Airworthiness Matters: Next Generation Maintenance Human Factors

Aerossurance’s Andy Evans wrote an article in the 2016 issue of the International Federation of Airworthiness (IFA) Airworthiness Matters magazine on: Next Generation Maintenance Human Factors (available here: IFA Airworthiness Matters 2016).

ANA maintenance personnel inspecting an engine at Tokyo-Haneda (Credit: Maarten Visser CC BY-SA 2.0)

The article starts by discussing a Royal Aeronautical Society (RAeS) conference: Maintenance Human Factors: The Next Generation.

At that event Professor Dave King highlighted we needed to think “about a next generation approach to human factors in engineering”:

Over the last 10-15 years, much attention has been focused on maintenance human factors training and reporting & investigating errors. While we could concentrate on simply doing more of these and certainly can find ways to do these things better, perhaps the next generation approach needs to include a much wider range of activities.

At the conference the results of an on-line RAeS survey were discussed that indicated a need to:

- Share data better across the industry.

- Integrate HF more fully into Safety Management Systems.

- Get better at actually implementing improvements.

In relation to improvements, the Airworthiness Matters article goes on to discuss topics first raised in our on-line article: Aircraft Maintenance: Going for Gold? This posed the question: Can aviation maintenance learn lessons from championship athletes? It advocated seeing aircraft maintenance engineers less as the generators of errors and more a needing to deliver peak performance every day, hence the need for:

…a near obsessive attention to detail, to focus on every element that can affect human performance, seeking out opportunities to make small improvements, that collectively lead to noticeable performance improvement.

This also means less time spent on determining if someone should be blamed after an error and more time on systemic improvement. Evans quotes management consultant Yves Morieux of BCG commented in a TED Talk on business generally:

If you think about it, we pay more attention to knowing who to blame in case we fail, than to creating the conditions to succeed. We are creating organizations able to fail, but in a compliant way, with somebody clearly accountable when we fail. And we are quite effective at that: failing.

Evans discusses the misapplication of bureaucratic Just Culture ‘decision aids’ to ‘judge’:

…individuals not the system, with the potential to inadvertently reduce trust rather than enhance it. The circumstances that influenced an individual’s performance are seen as factors that mitigate culpability rather than systemic opportunities to improve. Inappropriate use of these mechanisms help normalise failure at the expense of collective improvement.

The destructive misuse of such Just Culture tools, like a modern day ducking stool, has a negative cultural effect, completely the opposite of some misguided advocates, who without realising it are taking a ‘Just Culpability’ approach (sometimes this is semantically turned to judging ‘accountability’, but still focused exclusively on the front line individual(s) and their behaviour). Its well worth considering Trust vs Control and How do we find belonging at work?.

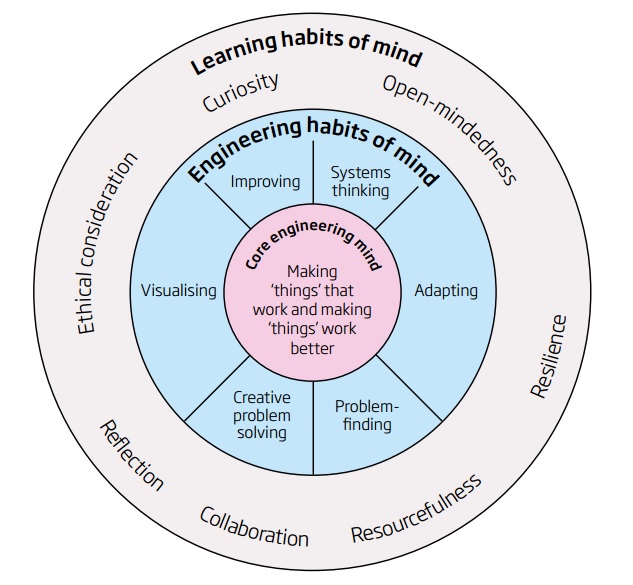

A 2014 report published by the Royal Academy of Engineering identified six engineering habits of mind (EHoM) which, taken together, describe the ways engineers think and act, all of which should help manage human factors and enhance human performance:

- Systems thinking

- Adapting

- Problem-finding

- Creative problem-solving

- Visualising

- Improving

Engineering habits of mind (EHoM) and wider learning habits of mind (LHoM) (Credit: Royal Academy of Engineering)

That report looked at how the education system suppressed children’s natural tenancies to develop these habits. Are we doing the same in the maintenance sector by over-enthusiasm for compliance with the status quo?

