Search and Rescue (SAR) AS365N3 Flying Control Disconnect (BFU Investigation: Northern HeliCopter D-HNHA)

On 1 June 2020 Northern HeliCopter Search and Rescue (SAR) Airbus Helicopters AS365N3 D-HNHA was involved in a serious incident at St. Peter-Ording Airfield in Schleswig-Holstein, Germany after a disconnect in the flight control system occurred.

The Serious Incident

During take-off the helicopter entered a nose-up attitude, the tail contacted the ground and the helicopter touched-down hard according to the German Federal Bureau of Aircraft Accident Investigation (BFU).

In their preliminary investigation report (UPDATE and a final report issued in June 2021) the BFU explain that the four person crew were tasked to conduct a SAR mission on what was their second flight of the day:

During a shortened procedure, known as Scramble Take-off, the engines were started and the helicopter taxied to runway 07.

Among the items omitted in this shortened procedure are hydraulic control checks.

According to…the Pilot in Command (PIC), the co-pilot in the right-hand seat, who was also Pilot Flying (PF) during taxi, noticed that the pitch control’s position was unusually far forward and the helicopter needed an exceptional amount of thrust and still taxied slowly. Since there were no warning lights (limit light, caution or warning) and the rotor disc was in “normal” position, they therefore assumed a grinding wheel brake or being wrong about it [i.e. that this was normal] since they had recently been flying a different helicopter type.

Once they had reached runway 07, at about 1547 the PF increased thrust and the helicopter began to hover. It immediately began to pitch up, impacted the ground with the tail and touched down hard with the main landing gear.

The crew were uninjured, but the helicopter was ‘”slightly damaged”.

Subsequently, the crew determined that forward and backward control inputs via the pitch control did not have any effect on the rotor disc’s position.

The engines were shut down while still on the runway. The helicopter was towed back to the operator’s ramp.

…the asphalt runway only showed scrub marks of the tail skid. The tail skid, which consisted of composite material, was torn and the metal protection at the end showed scrub marks.

There were also isolated scrub marks on the lower tail fin fairing.

The Safety Investigation

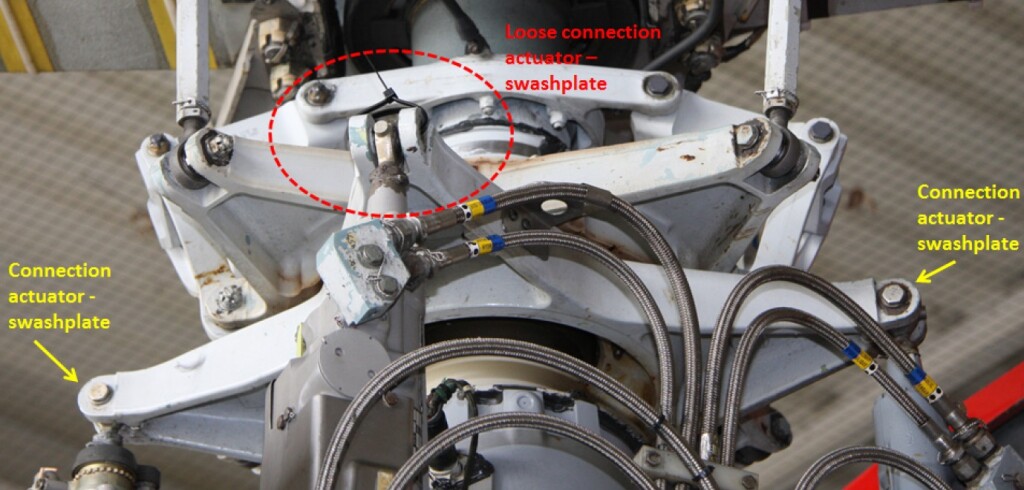

During the subsequent check in the hangar the crew determined that the connection of the left actuator to the swashplate was missing.

The missing bolt, two washers, and one crown nut were found on the gear box compartment below.

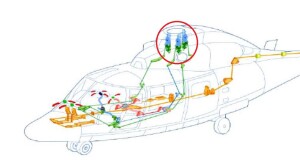

The…actuators are located directly underneath the stationary part of the swashplate.

