Insecure Pitch Link Fatal R44 Accident

During a post-maintenance check flight the main rotor separated from an R44 after a maintenance assembly error.

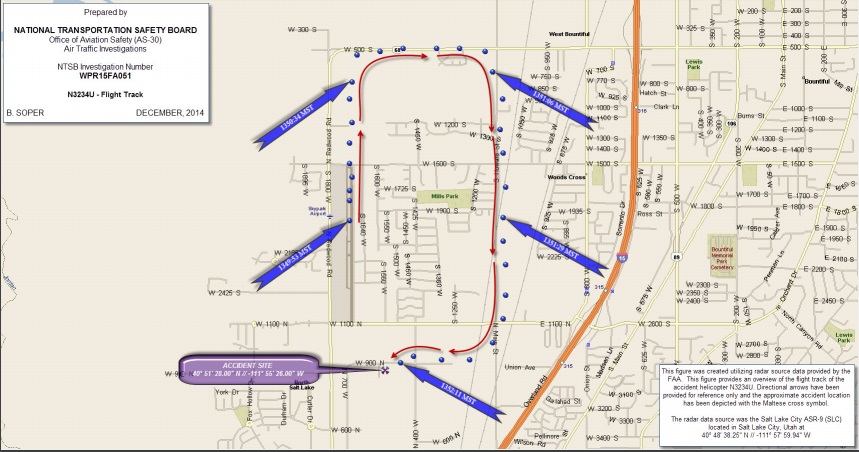

A US National Transportation Safety Board (NTSB) report describes the fatal accident to Robinson R44 N3234U operated by Native Range Capture Services in Utah on 2 December 2014:

The helicopter’s owner stated that, during a flight in the accident helicopter the month before the accident, the helicopter “had a bit of a vertical [vertical vibrations]”. The blades also had noticeable slop and movement in the pitch change link bolt attachment to the swashplate. During a 100-hour inspection, on November 2, 2014, at 582 hours of helicopter total time, the owner and pilot/mechanic recommended sending the blades out for rework. …the [red] main rotor blade pitch horn was replaced… …the owner hired the pilot-rated mechanic to install the blades and track them in a heavier configuration.

A mechanic, who spoke with the pilot a few weeks before the accident, stated that they had a discussion about an elongated pitch change link attachment hole on the accident helicopter and how to address it. On the night before the accident flight, they spoke again; the pilot was having trouble tracking the blades on the accident helicopter. The pilot stated that he could not get the blades to track any better, and that he was trying to change the track with the trim tabs.

During the accident flight witnesses heard “popping” or “banging” sounds, before seeing the main rotor and empennage separate from the helicopter.

The NTSB state that:

Witness statements and wreckage documentation were consistent with a main rotor blade striking the tail and subsequently, a mast bump, which resulted in the helicopter descending uncontrollably.

The damage observed on the components of the main rotor system was consistent with an in-flight separation of the pitch change link for the red blade, with separation occurring at the location where the pitch change link attached to the swashplate. …a series of impressions corresponding to contact with threads on the red blade pitch change link attachment bolt were observed on the attachment hole bore through the swashplate in an area that should have only contacted the grip portion of the bolt. Thus, it is likely that the intact bolt separated from the attachment due to loss of the lock nut and palnut.

According to manufacturer’s maintenance instructions, the attachment bolts used at the upper and lower ends of the pitch change links are NAS6605 series bolts. The locknuts for the NAS6605 series bolts should be fastened to a dry torque value of 240 lb-in ± 24 lb-in, and palnuts used on NAS6605 series bolts should be applied with a dry torque of 20 lb-in to 40 lb-in. During installation, the palnuts are installed over the top of the locking nut.

Torque measurements were obtained on the locknuts installed on the three recovered pitch change link attachment bolts. All measured torque values were lower than that specified in the helicopter’s maintenance manual, indicating that the fasteners were improperly torqued before the accident.

While torque for the missing attachment bolt could not be measured, the torque measured on the remaining pitch change link attachment bolts and witness marks on the attachment hole bore in the swashplate suggest that the bolt likely separated due to insufficient torque applied at the time of installation, which led to the loss of the locknut and palnut due to vibrational loads under normal operation.