Amy Edmonson discusses psychological safety and openness, another function of good leadership that builds trust and aids learning:

Questions we need to ask therefore are:

- Are we over-emphasising formal reporting at the expense of open, continuous and proactive dialogue?

- Are we applying our just culture process (i.e. judging culpability) too often and just highlighting we don’t trust our

- own people?

- Do we spend as much time proactively optimising our process for improvement and building trust as we waste reactively judging people?

- Do we value continuous improvement more than compliance with the status quo?

Evans goes on to advocate that:

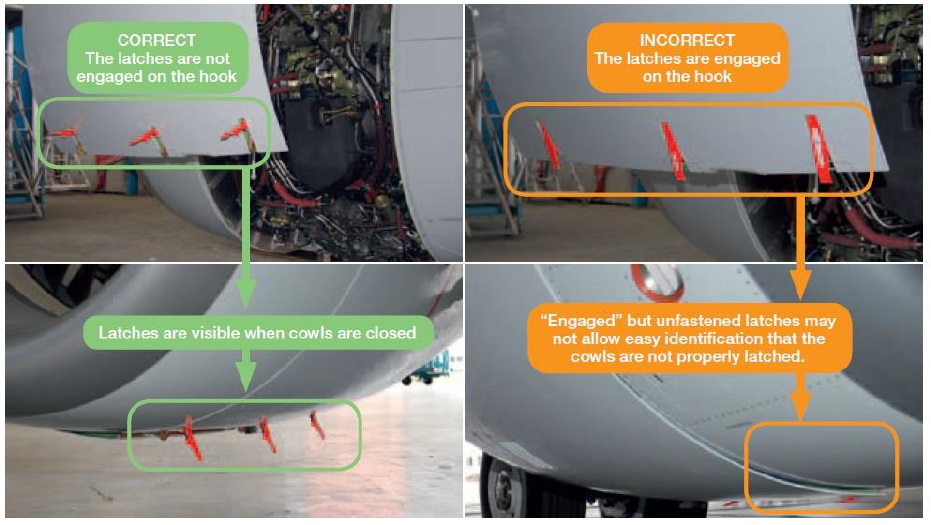

As an industry we need to be better at eliminating hazards in the design and planning stages. Design Organisations shape both the products being maintained and the supporting data. In the last few years UK AAIB have published a number of reports that highlighted maintenance tasks that are vulnerable to human error.

Examples include:

- BA A319 Double Cowling Loss and Fire – AAIB Report

- ANSV Report on EasyJet A320 Fan Cowl Door Loss

- When Down Is Up: 747 Actuator Installation Incident

The RAeS Human Factors Group: Engineering (HFG:E) has published a short guidance document on 11 steps an aviation Design Organisation (DO) can take to “deliver safer, more effective and reliable aircraft through improved design for maintenance”: First Eleven: Guidance for Designers on Maintenance Human Performance

However to really make progress managing Maintenance Human Factors, we need a collaborative effort between designers and maintainers.

In Conclusion

Evans says:

As an industry we need to put a greater emphasis on collaborative improvement if we are to break the cycle of repetitive failure and use a wider range of techniques than traditionally.

In his introduction to the whole issue, IFA President Frank Turner says, that while learning from investigations has been:

…an effective approach in the past, it is no longer appropriate for the future of a very safe industry, but one affected more than most by social media that will expose and sensationalise any shortcomings in the industries’ ability to adequately predict risk and effectively mitigate it.

Turner then echoes the Aerossurance view:

You will see from this magazine a number of papers which approach this subject, but we in IFA believe that to meet our objective of continuously improving airworthiness, we need to take the Olympic Athlete’s approach of continuous improvement in identifying those weaknesses in our risk prediction across the critical interfaces, from design through to senior management We are going for “Gold” on this one.