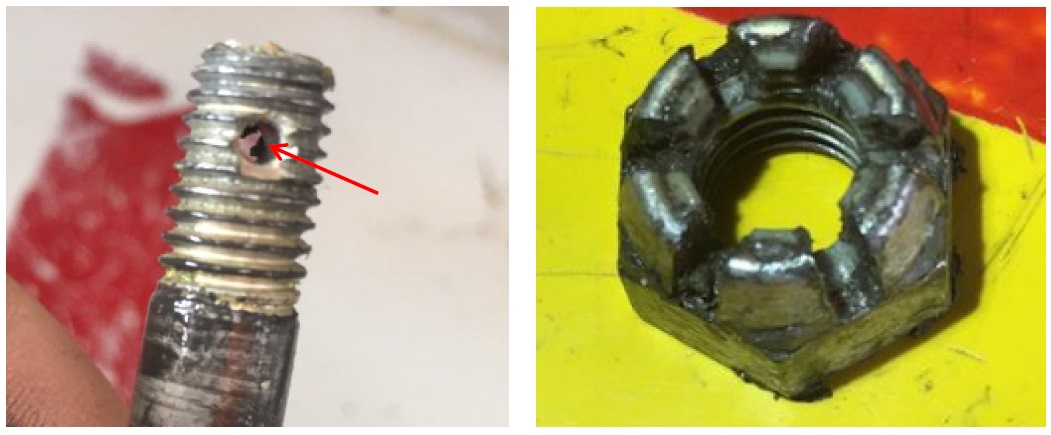

Each working piston of the actuators is fitted with a ball head. A 60 mm x 8 mm threaded bole serves as axis and connection with the swashplate.

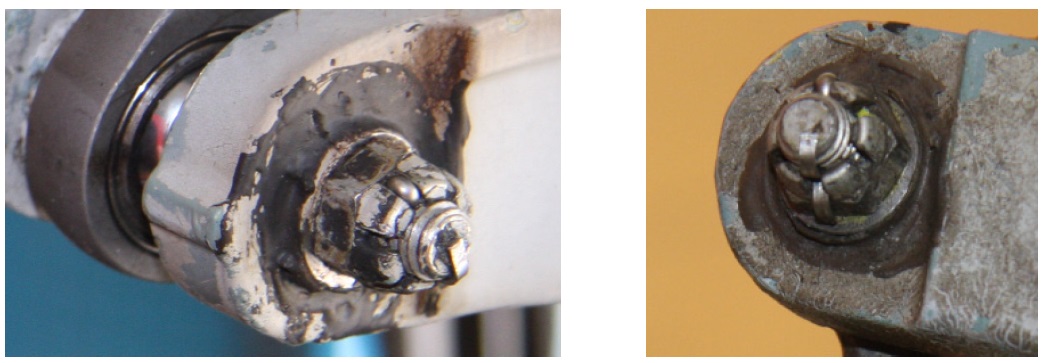

Actual Bolt / Nyloc Nut (Upper) Northern HeliCopter SAR AS365N3 D-HNHA and Exemplar Bolt / Nyloc Nut (Lower) (Credit: BFU)

The bolt is kept in position with a nylon stop crown nut [i.e. castle-headed nyloc nut] and cotter pin.

The associated cotter pin was not found.

