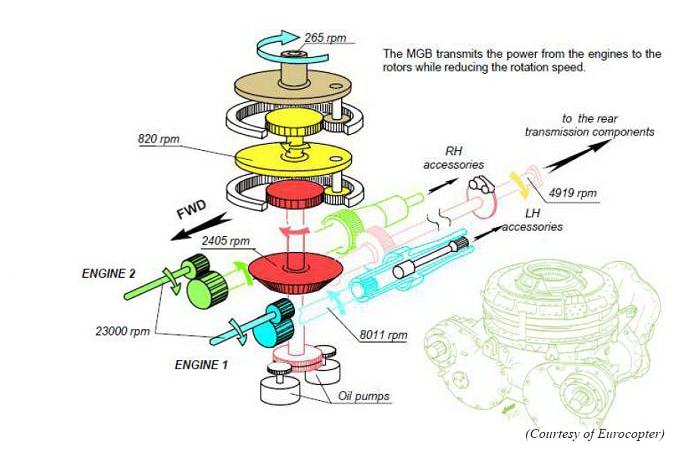

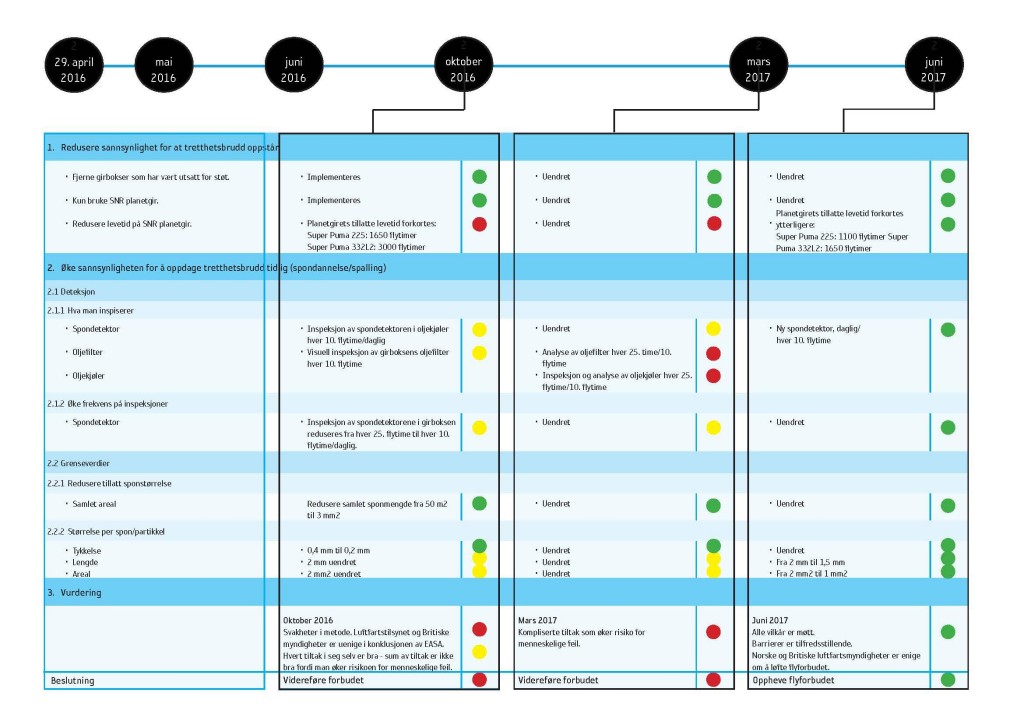

CHC Airbus Helicopters EC225 LN-OJF Accident Norway (29 April 2016) Investigation Timeline

On 29 April 2016, while making a return flight to Bergen-Flesland Airport, Norway from the Statoil Gullfaks B offshore installation, CHC Helikopter Service Airbus Helicopters EC225/H225 LN-OJF broke up in flight, with wreckage falling on land and in coastal waters at Turøy, west of Bergen, Norway.

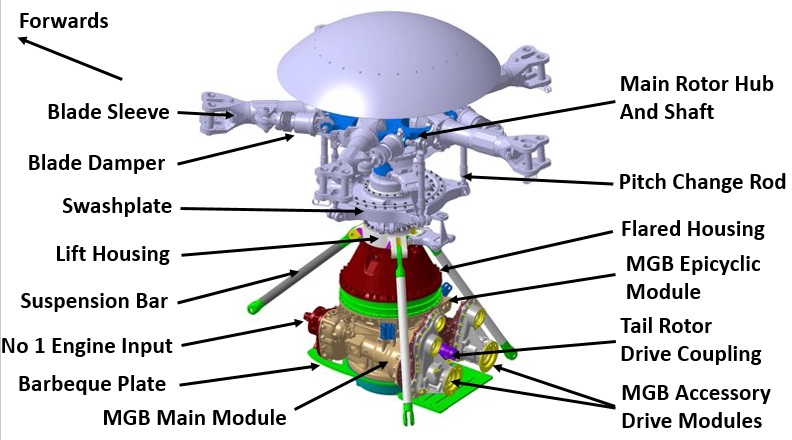

Main Rotor Head and Blades of CHC Airbus Helicopters EC225 LN-OJF near Turoy, Norway (Credit: AIB Norway)

The 13 people on board died in the accident. Witnesses captured video of the main rotor falling separate from the fuselage.

The independent Accident Investigation Board Norway (AIBN – the Statens Havarikommisjon for Transport [SHT] in Norwegian) is leading the LN-OJF accident investigation in accordance with the International Civil Aviation Organisation (ICAO) Annex 13 on air accident investigation. On the day of the accident the local aviation regulator, the Norwegian Civil Aviation Authority (the NCAA or Luftfartstilsynet) and then the UK CAA issued operational Safety Directives temporarily prohibiting the use of the type for Commercial Air Transport (CAT):

We have previously examined the EC225 Main Rotor Head and Main Gear Box Design in detail in a popular background article.

Initial Investigation Progress and Early Regulatory Action On 1 May 2016 the AIBN issued the following press release: The Helicopter Accident: The work continues

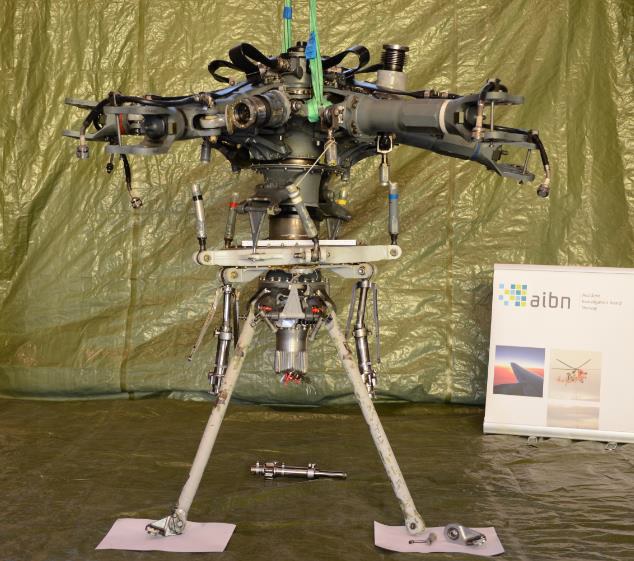

Helicopter wreckage was retrieved from land and the sea bottom Saturday [30 April 2016] and was then transferred to Haakonsvern naval base (Bergen) by ship.

The combined Flight Data and Cockpit Voice Recorder was retrieved from the wreckage Friday night [29 April 2016].

The Memory Unit Retrieved from the Honeywell Cockpit Voice / Flight Data and Recorder (CVFDR) of EC225 LN-OJF (Credit: AIBN)

The unit was taken to AAIB in England where the process of downloading data has started. Today, Sunday [1 May 2016], the work continues with search for more parts of the helicopter wreckage both at sea and on land. At the same time, the main wreckage and the large components are brought to Haakonsvern (Bergen) for further investigation.

On 2 May 2016 AIBN issued an update: The Helicopter Accident: Data from the combined FDR and CVR retrieved. Data is of good quality

On 3 May 2016 the European Aviation Safety Agency (EASA), the competent authority for airworthiness across the EU and other EASA Member States, issued Emergency Airworthiness Directive (EAD) 2016-0089-E. This called for a mandatory inspection before next flight to:

Check the correct installation of the Front and Right Hand and Left Hand Rear MGB suspension bars in accordance with the instructions of Airbus Helicopters (AH) EC225 Alert Service Bulletin No.53A058.

It also calls for the precautionary examination of the MGB Magnetic Chip Detectors (MCDs), MGB oil filter and M’ARMS Health and Usage Monitoring System (HUMS) / Vibration Health Monitoring (VHM) data. This AD did result in findings. For example Australian SDR 510023163:

During inspections IAW EASB EC225-53A058, forward suspension bar fitting was found to have bolts more than 20 per cent below the minimum torque as specified in the MMA. Check was previously carried out per AD 2006-0163 four months ago with the results satisfactory. Two similar defects reported. P/No: 332A22161321. TSN: 863 hours/915 cycles.

By 6 May 2016, wreckage had been moved from the temporary location in Bergen to the AIBN facility at Lillestrøm, just outside of Oslo: The Helicopter Accident: The search for components is resumed

Here, the AIBN will continue its efforts to sort and analyze both components and other information. The participants in the investigation are currently working from their home bases, before the team gathers in Lillestrøm early next week to continue the work together.

