Inadequately Secured Cargo Caused B747F Crash at Bagram, Afghanistan

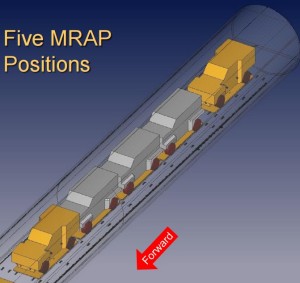

The US National Transportation Safety Board (NTSB) has determined that a National Airlines Boeing 747 Freighter N949CA that crashed on take-off on 29 April 2013 did so because the five armoured military vehicles (2x12t and 3x18t) on-board were inadequately restrained.

As the NTSB explain:

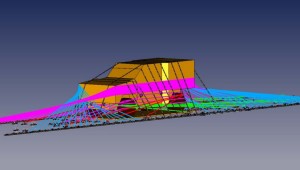

These vehicles were considered a special cargo load because they could not be placed in unit load devices (ULDs) and restrained…using the…main deck cargo handling system. Instead, the vehicles were secured to centerline-loaded floating pallets and restrained to the airplane’s main deck using tie-down straps.

The rearmost vehicle moved rearward into the rear pressure bulkhead, crippling two hydraulic systems and damaging horizontal stabilizer components. This rendered the airplane uncontrollable. All seven crewmembers were killed in the accident on 29 April 2013 at Bagram, Kabul, Afghanistan. The aircraft was on charter to the US Air Mobility Command.

As they describe in their press release, NTSB Finds Damage From Inadequately Secured Cargo Caused Boeing 747 Crash in Bagram, Afghanistan:

Contributing to the accident was the Federal Aviation Administration’s inadequate oversight of National Airlines’ (NAL’s) handling of special cargo loads, such as that being carried on the accident flight. The Boeing 747-400 freighter was carrying five mine-resistant ambush-protected (MRAP) vehicles. There was no evidence found to suggest that the airplane was brought down by an explosive device or hostile acts.

The investigation found that National Airlines’ cargo operations manual not only omitted critical information from Boeing and from the cargo handling system manufacturer about properly securing cargo, but it also contained incorrect restraining methods for special cargo loads.

The Board recommended that the FAA create a certification process for personnel responsible for the loading, restraint, and documentation of special cargo loads on transport-category airplanes. Other recommendations call on the FAA to improve its ability to inspect cargo aircraft operations, specifically those involving special cargo loads.

Three points that we thought noticeable during the Board Meeting and the staff presentations were:

- Boeing’s analysis was that loading of only one vehicle was permissible (and then one of the smaller vehicles) because of the space needed to fit longitudinal securing straps (see illustration below), and they would have used 60 straps not the 24 used by National.

- The loadmaster had been on duty for 21 hours at the time of the accident.

- The load had been found to have shifted during the short flight from Camp Bastion in Helmand province to Kabul for fuel. However, apart from retightening and adding just two more straps, it appears little was done before the next sector.

To view the findings, and recommendations, click on the following link: http://go.usa.gov/3fHTS or by looking in the public docket.

The National Transportation Safety Board determines that the probable cause of this accident was National Airlines’ inadequate procedures for restraining special cargo loads, which resulted in the loadmaster’s improper restraint of the cargo, which moved aft and damaged hydraulic systems Nos. 1 and 2 and horizontal stabilizer drive mechanism components, rendering the airplane uncontrollable. Contributing to the accident was the Federal Aviation Administration’s inadequate oversight of National Airlines’ handling of special cargo loads.

The NTSB have now made the presentations and opening / closing remarks available:

- Opening Statement – Chairman Christopher A. Hart

- Opening Statement– Investigator in Charge

- Aircraft Structures

- Operational Issues

- Closing Statement – Chairman Christopher A. Hart

UPDATE 22 July 2015: NTSB Board Member Robert Sumwalt gave a presentation on cargo safety (including discussion of this accident) to the Airline Pilots Association (ALPA) Air Safety Forum.

UPDATE 2 September 2016: The FAA Civil Aerospace Medical Institute (CAMI) have issued report DOT/FAA/AM-16/6:

Evaluation of Fatigue and Responsibilities of Cargo Supervisors and Flight Mechanic Cargo Supervisors (abstract / report):

In response to an open National Transportation Safety Board (NTSB) recommendation (2016; A-15-014) and at the request of the Federal Aviation Administration’s (FAA’s) Aircraft Maintenance Division (ASF-300), a study was conducted to document the current rest and fatigue status of cargo load supervisors as well as collect information regarding the perceived responsibilities of load supervisors while performing regular duties.

A total of four organizations agreed to have researchers observe daily cargo operations and recruit participants for each of the three studies: (a) a general fatigue survey, (b) a 14-day field study, and (c) a twohour interview.

Findings supported previous research on fatigue risk in shift workers and indicated that load supervisors were at risk of fatigue on all seven primary and contributing factors of fatigue: Time of day, Time awake, Time on task, Time asleep, Adequate sleep, Work schedule factors, and Cumulative sleep debt.