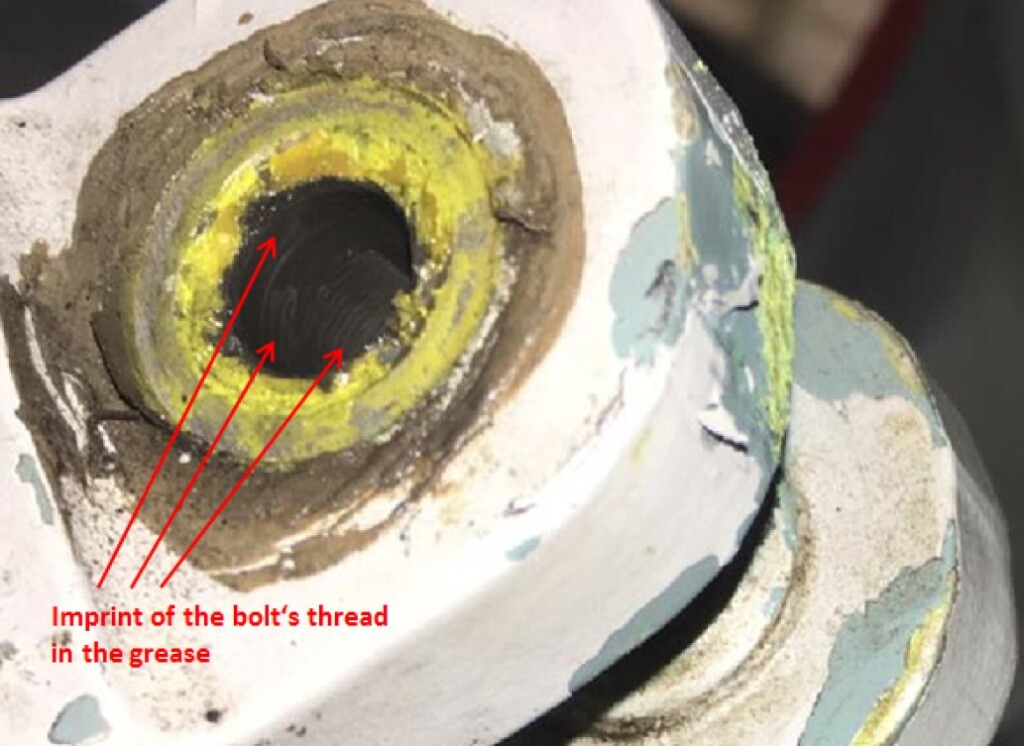

The investigators also noted that the bolt was lubricated. The BFU show a Maintenance Manual illustration that is marked with a torque range and a ‘no lubrication’ symbol.

The bolt and the nyloc nut showed traces of wear. The thread on bolt and washer did not show any visible damage. The thread pitches were partially contaminated. When the nyloc nut was twisted on to the bolt it was possible to do so without any effort for the first 3.5 turns. The subsequent 4 turns, until the hole for the cotter pin became visible, more effort was required. But it was still possible [to turn] by hand, no tool was required. In this position the nyloc nut jammed in a way which should not allow loosening by vibrations or oscillations.

By comparison, a new nyloc nut could only be turned using a tool once the nylon stop application was reached.

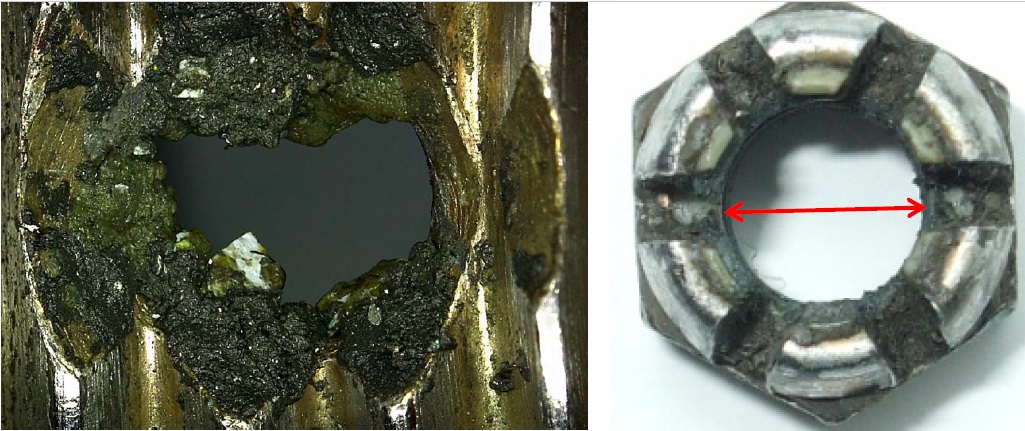

The hole for the cotter pin and the 6 cut-outs of the nut showed signs of “contamination”.