On 11 May 2016, twelve days after the fatal EC225 accident, the NCAA announce that NCAA and UKCAA restrictions are being extended to the AS332L2 but partially relaxed to allow SAR training.

Neither regulator mention any new information and only cite the ‘similarities’ between the helicopters.

First AIBN LN-OJF Preliminary Report (13 May 2016)

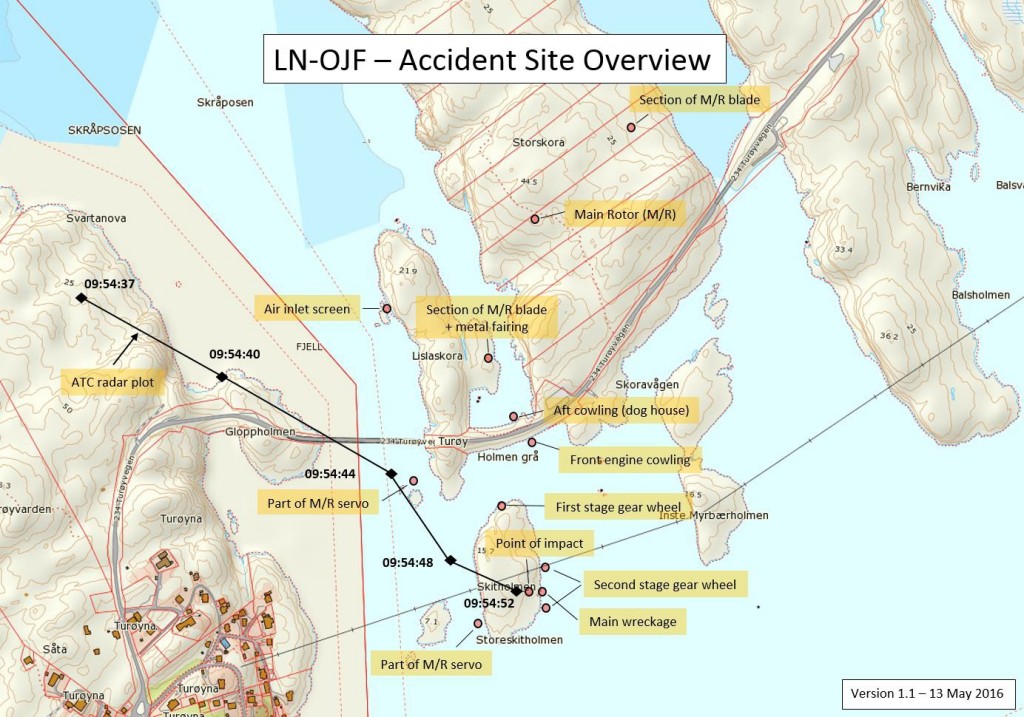

On the evening of 13 May 2016 the AIBN issued their first preliminary report. It confirms the aircraft was cruising at 200ft when the Main Rotor head (MRH) and mast suddenly detached. They state:

The recordings on the CVFDR showed that everything appeared to be normal until a sudden catastrophic failure developed in 1-2 seconds. The CVFDR recordings ended abruptly at the same time. There are no indications that flight crew actions were a factor in the accident. The AIBN is currently focussing on the examination of the [Main Rotor Head] MRH suspension bar assembly, the main gearbox and the main rotor head. Retrieved wreckage parts and other components are stored for future examinations as required.

Parts from EC225 LN-OJF 2nd Stage (i.e. upper) Epicyclic Stage with a Fractured Planet Gear Placed on Top of a New Gear (Credit: AIBN)

However, several key components are still missing. A significant sea and land search is on-going in order to retrieve these components.

Debris Plot for EC225 LN-OJF Note: Time on ATC Radar Plot is UTC (Credit: Norwegian mapping Authority and AIBN)

At this preliminary stage of the investigation, detailed metallurgical examinations have not been performed. The examinations so far have not shown any sign of fatigue failure.

HUMS / VHM data from the flight has been recovered. VHM data and maintenance records were still to be examined at this stage.

Second AIBN LN-OJF Preliminary Report (27 May 2016)

On 27 May 2016 the second preliminary report was issued by AIBN. It stated:

A spectral analysis of the CVR data has been carried out. There was no obvious indication of an abnormality before the sudden detachment of the rotor head. The Health and Usage Monitoring System (HUMS/PCMCIA) card was retrieved and has been examined by BEA. The logic of the HUMS system is that HUMS data is saved to the card after the helicopter has landed onshore. Thus, data from the accident flight was not available. However, the system also stores some Flight Data parameters that are used for Flight Data Monitoring (FDM). On 12 May, the BEA succeeded in downloading FDM data that extended approximately 13 seconds beyond the CVFDR data. A preliminary analysis was ready a week later. It provides valuable information about the sequence of events and will be analysed further. On 20 May, key pieces of wreckage were sent to selected laboratories, including Airbus Helicopters, for detailed examination. …some key components are still missing. These components are in particular the epicyclical second stage planet gear carrier and parts of the forward suspension bar.

The official investigation team led by AIB Norway (AIBN) met at Airbus Helicopters (AH) in Marignane on 24, 25 and 26 May 2016 with the additional participation, BEA France, AAIB UK, EASA, CAA UK and CHC. The main purpose of this 3 days meeting was to agree on further investigation of the parts that the AIBN had sealed and sent to Airbus Helicopters, and to discuss a list of possible scenarios that could explain the detachment of the main rotor.

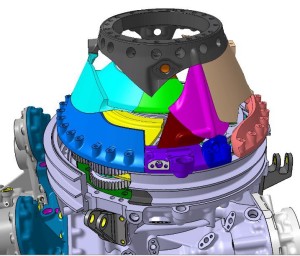

The investigation team has discussed a list of scenarios that Airbus Helicopter prepared based on fault tree analysis. At this stage, the AIBN can confirm that the scenarios under consideration include failure of epicyclic module, suspension bar (lift strut) attachment and MGB conical housing.

Airbus Helicopters issued a Safety Information Notice (SIN 3043-S-00) on 30 May 2016 that described 7 scenarios that had been / were under investigation:

- Epicyclic ring gear failure due to fatigue failure – rejected as inconsistent with evidence gathered

-

Abnormal loads on the main rotor (e.g. due to impact with FOD, a flight control issue, blade damage etc) – rejected as inconsistent with evidence gathered

-

BBQ plate loss of attachment – rejected as inconsistent with evidence gathered

-

Conical housing failure

-

Jamming / seizing of the epicyclic module – rejected as inconsistent with evidence gathered

-

Epicyclic ring gear failure following internal epicyclic module damage

- Suspension bar attachment failure.

Third AIBN LN-OJF Preliminary Report (1 June 2016) The third AIBN preliminary report was issued on 1 June 2016. This contained an urgent safety recommendation addressed to EASA:

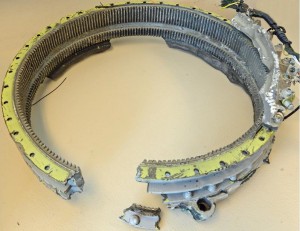

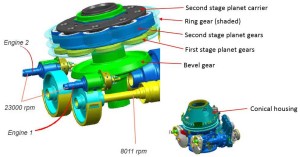

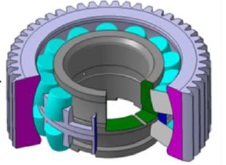

Detailed metallurgical examinations have been ongoing since 19 May. Several parts from the second stage epicyclic module were retrieved from the accident site. The epicyclic module planet gears are designed as a combined gear and bearing assembly.

Planet gears have a double function, acting as a gear on the outside while at the same time functioning as the outer race of a roller bearing on the inside.

In order to improve wear resistance it has been given a hard outer surface through a carburization process. Among the recovered parts were two pieces which together form approximately half a second stage planet gear.

Almost Half of One Particular 2nd Stage Planet Gear from LN-OJF was Recovered. It was in Two Pieces (Credit: QinetiQ via AIBN)

Examinations of these parts have revealed features strongly consistent with fatigue. The fatigue appears to have its origin in the outer race of the bearing (inside of the gear), propagating towards the web of the gear teeth. There is sign of spalling in front of the fracture surface. It cannot be ruled out that this signifies a possible safety issue that can affect other MGBs of the same type.

A View from Below of a 2nd Stage Epicyclic Stage. Note the 8 Planet Gears and the Bearings within them (Credit: AAIBN)

Although preliminary, the AIBN considers these findings to be of such significance that it has decided to issue the following safety recommendation to ensure the continuing airworthiness of the Main Gear Box (MGB).

Safety Recommendation: Recent metallurgical findings have revealed features strongly consistent with fatigue in the outer race of a second stage planet gear in the epicyclic module of the MGB. It cannot be ruled out that this signifies a possible safety issue that can affect other MGBs of the same type. The nature of the catastrophic failure of the LN-OJF main rotor system indicates that the current means to detect a failure in advance are not effective. The AIBN therefore recommends that EASA take immediate action to ensure the safety of the Airbus Helicopters H225 Main Gear Box.

