Beech 99A MLG Collapse (N326CA, Alpine Air)

On 19 January 2017 Beech 99A N326CA of Alpine Air experienced a landing gear collapse on landing at the Billings Logan International Airport (BIL), Montana while making a Part 135 cargo flight. The pilot was uninjured.

According to the US National Transportation Safety Board (NTSB) safety investigation report (released 13 April 2020), after take off from BIL the pilot retracted the landing gear and heard a ‘thud’. The Main Landing Gear (MLG) ‘unsafe’ light illuminated, and the left MLG light remained green, indicating that it was still extended.

The pilot returned to BIL and just before touch down, feathered the propellers and decreased the airspeed. During touchdown, the right MLG collapsed. This caused substantial damage to the right aileron and right wing spar.

The NTSB say:

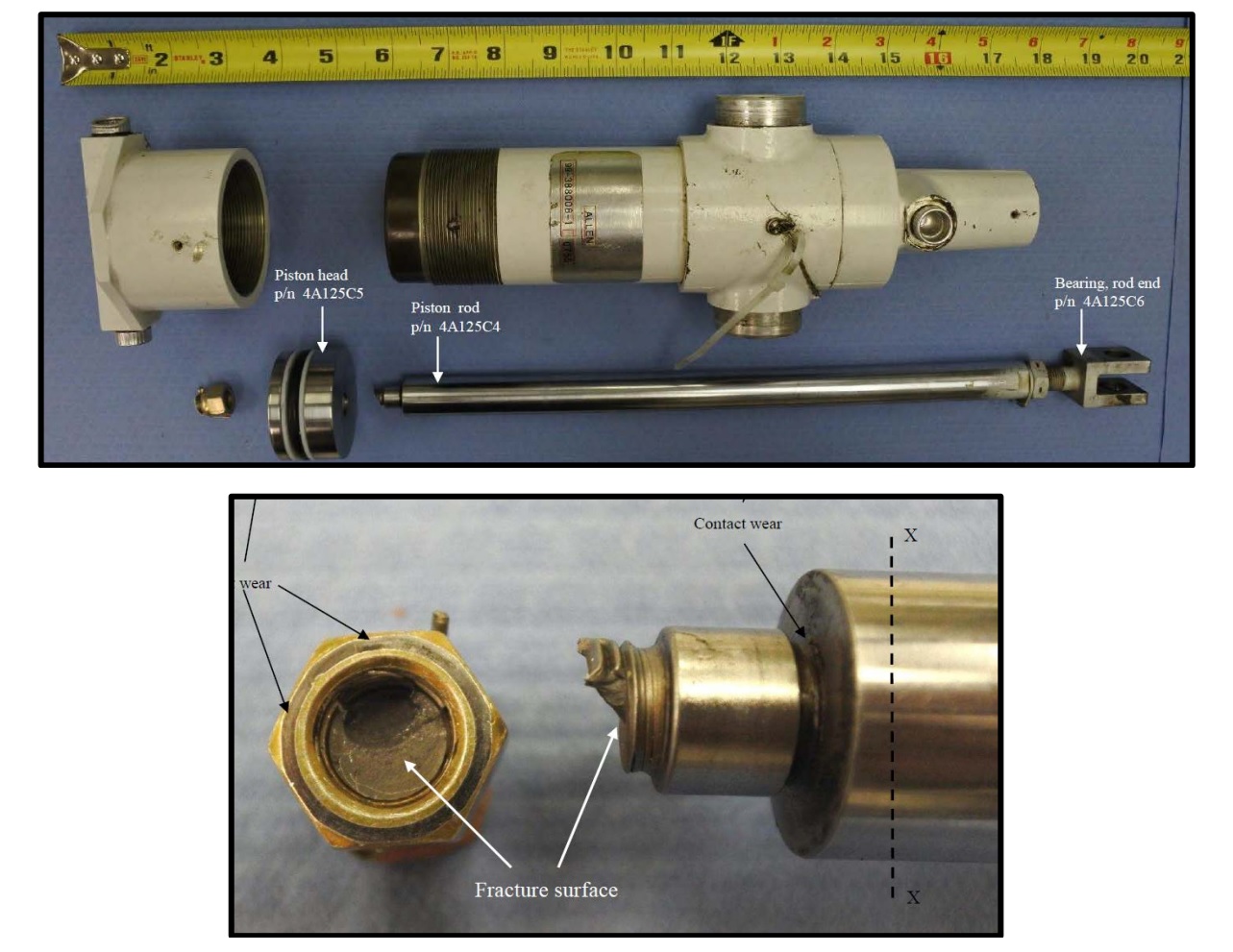

During the post-accident examination of the landing gear, the left MLG actuator’s piston rod was found fractured.

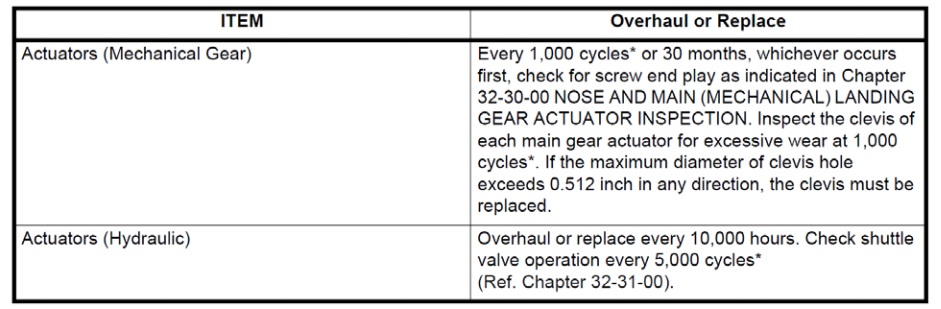

Metallurgical examination of the piston rod revealed that the rod had failed in its threaded section due to fatigue cracking over about 60% of the cross-section. Contact wear was observed on the faying surface of the retaining nut and piston head and the shoulder of the piston rod.

These signatures were consistent with the nut not being tight enough to mitigate sliding of the piston head relative to the piston rod and retaining nut.

Surprisingly:

It could not be determined if the manufacturer required a specific torque to be applied to the nut during assembly.