Night shift load supervisors exhibited a greater risk of fatigue than their day shift counterparts. Interviews revealed that load supervisors perceived a majority of their responsibilities to be shared with cargo personnel, as opposed to holding sole responsibility. Recommendations include fatigue awareness training, monitoring of load supervisor duty/rest times inclusive of overtime, the use of Safety Management Systems (SMS) and Fatigue Risk Management Systems (FRMS) to reduce risk, and having clearly defined roles and responsibilities for load supervisor duties.

UPDATE 19 September 2016: National Airlines needs US safety rule exemption to fly more oversize cargo

UPDATE 17 March 2017: Almost 4 years after the accident at Bagram the FAA’s Cargo Focus Team (CFT) has identified safety concerns and operational compliance issues during its review of Part 121 air carrier’s Weight and Balance Program, resulting in issue of a Safety Alert for Operators (SAFO): SAFO 17003 Non-compliance with a Manufacturer’s Federal Aviation Administration (FAA)-approved Aircraft Weight and Balance Manual (WBM)

Among the CFT findings are that:

[Some] Air carriers have developed their own WBP, which allows for restraint methods that are not approved. These unapproved restraint methods are contrary to the aircraft’s FAA-approved flight manual limitations and may exceed the aircraft structural design capability. Air carriers are not permitted to use any cargo restraint methods that are not specifically approved in the [Design Oerganisation’s Weight and Balance Manual] WBM or WBM supplement.

Other issues of concern identified…included a lack of documentation of the aircraft’s current cargo loading system (CLS). Due to the installation and removal of multiple STCs over time, the cargo configuration of some aircraft could not be determined. In some isolated cases, air carriers have developed procedures for aircraft loading that exceeds the structural design capability of the aircraft. Exceeding this capability can lead to catastrophic failure of the aircraft.

Recommended Action: Air carriers should review their WBM and cargo loading documents to validate adherence to the manufacturer’s FAA-approved WBM or STC WBM supplement for each aircraft on their Operations Specifications. The air carrier may contact the design approval holder to obtain the WBM.

UPDATE 13 July 2017: A has returned a verdict in favor of the families of three of seven crew members.

The plaintiffs sued National Air Cargo, Inc., an affiliated company of National Airlines, which through the employees of its regional office in the Middle East, planned, loaded and restrained five Mine Resistant Armor Protected (“MRAP”) vehicles…

The jury awarded the estate of Captain Brad Hasler a total of $47.25 million in damages. The estate of First Officer Jamie Brokaw was awarded $43 million, and the estate of Captain Jeremy Lipka, an off-duty pilot in the cockpit, was awarded $25.5 million. Each of these awards included an amount of $5 million for the shock and fright each of the men experienced from the time of takeoff until the time of the airplane’s impact with the ground.

Trials in the cases for the remaining four crew members are expected to be set shortly.

Extra Resources

We have covered other loading events:

- Misloading Caused Fatal 2013 DHC-3 Accident

- Culture + Non Compliance + Mechanical Failures = DC3 Accident

- Wait to Weight & Balance – Lessons from a Loss of Control

- The Passengers Who Caused a 737 Tail Strike: Ground Handling Lessons

Australian Transport Safety Bureau (ATSB) report Aircraft loading occurrences July 2003 to June 2010

A previous NTSB investigation into the loss of Fine Air Douglas DC-8-61 cargo aircraft N27UA on 7 August 1997 at Miami is also worth examination. Safety issues discussed subsequently by the NTSB include the effects of improper cargo loading on aircraft performance and handling, operator oversight of cargo loading and training of cargo loading personnel, the loss of critical flight data recorder information, and FAA surveillance of cargo carrier operations.

The National Transportation Safety Board determines that the probable cause of the accident, which resulted from the airplane being misloaded to produce a more aft center of gravity and a correspondingly incorrect stabilizer trim setting that precipitated an extreme pitch-up at rotation, was (1) the failure of Fine Air to exercise operational control over the cargo loading process; and (2) the failure of Aeromar to load the airplane as specified by Fine Air. Contributing to the accident was the failure of the Federal Aviation Administration (FAA) to adequately monitor Fine Air’s operational control responsibilities for cargo loading and the failure of the FAA to ensure that known cargo-related deficiencies were corrected at Fine Air.

UPDATE 13 April 2020: Inadequately Secured Pallets Penetrate the Rear Pressure Bulkhead of a Cargo B737

Aerossurance is pleased to be supporting the annual Chartered Institute of Ergonomics & Human Factors’ (CIEHF) Human Factors in Aviation Safety Conference for the third year running. We will be presenting for the second year running too. This year the conference takes place 13 to 14 November 2017 at the Hilton London Gatwick Airport, UK with the theme: How do we improve human performance in today’s aviation business?

Recent Comments