The gear is made from 16NCD13 steel. On the same day NCAA extend their Safety Directive to stop all EC225 and AS332L2 flights: NCAA SD 16/05616-9 An EASA EAD, EAD 2016-0103-E with wider applicability to the AS332L2, was coincidentally issued the same day. This however was focused on findings from the earlier EAD:

The review of the data reported in accomplishing AD 2016-0089-E, revealed installation findings for the MGB upper deck fittings of the three MBG suspension bars, to include, among others, tightening torque values on the attachment bolts of the fittings being out of tolerance and some incorrect washers positioning in the fitting assemblies. Prompted by these findings, Airbus Helicopters (AH) issued EC225 ASB No. 53A059 (hereafter referred to as ‘the applicable ASB’ in this AD) to provide further inspection and replacement instructions for correct installation of the MGB suspension bars and attachment fittings.

On 2 June 2016 UKCAA also extended their Safety Directive to stop all EC225 and AS332L2 flights and EASA issued a flight prohibition EAD:

EASA say in the EAD (which does not affect State Aircraft, which remain under national legislation in EASA Member States):

The review of the data reported in accomplishing AD 2016-0089-E, revealed installation findings for the MGB upper deck fittings of the three MBG suspension bars. Prompted by these findings, EASA issued superseding AD 2016-0103-E for further inspection and replacement instructions for correct installation of the MGB suspension bars and attachment fittings.

Soon after EASA AD 2016-0103-E was issued, a second preliminary report from the investigation board indicated metallurgical findings of fatigue and surface degradation in the outer race of a second stage planet gear of the MGB epi-cyclic module. At this time, it cannot be determined if this is a contributing causal factor or subsequent failure from another initiating factor. Pending further investigation to determine the root cause(s) of the reported damage, and development of mitigating measures by Airbus Helicopters, EASA has decided, as an additional precautionary measure, to temporarily ground the fleet.

For the reason described above, this AD prohibits flight of the AS 332 L2 and EC 225 LP helicopters.

Airbus Helicopters stated on 2 June 2016 that:

In light of new findings from the AIBN’s preliminary accident investigation report, Airbus Helicopters supports EASA’s cautious approach. We continue to fully support the AIBN, EASA, our customers and the ongoing investigation by providing information in full transparency, while working with the wider industry to ensure safety.

HeliOffshore issued a statement on 3 June 2016 that:

This combination of [regulated] processes with a detailed investigation being undertaken by AIBN, supported by Airbus and others, gives us the belief that the root cause will, in time, be fully understood; then and only then, can the appropriate corrective measures be put in place to ensure that the issue is resolved… Our commitment to the investigation remains absolute; our commitment to identifying and addressing the root cause remains absolute; our commitment through collaboration with all stakeholders, not least the offshore workforce, to only returning the aircraft to service when it is safe to do so remains absolute.

On 15 June 2016 Airbus Helicopters issued Emergency Alert Service Bulletins (EASBs) on the AS332L2 (EASB 05.01.07), the military AS532A2 and U2 (EASB 05.00.82), the EC225 (EASB 05A049) and military EC725 (EASB 05A045), which effectively are applicable only to aircraft unaffected by the EASA Flight Prohibition. These require:

-

Inspection of the MGB oil filter and chip detectors after the last flight of the day

-

Cessation of flying with epicyclic modules which have been involved in an unusual event since new or Complete Overhaul and return for Complete Overhaul

Airbus Helicopters note the investigation in Norway is on-going and although no conclusions have been reached these EASBs have been introduced as a precautionary measure as:

…the MGB of the helicopter involved in the accident had been subject to a shock impact during road transport a few months previously.

On 3 June 2016 the US Federal Aviation Administration (FAA) also issued an EAD.

Fourth AIBN LN-OJF Preliminary Report (28 June 2016)

On 28 June 2016 the AIBN release a fourth preliminary report.

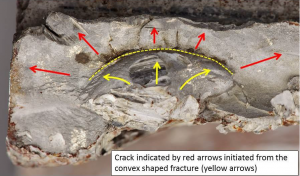

Two pieces of the recovered parts have been of particular interest. Together they make up approximately half of a second stage planet gear P/N 332A32.3335.07, S/N 10-1292. Examinations of these parts show that one of the fracture surfaces can be described as being close to 100% fatigue.

Crack In 2nd Stage Planetary Gear from EC225 LN-OJF Viewing the End of One of the Recovered Pieces (Credit: QinetiQ via AIBN)

Growth of a fatigue crack requires repeated load cycles, for example through rotation of a gear or a main rotor start/stop cycle. The fatigue appears to have its origin in the outer race of the bearing (inside of the gear), propagating towards the web of the gear teeth.

The AIBN say there are similarities (but some differences) to the 1 April 2009 Bond G-REDL AS332L2 accident. The fatigue origin apparently sub-surface near the bearing outer race, propagating outwards towards the teeth. A Computed Tomography (CT or CAT) scan conducted at the University of Southampton identified sub-surface cracking between patches of inner race surface spalling.

CT scan showing a subsurface crack propagating from the RH spalling to the left. The red colour is a frame-by-frame mapping performed by hand to highlight the crack. (Credit: University of Southampton via AIBN)

Therefore the AIBN have tentatively concluded:

At this stage of the investigation, the AIBN finds that the accident most likely was a result of a fatigue fracture in one of the eight second stage planet gears. It appears that the fracture has propagated in a manner which is unlikely to become detected by existing mandatory or supplementary systems for warning of an imminent failure. What initiated the fracture has not yet been determined. AIBN will also look into the follow-up of safety recommendations issued after the Super Puma accident in Scotland in 2009 [G-REDL].

The AIBN suggests the crack propagation was contrary to design assumptions that the compressive stress near the surface of the inner race would effect sub-surface cracks. AIBN say no debris had been found previously and no procedural maintenance failures occurred. The AIBN also suggest the defect may not be detectable by HUMS. The AIBN confirm the Time Since New (TSN) of the MGB was 1340 hours (260 hours since installation on LN-OJF on 15 January 2016). The transit damage, mentioned in earlier Airbus Helicopters Emergency Alert Service Bulletins is still under investigation. AIBN updates are now predicted to be less regular. Airbus Helicopters have said:

Airbus Helicopters takes note of the AIBN’s preliminary report update and welcomes the significant progress made by the investigation. We continue to focus our efforts on providing assistance to the investigation team and the authorities as they work toward the identification of the accident root cause. In parallel, we are putting precautionary measures in place to support our global customers and address potential initiating events.

On 29 June 2016 Airbus Helicopters issue EASBs on the AS332L2 (EASB 63.00.83), the military AS532A2 and U2 (EASB 63.00.38), the EC225 (EASB 63A030) and military EC725 (EASB 63A029). These state:

As a precautionary measure, it was decided to maintain only one of the two types of epicyclic module second stage planet gears in service.

This is because:

- The detailed design of [one type of] the planet gear bearing has an increased damage tolerance.

- Modelling and calculation reveal a lower load level on the external race of the planet gear bearing.

- In-service experience shows enhanced reliability.

The EASBs require the replacement of the other type within 15 flying hours. Airbus Helicopters (AH) also issued SIN 3053-S-00 on 29 June 2016 that described 7 scenarios that had been under investigation:

- Epicyclic ring gear failure due to fatigue failure – previously rejected as inconsistent with evidence gathered

-

Abnormal loads on the main rotor – previously rejected as inconsistent with evidence gathered

-

BBQ plate loss of attachment – previously rejected as inconsistent with evidence gathered

-

Conical housing failure – “AH still assesses this as a consequence and not as a cause. Work is in progress to definitely close this scenario”.

-

Jamming / seizing of the epicyclic module – “AH observes that the jamming event is contradicted by available evidences. Work is in progress to definitely close this scenario.” The relevant evidence is believe to include evidence that the tail rotor continued to be powered via the MGB at impact.

-

Epicyclic ring gear failure following internal epicyclic module damage – as discussed by AIBN (plus see below).

- Suspension bar attachment failure – still subject to further AH tests and EASBs on verifying individual installations to fully eliminate all concerns.

In relation to scenario 6 and the current AIBN focus, Airbus Helicopters say:

The cause for the initiation of the fatigue fracture remains to be determined. It may be the followings:

- Unusual event suffered by the MGB (for example a transport incident)

- FOD in the MGB

- Other MGB causes (including manufacturing process, metallurgical issues,…)

Some tests and calculation are being performed on the second stage planet gears. The purpose of these tests is to reproduce the fatigue crack, determine its origin and better define its speed propagation.

Further Developments

UPDATE 20 July 2016: It is reported that the Norwegian Government has granted additional funding to the AIBN to cover the extra costs of the investigation:

According to reports in Norwegian media, the amount provided is said to be around five million Norwegian Krone. However the AIBN would not confirm the amount provided by the government but said it was “enough” to help them carry out their work. A spokesman for the AIBN said: “The Norwegian Government provides funding as needed for investigations. “When a major incident happens like this we will ask for more money as needed in addition to the regular budget.”

UPDATE 27 July 2016: Flight International report that during a half-year results call on 27 July 2016 Airbus Group CEO Tom Enders said:

…the company is making “good progress” with EASA towards understanding how soon the H225 and AS332 fleets might be returned to flight. “We are engaged in discussions with EASA to see when we can release the Super Puma fleet again. We want to get out of this situation as quickly as possible,” Enders says, noting that about 80% of the fleet remains grounded. Airbus Helicopters says talks with EASA are key to lifting the grounding, but declines to comment on any timeline for that to be achieved.

UPDATE 19 August 2016: Former Bristow Director Allan Blake writes for HeliHub: The distressed EC225 fleet – A review

UPDATE 31 August 2016: Airbus Helicopters braces for post-Turøy impact

UPDATE 5 September 2016: We are very sad to learn that one of the AIBN investigators, Edith Irgens, passed away last month (Norwegian language obituary).