The 1970 made aircraft had accumulated 46,416.3 flying hours. The left actuator was last overhauled in November 2001, at which time the piston rod was replaced. The part had 7,445.2 hours and 8,267 cycles since overhaul. The landing gear hydraulic actuators need to be overhauled or replaced every 10,000 hours.

The NTSB concluded:

Based on the evidence, it is likely that inadequate torque on the nut reduced the preload on the threaded section of the piston rod and contributed to premature fatigue crack propagation in the rod and its eventual failure.

The failure of the piston rod allowed hydraulic fluid to pass freely from the down-side to the up-side of the piston, which prevented the hydraulic system from producing pressure to control the MLG’s position.

Safety Resources

- Eclipse 500 Landing Gear Production Defect

- Significant Twin Otter NLG Crack

- “Shoulda gone around”: B727 Landing with NLG Retracted

- Poor Painting Prevents Proper Performance: Shorts Sherpa NLG Collapse

- B1900D Emergency Landing: Maintenance Standards & Practices

- A Lufthansa MD-11F Nose Wheel Detached after Maintenance Error

- ATR72 VH-FVR Missed Damage: Maintenance Lessons

- B747 Landing Gear Failure Due to Omission of Rig Pin During Maintenance

- When Down Is Up: 747 Actuator Installation Incident

- Lost in Translation: Misrigged Main Landing Gear

- Maintenance Human Factors in Finnish F406 Landing Gear Collapse

- S-92A Nose Landing Gear Incidents

- UPDATE 3 June 2020: Beechcraft 1900C Landing Gear Collapse at San Antonio, TX

- UPDATE 12 October 2020: Frozen Dash 8-100 Landing Gear After ‘Improper Maintenance Practices’ Say NTSB

Recent Comments