The big question is: are you and your suppliers?!

Other articles in the same Airworthiness Matter issue include:

- Implementing a Regulatory Safety Management System to Enable Performance Based Regulation by Matthew Margesson, UK CAA

- The FAA Compliance Philosophy by Bill Johnson, Chief Scientist and Technical Advisor for Human Factors in Aircraft

- Maintenance Systems, FAA

- Risk Culture – The Missing Link in the Safety Culture Debate by Cengiz Turkoglu, IFA Chair of Technical Committee

Aerossurance worked with the Flight Safety Foundation (FSF) to create a Maintenance Observation Program (MOP) requirement for their contractible BARSOHO offshore helicopter Safety Performance Requirements to help learning about routine maintenance and then to initiate safety improvements:

Aerossurance can provide practice guidance and specialist support to successfully implement a MOP.

See also our article in Airmed & Rescue on contracting for aviation services: The Tender Trap

UPDATE 6 February 2017: Qantas discuss a more people-centred approach to safety, where people are seen as the solution’ to building positive outcomes: Human after all

UPDATE 16 February 2017: See also our article Consultants & Culture: The Good, the Bad and the Ugly

UPDATE 16 February 2017: Aerossurance is delighted to be sponsoring an RAeS HFG:E conference at Cranfield University on 9 May 2017, on the topic of Staying Alert: Managing Fatigue in Maintenance. This event will feature presentations and interactive workshop sessions.

UPDATE 26 February 2017: Smoke in Cabin: Anatomy of a Wash Rig Error

UPDATE 1 March 2017: Safety Performance Listening and Learning – AEROSPACE March 2017

Organisations need to be confident that they are hearing all the safety concerns and observations of their workforce. They also need the assurance that their safety decisions are being actioned. The RAeS Human Factors Group: Engineering (HFG:E) set out to find out a way to check if organisations are truly listening and learning.

The result was a self-reflective approach to find ways to stimulate improvement.

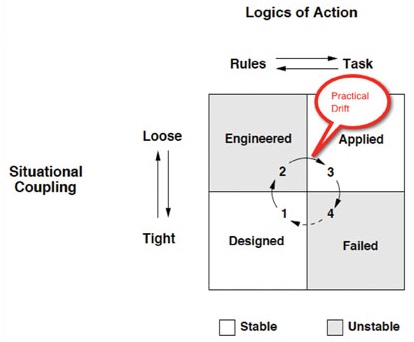

UPDATE 19 March 2017: The Rule Illusion: Organisations should beware of a ‘rules bias’, a tendency to give in to risk aversion by establishing ever more rules:

Just like in the real world, stricter rules in an organization are rarely effective in stopping the most egregious transgressions.

In practice, those who make the rules are often insulated from the true consequences. The lack of a good feedback mechanism to adjust the rules would be bad enough if the rules were based on evidence and logic. But it’s often even worse, because rules often originate from received (but dubious) wisdom, unproven ‘common sense’, or reactions to one-off events. Rules that are based on beliefs rather than evidence, and never tested, are unlikely to produce net benefits. Yet such rules are precisely the ones the makers feel most protective of. Attempts to budge them meet with the backfire effect. That’s how we end up with sledgehammers to crack a nut.

Many rules were originally intended to be guidelines to help shape behaviour, but instead over time get codified into rigid laws. Often most people in the organization no longer know why the rules were even implemented.

“Rule Nazis …. They cling to the rules like Leonardo DiCaprio clung to that door in Titanic — as if their lives depend on it. And they make sure everyone else does too, even when the rule doesn’t make sense or stands in the way of productivity,” as Heidi Grant says.

However:

A recent post on the Science For Work blog sets out how important this sense of justice at work really is. Poorly enforced rules can easily undo all the other efforts.

Rules mostly creep in one by one. As their number grows, they contribute to a culture of conformity, rather than one of intelligent judgement and empowered employees who do what is right.

Hence the need to only establish the right rules and still leave room for empowered good judgement.

UPDATE 21 March 2017: How Middle Managers Provide Leadership Everyday

Providing leadership as a middle manager requires an expanded understanding of your role and a willingness to take the risk to think and act more broadly.

