Incomplete Maintenance Leads to Fatal Collective Control Loss on B407 (N427 TVA)

Bell 407 N427TV of the Tennessee Valley Authority (TVA) crashed on approach to a landing site in Kentucky on 11 July 2016 after maintenance errors during a critical maintenance task 38 flying hours prior.

The Accident Flight

The US National Transportation Safety Board (NTSB) report:

A witness reported that there were no abnormalities…until it was approximately 75 to 100 feet above the ground. Suddenly, the main rotor tilted to the right. Immediately after, the entire helicopter banked to its right and fell to the ground on its right side, where it came to rest.

The pilot was killed in the impact.

The Safety Investigation

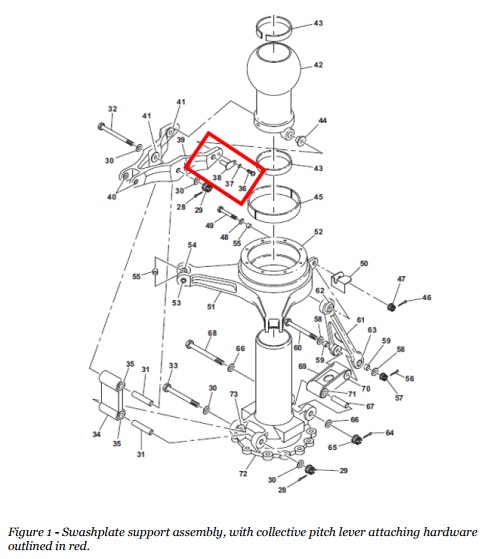

Initial examination of the wreckage revealed that the collective lever, which connected the cockpit collective controls to the main rotor, was disconnected from the pivot sleeve.

The collective lever is located to the front and bottom of the swashplate support. It is linked to the cockpit collective leaver and vertically moves the pivot sleeve to simultaneously change the pitch on all four main rotor blades.

The collective lever pins and screws that attached the collective lever to the pivot sleeve were missing;

…they were later found loose, near the main rotor area.

The safety wires [i.e the wire locking] intended to secure the screws to the pins were missing. Examination of the hardware at the NTSB Materials Laboratory revealed that the safety wires not present, and the screws backed out over time, resulting in the complete loss of collective control in flight.

The NTSB elaborate:

The maintenance tasks performed during the inspections between May 31, 2016, and June 20, 2016 [38 flying hours previously], did not require the removal of the collective lever or the disconnection or inspection of the collective lever pins or screws. Although an inspection of the condition of the flight control bolts and nuts was one of the maintenance tasks performed, an inspection of the collective lever pins, screws, and corresponding lockwire was not included in that inspection.

The maintenance and inspections of the helicopter’s flight controls, including the collective control, were performed by two TVA airframe and powerplant mechanics and one TVA foreman, who assisted in the work and supervised the operation.

One of the mechanics re-installed an anti-drive lever assembly. He did not recall removing the lockwire on the collective lever pin screws or removing the pins. He stated that the other mechanic performed the 24-month inspection of the flight control bolts and nuts. He further stated that the collective lever pins were not part of that inspection.

The other mechanic performed the 24-month inspection of the flight control bolts and nuts. When asked if he removed the collective lever pins, he responded, “No, I don’t remember doing it. If anyone would have done it, it would have been me, but I don’t remember doing it.”

The foreman inspected the work performed in the area of the flight controls. He reported that the removal of the collective lever pins “…was not part of the required maintenance performed.” He was not aware that the pins were removed or that any lockwire was removed. He added further, “I could see why it could have been done. The 24-month flight control bolt inspection was being performed, why not pull them and look at them too. I’ve done it before.”

Both mechanics reported that they would occasionally be “pulled off” an aircraft to perform work on another project. One mechanic stated that there was a lack of documentation of what parts were removed, such as a continuation sheet.

Probable Cause

Company maintenance personnel’s inappropriate removal without replacement of the safety wires on the collective lever pin screws during a recent maintenance inspection, which resulted in the screws backing out and led to a loss of collective control in flight.