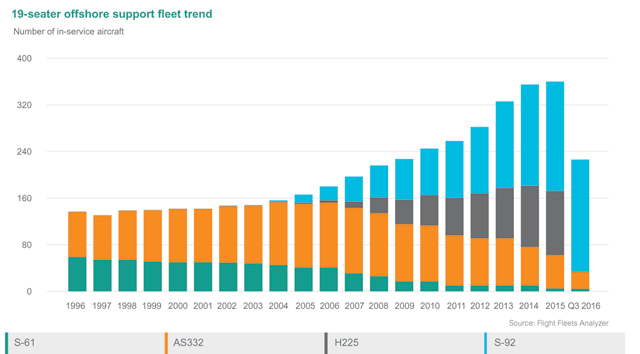

UPDATE 20 September 2016: AW&ST publish: S-92 Usage Leaps After EC225 Grounding, Sikorsky Says

UPDATE 23 September 2016: Flight International publish: Market turmoil for offshore operators

The above graphic shows how reliant the industry is currently on a stretched S-92A fleet.

UPDATE 23 September 2016: Statoil issue their internal investigation into their handling of the accident and flight safety.

UPDATE 29 September 2016: Statoil release the English language version of their internal investigation. The aim of this report is said to be to determine:

- How can Statoil’s helicopter safety-related work be strengthened?

- Was the emergency response to the Turøy accident handled in accordance with Statoil’s governing documentation?

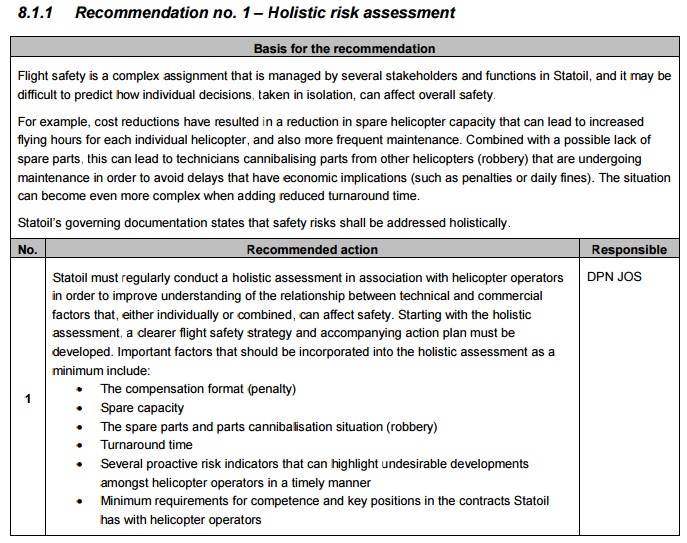

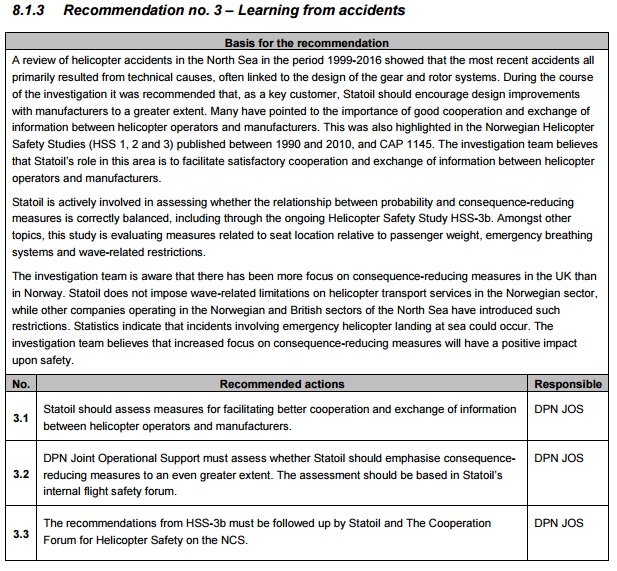

They emphasise they did not aim to determine the cause of the LN-OJF accident as that is the role of the AIBN. In their conclusions they say:

Helicopter safety is a complex assignment that is managed by several stakeholders and functions in Statoil, and it may be difficult to predict how individual decisions, taken in isolation, can affect overall safety. There is a need to strengthen safety by highlighting and better understanding the relationship between technical and commercial factors that, either individually or combined, can affect safety. With this as a starting point, a clearer flight safety strategy and associated plan of action must be prepared. The organisation of helicopter safety-related work in Statoil appears to be complicated, with many participants and a varying understanding of each individual participant’s role. Although it is not apparent that this has impacted negatively upon the quality of helicopter safety-related work to date, the investigation team recommends that a review of the organisation of helicopter safety-related work in Statoil be conducted to ensure simplification and a clearer description of participants’ roles. This particularly applies to the distribution of roles between the departments for flight safety, air transport and procurement, and personnel with the role of Company Representative (CR).

They also comment:

Statoil’s strategy has been to utilise at least two different types of helicopter, primarily to ensure business continuity and robustness in the event of one type of helicopter being grounded for any reason. Following the accident on 29 April 2016, all Airbus H225 and L2 Super Puma helicopters were grounded, and as a result Statoil could only use the Sikorsky S-92 helicopter for offshore personnel transport. The investigation team is of the opinion that using just one type of helicopter may increase the operational risk related to personnel transport, but it does not increase the safety risk. Statoil has initiated a project to look into alternative helicopter transport solutions. The project will, amongst other things, propose a strategy for backup solutions for the existing Sikorsky S-92 helicopter and other alternative transport solutions. A recommended strategy for realising the proposed solutions will also be developed.

Another aspect examined was commercial rates and penalties:

During the contract period Statoil can make commercial dispositions that affect the helicopter operators’ financial position, including cancelling the contract or renegotiating the rates. A reduced need for helicopters, combined with a need to reduce costs, has led to an increase in the scope of such dispositions in recent years. Several of the individuals that the investigation team has spoken with have questioned whether the “penalty” regime [for late or delayed flights] may negatively affect helicopter safety. The investigation team believes that further work must now be done with this recommendation, and to see whether other systems that stimulate punctuality and regularity can be found, without the negative effects that are highlighted above. One possible system is described in the {2010 HSS-3] SINTEF study: “One suggestion is that fines are not imposed on the basis of single flights, rather that they are based upon relevant monthly statistics and current indicators”.

The investigation made eight recommendations in 4 areas.

- Statoil’s organisation and activities related to helicopter services – recommendations 1, 2 and 5

- Following up and learning from helicopter incidents – recommendation 3

- New EU regulations – recommendation 4

- Emergency response – recommendations 6, 7 and 8

In particular these are of most interest:

This is further discussed in an article by Allan Blake for HeliHub: Stretching Safety too Far – a Withering Safety Culture UPDATE 7 October 2016: EASA issue AD 2016-0199 that responds to the AIBN recommendation, lifting the flight prohibition. EASA say that following further investigation of:

This is further discussed in an article by Allan Blake for HeliHub: Stretching Safety too Far – a Withering Safety Culture UPDATE 7 October 2016: EASA issue AD 2016-0199 that responds to the AIBN recommendation, lifting the flight prohibition. EASA say that following further investigation of:

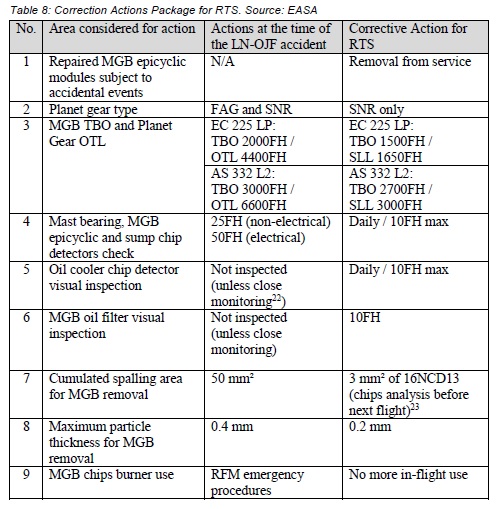

…possible accident contributory factors and determined that the likely cause relates to the rupture of the second stage planet gear, which was found with fatigue and surface degradation. Although the root cause of this failure is still not fully understood, it involved cracking of the planet gear bearing outer race, some spalling and propagation of a crack into the rim of the gear, finally resulting in its rupture.

There are two configurations of planet gear. Each features different bearings.

In depth review of the design and service data showed that one configuration has higher operating stress levels that result in more frequent events of spalling, associated with rolling contact fatigue, while the other exhibits better reliability behaviour. By limiting the type design to the gear configuration with lower stress levels and better reliability and specifying a reduced life limit, combined with more effective oil debris monitoring procedures and other operational controls, an acceptable level of safety can be restored.

Airbus Helicopters has issued AS332 Emergency Alert Service Bulletin (ASB) 63.00.83 and EC225 ASB 63A030 (single document at Revision 1), and AS332 Emergency ASB 05.01.07 and EC225 ASB 05A049 (single document at Revision 2). In addition the Service Life Limit (SLL) of the remaining planet gear is reduced and replacement of parts involved in any unusual events (such as a lightning strike or ground handling/transport damage) is made mandatory. UK CAA has issued a very brief statement that at this time their:

…existing restriction, prohibiting all commercial flying of this type by UK operators, is to remain in place.

We are united in our approach with the Norwegian Civil Aviation Authority. Both agencies now await further information from the accident investigation before considering any future action.