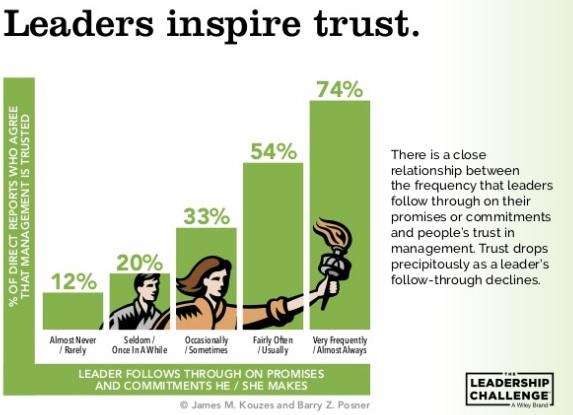

UPDATE 22 March 2017: Which difference do you want to make through leadership? (a presentation based on the work of Jim Kouzes and Barry Posner). Note slide 6 in particular:

UPDATE 25 March 2017: In a commentary on the NHS annual staff survey, trust is emphasised again:

Developing a culture where quality and improvement are central to an organisation’s strategy requires high levels of trust, and trust that issues can be raised and dealt with as an opportunity for improvement. There is no doubt that without this learning culture, with trust as a central behaviour, errors and incidents will only increase.

UPDATE 12 April 2017: See our article: Leadership and Trust

UPDATE 28 April 2017: See also our article for the Flight Safety Foundation: Maintenance Human Factors: Beyond Error to Performance

UPDATE 23 June 2017: Further undermining some of the ‘Just Culture/’Just Culpability’ decision aid approach, Steven Shorrock discusses Just Culture: Who are we really afraid of?

The judgements of those closest to us are of most concern to us for two key reasons. Co-worker judgements therefore hit closer to home. Co-workers can point out our errors in the same way that we can point out theirs. They know the work and may do it themselves, so their judgements carry most weight.

Our everyday judgements…are formed and expressed in haste…

On an operational level, blame by colleagues can lead to non-cooperation, such as the withholding of operationally relevant information within or between teams. This, in turn, becomes a safety issue.

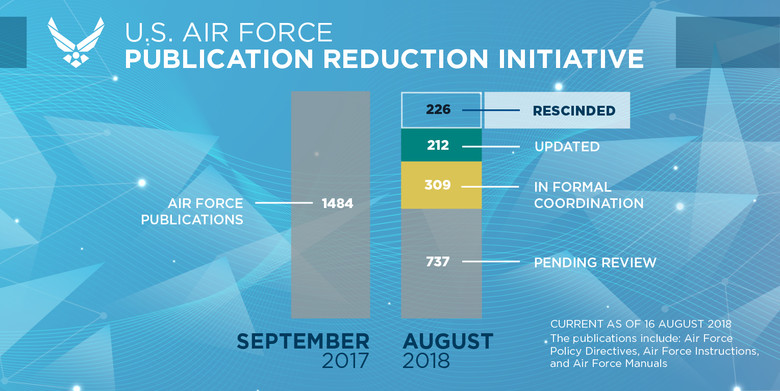

UPDATE 4 August 2017: The US Air Force plans to “significantly reduce unnecessary Air Force instructions over the next 24 months“.

Secretary of the Air Force Heather Wilson said that “the 1,300 official instructions are often outdated and inconsistent, breeding cynicism when Airmen feel they cannot possibly follow every written rule”.

The effort will start with the 40 percent of instructions that are out of date and those identified by Airmen as top priorities.

“The first step will target immediate rescission,” Wilson said. “We want to significantly reduce the number of publications, and make sure the remaining ones are current and relevant.”

The second phase will be a review of all other directive publications issued by Headquarters Air Force. These publications contain more than 130,000 compliance items at the wing level. Publications should add value, set policy and describe best practices, she said.

Wilson emphasises trust, trust in the judgement, experience and training of airmen, rather than prescribing everything.

Think about that. There are 130,000 ways a ‘culpability decision aid’ could be used, counter-productively, against 320,000 service personnel and 140,000 civilians.