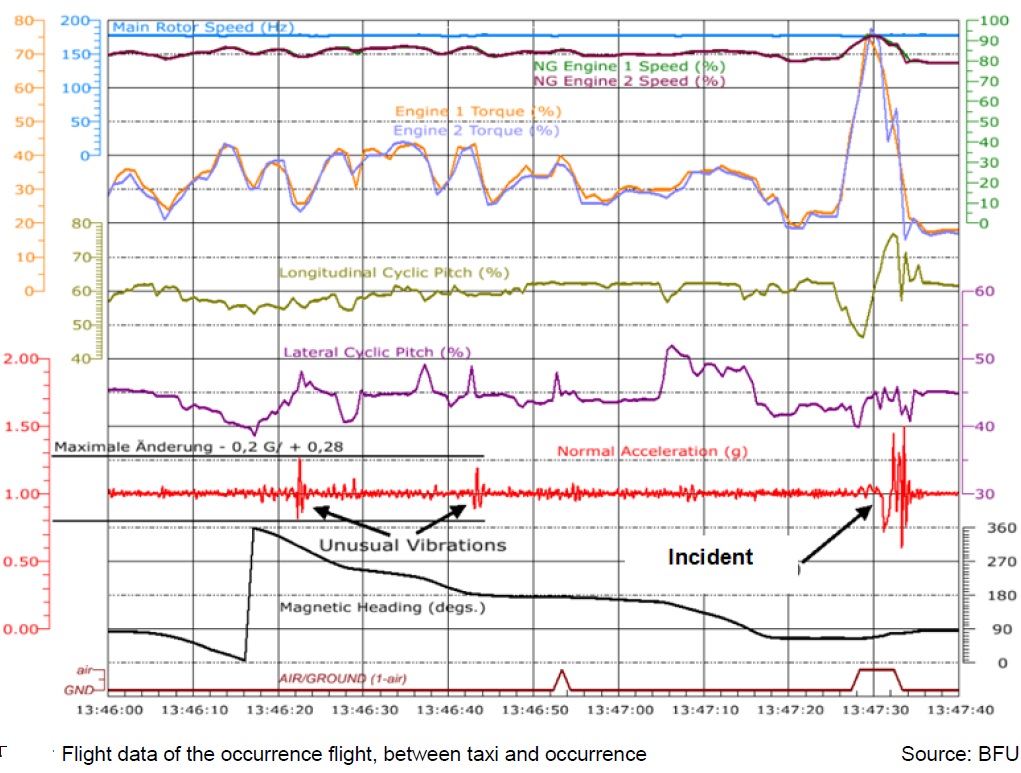

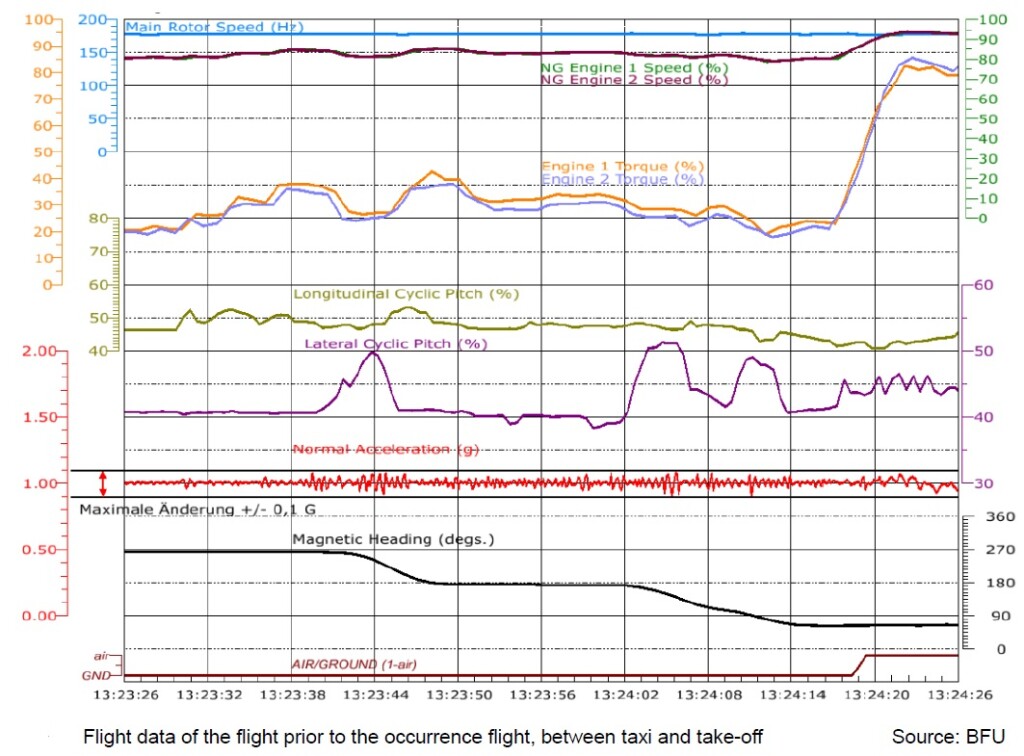

The helicopter was equipped with a Honeywell CVR/FDR Combi Recorder AR 602C. The CVR data for occurrence had been overwritten because the recorder had remained powered for more than 60 minutes after the event. The FDR data was however available to the BFU.

The FDR data showed a maximum acceleration of about 1.5 g during the hard touch-down.

Two acceleration peaks were determined during the occurrence flight compared with the engine start-up, taxiing and take-off of the previous flight on the same day.

