Super Puma Second Stage Planet Gear Background

The investigation into loss of CHC Helikopter Service Airbus Helicopters EC225/H225 LN-OJF on 29 April 2016 and the similarities to the 1 April 2009 Bond G-REDL AS332L2 Super Puma accident, has created interest in the second stage epicyclic planet gears used in later members of the Super Puma family.

This article draws on a the most recent Accident Investigation Board Norway (AIBN – the Statens Havarikommisjon for Transport [SHT] in Norwegian) 102 page preliminary report on the LN-OJF accident, issued on 28 April 2017.

- Readers wishing to understand the wider gearbox architecture are advised to read Aerossurance’s article: EC225 Main Rotor Head and Main Gear Box Design

- We examined the wider aspects of the accident in our feature: EC225 LN-OJF Norway Accident Investigation Timeline

Description of the Second Stage Planet Gear Layout

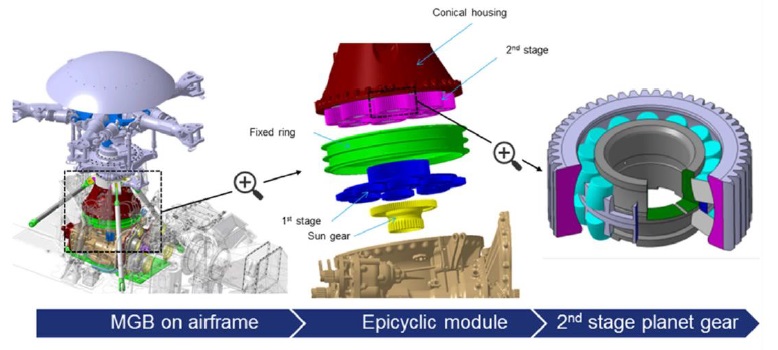

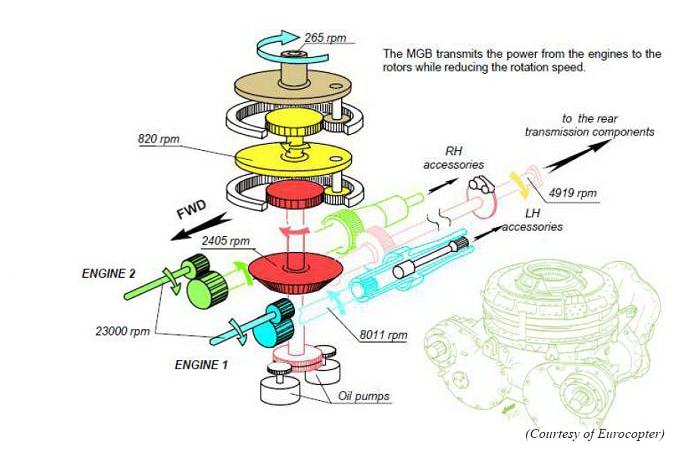

The EC225/AS332L2 Main Gear Box (MGB) features two stages of epicyclic gear (shown in yellow and brown below).

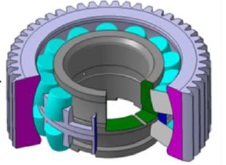

The second stage has eight planet gears (shown in the diagram below in purple), running between a sun gear (driven by the first stage epicyclic, shown in blue below) and a fixed outer ring gear (green below).

MGB, Exploded View of Epicyclic Module and a Second Stage Planet Gear (Credit: Airbus Helicopters via AIBN).

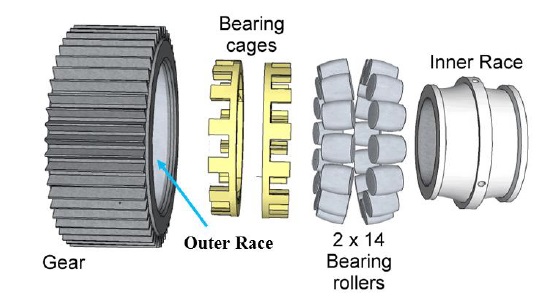

The Second Stage Planet Gear consists of an outer gear (light grey/purple in the diagram above, right), bearing rolling elements and cages (turquoise and light grey respectively) and a bearing inner race (dark grey/green). The eight 2nd stage planet gears are mounted on a planet carrier that drives the main rotor.

