Jetstar Boeing 787-8 VH-VKJ General Electric GEnx-1B Engine Biocide Serious Incident near Kansai

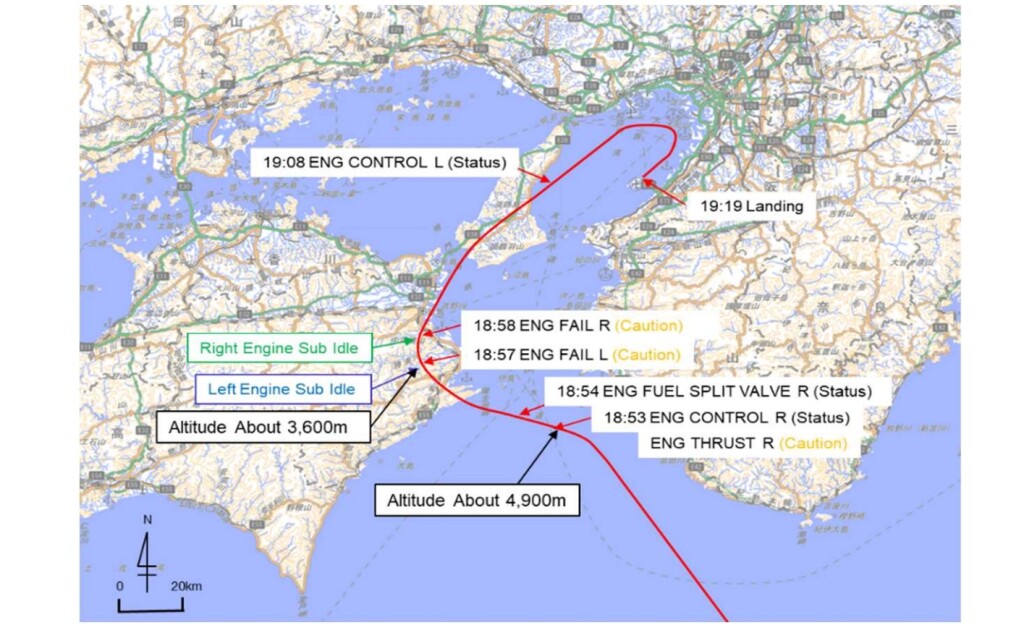

On 29 March 2019 the No 1 General Electric GEnx-1B engine of Jetstar Airways Boeing 787-8 VH-VKJ, flying from Cairns, Australia to Osaka Kansai International, Japan, fell below idle during the descent at an altitude of about 16,000 ft for 8 seconds. The No 2 engine then fell below idle too for 81 seconds. The aircraft safely landed at Kansai International less than 30 minutes later.

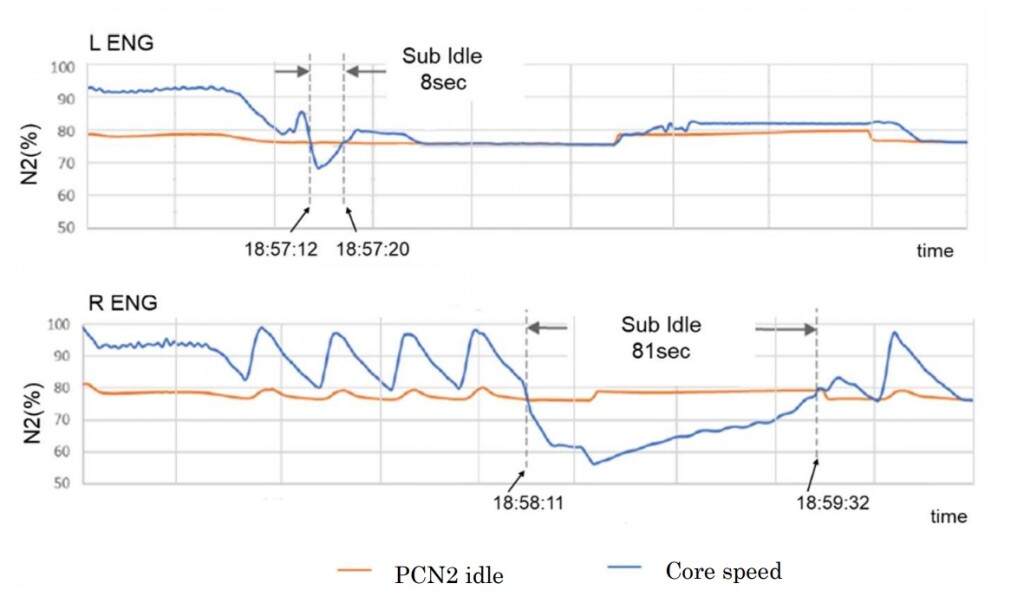

The Japan Transport Safety Board (JTSB) explain in their safety investigation report (issued 25 June 2020) that engine rpm oscillations had been recorded during the incident.