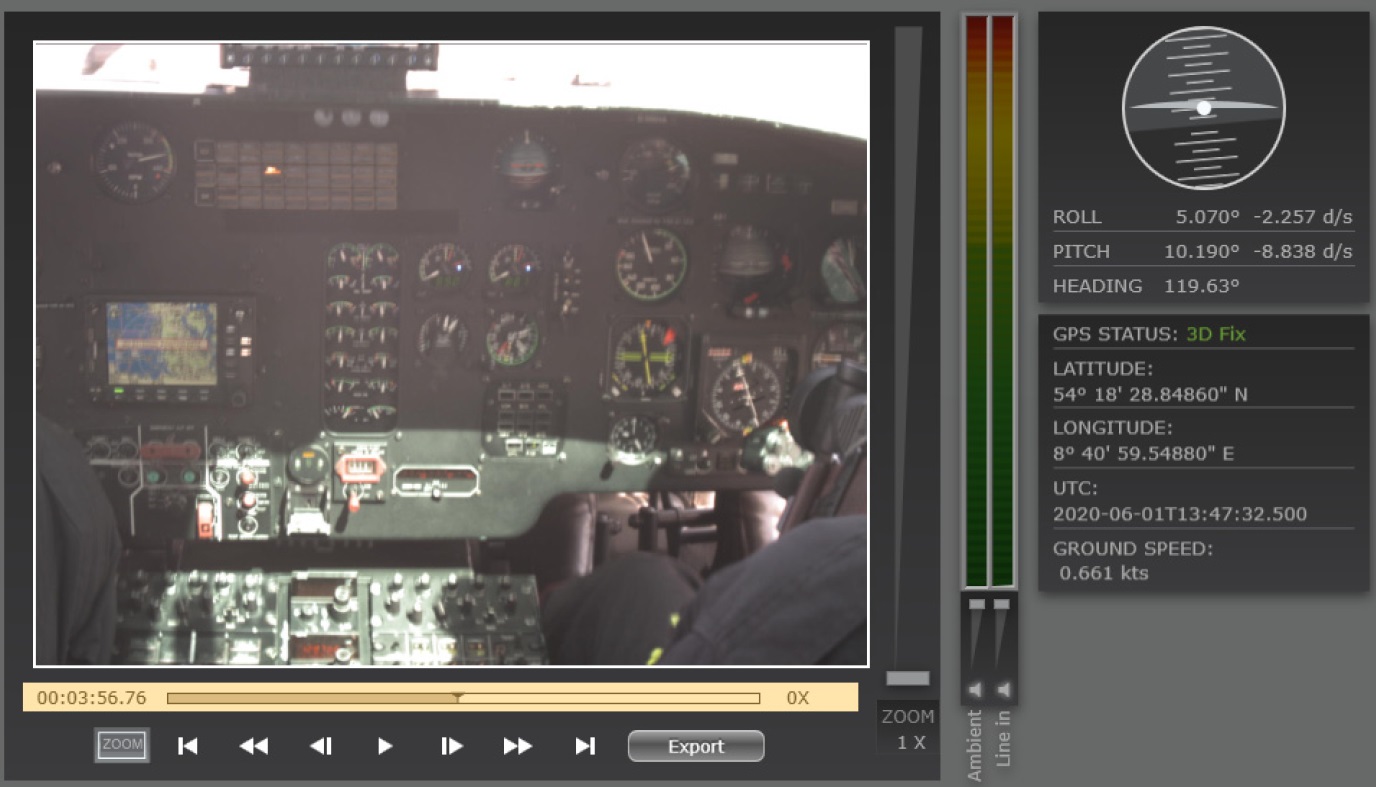

Usefully the 2004 helicopter had been retrofitted with an Appareo Vision 1000 unit. It includes a cockpit camera, GPS-based flight data and background audio recording.

This data was been provided to the BFU.

The BFU discuss the maintenance history:

Over the course of several weeks, until the middle of May 2020, extensive maintenance work was carried out on the helicopter and on 30 April 2020 a checkflight after maintenance conducted.

As part of the troubleshooting the leaking main gear box output to the rotor brake was fitted with a new seal.

To do this task, the left actuator was disconnected from the swashplate. UPDATE in the final report, the BFU explain that:

…the leakage repair was performed by Licensed Aircraft Mechanics with several years of experience. The work, including the screw fitting involved, was checked by an experienced examiner. The findings and work report showed, however, that the check had been signed a few days after the occurrence.

In other words, the records had not been completed before the aircraft entered service after the maintenance.

It is highly likely that the crown nut was not tightened and the cotter pin not set. This was supported by the traces and contaminations found in the cotter pin hole of the bolt and the cut-outs of the crown nut. Two opposite cut-outs showed traces which indicated the position of the cotter pin prior to disassembly. All other four crown nut cut-outs were so dirty that it is absolute certain there neither was a cotter pin set before or after disassembly. It would be a very unlikely coincidence if the position of the crown nut after actuator assembly at the swashplate and the tightening of the nut was the same as before. This means after the