One wonders how many were created by a lack of trust or due to practical drift (a concept discussed in Friendly Fire: The Accidental Shootdown of U.S. Black Hawks over Northern Iraq). Despite self-serving nonsense pushed by some consultants who haven’t studied Snook, this practical drift is not about drifting from procedures as designed, but the continual addition of bureaucracy until the point the system becomes unworkable and a failure occurs.

UPDATE 4 December 2017: United Airways Suffers from ED (Error Dysfunction). The US airline shows a strange grasp of human factors principles and argues AGAINST a human centred design change intended to address a long running series of maintenance errors.

UPDATE 2 March 2018: An excellent initiative to create more Human Centred Design by use of a Human Hazard Analysis (HHA) is described in Designing out human error

HeliOffshore, the global safety-focused organisation for the offshore helicopter industry, is exploring a fresh approach to reducing safety risk from aircraft maintenance. Recent trials with Airbus Helicopters and HeliOne show that this new direction has promise. The approach is based on an analysis of the aircraft design to identify where ‘error proofing’ features or other mitigations are most needed to support the maintenance engineer during critical maintenance tasks.

The trial identified the opportunity for some process improvements, and discussions facilitated by HeliOffshore are planned for early 2018.

UPDATE 16 March 2018: USAF F-16C Crash: Engine Maintenance Error

UPDATE 11 April 2018: The Two Traits of the Best Problem-Solving Teams (emphasis added):

…groups that performed well treated mistakes with curiosity and shared responsibility for the outcomes. As a result people could express themselves, their thoughts and ideas without fear of social retribution. The environment they created through their interaction was one of psychological safety.

Without behaviors that create and maintain a level of psychological safety in a group, people do not fully contribute — and when they don’t, the power of cognitive diversity is left unrealized. Furthermore, anxiety rises and defensive behavior prevails.

We choose our behavior. We need to be more curious, inquiring, experimental and nurturing. We need to stop being hierarchical, directive, controlling, and conforming.

We believe this applies to all teams not just those solving problems. Retrospective management application of culpability decisions aids have no more a place when trying to solve problems than they do in other work activities.

UPDATE 24 June 2018: B1900D Emergency Landing: Maintenance Standards & Practices The TSB report posses many questions on the management and oversight of aircraft maintenance, competency and maintenance standards & practices. We look opportunities for forward thinking MROs to improve their maintenance standards and practices.

UPDATE 22 July 2018: Fire After O-Ring Nipped on Installation

UPDATE 25 August 2018: Crossed Cables: Colgan Air B1900D N240CJ Maintenance Error On 26 August 2003 a B1900D crashed on take off after errors during flying control maintenance. We look at the maintenance human factor safety lessons from this and another B1900 accident that year.

UPDATE 29 August 2018: An update on the USAF Publication Reduction Initiative.

UPDATE 3 November 2018: A Lufthansa MD-11F Nose Wheel Detached after Maintenance Error

UPDATE 13 November 2018: Inadequate Maintenance, An Engine Failure and Mishandling: Crash of a USAF WC-130H: investigators discuss a strong cultural overtone in this accident that killed 9.

UPDATE 18 December 2018: USAF Engine Shop in “Disarray” with a “Method of the Madness”: F-16CM Engine Fire

UPDATE 27 December 2018: Inadequate Maintenance at a USAF Depot Featured in Fatal USMC KC-130T Accident

UPDATE 24 October 2022: The Royal Aeronautical Society (RAeS) has launched the Development of a Strategy to Enhance Human-Centred Design for Maintenance. Aerossurance‘s Andy Evans is pleased to have had the chance to participate in this initiative.

Aerossurance is pleased to be supporting the annual Chartered Institute of Ergonomics & Human Factors’ (CIEHF) Human Factors in Aviation Safety Conference for the third year running. This year the conference takes place 13 to 14 November 2017 at the Hilton London Gatwick Airport, UK with the theme: How do we improve human performance in today’s aviation business?

Aerossurance is pleased to be both sponsoring and presenting at a Royal Aeronautical Society (RAeS) Human Factors Group: Engineering seminar Maintenance Error: Are we learning? to be held on 9 May 2019 at Cranfield University.

Recent Comments