Jetstar Airways Boeing 787-8 VH-VKJ GEnx-1B Engine Speed Oscillations for No1/Left and No2/Right (Credit: JTSB)

In fact oscillations had been recorded by the FDR since a fuel biocide treatment had occurred on 27 March 2019. However, these oscillations had been so small as not to have been noticed until the descent on 29 March 2019 when “ENG FAIL L” and “ENG FAIL R” EICAS messages also appeared. During the subsequent investigation…

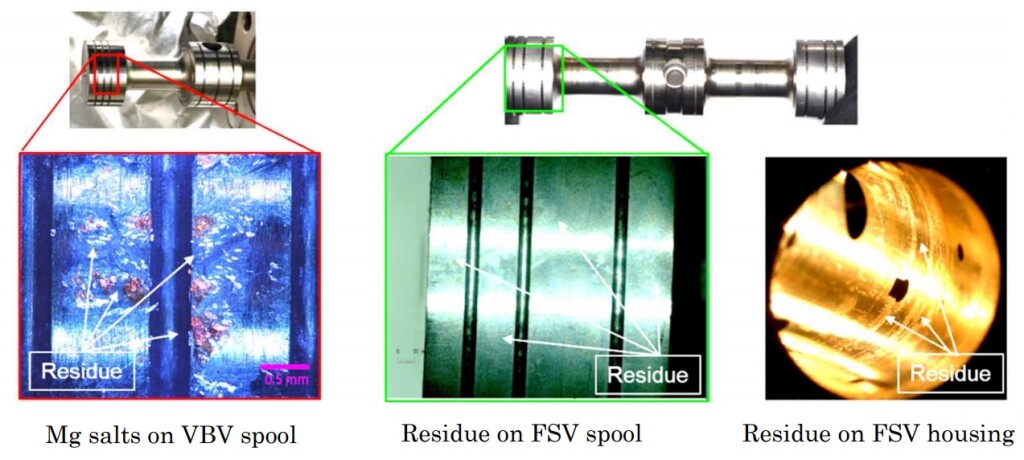

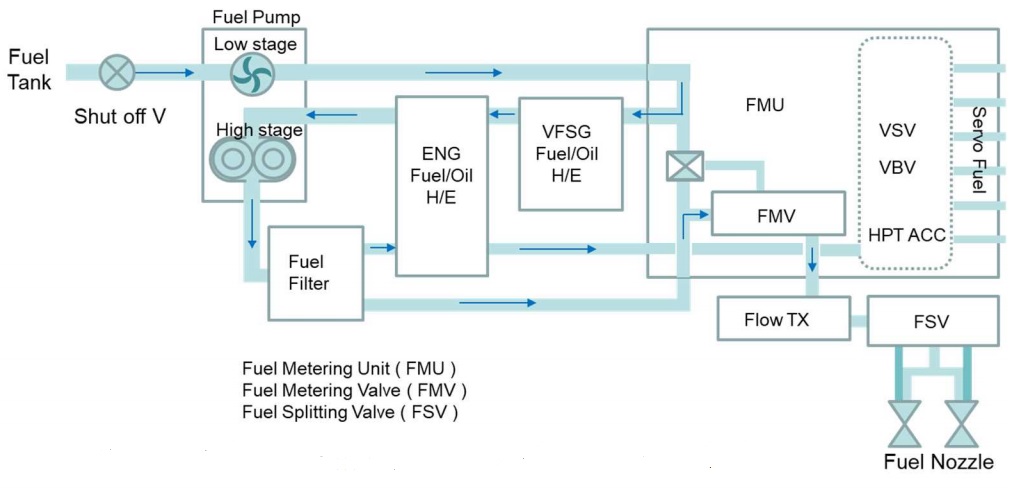

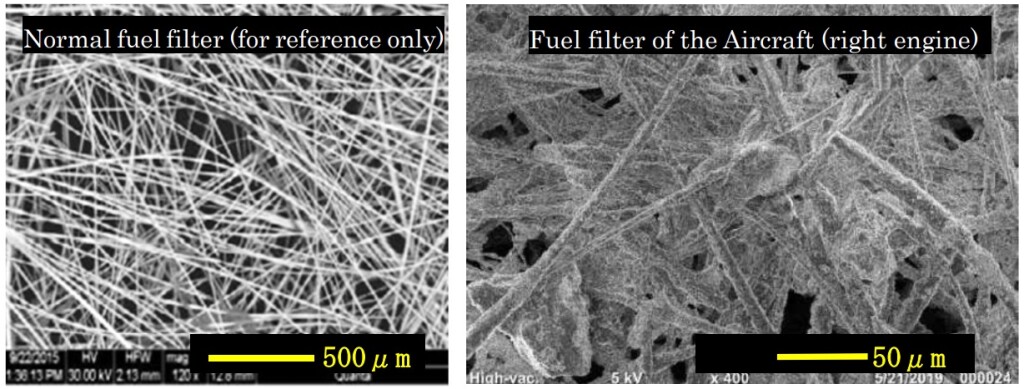

….a residue, primarily composed of magnesium salts was observed in multiple locations (fuel filter, fuel metering valve [FMV] spool, fuel splitting valve [FSV] spool, variable bleed valve [VBV] spool and high pressure turbine [HPT] active clearance control [ACC spool]).

Testing showed that up to 320 times more force was needed to move the control servos with the residue.

Jetstar Airways Boeing 787-8 VH-VKJ GEnx-1B Spool’s Contaminated with Magnesium Salts (Credit: JTSB)

The JTSB therefore concluded that when fuel pressure was low when descending at flight idle, “the FMV spool and FSV spool had restricted freedom of movement” and that the engines had dropped below idle due to the FSV sticking.

JTSB say:

It is probable that biocide treatment inside fuel tanks conducted two days before the serious incident was involved in the accumulation of [the] residue…because the composition of the residue were similar to the Kathon FP1.5.

Biocide treatment is used to prevent microbial growth that can cause corrosion and damage fuel and engine systems.

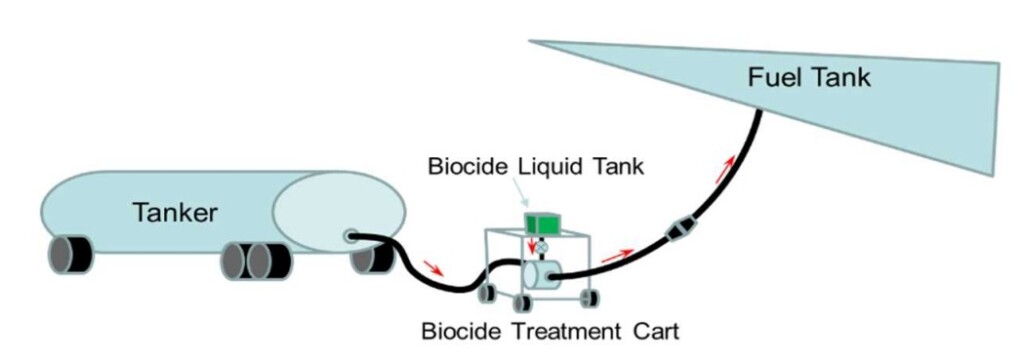