The Second Stage Planet Gear Design and Manufacture

The AIBN explain that:

The planet gear wheel without the bearing, including its rim and teeth, is designed and manufactured by Airbus Helicopters. The planet gear bearings were manufactured by FAG and SNR respectively following a Build to Specification process approved by Airbus Helicopters.

For industrial reasons, the aim was to have two suppliers…

…hence two bearing manufacturers were invited to tender for the AS332L2 planet gear bearings in 1986:

The invitation specified a number of criteria. One such criterion was that it should be based on the existing design used in the AS 365 Dauphin gearbox, a gear already produced by FAG. Specifically, the focus was on limiting spalling on the inner raceway, as this had been a problem with the AS 332 L1.

The planet gear, made from 16NCD13 steel, was classified as a “critical part”, i.e. a failure would be catastrophic and so subject to the extra requirements of certification requirement 29.602.

Because the outer race of the planet gear bearing is integrated into the planet gear, a specific workshare is established between Airbus Helicopters and the bearing manufacturers. This workshare covers each phase of the design, the substantiation and the manufacturing process of the planet gear bearing. The design characteristics of the bearing inner race, rollers, cage and outer race finishing process are usually proposed by the bearing suppliers.

Airbus Helicopters manufactures the planet gear wheel including the outer race and provides it to the bearing supplier with a partly finished bearing outer race surface. The supplier manufactures the bearing and performs the grinding of the planet gear outer race. Then, the supplier assembles the bearing and the planet gear wheels. The completely assembled planet gear including the bearing is supplied to Airbus Helicopters. The gears manufactured by FAG were given part number 332A32-3335-07 and gears manufactured by SNR part number 332A32-3335-06.

Airbus Helicopters had approved that gears from both FAG and SNR could be mixed on a second stage planet gear carrier. According to Airbus Helicopters the key driving factors in a planet gear bearing are the following:

– Rolling kinematics

– Load applied on the planet gear bearing

– Hertz pressure on the contact between rolling element and inner/outer races

– Stiffness of the outer race and gear rim.

The AIBN say:

The investigation has revealed there is a difference in contact pattern on the outer race between planet gears from different vendors (SNR and FAG)…

In addition, the differences in the finishing process performed by the suppliers can affect the outer race surface residual stress, with FAG having a significantly higher compressive stress at the race surface.

Both the fractured second stage planet gear from the G-REDL helicopter and the gear from LN-OJF were supplied by FAG.

In-Service Experience

In accordance with the requirements of Commission Regulation (EU) No 748/2012, Annex 1 (Part 21)…Airbus Helicopters is obliged to operate a Continued Airworthiness program to investigate and analyze component failures which may have had an adverse effect on the continuing airworthiness of its products.

Spalling is a phenomenon which can be found in rolling element bearings and is one of the most common reasons for bearing failure.

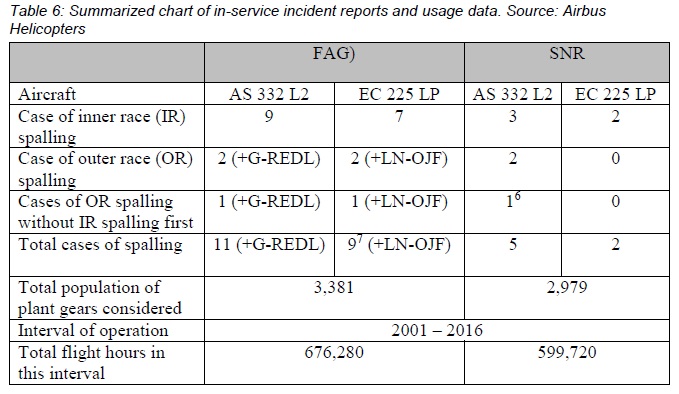

Following the accident, Airbus Helicopters has assessed the in-service experience of gears supplied by FAG and SNR respectively in the 2001 – 2016 period on the Super Puma AS 332 L2 / EC 225 LP / EC 725 fleet.

