Reversing the Trend: Offshore Safety in Norway

Recently a small envelope with an A5 booklet and pen dropped through the Aerossurance letter box.  The booklet was the latest in the Petroleum Safety Authority (PSA) of Norway‘s Dialogue series, entitled Reversing the Trend. The PSA say that safety “trends are moving in the wrong direction in a number of areas”. They say that:

The booklet was the latest in the Petroleum Safety Authority (PSA) of Norway‘s Dialogue series, entitled Reversing the Trend. The PSA say that safety “trends are moving in the wrong direction in a number of areas”. They say that:

The past two years have been characterised by serious incidents and challenges.

Two years, roughly, is the length of the recent drop in oil prices. The rise in incidents offshore has prompted the Labour and Social Affairs Minister, Anniken Hauglie, to launch a working group to produce a white paper, on offshore safety, expected in October 2017, saying:

We have seen several examples of incidents where we believe questions need to be asked. Given our current situation, it is perhaps more important than ever that the parties collaborate to find good solutions and that the people who are most directly affected are heard from when discussing how to cut costs without compromising safety. I therefore think that…the time is right to prepare a white paper.

The CEO of Norwegian oil company Statoil has recently denied there is any connection between cost-cutting and safety concerns after a series of incidents in a matter of weeks (including a fire, two gas leaks and a well control incident) despite HSE job cuts.

Though currently light on detail, ‘Reversing the Trend’ will have a high priority with the PSA and industry in 2017 they say, with both short term quick wins and longer term efforts.

The pen was part of the booklet’s emphasis that ‘Norway’s safety history is written every day’, with sections of the booklet for readers to complete sections to describe what their organisation will contribute. Not only are we always fascinated by safety matters at Aerossurance, but we do like a good safety promotion gimmick so we read on!

The PSA have a triple focus:

- Collaboration

- Robustness

- Standardisation

These are three good focus areas and we look forward to seeing this initiative develop.

These are three good focus areas and we look forward to seeing this initiative develop.

Professor Per Morten Schiefloe at the Department of Sociology and Political Science at the Norwegian University of Science and Technology (NTNU) says:

In Norway, we have lived in a sheltered environment, feeling that nothing will ever go wrong here. However, incidents in recent years have shown that we too are vulnerable. We are therefore witnessing a social trend where organisations that do not seem very vulnerable to hazards are also beginning to give more thought to safety.

UPDATE 9 January 2017: It is reported that a fire on the Odfjell Drilling Deepsea Atlantic semi-submersible drilling rig while it was working for Statoil on the on the Johan Sverdrup field on 4 January 2017 is under investigation:

It was initially extinguished but flared up again but the situation was brought under control around an hour later.

UPDATE 21 January 2017: A new Statoil safety report on two incidents in 2016 reveals that operational and maintenance oversight could be stronger. They specifically discuss a well control incident on the Songa Endurance in the Troll field and a gas leak at the Mongstad isomerization plant.

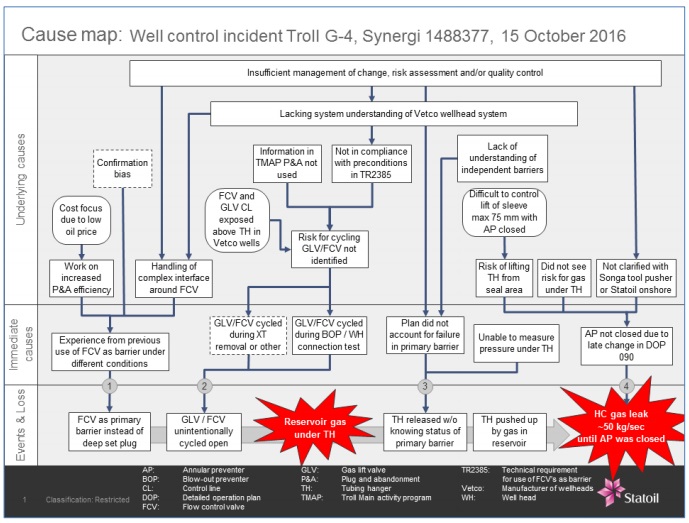

On the well control incident:

Statoil’s internal investigation defines the incident to have a high degree of seriousness, and concludes that at worst it could have led to loss of life if the safety equipment had failed to function as intended, or if the gas had been ignited. The BOP [Blow Out Preventer] was quickly activated and stopped the gas leak, and five gas detectors automatically turned off equipment that could have produced sparks.