The Aircraft [had been] ferried to Auckland International Airport, New Zealand to borrow facilities of other company to conduct biocide treatment inside all three fuel tanks (left, center and right) because the Operator did not have their own facilities.

…biocide treatment is conducted by connecting biocide treatment cart to a certain position of fueling hose to mix biocide with fuel for loading into fuel tank. AMM stipulates that biocide of either Kathon FP1.5 or Biobor JF is used, and the Operator used Kathon FP1.5.

Kathon FP1.5 (MIL-S-53021A) composition is: Glycol: 90.0%, Water: 5.85%, Magnesium salts: 2.65%, 5-Chloro-2-Methyl-4-Isothiazolin-3-one: 1.15% and 2-Methyl-4-Isothiazoliln-3-one: 0.35%. The magnesium salts contained in Kathon FP 1.5 are insoluble in fuel but will dissolve into water if a water phase is present in the fuel.

When Kathon FP1.5 is used, biocide and fuel are loaded to make concentration ratio inside fuel tank 100 ppm (parts per million) by volume. Therefore, in the event that fuel remains in aircraft, fuel and biocide to be loaded require adjustments to obtain a higher concentration ratio for loading into aircraft so that the final concentration ratio inside the tank can be 100 ppm. After completing fuel loading, biocide treatment is completed by soaking fuel for 12 to 24 hours keeping concentration ratio inside fuel tank at 100 ppm.

The certifying staff involved had not recorded details of the biocide quantity added. JTSB comment that “It is desirable to keep these records because they are considered to be important for traceability of maintenance work.”. JTSB determines that the actual concentration was 250 ppm in the left tank and about 285 ppm in the right tank. There was fuel at a lower dosage in the centre tank but it appears that mixing if biocide through the fuel system was not sufficient;y rapid to ensure the outer tanks were diluted.