During the period considered, the distribution of fitted planet gears in the Super Puma fleet is 53 % for FAG and 47 % for SNR respectively. [T]here are more spalling events on FAG planet gears than SNR. [O]nly two second stage planet gears have been removed…as a result of spalling or micro-pits on the outer race during the period between 2009 and the LN-OJF accident in 2016.

The Failure on LN-OJF

AIBN say that the second stage planet gear fatigue failure…

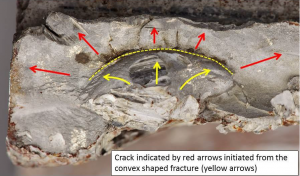

…had its origin in the surface of the upper outer gear race of the planet gear. It started at the surface and propagated sub-surface with a shallow angle into the bulk material, turning towards the web of the gear teeth and the final through-thickness fracture.

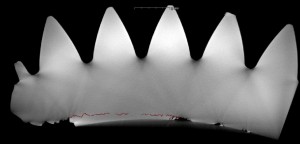

CT scan showing a subsurface crack propagating from the RH spalling to the left. The red colour is a frame-by-frame mapping performed by hand to highlight the crack. (Credit: University of Southampton via AIBN)

The metallurgical examinations have given a reasonable, but not full, understanding… The fatigue cracks appear to have initiated from a surface micro-pit. The cause for the formation of the micro-pit has not been established. It has furthermore not been possible to get a comprehensive understanding of the different phases of the crack propagation.

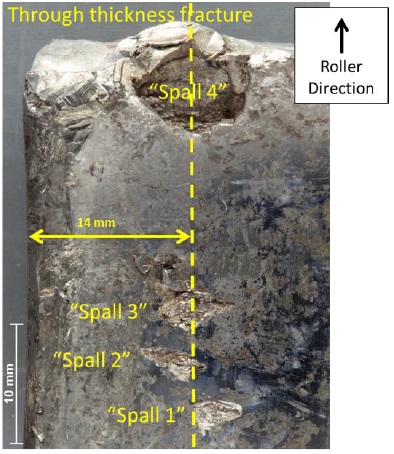

The AIBN is of the opinion that it has been impossible to conclude on the propagation time from initiation to final through-thickness fracture based on the fractography. In front of the through-thickness fracture…there are four spalls in the race of the gear.

The AIBN is of the opinion that the fatigue cracks grew in the direction from spall one to spall four…

AIBN say “Spall 1, 2 and 3 have in total released a maximum of 28 mm² of metal particles”, though they can’t say when. “Evidence indicate that spall 4 was released during the break-up phase”.

The oil cooler was initially inspected for internal particles at the AIBN’s premises in Lillestrøm [and] later sent to Airbus Helicopters for further investigations. During additional cleaning processes, performed in accordance with the procedure described in the latest Emergency Alert Service Bulletins [see AD 2017-0042 from February 2017]…particles of 16NCD13 were found, notably one particle with a surface area of 1.8 mm² (length 1.8 mm, width 1.3 mm). During all of the ten additional cleaning processes at Airbus Helicopters more particles were salvaged. The analysis of the particles recovered during these additional cleaning processes has revealed 4.69 mm2 (5 particles) identified by Airbus Helicopters as 16NCD13 spalls and 18 mm² of further 16NCD13 particles which could be spalls but too damaged to be affirmative.

The AIBN currently believe there were “at least three different phases of the crack propagation”:

- Initiation of a micro-pit and then through the hardened carburized layer (which has the highest residual compressive stress).

- Growth through the remaining carburized layer towards the bulk material in the roller direction.