maintenance action the new cotter pin was set exactly in the same cut-out as the cotter pin before disassembly. The inserting and bending of a new cotter pin would very probably have removed the contamination in the cotter pin hole and the corresponding crown nut cut-outs.

The results of [laboratory] examination supported the fact that the crown nut was neither tightened with the friction torque the manufacturer required nor that a cotter pin had been set. In flight, under load at the main rotor and constantly changing aerodynamic forces and by control inputs and subsequent mechanical forces of the actuator, the bolt involved was probably jammed between swashplate hole and ball head of the actuator.

In spite of a missing nut it would probably not “move out”. The imprint traces of the bolt thread in the lubricant supported this assumption.

On the ground, during engine start-up and shut-down, when the pitch lever was pushed all the way down and the rotor was unloaded, e.g. did not supply lift, and the stick was at the centre as much as possible, in order to prevent side load from the rotor head to the main rotor shaft, only minor or no forces at all influenced the bolt. In this phase, it was possible that the bolt, not retained by a nut, could move out of its lead due to oscillations and vibrations especially since it was lubricated, contrary to the manufacturer’s instructions.

Subsequently:

Between 18 May 2020, when the Part-145 [maintenance organisation] company had returned the helicopter, and the day of the occurrence, it had been operated 7 days and a total of 8:46 flight hours.

On 30 May 2020, the last 7-day/10-flight-hour inspection was conducted and the last release to service issued, i.e. 1:11 flight hours prior to the occurrence.