The Norwegian CAA has issued a statements in Norwegian and English.

HeliOffshore has issued an explanatory statement (as have Step Change in Safety). They say:

HeliOffshore members who operate these aircraft types will review the evidence and determine, with customers, the implications of the EASA Directive for search-and-rescue and oil-and-gas operations – with safety being their primary consideration. At each step, for every organisation involved, the safety of passengers and crew comes first.

Airbus Helicopters has commented:

We are providing assistance to our customers and working with related stakeholders in order to help them return their aircraft to service at the appropriate time. Meanwhile, we maintain our full support to the AIBN in the frame of the ongoing investigation.

Extensive liaison has been underway in the last few days and further engagement between the multiple stakeholders is expected in the coming days.

UPDATE 12 October 2016: In an interview with Flight International Airbus Helicopters CEO Guillaume Faury says:

“Some people say we have not understood [the root cause]. We know a lot. We are down to a small number of scenarios, which are very precise scenarios, for which we can put appropriate protections in place,” he says. He is adamant that “it is not the case” that the Super Puma is no longer wanted by North Sea operators, but admits there has been “a significant loss of trust”. “It is something we fully recognise and are fully aware of and we have to go through the steps to restore that trust. That has to be based on very robust, convincing, solid arguments.”

Faury says that it will now begin a wide-ranging engagement process with all stakeholders as it looks for a full return to service.

However, Faury acknowledges that the process cannot be rushed and that it must proceed “step by step”. It is a “process that’s going to take time”, he says, of which EASA’s move is only the start.

Meanwhile in an article for HeliHub, Allan Blake reports:

An Airbus source explained that they had conducted over 20,000 bench hours of tests to identify the cause of the accident, the results of which were passed to EASA.

Blake also quotes Aerossurance own Andy Evans, a former UK CAA / JAA Rotors and Transmission Specialist:

While clearly there will be a challenge to rebuild passenger confidence it’s vitally important for the whole industry (operators, their customers and all OEMs) that rational decisions are made with full understanding of the available information.

UPDATE 22 October 2016: H175 helicopters add resilience to North Sea industry, safety chief says as NHV open new Aberdeen heliport.

UPDATE 28 October 2016: Many hurdles ahead before H225 can return to flight

UPDATE 6 December 2016: Statoil to Stop Using H225 Helicopter Variant Involved in Crash (though our continuing to use two AS332L1s for LIMSAR).

UPDATE 9 December 2016: Airbus Helicopters sued by three companies over H225 situation (two lessors and ERA).

UPDATE 15 December 2016: It is reported that the FAA approves return to service of H225 helicopter:

Via an alternative means of compliance (AMOC) notice, the FAA has adopted a number of measures contained in an emergency airworthiness directive (EAD) issued by European regulators in early October, designed to detect the warning signs of an imminent main gearbox failure.

“We will follow this in the coming months with [a new] airworthiness directive, but the AMOC provides the approval to accomplish what needs to be done,” says the FAA.

UPDATE 15 December 2016: Reversing the Trend: Offshore Safety in Norway

UPDATE 30 December 2016: This was our 11th most popular article of 2016.

UPDATE 3 January 2017: Airbus Malaysia have just completed a G check on a Southern Vietnam Helicopter (VNHS) AS332L2, suggesting that the type has, or is just about to resume service offshore in Vietnam. Its not clear which oil company/companies are the customer.

UPDATE 10 January 2017: Waypoint Leasing announced it is leasing one H225 helicopter to Global Helicopter Service (GHS), a German operator active in Africa, for utility and humanitarian support missions.

UPDATE 13 January 2017: The same week as widespread disruption occurred due to an Alert Service Bulletin on the S-92A after a tail rotor control failure, Flight International reports that Airbus Helicopters meets regulators to discuss H225 grounding. The NCAA say:

…its representatives, along with those from the UK, attended a meeting in Marigane on 10 January to discuss the H225. Petter Haugen, acting director-general of the Norwegian CAA, says: “The purpose of the meeting was to exchange views regarding to the situation, and seek mutual knowledge and understanding. It was a constructive meeting with an open dialogue. We will continue co-operation and dialogue regarding short- and long-term measures.”

The UK CAA confirmed that the H225 was on the agenda of a recent ‘routine’ meeting. There is industry speculation that both nations are potentially in breech of European Law by persisting with airworthiness related operational directives following EASA AD 2016-0199 that are outside of their legal competence.

UPDATE 27 January 2017: In a Reuters article, Airbus Helicopters CEO Guillaume Faury is quoted as saying:

We don’t want to solve the problem and move forward…we want to grow out of this crisis much strong and much better.

Reuters say:

Faury said he expected Norway to release its final report on the Norwegian accident “in the next few months”.

He pledged to review processes to raise safety across the offshore industry… More monitoring and sensors could play a role.

UPDATE 2 February 2017: In a short update the AIBN seem to scotch any notion of an immanent final report. they say:

The scope and complexity of the investigation means that it is not feasible to estimate a completion date for the final report. The investigation continues with the same high activity. Aviation authorities in Norway and Europe are continually updated about the investigation.

The AIBN intends to issue a new preliminary report on 29 April 2017, unless there are significant new discoveries necessitating an interim report in the meantime.

They comment:

The investigation is complex, and has a wide scope. So far, the metallurgical studies have been a major focus. These are efforts to map and understand why fatigue cracks could form and evolve. This work has not yet been completed. At present time, the primary focus of the AIBN investigation is certification aspects of the main gearbox and the robustness of past and present design requirements. This includes the follow-up on safety recommendations issued by the AAIB in connection with the accident involving G-REDL and continuing airworthiness of the gearbox. This work requires good collaboration with the responsible entities, primarily the helicopter manufacturer and the European Aviation Safety Authority (EASA).

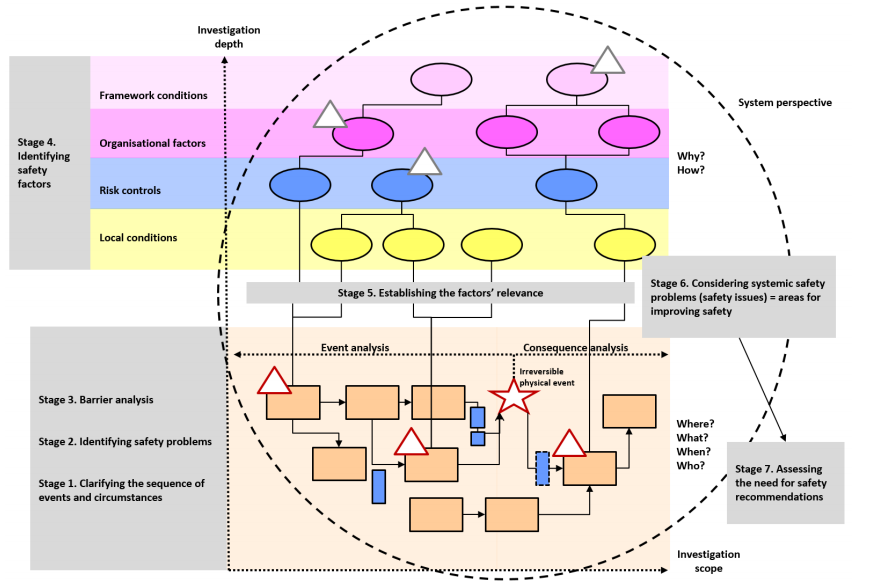

UPDATE 7 February 2017: The AIBN has also published their accident investigation and analysis methodology. The process is divided into the following seven stages:

- Stage 1: Clarifying the sequence of events and circumstances of the accident.

- Stage 2: Identifying safety problems = ‘what went wrong’ in the sequence of events.

- Stage 3: Barrier analysis.

- Stage 4: Identifying safety factors.

- Stage 5: Establishing the factors’ relevance (existence, influence and importance).

- Stage 6: Considering systemic safety problems (safety issues) = areas for improving safety.

- Stage 7: Assessing the need for safety recommendations.

UPDATE 7 February 2017: Airbus Helicopters has issued an ASB for a one-time inspection to check for the presence of metallic particles in the oil cooler on EC225 and AS332L2 whose second-stage planet gears have accumulated over 300 hours of flight time since new. This ASB is subject to EASA AD 2017-0042 in which EASA say:

UPDATE 7 February 2017: Airbus Helicopters has issued an ASB for a one-time inspection to check for the presence of metallic particles in the oil cooler on EC225 and AS332L2 whose second-stage planet gears have accumulated over 300 hours of flight time since new. This ASB is subject to EASA AD 2017-0042 in which EASA say:

…further testing investigation has delivered additional results as regards the close monitoring provisions. Those results require to amend the inspection regime in place with a one-time inspection of the oil cooler to acquire additional information on the condition of the MGB oil system.

Airbus has commented that “this new inspection further enhances the protective measures currently in place and are part of the wider safety case addressing EC225/AS332L2 operations worldwide”.

UPDATE 8 March 2017: AIBN announce that divers from the Norwegian Naval Diving School have recovered the epicyclic gear 2nd stage planet gear carrier.