- Propagation into the bulk material towards final fracture.

The driving force was probably not the same in these different phases. Observation on the LN-OJF crack propagation shows that the sub-surface cracks branch in different directions. Some of the cracks which deviate towards the race surface appear to stop before they reach the surface and thus do not release metallic particles (spalls). The investigation is looking at the possible relation between this phenomena and the progressively higher compressive stress in the area where the cracks stop.

Parts from EC225 LN-OJF 2nd Stage (i.e. upper) Epicyclic Stage with a Fractured Planet Gear Placed on Top of a New Gear (Credit: AIBN)

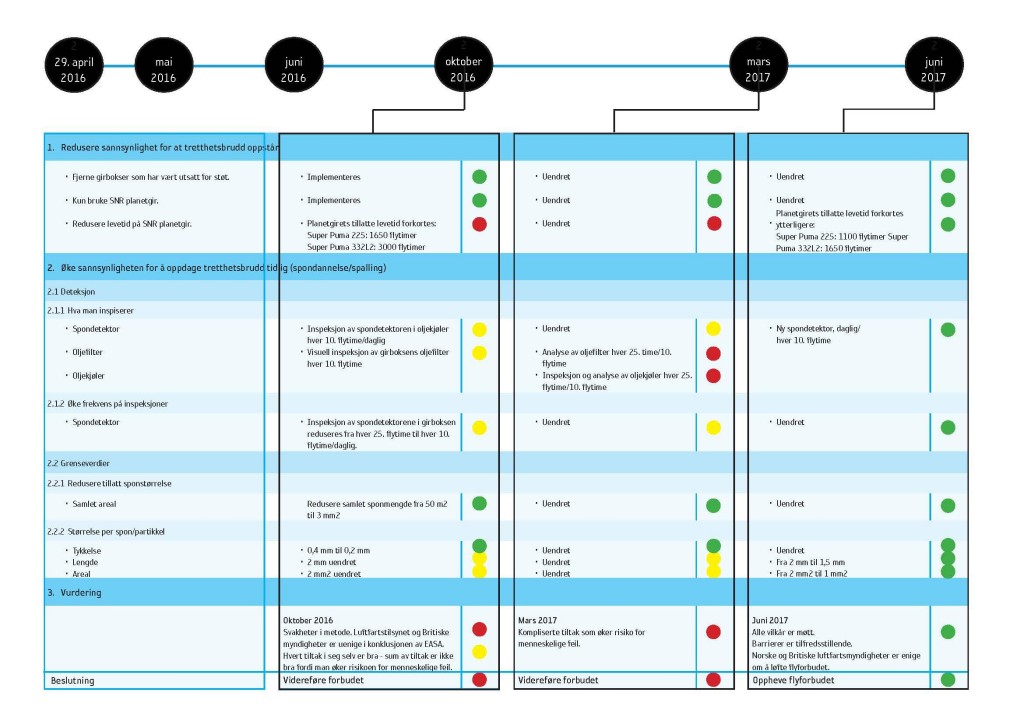

Regulatory Action

Six months before this AIBN preliminary report, the European Aviation Safety Agency (EASA) had issued Airworthiness Directive 2016-0199, saying:

In depth review of the design and service data showed that one configuration [of planet gear] has higher operating stress levels that result in more frequent events of spalling, associated with rolling contact fatigue, while the other exhibits better reliability behaviour.

The AD went on to remove all gears with part number 332A32-3335-07 (and therefore FAG bearings):

By limiting the type design to the gear configuration with lower stress levels and better reliability and specifying a reduced life limit, combined with more effective oil debris monitoring procedures and other operational controls, an acceptable level of safety can be restored.

