Inadvertent Fire Bottle Discharge During Maintenance

The CHIRP Charitable Trust, who run the UK’s Confidential Human Factors Incident Reporting Programme, has reported on an inadvertent fire bottle discharge incident during maintenance in their Air Transport FEEDBACK Issue 113.

The Aircraft was on a heavy maintenance input and several teams were busy working in the flight deck area. Three tasks were being worked simultaneously. Two engineers were assigned to the task of checking the APU [Auxiliary Power Unit] fire bottle squib circuit test. Engineer A, who was in the flight deck, believed that engineer B had disconnected the squib and was set-up to perform the check. Engineer A pulled the fire handle and fired the APU fire bottle which discharged.

Engineer B indicated that he did not have the task sheet available as Engineer A had them, despite the fact that one was working in the flight deck the other was at the tail area. There were six people on the intercom system and the flight deck was very busy with a number of activities taking place simultaneously, this resulted in avoidable distractions and poor communication.

CHIRP provide the following analysis:

Distractions – The engineer lost his train of thought at important stages of the work due to numerous people on the intercom system.

Organisational Factors – The company identified that the method of operation (when performing function checks at the end of the check) was not an isolated one and that there was some degree of this being the accepted norm.

CHIRP go on to comment:

This event highlights some routine HF [Human Factors] related problems. As well as looking at the individual HF errors, the organisation involved has taken steps to ensure there is a more co-ordinated approach to carrying out checks and functions. This applies particularly at busy times – typically towards the end of the maintenance input.

While this is an easy mistake to make, it can serve as a lesson to ensure we have put processes and communications in place when carrying out function checks.

Safety Resources

Aerossurance has previously written about Professor James Reason’s 12 Principles of Error Management.

UPDATE 8 April 2020: NTSB Confirms United Airlines Maintenance Error After 12 Years

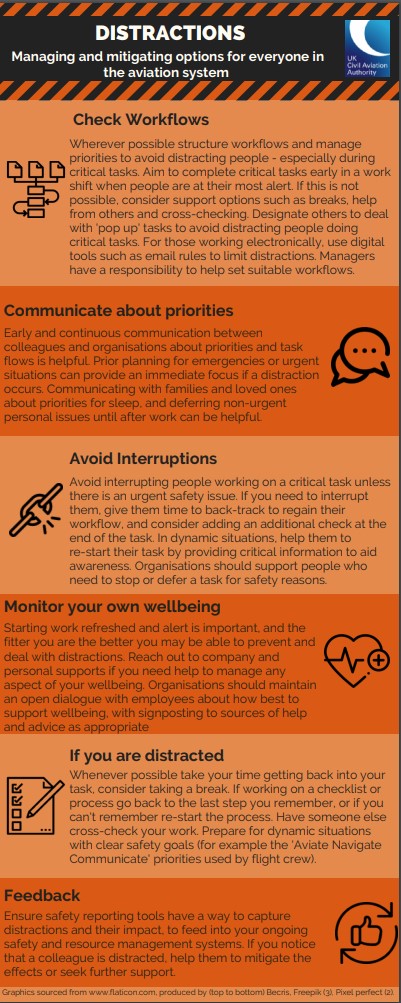

The UK CAA has issued this infographic on distractions:

For support on maintenance human factors, preventing maintenance errors and improving maintenance performance you can trust, contact aviation consultancy Aerossurance: enquiries@aerossurance.com

Follow us on LinkedIn and on Twitter @Aerossurance for our latest updates.

Recent Comments