Airworthiness Directive after Two Fatal Bell 430 Accidents: Main Rotor – Pitch Link Clevis Fractures Angola and South Africa

Transport Canada has issued Airworthiness Directive (AD) CF-2021-26 to inspect the main rotor pitch link clevises and rod ends of the Bell 430. This followed two accidents that cost the lives of 11 people. The AD is considered an interim action and a further AD could follow. They explain:

In January 2021, a model 430 helicopter experienced an in-flight failure of a main rotor pitch link clevis resulting in loss of control of the helicopter and fatal injury to the five occupants on-board.

That accident occurred on 21 January 2021 to B430 ZT-RRT, operated by National Airways Corporation (NAC) as an air ambulance for Netcare 911, while en-route from Johannesburg to Pietermaritzburg in South Africa.

The Accident and Incident Investigations Division of the South African CAA has already published a preliminary report. That describes how approximately 1.5 hours into the flight and while cruising at 725 feet AGL, eyewitnesses report that “the helicopter suddenly started to spin around whilst losing height rapidly” and “saw what looked like helicopter parts breaking off before it crashed and burst into flames”. The wreckage was scattered over a 500 m radius. All 5 persons on board died.

The Transport Canada AD states that in that accident:

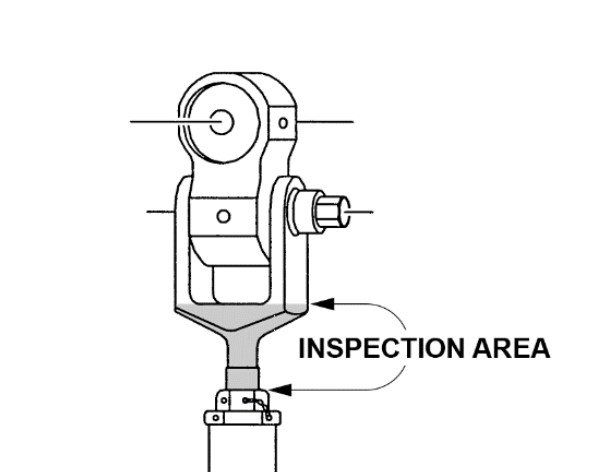

The main rotor pitch link clevis part number (P/N) 430-010-432-101 fractured at the exposed thread area above the nut and the fracture was consistent with fatigue damage.

Inspection of the failed part from the 2021 accident determined that the universal bearing P/N 212-010- 412-001 of the main rotor pitch link assembly was found with excessive wear and had increased resistance to rotation. Restriction in freedom of movement of the universal bearing can cause increased loads on the main rotor pitch link assembly and subsequent fatigue failure of the clevis prior to its life limit. The accident investigation is still ongoing.

They go on to reveal that:

A similar accident previously occurred in September 2016 on a model 430 helicopter where the main rotor pitch link clevis was found to have fractured at the neck area via fatigue damage that originated at a corrosion pit.

That accident occurred on 26 September 2016 to B430 D2-EYI of Heli Malongo. This offshore helicopter was returning from an oil and gas installation when it crashed into the sea.

Transport Canada explain that:

This condition, if not corrected, could lead to crack initiation at the main rotor pitch link clevis neck or threaded area and consequent failure of the main rotor pitch link, resulting in loss of control of the helicopter. To address this unsafe condition, this AD requires an initial special detailed inspection (SDI) of the main rotor pitch link clevises and detailed visual inspection (DVI) of the universal bearings, and rectification, as required.

This AD also mandates a repetitive DVI of the main rotor pitch link clevises and universal bearings, and rectification, as required. Bell issued Alert Service Bulletin (ASB) 430-21-60 to provide instructions for inspection and replacement of the affected parts.

The Bell ASB states no reason for the inspection.

UPDATE 1 Match 2022: SA CAA Final Report Issued for ZS-RRT

The SA CAA final report states the probable cause was:

The clevis on the pitch control lever of the Orange blade failed in-flight, resulting in the instability of the main rotor disc which, in turn, severed the most rear section of the tail boom. As a result, the main rotor blades subsequently failed. The combination of the severed most rear section of the tail boom and the main rotor failure resulted in the pilot losing control of the helicopter and, thus, the subsequent crash. Corrosion fatigue/metal fatigue, mechanical failure and improper maintenance.

The contributing factor was:

Failure to identify the fatigue crack on the clevis threaded section during a magnetic particle inspection as well as during the MPI.

However they also clarify that:

The NDT that was conducted only considered manufacturer’s practises and did not consider the environmental (high level of humidity and chlorine) and operational context in which the helicopter was operated for more than 10 years.

The Bell maintenance manual specifies that the PCL components must be subjected to a magnetic particle inspection NDT every 2500 airframe hours, and that only the rod section is to be subjected to FPI testing, as well as that the clevis must be subjected to MPI testing.

And that:

The PCL tested by Bell Engineering Laboratories (2017 {after the accident in Angola]) found that the upper pitch link clevis for the Orange main rotor blade was fractured due to fatigue. The fatigue originated at pitting corrosion, which was less than 0.001 inch deep. This fracture would have resulted in the Orange blade losing pitch control. According to the records, the manufacturer – Bell, never made any recommendations to remedy the situation.

Safety Resources

The European Safety Promotion Network Rotorcraft (ESPN-R) has a helicopter safety discussion group on LinkedIn. You may also find these Aerossurance articles of interest:

- AAR Bell 214ST Accident in Afghanistan in 2012: NTSB Report

- EC135 Main Rotor Actuator Tie-Bar Failure

- S-61N Damaged During Take Off When Swashplate Seized Due to Corrosion

- 2009 Newfoundland S-92A C-GZCH Accident: A Failure of Design and Certification

- AAIB Report on the Ditchings of EC225 G-REDW 10 May 2012 & G-CHCN 22 Oct 2012

- EC225 LN-OJF Norway Accident Investigation Timeline

- In-Flight Flying Control Failure: Indonesian Sikorsky S-76C+ PK-FUP

- UPDATE 17 September 2022: Canadian B212 Crash: A Defective Production Process

- UPDATE 10 December 2022: Main Rotor Blade Certification Anomaly in Fatal Canadian Accident

- UPDATE 24 December 2022: S-61N Accident in Afghanistan: Investigators Focus on Auxiliary Servocylinder

- UPDATE 29 July 2023: Missing Cotter Pin Causes Fatal S-61N Accident

Recent Comments