The investigation report concludes that two main findings have weakened the barriers and helped gas reach the drill floor.

…existing downhole valves were used as barriers against the reservoir and were unintentionally opened.

…the annular preventer inside the BOP…should have been closed before the operation was started, because it was not possible to measure the pressure below the wellhead sealing.

Statoil’s Executive VP for Technology, Projects and Drilling, Margareth Øvrum, said:

This is a very serious well control incident. The actions taken will improve our ability to assess risk, both before and during operations. We will share our experience from this incident with the rest of the industry.

Of the onshore refinery leak:

During pipe inspection in connection with surface maintenance in the isomerization plant at Mongstad, a portable gas detector was triggered close to a valve. When an attempt was made to close the valve, the pipe socket broke and high-pressure hydrogen-rich gas was released.

Two people were in the vicinity…. The evacuation alarm was activated immediately, followed by evacuation of employees, shutdown of the facility involved and pressure relief to flare. After about one hour the situation was clarified.

The investigation points to external corrosion as the triggering cause.

Wrong prioritisation of maintenance as a result of insufficient risk understanding was identified as root causes. The report concludes that the incident was serious and at worst it could have led to loss of life.

It has been decided to intensify the programme surface maintenance over the next two years. Safety management will furthermore be improved by increased management presence at the plant. New detection technology will be considered to improve our ability to detect leaks.

UPDATE 23 January 2017: Probe after worker gets foot trapped under container on Pro Safe’s Safe Scandinavia tender support vessel, alongside the Statoil Oseberg East platform.

UPDATE 30 January 2017: Norwegian union blames near-fatal refinery leak on maintenance backlog. They claim:

We are talking both about the lack of maintenance and…deferred maintenance.

[Statoil’s]…annual maintenance project was reduced from 160 million to 105 million. In the first quarter of 2012 [well before the drop in oil prices] the maintenance budget was cut further, from 105 million to 82.5 million kroner. When the budget halves and it is called “economically driven maintenance” they gamble with both the plant and people who work there.

The warnings have literally rained down over several years.

UPDATE 20 February 2017: Cost Cuts Appear to Harm Norway Oil Industry Safety -Watchdog

Cost cuts by Norway’s oil and gas industry appear to have contributed to a rise in accidents in recent years, the head of the country’s Petroleum Safety Authority (PSA) said on Monday.

“In summary, we see that developments over the past two years have been characterised by security challenges and serious situations,” Anne Myhrvold said in an interview published on the PSA’s website. “Cost cuts appear to be a contributing factor.”

The PSA later removed the posting from its web site, saying it had been intended for publication later this week. A spokeswoman confirmed the report however and said the PSA would make further comments on Feb. 23.

UPDATE 24 February 2017: ‘Cost cuts affecting safety, time to reverse the trend’, claims Norwegian safety body

The PSA have set a goal for 2017 to kickstart the reverse of declining safety standards.

Myhrvold said this will require an “extensive collective effort by the whole industry”.

“We’re fully aware that it’s very difficult to complete a big turnaround operation in just one year.

“However, we expect the companies to achieve visible and measurable results during 2017 in key safety areas. And we expect the work to continue for as long as necessary.”

The full PSA article is here.

UPDATE 7 March 2017: Statoil rapped over Statfjord fire

UPDATE 17 March 2017: In Statoil’s annual report, CEO Eldar Saetre said the company had exceeded its cost improvement target last year and wanted to go further this year, However:

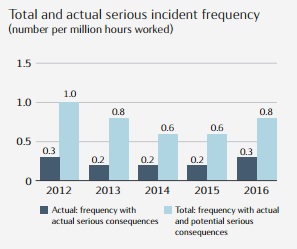

….the company’s serious incident frequency [globally] went up to 0.8

A contractor died during construction work in South Korea, while 13 colleagues passed away when a helicopter crashed on its way from Gullfaks B to Bergen in April.