UPDATE 13 March 2017: The fate of the North Sea’s Super Puma helicopter fleet could ultimately be decided by factors like public confidence not just safety assurances, UK union leader Jake Molloy today claimed. This followed a meeting of the Offshore Helicopter Safety Leadership Group (OHSLG) in Aberdeen on 28 February 2017:

A spokesperson for the UK Civil Aviation Authority, said: “The UK and Norwegian authorities have confirmed that existing restrictions, preventing commercial use of the H225LP and AS332L2 Super Puma helicopters in the two countries, remains in place. “At a meeting in Aberdeen on February 28, workforce representatives, helicopter operators and the offshore industry were updated by Airbus Helicopters and the European Aviation Safety Agency on the progress that has been made on developing significant changes and inspections to the helicopter type that could, in the future, allow the UK and Norwegian authorities to lift restrictions. “Significant information from the investigation of the tragic 2016 Norwegian accident is now available and we await further information. Any decision will be made only after extensive consultation, investigation and consideration. At the meeting Airbus Helicopters provided an update on the progress made in relation to the LN-OJF investigation. Step Change in Safety Executive Director Les Linklater…said: “All members were given a presentation by Airbus Helicopters providing an update on the progress made on the LN-OJF [Norway] investigation. “The meeting was a transparent, informative and focused session to discuss advances being made into raising standards in flight safety”.

UPDATE 17 March 2017: EASA issue EAD 2017-0050-E:

Since EASA AD 2016-0199 was issued, further testing investigation provided additional results regarding the close monitoring provisions. Following those results, EASA issued AD 2017-0042 (later revised) to require a one-time inspection of the oil cooler and the reporting of findings to acquire more information on the condition of the MGB oil system. Additional analysis and flight testing determined the need to amend the inspections required by EASA AD 2016-0199 to improve the detection capability of MGB planet gear degradation.

Consequently, AH issued AS332 Emergency ASB 05.01.07 and EC225 ASB 05A049 (single document at Revision 4) to provide the necessary instructions. For the reasons described above, this AD retains the requirements of EASA AD 2016-0199, which is superseded, modifies the MGB oil filter inspections regime, additionally requires repetitive inspections of the MGB oil cooler and, depending on findings, accomplishment of applicable corrective action(s).

UPDATE 24 April 2017: The AIBN have announced they will hold a press conference in Lillestrøm Friday 28 April at 1300 hours. Prior to that they will issue a preliminary report in English:

…in order to present an updated status of the investigation. The report contains mainly factual information available so far in the investigation. The report also contains some AIBN comments.

UPDATE 25 April 2017: The press report that the UK CAA has written to a number of stakeholders. While they say the:

The report is comprehensive (101 pages) and provides significant detail. No new information for the CAA has emerged from the report and there are no safety recommendations.

However:

Developments on the lifting and the detection capability look promising and we are hopeful that after obtaining further information we will be closer to removing our directives. At this time however the [Norwegian and UK] directives remain in place.

Meanwhile, union leaders suggest that further confidence building will be necessary with the workforce. UPDATE 27 April 2017: The Petroleum Safety Authority (PSA) of Norway comment on their 2016 study of trends in risk level in Norway’s petroleum activity (RNNP) that there are:

…a number of bright spots [but] important findings…give PSA director general Anne Myhrvold cause for concern. “It’s worrying that the major accident indicator for 2016 and 2015 is higher than for the two previous years,” says Myhrvold.

However:

“Good results are no guarantee against future incidents,” she warns, and points to the helicopter crash at Turøy near Bergen in April 2016 when 13 people died. This accident occurred the day after the 2015 RNNP report was presented, and highlighted the positive trend for helicopter safety.

UPDATE 28 April 2017: The AIBN have issued a new preliminary report. At 102 pages the report is much closer to a partial final report than a normal preliminary or interim report, with ‘comment’ in section 2, that is effectively ‘analysis’ by another name. Perhaps significantly, the AIBN has issued no new safety recommendations and re-affirms that: “decisions concerning the fleet airworthiness are not within the mandate of the safety investigation authorities. This is the responsibility of the regulatory authorities” (i.e. EASA, the European competent authority for, among others matters, airworthiness of aircraft types).

AIBN Comments on the Accident Sequence (Section 2.2) LN-OJF has been at 2,000 ft for about two minutes when the second stage planet gear failed. There was no indication to the crew prior to noise just prior to the main rotor separating. AIBN say:

The gear mesh became disrupted when the fatigue crack grew large enough to split one of the second stage planet gears. Teeth colliding caused an abrupt seizure of the gearbox. Torque from the engines via the main module and inertia from the main rotor started to break the gearbox apart. Several of the 17 bolts at the flexible mounting plate [the ‘BBQ Plate’] aft attachment showed clear signs of being sheared by a force acting towards the left. This is consistent with an immediate jamming of the gearbox… The jamming…caused a rupture of the epicyclic ring gear and a break-up of the conical housing. The upper part of the conical housing, including the main rotor mast, became disconnected from the main module and allowed independent movement. The flight control servos are connected to the main module, and any relative movement between the rotor and the main module will cause erratic flight control inputs to the main rotor. The main rotor was at that point still attached to the helicopter via the three suspension bars. The loss of MGB structural integrity and the erratic flight control input initiated by the same loss of structural integrity, caused an uncontrolled forceful movement of the main rotor. This ultimately pulled apart all three suspension bars and allowed the main rotor to separate from the helicopter.

This is believed to have resulted in exceeding the 6 G threshold for the CVFDR g-switch, causing the CVFDR to stop 1.5s later though the Quick Access Recorder continued to record for another 12.65s. The MGB had a Time Since New (TSN) of 1340 hours.

AIBN Comments on the Technical Investigation (Section 2.3) The second stage planet gear fatigue:

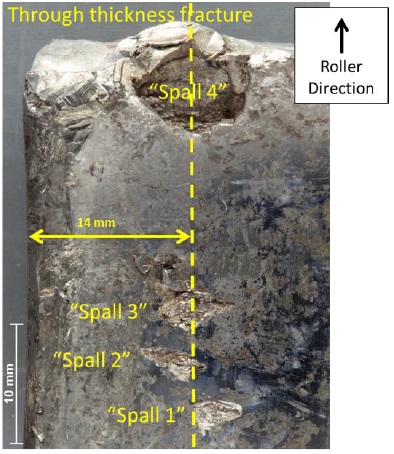

…had its origin in the surface of the upper outer gear race of the planet gear. It started at the surface and propagated sub-surface with a shallow angle into the bulk material, turning towards the web of the gear teeth and the final through-thickness fracture. The metallurgical examinations have given a reasonable, but not full, understanding… The fatigue cracks appear to have initiated from a surface micro-pit. The cause for the formation of the micro-pit has not been established. It has furthermore not been possible to get a comprehensive understanding of the different phases of the crack propagation. The AIBN is of the opinion that it has been impossible to conclude on the propagation time from initiation to final through-thickness fracture based on the fractography (see chapter 1.16.3.6 and 1.16.3.16). In front of the through-thickness fracture…there are four spalls in the race of the gear.

Spalling Found on the Outer Race of the Failed 2nd Stage Planet Gear from LN-OJF (Credit: AIBN/QinetiQ)

The AIBN is of the opinion that the fatigue cracks grew in the direction from spall one to spall four… Airbus Helicopters does not support this view.

In Section 2.4 the AIBN say “Spall 1, 2 and 3 have in total released a maximum of 28 mm² of metal particles”, though they can’t say when. “Evidence indicate that spall 4 was released during the break-up phase”. The AIBN currently believe there were “at least three different phases of the crack propagation”:

- Initiation of a micro-pit and then through the hardened carburized layer (which has the highest residual compressive stress).

- Growth through the remaining carburized layer towards the bulk material in the roller direction.

- Propagation into the bulk material towards final fracture.

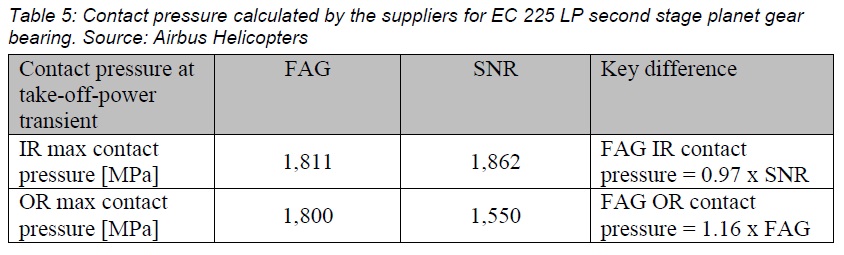

The driving force was probably not the same in these different phases. Observation on the LN-OJF crack propagation shows that the sub-surface cracks branch in different directions. Some of the cracks which deviate towards the race surface appear to stop before they reach the surface and thus do not release metallic particles (spalls). The investigation is looking at the possible relation between this phenomena and the progressively higher compressive stress in the area where the cracks stop. How the failure could develop and grow with limited spalling is currently not fully understood. The investigation has revealed there is a difference in contact pattern on the outer race between planet gears from different vendors (SNR and FAG) (see chapter 1.6.8.3).

In addition, the differences in the finishing process performed by the suppliers can affect the outer race surface residual stress, with FAG having a significantly higher compressive stress at the race surface. Both the fractured second stage planet gear from the G-REDL helicopter and the gear from LN-OJF were supplied by FAG.