Safety Actions

Subsequent to the accident, the operator implemented numerous safety initiatives to prevent recurrence, including two independent safety audits, a formal fatigue risk management program, a safety management system, a formal tool/material accountability program, new work interruption policies, creation of a formally-trained safety officer position, and a formal process for the communication of safety-critical information.

Safety Resources from Aerossurance

- Critical Maintenance Tasks: EASA Part-M & -145 Change

- Professor James Reason’s 12 Principles of Error Management

- How To Develop Your Organisation’s Safety Culture

- Fatal $16 Million Maintenance Errors

- Inadvertent Fire Bottle Discharge During Maintenance

- FOD Damages 737 Flying Controls

- Cessna Citation Excel Controls Freeze

- B767 Engine Fire – Ignition from Misrouted / Chaffed Cables

- A319 Double Cowling Loss and Fire – AAIB Report

- Loose B-Nut: Accident During Helicopter Maintenance Check Flight

- USAF RC-135V Rivet Joint Oxygen Fire

- The Missing Igniters: Fatigue & Management of Change Shortcomings

- Maintenance Human Factors: The Next Generation

- Aircraft Maintenance: Going for Gold?

- Misassembled Anti-Torque Pedals Cause EC135 Accident

- EC130B4 Accident: Incorrect TRDS Bearing Installation

- Airworthiness Matters: Next Generation Maintenance Human Factors

- Cessna 208 Forced Landing: Engine Failure Due To Re-Assembly Error

- Insecure Pitch Link Fatal R44 Accident

- Bell 429 TR Pitch Change Link Bearing Failure

- Maintenance Human Factors in Finnish F406 Landing Gear Collapse

- Load Lost Due to Misrigged Under Slung Load Control Cable

- UPDATE 9 August 2017: A320 Flown on After Damaging Heavy Landing

- UPDATE 10 August 2017: A320 Rolls Back on Stand: Incomplete Maintenance Procedures and Ground Handling Deviations

- UPDATE 24 June 2018: B1900D Emergency Landing: Maintenance Standards & Practices The TSB report posses many questions on the management and oversight of aircraft maintenance, competency and maintenance standards & practices. We look at opportunities for forward-thinking MROs to improve their maintenance standards and practices.

- UPDATE 25 August 2018: Crossed Cables: Colgan Air B1900D N240CJ Maintenance Error On 26 August 2003 a B1900D crashed on take off after errors during flying control maintenance. We look at the maintenance human factor safety lessons from this and another B1900 accident that year.

- UPDATE 30 October 2019: ‘Crazy’ KC-10 Boom Loss: Informal Maintenance Shift Handovers and Skipped Tasks

- UPDATE 10 June 2020: B767 Fire and Uncommanded Evacuation After Lockwire Omitted

- UPDATE 28 June 2020: Maintenance Issues in Fire-Fighting S-61A Accident (lock wire incorrectly fitted on a quick release)

- UPDATE 9 July 2022: R44 Ditched After Loss of TGB & TR: Improper Maintenance

Aerossurance worked with the Flight Safety Foundation (FSF) to create a Maintenance Observation Program (MOP) requirement for their contractible BARSOHO offshore helicopter Safety Performance Requirements to help learning about routine maintenance and then to initiate safety improvements:

Aerossurance can provide practice guidance and specialist support to successfully implement a MOP.

Aerossurance sponsored the 2017 European Society of Air Safety Investigators (ESASI) 8th Regional Seminar in Ljubljana, Slovenia on 19 and 20 April 2017. ESASI is the European chapter of the International Society of Air Safety Investigators (ISASI).

Aerossurance sponsored an RAeS HFG:E conference at Cranfield University on 9 May 2017, on the topic of Staying Alert: Managing Fatigue in Maintenance.

Aerossurance is pleased to be supporting the annual Chartered Institute of Ergonomics & Human Factors’ (CIEHF) Human Factors in Aviation Safety Conference for the third year running. We will be presenting for the second year running too. This year the conference takes place 13 to 14 November 2017 at the Hilton London Gatwick Airport, UK with the theme: How do we improve human performance in today’s aviation business?

Aerossurance is pleased to be both sponsoring and presenting at a Royal Aeronautical Society (RAeS) Human Factors Group: Engineering seminar Maintenance Error: Are we learning? to be held on 9 May 2019 at Cranfield University.

Recent Comments