Mr Sætre said: “We are not satisfied with this development and have taken several steps to reinforce safety measures throughout the company.”

Statoil has 85% of its workforce and over 60% of its production in Norway.

UPDATE 20 March 2017: The North Sea Offshore Authorities Forum (NSOAF) is aiming to secure and share experience on the safe operation and maintenance of ageing facilities, producing a report in 2018.

The PSA commented:

It is because of the potential for major accidents that maintenance management in general, and the maintenance of safety-critical equipment in particular, have been given so much emphasis in the petroleum industry in these countries.

Maintenance management and safe operations are also relevant for the NSOAF countries in the light of the substantial cost reductions the industry is making due to the fall in the oil price.

UPDATE 27 April 2017: The PSA comment on their 2016 study of trends in risk level in Norway’s petroleum activity (RNNP) that there are:

…a number of bright spots [but] important findings…give PSA director general Anne Myhrvold cause for concern.

“The survey results show that we’re on the right road in certain areas,” she says. “But I’m worried about developments for key parameters such as hydrocarbon leaks and well control incidents. It’s worrying that the major accident indicator for 2016 and 2015 is higher than for the two previous years,” says Myhrvold.

“Over the past couple of years, we’ve witnessed a number of serious incidents in the Norwegian petroleum sector. Several of these could have developed into a major accident under marginally different circumstances.” The serious well control incident on Songa Endurance on the Troll field in 2016 was one of the biggest contributors to the major accident indicator.

“Good results are no guarantee against future incidents,” she warns, and points to the helicopter crash at Turøy near Bergen in April 2016 when 13 people died. This accident occurred the day after the 2015 RNNP report was presented, and highlighted the positive trend for helicopter safety.

On the same day the Norwegian Oil and Gas Association published a report from Menon Economics that claims that cost cuts have not increase the likelihood of accidents.

UPDATE 11 May 2017: A group of prominent Norwegian safety researchers say that the Menon report is a “thin basis” for drawing conclusions and “does not provide a knowledge-based basis for good decisions”.

UPDATE 11 September 2017: A gas leak in the Norwegian sector of the North Sea could have resulted in fatalities, an investigation has found.

More than 30 tonnes of gas escaped from a Statoil operated well in the Asgard field, 200km offshore Norway on March 10. It occurred while portable drilling facility Deepsea Bergen carried out planned activity for connecting a subsea well.

The investigation revealed that the gas leak occurred when an insulating valve was removed. This valve was not tested and secured as a barrier.

The PSA say:

The consequence of the incident was that gas and condensate escaped to the sea and the atmosphere. Currents and wind direction were favourable, so that little gas flowed to Deepsea Bergen.

Gas hazard analyses by Statoil show that the discharge could have led, under different weather conditions, to ignitable gas entering Deepsea Bergen’s moonpool. These analyses show that ignition of the gas would not have threatened the integrity of the facility, but could have led to fatalities had there been personnel in the area.

The investigation identified five nonconformities:.

- Barriers – no barriers were established to prevent discharges to the sea during work on the template.

- Risk assessments – in connection with planning and executing the operations on well S-4, important contributors to risk and changes in risk were not identified and assessed.

- Responsibility – responsibility for testing isolation valves was not unambiguously defined and coordinated in connection with the operations being conducted.

- Knowledge of governing documents – personnel involved had little knowledge of barrier requirements in governing documentation for work on the template.

- Documentation on requirements – relevant requirements in governing documents concerning isolation valves were not clarified in the operational procedures.

It identified one further improvement point:

- Follow-up – follow-up by management has not contributed to identifying technical, operational or organisational weaknesses, errors and deficiencies.

UPDATE 4 January 2018: Serious shortcomings’ in procedures caused worker’s death in Aker BP Tambar field: The PSA say a seawater pump was being lifted into place for installation on Maersk Interceptor drilling rig when the incident occurred on 7 December 2017. A worker died after a resulting fall and another injured.

UPDATE 15 January 2019: A report from Norway’s Auditor General criticises several aspects of the way HSE in the Norwegian oil and gas industry is followed up by the PSA

UPDATE 1 April 2019: Union reaction to the Auditor General’s report and comments from Equinor. There is however a need for trust says Ole Andreas Engen of the University of Stavanger.