JTSB Probable Cause

In this serious incident, it is highly probable that, when the Aircraft was descending for landing, there occurred oscillation in rpm of each engine causing both engines to temporarily fall below idle at separate times because residue primarily composed of magnesium salts accumulated in spools impeded movement of spools that involved in fuel metering of both engines. As for the higher accumulation of residue primarily composed magnesium salts in spools, it is somewhat likely that the fuel with a higher concentration ratio of biocide, which was loaded in the biocide treatment two days before the serious incident, did not mix evenly with the remaining fuel in wing tanks, and was fed to the engines.

Safety Actions

(1) The Operator suspended biocide treatment using Kathon FP1.5 inside fuel tanks of the same type of aircraft. The Operator is reviewing maintenance procedures that occur infrequently, to identify task- specific training opportunities for maintenance personnel based on AMM.

(2) GE issued service bulletin (SB) for aircraft equipped with GEnx engine to notify operators to suspend biocide treatment using Kathon FP1.5. (SB 73– 0086 R00 ENGINE FUEL AND CONTROL – GENERAL (73-00-00) – SUSPENSION OF THE USE OF KATHON FP 1.5 BIOCIDE TREATMENT ISSUED SEP/30/2019)

(3) Boeing deleted biocide treatment procedures using Kathon FP1.5 from the AMM of the same type of aircraft equipped with GEnx engine following SB issued by the design and manufacturer of the engine. The design and manufacturer of the aircraft also updated the AMM for all models of aircraft to explicitly describe the maximum allowable biocide concentration ratio and to record calculation of biocide amount and the amount used.

(4) After receiving multiple reports of similar cases using Kathon FP1.5, the Federal Aviation Administration (FAA) issued SPECIAL AIRWORTHINESS INFORMATION BULLETIN(SAIB NE-20-04 Date: March 25, 2020 Engine Fuel – Jet Fuel Biocide Additive)and the European Union Aviation Safety Agency (EASA) issued Safety Information Bulletin (SIB No.: 2020-06 Issued: 20 March 2020 Use of DuPont Kathon FP 1.5 Biocide)to notify operators, repair stations, aircraft and engine manufacturers regarding the use of Kathon FP1.5. In addition, the Civil Aviation Safety Authority (CASA) issued AIRWORTHINESS BULLETIN (AWB 28-018 Issue 1 – 26 March 2020 Suspending Use of Kathon Biocide for Treating Micro-biological Growth in Aviation Fuel) to strongly recommend to suspend the use of Kathon FP1.5 for biocide treatment.

UPDATE 29 June 2020: Flight International Jetstar 787 biocide treatment led to dual engine thrust roll-back

Safety Resources

The UK Air Accidents Investigation Branch (AAIB) has published a Special Bulletin concerning a serious incident involving an Airbus A321 G-POWN of Titan Airways on 26 February 2020. The aircraft…

…suffered problems with both engines shortly after take-off from London Gatwick Airport on a positioning flight to Stansted Airport with seven crew members and no passengers on board. The aircraft returned for an immediate landing at Gatwick, which was completed successfully.

The investigation has determined that during biocidal shock treatment to combat microbial contamination, an excessive quantity of Kathon biocide was introduced into the aircraft’s wing fuel tanks, equating to 37 times the maximum permitted dosage. This Special Bulletin contains preliminary information about the investigation and is intended to highlight the importance of using correct procedures when dosing fuel with biocide.

Also see these Aerossurance articles:

- Turbine Dromader M18A Downed by Fuel Contamination: Shell Detector Capsules Misused

- The Wrong Fuel: Three Misfuelling Accidents

- Singapore Airlines B777 41t Fuel Discrepancy Incident

- Fuel System Maintenance Error: Tuniter ATR72 TS-LBB Ditching 6 August 2005

- B1900D Emergency Landing: Maintenance Standards & Practices

- Airworthiness Matters: Next Generation Maintenance Human Factors

- Rockets Sleds, Steamships and Human Factors: Murphy’s Law or Holt’s Law?

- ERJ-190 Flying Control Rigging Error

- Myanmar National Embraer 190 NLG Jam: Maintenance Error? We’re Not Convinced!

- Professor James Reason’s 12 Principles of Error Management

- Back to the Future: Error Management

- UPDATE 28 June 2020: Maintenance Issues in Fire-Fighting S-61A Accident

- UPDATE 22 July 2020: NDI Process Failures Preceded B777 PW4077 Engine FBO

- UPDATE 10 November 2020: King Air 100 Uncontained TPE331-6 Failure – Inappropriate Repair Scheme

Recent Comments