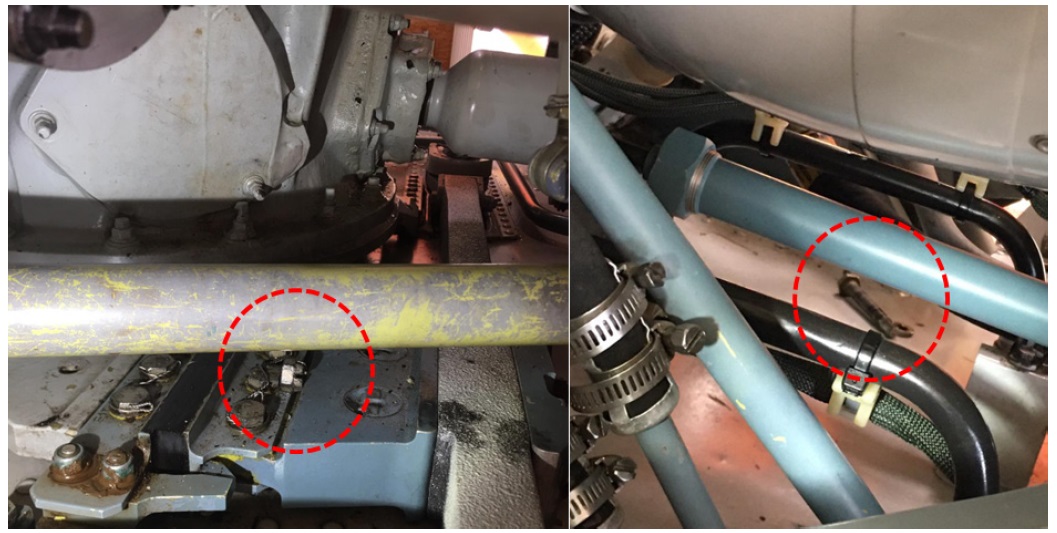

The mechanics, who performed the 7-day/10-flight-hour inspection, stated that they had not paid special attention to the connection of actuator and swashplate, which is located in a barely visible area and therefore they could not say if the nyloc nut and cotter pin had been present.

Checking the connection of the controls with the swashplate was not required as part of the pre-flight check. This area cannot be seen from the ground if faring and maintenance hatches are closed.

UPDATE: In their final report, the BFU comment that:

According to the operator, at about 1600 hrs [on the day of the accident], the PIC had informed the post-holder flight operations about the occurrence. In the following hours several phone calls were conducted between the responsible personnel of the operator. They had not viewed the occurrence as serious incident based on the available information.

In the morning of the following day a meeting of the post-holder flight operations, the managing director and the technician on duty took place at the helicopter at St. Peter Ording. On site, an appraisal of the helicopter, conversations with the crew and the transfer of equipment to a substitute helicopter were conducted.

BFU Final Report Conclusions

This serious incident was most likely caused by:

- Maintenance work where the screw fitting involved was loosened and tightened again

- Use of a worn Nylon stop crown nut with insufficient friction torque

- Application of an insufficient torque of the crown nut

- Omission of a cotter pin protection of the crown nut

- Insufficient check of the work by the examiner

- Omitted check of the screw fitting of the flight controls during the 10-flighthour/7-day-inspection.

Safety Actions

The BFU report that:

The serious incident was internally examined and analysed as part of the Safety Management Process. Possible changes and potentially necessary improvements were discussed during Safety Review Board Meetings…

Specific actions planned included:

- Based on the Base Maintenance Concept, the CAMO shall amend the transfer procedure of aircraft after maintenance work.

- The Aircraft Maintenance Program shall be reviewed and Critical Tasks be identified at the task level.

- In addition to the Release to Service, in future the immediate proof regarding all work completed (Tally Sheet) shall be provided. In order for the CAMO to verify double checks of Critical Tasks.

- The inspection list of the 10-flight-hour/7-day-inspection shall be reviewed and the responsible personnel sensitised.

Also:

Communications with the Part-145 company was intensified and mutual correction measures discussed. It was agreed to review the measurements after 12 months in the form of an audit.