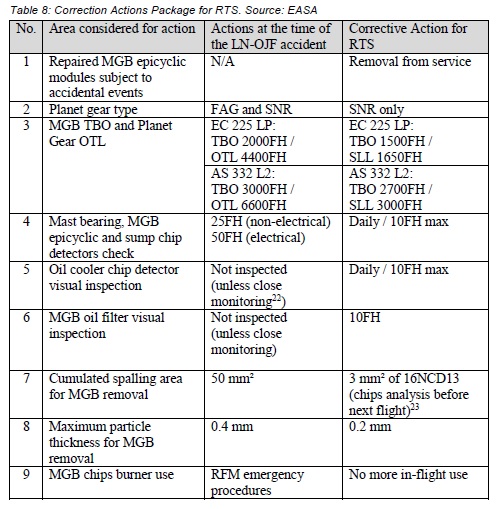

The measures, in the table below, were aimed at reducing the probability of spalling (1-3) and increasing the probability of spalling/particle detection (4-9):  Footnotes:

Footnotes:

Additionally EASA has issued a 17 point post-Return To Service (RTS) Continuing Airworthiness Review Item (CARI) with further actions.

UPDATE 6 June 2017: We expand on the recent AIBN report: Super Puma Epicyclic Gear Health Monitoring Background

UPDATE 14 June 2017: In the introduction to the Agency’s 12th annual safety review, EASA’s Executive Director Patrick Ky says:

…the tragic accident involving an EC225 helicopter in Norway in April 2016 shows the importance of joining forces and together maintaining safety as an aviation community.

UPDATE 26 June 2017: Speaking prior to the Paris Airshow Airbus CEO Tom Enders said he was “hopeful” that the operational directives on commercial H225 flights in UK and Norway would be lifted “any time soon. But at this time, after so many delays, we are not going to make any predictions.” He commented that these national directives were “somewhat awkward” as “under existing agreements with EASA they should do this [lift their flight restrictions]”.

HeliOffshore report two EASB were released on 23 June 2017 on on the reduction of the maintenance task burden and improvement of MGB reliability.

1. EASB 05A049 (EC225) Rev. 5:

In March 2017 the Rev. 4 of this EASB had called for a periodic oil cooler and filter check with different periodicities depending on the flight hours logged on the second stage planet gears. By the time we had announced that this measure will be temporary until the future introduction of an “ODM type” device. This device is called FFMP Full flow magnetic plug and has just been certified by EASA.

The Rev. 5 of the EASB requires the mandatory installation of the FFMP which will collect particles before reaching the oil cooler. The installation of the FFMP will cancel the periodic oil cooler and filter checks and thus represent a significant reduction of the maintenance burden. The FFMP is not part of the MGB and can be installed by the customer through SB released with the EASB.

AS332 MK2

The Rev. 5 is currently only available for the H225 . A very similar definition is under development for the AS332 MK2.

2. EASB EC225 63A030 Rev2

As a reminder, this EASB Rev. 0 and 1 had called for

• the replacement of 07 type 2nd stage planet gears by 06 type (D-level retrofit)

• closer MGB particle monitoring and

• a reduction of the TBO of the epicyclic module and reduction of the SLL of the 2nd stage planet gears as follows:The new Rev. 2 introduces the following modifications (similar logic for AS332 Mk2):

1. increase of the TBO of the epicyclic module back to the usual timeline (2000 fh for H225/H225M )

2. return to AH (or approved repair center) at mid TBO of the epicyclic module for a progressive “reconditioning” and SLL on the second stage planet of 1100 fh to match the mid TBO

3. suppression of the modularity of the MGB in order to limit FOD ingestion and perform the reconditioning on the whole MGB.The objective of this measure is to gradually realign the timelines of the different modules thus simplifying the maintenance forecast. During the mid TBO return AH will progressively take the opportunity to bring a certain number of improvements to the MGB and upgrade it with latest standard modifications. This “reconditioning” will reduce the probability of unscheduled removals before the TBO is reached, thus improving aircraft availability and avoiding operation disruptions.

UPDATE 30 June 2017: Workers asked for North Sea helicopter safety feedback

UPDATE 2 July 2017: Energy Voice Report: Could Super Puma return to North Sea skies?