UPDATE 14 Octover 2020: Negative trend: series of accidents arouse concern

The SA is worried about a rising number of serious incidents in the industry and has asked the companies to prioritise work on safety. “The sum of the strong and weak signals we’re now seeing makes us uneasy,” says director general Anne Myhrvold. A disquieting rise in serious incidents reported to the PSA has been registered in 2020. Figures to 31 September show more than 50 of these – twice as many as in the same period of last year and more than four times the 2018 figure.

Action by Myhrvold over the next few weeks includes meetings with the management of all the large operator companies…about the safety challenges in the industry. “My message to top management now is that they must now give priority to safety work, so that we can avoid accidents and serious incidents in petroleum operations,” she says.

Investigations in 2020

- Equinor/Floatel International – Floatel Endurance – unintentional disconnection of walkway

- Wintershall/Seadrill – West Mira – unintentional disconnection of lower marine riser package

- Equinor – Oseberg B – lifting incident with personal injury

- Equinor – Mongstad – steam leak and personal injury

- Gassco – Kårstø – electric arcing and personal injury

- Equinor – Statfjord B – electric arcing and personal injury

- ExxonMobil – Slagentangen – naphtha leak

- Equinor – Johan Castberg project

- Valaris – Rowan Stavanger – BOP, component came loose

- Equinor – Hammerfest LNG – turbine fire

- Neptune/Odfjell – Gjøa – well control incident

- Seadrill – West Bollsta – dropped object incident

(Updated per 20. October 2020)

Offshore Helicopter Safety

Offshore helicopter operations are not regulated by the PSA but the Norwegian Civil Aviation Authority (the NCAA or Luftfartstilsynet), as well as the European Aviation Safety Agency (EASA).

The fatal accident to offshore helicopter LN-OJF, on charter to Statoil on 29 April 2016 however will have added to the workforce concerns about their safety generally. Statoil have already released their internal investigation report on the circumstances surrounding that accident. That report is further discussed in an article by Allan Blake for HeliHub: Stretching Safety too Far – a Withering Safety Culture

Its noticeable that in the offshore helicopter safety sector the first and second of the PSA’s focus areas are also major focus areas of helicopter safety association HeliOffshore. We discussed their approach to cross-industry collaboration, their Safety Performance Model (SPM) and their safety information exchange, ‘system reliability and resilience and operational effectiveness activities in: Offshore Helicopter Safety Performance: 2016 HeliOffshore Conference Report.

The third is an area that the Flight Safety Foundation (FSF) is attending to with an offshore helicopter version of their award winning Basic Aviation Risk Standard (available to download on the FSF website) which we discussed here: FSF Launches Offshore Helicopter Standard (BARSOHO). A update of BARSOHO (Version 3), fully aligned with the HeliOffshore SPM, is now available.

Aerossurance is pleased to be supporting both HeliOffshore and the Flight Safety Foundation in their work to improve offshore helicopter safety.

Also expected shortly are both the oil company funded Norwegian SINTEF Helicopter Safety Study 3b (an update of the 1999-2009 HSS3 study, to include data from 2009 to 2015) and EASA North Sea Helicopter Operations Management Current Practices Safety Review (EASA.2015.HVP.01). We will cover both in more detail when they are published.

UPDATE 6 March 2017: HSS3b is issued (initially in Norwegian, with an English Exec Summary).