The Safety Management Manual, chapter on Occurrence Reporting was reviewed. Item 12.4 Reporting and Registration Deadlines now includes the following in regard to reporting accidents and serious incidents: Accidents or serious incidents: In the event of an accident or serious incident, the BFU must be informed immediately.

Safety Resources

Without prejudging the outcome of the investigation, the UK Air Accidents Investigation Branch (AAIB) has previously reported on an accident where the main rotor blade spindle fractured on AS332L G-PUMI in Aberdeen on Friday 13 October 2006. Investigators identified that there was an…

Excessive clamping pre-load across the yoke, due to the tie bolt being torqued to the specified dry value in the presence of grease when it was reinstalled some 175 hours prior to failure of the yoke.

In July 2009 the manufacturer issued Service Bulletins which introduced a ‘wet’ assembly procedure, with new nuts, for the main rotor blade spindles.

They did also note flight loads were slightly higher than assumed during design and there were also two minor production anomalies in relation to a corner radius and shotpeening.

We have previously written:

- Misassembled Anti-Torque Pedals Cause EC135 Accident

- In-Flight Flying Control Failure: Indonesian Sikorsky S-76C+ PK-FUP

- AAR Bell 214ST Accident in Afghanistan in 2012: NTSB Report

- EC130B4 Accident: Incorrect TRDS Bearing Installation

- Fatal $16 Million Maintenance Errors

- Loose Engine B-Nut Triggers Fatal Forced Landing

- Loose B-Nut: Accident During EC130B4 Maintenance Check Flight

- Robinson R44 Power Loss: Excessive Lubricant

- Wasp Stung By Lack of Lubrication

- For Rotors Grease is the Word

- Maintenance Misdiagnosis Precursor to EC135T2 Tail Rotor Control Failure

- Fatal S-61N Dual Power Loss During Post Maintenance Check Flight

- EC135 Main Rotor Actuator Tie-Bar Failure

- Bell 429 TR Pitch Change Link Bearing Failure

- S-61N Damaged During Take Off When Swashplate Seized Due to Corrosion

- Tail Rotor Pitch Control Loss During Hoisting

- NTSB Report on 2013 S-76A++ Tail Rotor Blade Loss

- Sikorsky S-92A Loss of Tail Rotor Control Events

- AS350B2 Accident After Vibration from Unrecorded Maintenance

- UPDATE 13 September 2020: Hawaiian Air Tour EC130T2 Hard Landing after Power Loss (Part 1)

- UPDATE 27 December 2020: Fire-Fighting AS350 Hydraulics Accident: Dormant Miswiring

- UPDATE 15 March 2021: ATR 72 Rudder Travel Limitation Unit Incident: Latent Potential for Misassembly Meets Commercial Pressure

- UPDATE 8 January 2022: Fiery Fatal AW119 Accident in Russia After Loss of Tail Rotor Control

- UPDATE 9 July 2022: R44 Ditched After Loss of TGB & TR: Improper Maintenance

Among our other maintenance related articles are:

- Airworthiness Matters: Next Generation Maintenance Human Factors

- Maintenance Human Factors: The Next Generation

- Aircraft Maintenance: Going for Gold?

- Critical Maintenance Tasks: EASA Part-M & -145 Change

- B1900D Emergency Landing: Maintenance Standards & Practices

FSF Maintenance Observation Programme (MOP)

Aerossurance worked with the Flight Safety Foundation (FSF) to create a Maintenance Observation Program (MOP) requirement for their contractible BARSOHO offshore helicopter Safety Performance Requirements to help learning about routine maintenance and then to initiate safety improvements:

Aerossurance can provide practice guidance and specialist support to successfully implement a MOP.

Aerossurance’s Andy Evans was recently interviewed about safety investigations, the perils of WYLFIWYF (What-You-Look-For-Is-What-You-Find) and some other ‘stuff’ by with Sam Lee of Integra Aerospace:

Aerossurance is sponsoring and speaking at OGUK‘s 2021 aviation seminar, this year a free webinar spread across 30 June and 1 July.

Recent Comments