The FAG bearings have been withdrawn from the fleet as part of the lifting of the EASA Flight Prohibition AD in October 2016 (including improved monitoring and life limits). The measures ,in the table below, were aimed at reducing the probability of spalling (1-3) and increasing the probability of spalling/particle detection (4-9):  Footnotes:

Footnotes:  Additionally EASA has issued a 17 point post-Return To Service (RTS) Continuing Airworthiness Review Item (CARI) with further actions. We look at the components in more detail in our article: Super Puma Second Stage Planet Gear Background

Additionally EASA has issued a 17 point post-Return To Service (RTS) Continuing Airworthiness Review Item (CARI) with further actions. We look at the components in more detail in our article: Super Puma Second Stage Planet Gear Background

AIBN Comments on the Safety Barriers (Section 2.4)

An essential design philosophy is that a crack in the surface area should grow outward and create debris (spalling), which could be detected on the magnetic plugs (chip detection system, see 1.6.9). Bridging the axial gap (2.28 mm) of the magnetic plug requires a substantial amount of small particles or one or more large particles.

There were no debris warnings prior to the accident. The MGB chip detectors had also been inspected 15:22 flying hours prior and no debris was found. However they note that:

The [LN-OJF] oil cooler was initially inspected for internal particles at the AIBN’s premises in Lillestrøm [and] later sent to Airbus Helicopters for further investigations. During additional cleaning processes, performed in accordance with the procedure described in the latest Emergency Alert Service Bulletins [see AD 2017-0042 from February 2017]…particles of 16NCD13 were found, notably one particle with a surface area of 1.8 mm² (length 1.8 mm, width 1.3 mm). During all of the ten additional cleaning processes at Airbus Helicopters more particles were salvaged. The analysis of the particles recovered during these additional cleaning processes has revealed 4.69 mm2 (5 particles) identified by Airbus Helicopters as 16NCD13 spalls and 18 mm² of further 16NCD13 particles which could be spalls but too damaged to be affirmative.

AIBN go on:

Vibration monitoring (VHM / HUMS, see 1.11.2) is a potential additional means for detecting developing degradation…

However, in Section 1.11.2 they say:

Epicyclic module planet gear bearing monitoring is particularly challenging, with multiple components rotating on a moving axis. This is also because the energy produced by the meshing of gears tends to be higher than that produced by bearings.

Epicyclic bearing information is not synchronous with shaft rotation, meaning that filtering out of other noise is difficult and the distance from the varies and is typically further away than for other components, further complicating the detection capability. AIBN comment that research is ongoing in this area. We reported on some such EASA sponsored research in 2014.

The observed failure mode, i.e. crack initiation and propagation with limited spalling, in this accident seems to differ from what was expected or foreseen during the design and certification of this helicopter type. The fracture propagated in a manner which was unlikely to be detected by the maintenance procedures and the monitoring systems fitted to LN-OJF at the time of the accident…

Hence the changes in procedures and monitoring introduced last year.

AIBN Comments on G-REDL (Section 2.5) The AIBN note that unlike in their case, key debris was never recovered from the G-REDL accident. However:

In contrast to LN-OJF, there was indication of the impending failure of the second stage planet gear in G-REDL. Some 36 hours prior to the accident, a metallic particle had been discovered on the epicyclic chip detector during maintenance. Unfortunately, the actions taken resulted in the particle not being recognized as an indication of degradation of the second stage planet gear, which subsequently failed.

In that case the debris was allegedly misidentified, the gear box was not therefore opened, and the magnets then fitted on the collector plate (but removed after the accident across the AS332L2/EC225 fleet) were not examined.

For LN-OJF, the fact that the MGB degradation went on undetected by the chip detection system cannot be explained by the ring of magnets or by human factors/maintenance failure, as was the case with G-REDL.

The AIBN will focus…

…on the follow-up of the safety recommendations issued by the AAIB in connection with the G-REDL report, as well as the continuing airworthiness of the gearbox after 2009. The AIBN is aware that one should be careful to pass a critical judgement of the adequacy of the actions taken following the G-REDL accident, based on the hindsight created by the knowledge we have after LN-OJF. The actions made by the manufacturer and the authorities in the aftermath of G-REDL were based on the available knowledge and circumstances at the time. This knowledge was naturally limited for several reasons; most importantly, key elements of information were missing due to the fact that not all gear parts were recovered. It is, however, the mandate of the safety investigation authority to assess how and why two similar catastrophic accidents could happen only seven years apart to near identical helicopters. A more detailed assessment of the actions in response to the safety recommendations, and how they were documented and closed by EASA and Airbus Helicopters will follow in the final report.

EASA Comments on Issue of the 28 April 2017 Preliminary Report

…EASA continues to implement robust and proven certification processes taking into account all available information. EASA proactively takes all necessary actions to mitigate identified possible contributory factors, in order to guarantee the safety of flights. These actions will also be adapted on the basis of operational feed-back, continuing studies and investigations or research activities undertaken by AIBN and relevant stakeholders.

Airbus Helicopters CEO Guillaume Faury’s Comments on Issue of the 28 April 2017 Preliminary Report

Airbus Helicopters notes the publication of the preliminary report by the AIBN to mark the first anniversary of the H225 accident, which claimed the lives of 13 people off Turøy in Norway. We wish to express our deep regret at this tragedy, and again, we offer our sincere and profound sympathies to the bereaved families. Since the accident, we have been providing our full and complete support to the investigation. We have had regular technical meetings with the authorities as well as with all relevant helicopter industry bodies. We look forward to every opportunity to discuss with them the safety recommendations and technical points arising from the report.

We are totally committed to transparency in all matters regarding aviation safety and international helicopter regulations. Indeed, it is the essence of what we do. In the course of the AIBN investigation, additional elements brought by the 2016 accident showed that there were mechanical similarities between the 2016 accident and an earlier one, in 2009. We were not aware of any related issue at the time of the 2016 accident. The information available to us from the 2016 accident has allowed us to take protective measures that we could unfortunately not have put in place in 2009 based on the knowledge and evidence available at the time, and also because significant parts from the 2009 accident were never recovered.

We will continue to work with the European Aviation Safety Agency (EASA) and to comply with EASA airworthiness requirements. In the course of the investigation into the 2016 accident, we have implemented a set of protective measures which have been requested and validated by EASA. Nothing in this preliminary report alters this. We are using lessons learned from the ongoing investigations into the 2016 accident to set new standards for the helicopter industry. As part of these efforts, we are also looking to improve working practices across the sector.

Further Airbus Helicopters comment can be found here: Super Puma Family Information Centre. The AIBN investigation continues. It should be noted that in accordance with International Convention:

The purpose of AIBN investigations is to clarify the sequence of events and factors which are assumed to be of importance for the prevention of transport accidents. The AIBN shall not apportion blame or liability.

UPDATE 9 May 2017: The Cranfield University report on EASA research project EASA.2012.OP.13 VHM which followed G-REDL is now available at: EASA_REP_RESEA_2012_6 Vibration Health Monitoring or Alternative Techniques for Helicopters (note 45Mb!).

The research programme has shown that internal sensors for helicopter main rotor gearboxes are feasible and that they are able to offer improved detection when compared with traditional external vibration measurements.

UPDATE 6 June 2017: North Sea, Air Safety and Brexit

UPDATE 6 June 2017: We expand on the recent AIBN report: Super Puma Epicyclic Gear Health Monitoring Background

UPDATE 14 June 2017: In the introduction to the Agency’s 12th annual safety review, EASA’s Executive Director Patrick Ky says:

…the tragic accident involving an EC225 helicopter in Norway in April 2016 shows the importance of joining forces and together maintaining safety as an aviation community.

UPDATE 26 June 2017: Speaking prior to the Paris Airshow Airbus CEO Tom Enders said he was “hopeful” that the operational directives on commercial H225 flights in UK and Norway would be lifted “any time soon. But at this time, after so many delays, we are not going to make any predictions.” He commented that these national directives were “somewhat awkward” as “under existing agreements with EASA they should do this [lift their flight restrictions]”.

HeliOffshore report two EASB were released on 23 June 2017 on on the reduction of the maintenance task burden and improvement of MGB reliability.

1. EASB 05A049 (EC225) Rev. 5:

In March 2017 the Rev. 4 of this EASB had called for a periodic oil cooler and filter check with different periodicities depending on the flight hours logged on the second stage planet gears. By the time we had announced that this measure will be temporary until the future introduction of an “ODM type” device. This device is called FFMP Full flow magnetic plug and has just been certified by EASA.

The Rev. 5 of the EASB requires the mandatory installation of the FFMP which will collect particles before reaching the oil cooler. The installation of the FFMP will cancel the periodic oil cooler and filter checks and thus represent a significant reduction of the maintenance burden. The FFMP is not part of the MGB and can be installed by the customer through SB released with the EASB.

AS332 MK2

The Rev. 5 is currently only available for the H225 . A very similar definition is under development for the AS332 MK2.

2. EASB EC225 63A030 Rev2

As a reminder, this EASB Rev. 0 and 1 had called for

• the replacement of 07 type 2nd stage planet gears by 06 type (D-level retrofit)

• closer MGB particle monitoring and

• a reduction of the TBO of the epicyclic module and reduction of the SLL of the 2nd stage planet gears as follows:The new Rev. 2 introduces the following modifications (similar logic for AS332 Mk2):

1. increase of the TBO of the epicyclic module back to the usual timeline (2000 fh for H225/H225M )

2. return to AH (or approved repair center) at mid TBO of the epicyclic module for a progressive “reconditioning” and SLL on the second stage planet of 1100 fh to match the mid TBO

3. suppression of the modularity of the MGB in order to limit FOD ingestion and perform the reconditioning on the whole MGB.The objective of this measure is to gradually realign the timelines of the different modules thus simplifying the maintenance forecast. During the mid TBO return AH will progressively take the opportunity to bring a certain number of improvements to the MGB and upgrade it with latest standard modifications. This “reconditioning” will reduce the probability of unscheduled removals before the TBO is reached, thus improving aircraft availability and avoiding operation disruptions.