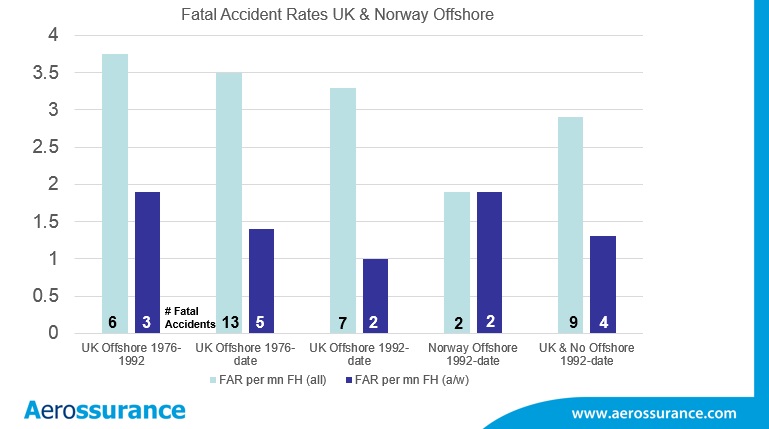

Aerossurance recently presented on helicopter safety at the 10th EASA Rotorcraft Symposium. One challenge when comparing offshore helicopter safety data for individual countries, even nations with big offshore helicopter fleets, in that the accident rate can be significantly influenced by just one one accident.

This chart presents data from UK CAA‘s CAP1145 report, updated with fatal accidents and usages estimates since 2012. While an imperfect measure of risk, identifying fatal accidents is generally unambiguous and standardised (though this still ignores one fatal passenger incident).

Here the Norwegian fatal accident rate can be seen to have doubled upon the accident to LN-OJF and the airworthiness accident rate went from equal to the UK to twice it. While the overall fatal accident rate in Norway is better than in the UK sector, Norway is only one fatal accident away from equalling the UK rate.

The devil is always in the detail, two of the UK fatal accidents involve fatal injuries to Helideck Landing Officers (HLOs), both in 1992 for example.

It will be interesting to see how the HSS3b study interprets the accident data.

UPDATE 6 March 2017: HSS3b is issued (initially in Norwegian, with an English Exec Summary).

UPDATE 24 April 2017: The AIBN have announced they will hold a press conference in Lillestrøm Friday 28 April at 1300 hours. Prior to that they will issue a preliminary report on LN-OJF in English:

…in order to present an updated status of the investigation. The report contains mainly factual information available so far in the investigation. The report also contains some AIBN comments.

UPDATE 25 April 2017: The press report that the UK CAA has written to a number of stakeholders. While they say the:

The report is comprehensive (101 pages) and provides significant detail. No new information for the CAA has emerged from the report and there are no safety recommendations.

However:

Developments on the lifting and the detection capability look promising and we are hopeful that after obtaining further information we will be closer to removing our directives. At this time however the [Norwegian and UK] directives remain in place.

UPDATE 28 April 2017: The AIBN have issued a new preliminary report on LN-OJF.

UPDATE 25 May 2017: The Ministry of Transport has announced that in their view offshore operations in Norwegian waters are outside the EEA.

UPDATE 14 June 2017: In the introduction to the Agency’s 12th annual safety review, EASA’s Executive Director Patrick Ky says:

…the tragic accident involving an EC225 helicopter in Norway in April 2016 shows the importance of joining forces and together maintaining safety as an aviation community.

UPDATE 26 June 2017: Speaking prior to the Paris Airshow Airbus CEO Tom Enders said he was “hopeful” that the operational directives on commercial H225 flights in UK and Norway would be lifted “any time soon. But at this time, after so many delays, we are not going to make any predictions.” He commented that these national directives were “somewhat awkward” as “under existing agreements with EASA they should do this [lift their flight restrictions]”.

UPDATE 30 June 2017: Workers asked for North Sea helicopter safety feedback

UPDATE 2 July 2017: Energy Voice Report: Could Super Puma return to North Sea skies?

UPDATE 7 July 2017: The Norwegian and UK CAA operational restrictions are being lifted.

UPDATE 25 July 2017: A bachelor’s thesis at the engineering college at the University College in West Norway mentions several points where the writers claim that the interaction between the agencies failed during the emergency response to the fatal accident to offshore helicopter LN-OJF on 29 April 2016.

UPDATE 24 April 2018: The AIBN made a statement on LN-OJF that:

A draft of the final report on the tragic accident near Turøy has been for consultation with the parties involved in the investigation. The consultation period is over and the AIBN is working on the comments. It is solely the AIBN’s decision whether or not a comment shall be accepted and incorporated into the final report. This is a laborious and time-consuming process, which will also involve clarifications and consultation with external contributors.

At the time being, we are unable to present a firm date for publication of the report. The work will continue without letup until the final report is ready for publication.

Recent Comments