UPDATE 7 July 2017: The Norwegian and UK CAA operational restrictions are being lifted. The NCAA in their Norwegian language press release (issued one hour after the UK one) post a ‘timeline’ (PDF version – which specifies a 14 July 2017 date, suggesting issue earlier than originally expected) that identifies recent changes:

The additional restrictions described include a tighter life limit on the remaining gears (1100 flying hours for the H225 and 1650 for the AS332L2), an MGB Time Between Overhaul reduction, the FFMP in the oil return line inspected daily (or 10 flying hours) and a reduced critical debris size (from a length of 2 mm to 1.5 mm and an area of 2 mm² to 1 mm²). Its the FFMP modification that is the reason the regulators are able to say flying won’t resume immediately in the UK or Norway. It however, based on the NCAA document, appears to be seen as less vulnerable to human error, addressing a key concern.

UPDATE 20 July 2017: The UK and Norwegian restrictions are officially lifted.

UPDATE 27 July 2017: EASA AD 2017-0134 supersedes EASA AD 2017-0111 dated 23 June 2017.

Since EASA AD 2017-0111 was issued, AH designed an improvement for FFMP of the EC225 LP helicopters (MOD 07 53052, available for in-service installation through Revision 1 of AH SB EC225-63-032) and a similar FFMP device for AS 332 L2 helicopters (MOD 07 53049, available for in-service installation through AH SB AS332-63.00.84). Consequently AH issued Revision 6 of AS332 ASB 05.01.07 and Revision 6 of EC225 ASB 05A049 to provide updated inspection regimes.

For the reason described above, this AD retains the requirements of EASA AD 2017-0111, which is superseded and requires additional work for the EC225 LP helicopters and installation of an FFMP device for AS 332 L2 helicopters with adaptation of the MGB oil filter and oil cooler inspections.

UPDATE 31 July 2017: Following the issue of EASA AD 2017-0134 the UK CAA have issued a revised Safety Directive (SD–2017/002).

UPDATE 4 October 2017: Airbus release a video.

https://youtu.be/lnhoLy2zVU0

Final Word

The AIBN investigation continues. It will further examine the response to 2009 G-REDL accident. See:

- Aircraft Accident Report 2/2011 – Aerospatiale (Eurocopter) AS332 L2 Super Puma, G-REDL, 1 April 2009

- G-REDL Fatal Accident Inquiry held under a Sheriff in Aberdeen in 2014

It should be noted that in accordance with International Convention:

The purpose of AIBN investigations is to clarify the sequence of events and factors which are assumed to be of importance for the prevention of transport accidents. The AIBN shall not apportion blame or liability.

UPDATE 24 April 2018: The AIBN made a statement that:

A draft of the final report on the tragic accident near Turøy has been for consultation with the parties involved in the investigation. The consultation period is over and the AIBN is working on the comments. It is solely the AIBN’s decision whether or not a comment shall be accepted and incorporated into the final report. This is a laborious and time-consuming process, which will also involve clarifications and consultation with external contributors.

At the time being, we are unable to present a firm date for publication of the report. The work will continue without letup until the final report is ready for publication.

UPDATE 25 June 2018: The AIBN LN-OJF final report will be issued on 5 July 2018.

UPDATE 5 July 2018: The AIBN final report is issued. They say:

From this investigation there are significant lessons to be learned related to gearbox design, safety assessment, fatigue evaluation, condition monitoring, certification requirements and continued airworthiness of the AS 332 L2 and the EC 225 LP helicopters, which also could be valid for other helicopter types.

Based on this investigation, the AIBN issues 12 safety recommendations.

Airbus comment:

Prior to 2016, the available degree of scientific and technical knowledge meant it was neither foreseeable nor foreseen that a crack in a plant gear could propagate in a sub-layer, and as a result generate very low levels of detectable particles.

With knowledge gained from this investigation, Airbus Helicopters has introduced a series of safety measures on the H225. Some of the technology that has been developed is ground-breaking for the helicopter industry.

Recent Comments