UPDATE 30 June 2017: Workers asked for North Sea helicopter safety feedback

UPDATE 2 July 2017: Energy Voice Report: Could Super Puma return to North Sea skies?

UPDATE 7 July 2017: The Norwegian and UK CAA operational restrictions are being lifted. UK CAA say in a press release (that was embargoed until 20:00):

Both the UK Civil Aviation Authority and the Civil Aviation Authority of Norway have remained in close contact with the European Aviation Safety Authority (EASA); UK and Norwegian operators; and with the manufacturer, Airbus Helicopters which has developed the modifications and enhanced safety measures for the type. Despite the helicopter being released back in to service by EASA in October 2016, the restrictions remain in place in the UK and Norway until these further enhancements have been made.

They have a list of “changes and modifications made to the helicopter and its maintenance”:

- Change in the design by removal of the components that were susceptible to premature deterioration.

- Earlier replacement of components

- Design change to introduce an improved maintenance inspection method to detect any deterioration at an early stage.

- More frequent inspections

- Reduction in the thresholds for rejecting components based upon early signs of any deterioration.

Most of these were in place in October 2016. The NCAA in their Norwegian language press release (issued one hour after the UK one) include a ‘timeline’ (PDF version – which specifies a 14 July 2017 date, suggesting issue earlier than originally expected) that identifies recent changes:

The additional restrictions described include a tighter life limit on the remaining gears (1100 flying hours for the H225 and 1650 for the AS332L2), an MGB Time Between Overhaul reduction, the FFMP in the oil return line inspected daily (or 10 flying hours) and a reduced critical debris size (from a length of 2 mm to 1.5 mm and an area of 2 mm² to 1 mm²). Its the FFMP modification that is the reason the regulators are able to say flying won’t resume immediately in the UK or Norway. It however, based on the NCAA document, appears to be seen as less vulnerable to human error, addressing a key concern.

The UK CAA go on to say:

…that helicopters will not begin flying immediately. A plan of checks, modifications and inspections needs to be undertaken before any flights take place. It will also be for operators and their customers to decide whether they wish to re-introduce the helicopters to service. In order to resume operations individual operators will need to supply safety cases to ensure that they have all the necessary measures (procedures, processes, tooling and training) in place for a return to service.

John McColl, Head of Airworthiness at the UK CAA, said:

This is not a decision we have taken lightly. It has only been made after receiving extensive information from the Norwegian accident investigators and being satisfied with the subsequent changes introduced by Airbus Helicopters through detailed assessment and analysis.

Meanwhile, Les Linklater, Executive Director of Step Change in Safety said:

Any re-introduction will require a robust safety case, as well as a requirement for a series of checks, modification and inspections that must be carried out before undertaking any flying.

At this time, there is an ongoing Airbus survey for pilots and passengers regarding these specific helicopters’ flight safety and comfort, which was issued just one week ago. It’s our understanding that this survey still has a further three weeks to run.

Given the importance of the workforce’s opinion regarding this highly emotive subject we do not feel it’s appropriate to make any further comment until Airbus has gathered, and shared, the survey’s results and can demonstrate how they intend to address any concerns raised by the workforce.

We would encourage all members of the workforce to participate and have their voices heard.

Airbus Helicopters CEO Guillaume Faury commented:

As the UK and Norway lift their restrictions on the H225, we are more committed than ever to raise the bar in safety for the industry.

A slightly higher gross weight version of the H225 is due for certification in early 2018. Flight tests in hot conditions are in progress and certification is scheduled for early 2018. The upgrade will increase the maximum take-off weight by 160kg to 11.16t.

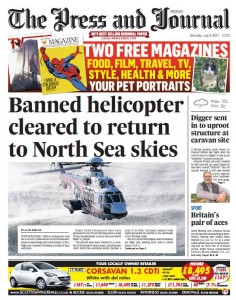

UPDATE 8 July 2017: The late evening press embargo did not affect the Aberdeen Press & Journal:

NCAA director Lars Kobberstad said:

We have always been committed to lifting the flight ban when we are sure that the helicopter is safe to fly with.

UPDATE 11 July 2017: An Offshore Helicopter Safety Action Group (OHSAG) meeting is taking place on 13 July 2017.

UPDATE 13 July 2017: The Union UNITE has called for greater workforce engagement.

UPDATE 20 July 2017: The UK and Norwegian restrictions are officially lifted.

UPDATE 21 July 2017: A Position Paper addresses the IOGP’s response to the recent lifting of the restrictions by the UK and Norwegian aviation authorities.

UPDATE 25 July 2017: A bachelor’s thesis at the engineering college at the University College in West Norway mentions several points where the writers claim that the interaction between the agencies failed during emergency response to the loss of LN-OJF on 29 April 2016.

UPDATE 27 July 2017: EASA AD 2017-0134 supersedes EASA AD 2017-0111 dated 23 June 2017.

Since EASA AD 2017-0111 was issued, AH designed an improvement for FFMP of the EC225 LP helicopters (MOD 07 53052, available for in-service installation through Revision 1 of AH SB EC225-63-032) and a similar FFMP device for AS 332 L2 helicopters (MOD 07 53049, available for in-service installation through AH SB AS332-63.00.84). Consequently AH issued Revision 6 of AS332 ASB 05.01.07 and Revision 6 of EC225 ASB 05A049 to provide updated inspection regimes.

For the reason described above, this AD retains the requirements of EASA AD 2017-0111, which is superseded and requires additional work for the EC225 LP helicopters and installation of an FFMP device for AS 332 L2 helicopters with adaptation of the MGB oil filter and oil cooler inspections.

UPDATE 31 July 2017: Following the issue of EASA AD 2017-0134 the UK CAA have issued a revised Safety Directive (SD–2017/002).

UPDATE 8 August 2017: Les Linklater: North Sea helicopters – just like Groundhog Day

UPDATE 24 April 2018: The AIBN made a statement that:

A draft of the final report on the tragic accident near Turøy has been for consultation with the parties involved in the investigation. The consultation period is over and the AIBN is working on the comments. It is solely the AIBN’s decision whether or not a comment shall be accepted and incorporated into the final report. This is a laborious and time-consuming process, which will also involve clarifications and consultation with external contributors.

At the time being, we are unable to present a firm date for publication of the report. The work will continue without letup until the final report is ready for publication.

UPDATE 25 June 2018: The AIBN LN-OJF final report will be issued on 5 July 2018.

UPDATE 5 July 2018: The AIBN final report is issued. They say:

The accident was a result of a fatigue fracture in a second stage planet gear in the epicyclic module of the main rotor gearbox. Cracks initiated from a micro-pit at the surface and developed subsurface to a catastrophic failure without being detected.

From this investigation there are significant lessons to be learned related to gearbox design, safety assessment, fatigue evaluation, condition monitoring, certification requirements and continued airworthiness of the AS 332 L2 and the EC 225 LP helicopters, which also could be valid for other helicopter types.

Based on this investigation, the AIBN issues 12 safety recommendations.

The main report is accompanied by a number of annexes:

- Appendix C Maintenance requirements Airbus Helicopters EC 225 LP 282kb

- Appendix D Metallurgical examination 12MB

- Appendix E CS-29 Selected extract 268kb

- Appendix F Safety actions following the LN-OJF accident 183kb

- Appendix G Relevant safety recommendations G-REDL 237kb

- Appendix H Planet gear bearing analysis report 10MB

Airbus comment:

Prior to 2016, the available degree of scientific and technical knowledge meant it was neither foreseeable nor foreseen that a crack in a plant gear could propagate in a sub-layer, and as a result generate very low levels of detectable particles.

With knowledge gained from this investigation, Airbus Helicopters has introduced a series of safety measures on the H225. Some of the technology that has been developed is ground-breaking for the helicopter industry.

UPDATE 12 September 2018: Despite some ill-informed on-line speculation that the loss of a Korean military Surion / Marineon on 17 July 2018 was similar to G-REDL / LN-OJF, Defense News reports that a batch problem with the rotor mast was responsible.

UPDATE 14 May 2020: The NCAA have removed their outstanding Safety Directive allowing the type’s return to service in Norway. Aerossurance expected this is most likely to be in the SAR sector. The UK CAA withdrew their Safety Directive on the same day.

Other Resources

See also:

- Aircraft Accident Report 2/2011 – Aerospatiale (Eurocopter) AS332 L2 Super Puma, G-REDL, 1 April 2009

- AAIB 2012 Annual Safety Report (in which most of the responses to the G-REDL investigation are examined)

- G-REDL Fatal Accident Inquiry held under a Sheriff in Aberdeen in 2014

- AAIB Report on the Ditchings of EC225 G-REDW 10 May 2012 & G-CHCN 22 Oct 2012 (on two prior unrelated EC225 shaft failures)

- Anniversary of 2009 Newfoundland S-92A Accident another fatal transmissions accident that involved a known design flaw and misleading statements prior to the accident

- UPDATE 9 May 2020: Ungreased Japanese AS332L Tail Rotor Fatally Failed

- UPDATE 17 September 2022: Canadian B212 Crash: A Defective Production Process

Recent Comments