018: The first AW169 accident occurred today, in the UK. G-VSKP (MSN 69018), owned by the same owners as Leicester City Football Club, crashed on take off from their ground, the King Power Stadium. The helicopter had climbed to c200ft before transitioning forward when it reportedly yawed and lost height. The helicopter came to rest on its right hand side and a post impact fire occurred. According to the UK CAA the aircraft was delivered on 20 July 2016 and had flown 283 hours as of the end of June 2018.

UPDATE 28 October 2018: All 5 persons on board are confirmed to have died in the G-VSKP accident. Among the dead was LCFC Chairman and owner Vichai Srivaddhanaprabha.

UPDATE 29 October 2018: The UK Air Accidents Investigation Branch (AAIB) have confirmed they have recovered the combined CVR / FDR from G-VSKP.

Today, our inspectors in Farnborough will start working on the recorder, which was subject to intense heat as a result of the post-accident fire.

We have inspectors here [at the accident site] from all four air accident investigation disciplines: engineering, operations, flight data and human factors.

Our inspectors are continuing to work with the police on site. We expect to be here until the end of the week, at which point we will transport the wreckage to our specialist facilities in Farnborough for more detailed examination. In the meantime, we are still gathering evidence as part of our investigation.

Dramatic CCTV footage emerges.

A company called Foxborough is listed as the AW169’s owner, with Surrey-based Amadeus Aviation the operator.

UPDATE 30 October 2018: Further footage emerges from within the stadium.

https://youtu.be/sS–OX-LPNU?t=4

UPDATE 2 November 2018: AAIB confirm that:

The wreckage has now arrived at our specialist facility in Farnborough, where it will be laid out and more detailed examination can continue.

The digital flight recorder is in our laboratory. Although subject to intense heat in the post-accident fire, initial work on it has allowed us to successfully download the recordings. Our inspectors are verifying the extracted information and have started the detailed analysis of its contents.

We would like to thank everyone who responded to our witness appeal. Our investigators are examining the videos and photographs we have received.

Leonardo AW169 G-VSKP on 13 July 2016 at Gloucestershire Airport (Credit: James, CC:by-sa)

UPDATE 6 November 2018: Flight Global report that Leonardo have issued an Alert Service Bulletin (ASB 169-120):

Unverified text of the service bulletin circulating on social media calls for an urgent check to ensure a specific component – the tail rotor servo-actuator feedback lever installation and interface – has been installed properly and is functioning correctly.

“Incorrect installation may lead to loss of tail rotor control which, depending on the flight condition, could lead to loss of control of the aircraft,” the bulletin warns.

A Coroner’s Inquest was also opened and adjourned.

UPDATE 7 November 2018: EASA issue an Emergency AD (EAD) on the AW169 and AW189 (our emphasis added):

An accident occurred on an AW169 helicopter, the root cause of which has not been identified and the technical investigation is still ongoing. While the helicopter was on a take-off phase at low forward speed, a loss of yaw control has been observed. As a precautionary measure, Leonardo issued ASB 169-120 for AW169 helicopters to provide inspection instructions to check correct installation of the tail rotor (TR) servo-actuator and, subsequently, ASB 189-213 with the same instructions for AW189 helicopters, since these have a TR flight control system of similar design to AW169 helicopters.

…any hypothesis on the cause of the accident is premature at this time and the AAIB investigation continues.

UPDATE 14 November 2018: AAIB Special Bulletin S1/2018 on Agusta AW169, G-VSKP

The cause of the apparent loss of yaw control has yet to be determined. Investigation of the tail rotor control system is being carried out as a priority.

UPDATE 19 November 2018: EASA have issued a new EAD that goes beyond the previous Leonardo ASB / EASA EAD and adds a tail rotor duplex bearing inspection.

UPDATE 3 December 2018: Following the last AD, new ASBs have now been issued and are referenced in a revised EAD.

…this AD requires repetitive inspections of the TR servo actuator’s back-end castellated nut slippage marking, and of the roughness and breakaway force of the TR duplex bearing…

UPDATE 6 December 2018: AAIB Special Bulletin S2/2018 on Agusta AW169, G-VSKP

The evidence gathered to date shows that the loss of control of the helicopter resulted from the tail rotor actuator control shaft becoming disconnected from the actuator lever mechanism. Disconnection of the control shaft from the lever prevented the feedback mechanism for the tail rotor actuator from operating and the tail rotor actuator from responding to yaw control inputs. Loss of the feedback mechanism rendered the yaw stops ineffective, allowing the tail rotor actuator to continue changing the pitch of the tail rotor blades until they reached the physical limit of their travel. This resulted in an uncontrollable right yaw.

Sufficient force and torque had been applied to the castellated nut on the actuator end of the control shaft to friction weld it to the pin carrier and to shear the installed split pin. The observed condition of the duplex bearing and the increased torque load on the castellated nut that remained on the spider end of the shaft is consistent with rotation of the tail rotor actuator control shaft. Whilst the shaft was rotating and a yaw control input was applied, the shaft “unscrewed” from the nut, disconnecting the shaft from the actuator lever mechanism, and causing the nut to become welded to the pin carrier.

The initiating cause and exact sequence of the failure that resulted in the loss of tail rotor control is being investigated as a priority. Work continues to identify the cause of the damage observed to the duplex bearing and to establish its contribution to the failure sequence.

UPDATE 1 February 2019: Two new EASA ADs were issued:

- AW139/169/189: AD 2019-0022 Duplex bearings batch replacement

- AW169/189 only: AD 2019-0023 thermal sticker / repeat inspection

UPDATE 27 December 2019: Leonardo delivered its 100th AW169 to Specialist Aviation Services for Cornwall Air Ambulance at Leonardo’s plant in Vergiate on 12 December 2019.

Recent Comments