The National Transportation Safety Board determined the probable cause to be: The pilot/mechanic’s failure to properly secure the pitch link hardware of one main rotor blade to the rotating swash plate, which resulted in the pitch link separating in flight and a subsequent loss of control.

There is no suggestion in the NTSB report that an independent inspection had been carried out, nor is one required under US regulation on this size of aircraft.

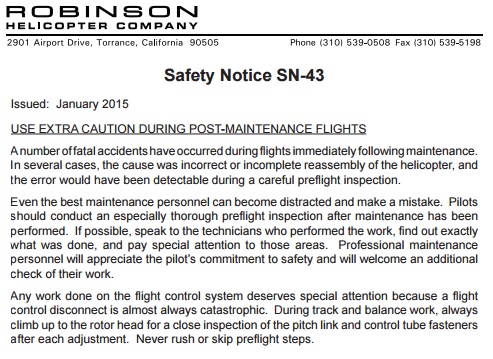

Robinson issued Safety Notice SN-43 in January 2015:

Safety Resources

We have written about Critical Maintenance Tasks previously in an enduring popular article. Also see our articles:

- Fatal $16 Million Maintenance Errors

- Loose B-Nut: Accident During Helicopter Maintenance Check Flight

- USAF RC-135V Rivet Joint Oxygen Fire

- The Missing Igniters: Fatigue & Management of Change Shortcomings

- Misassembled Anti-Torque Pedals Cause EC135 Accident

- EC130B4 Accident: Incorrect TRDS Bearing Installation

- Misrigged Flying Controls: Fatal Maintenance Check Flight Accident

- Cessna 208 Forced Landing: Engine Failure Due To Re-Assembly Error

- UPDATE 19 May 2018: Too Rushed to Check: Misrigged Flying Controls

- UPDATE 8 March 2019: Fatal S-61N Dual Power Loss During Post Maintenance Check Flight

- UPDATE 19 April 2019: FAA Rules Applied: So Misrigged Flying Controls Undetected in an accident to a Cessna 172 in Bermuda.

- UPDATE 9 May 2020: Ungreased Japanese AS332L Tail Rotor Fatally Failed

- UPDATE 9 July 2022: R44 Ditched After Loss of TGB & TR: Improper Maintenance

Also see our articles:

- Professor James Reason’s 12 Principles of Error Management

- How To Develop Your Organisation’s Safety Culture

- Aircraft Maintenance: Going for Gold?

- Airworthiness Matters: Next Generation Maintenance Human Factors

- Maintenance Check Flights: Safety Lessons

…and our review of The Field Guide to Understanding Human Error by Sidney Dekker presented to the Royal Aeronautical Society (RAeS): The Field Guide to Understanding Human Error – A Review

Aerossurance worked with the Flight Safety Foundation (FSF) to create a Maintenance Observation Program (MOP) requirement for their contractible BARSOHO offshore helicopter Safety Performance Requirements to help learning about routine maintenance and then to initiate safety improvements:

Aerossurance can provide practice guidance and specialist support to successfully implement a MOP.

An excellent initiative to create more Human Centred Design (HCD) by use of a Human Hazard Analysis (HHA) is described in Designing out human error

HeliOffshore, the global safety-focused organisation for the offshore helicopter industry, is exploring a fresh approach to reducing safety risk from aircraft maintenance. Recent trials with Airbus Helicopters and HeliOne show that this new direction has promise. The approach is based on an analysis of the aircraft design to identify where ‘error proofing’ features or other mitigations are most needed to support the maintenance engineer during critical maintenance tasks.

Aerossurance sponsored the 2017 European Society of Air Safety Investigators (ESASI) 8th Regional Seminar in Ljubljana, Slovenia on 19 and 20 April 2017. ESASI is the European chapter of the International Society of Air Safety Investigators (ISASI).

Aerossurance also pleased sponsored an RAeS HFG:E conference at Cranfield University on 9 May 2017, on the topic of Staying Alert: Managing Fatigue in Maintenance.

Aerossurance is supporting the annual Chartered Institute of Ergonomics & Human Factors’ (CIEHF) Human Factors in Aviation Safety Conference for the third year running. We will be presenting for the second year running too. This year the conference takes place 13 to 14 November 2017 at the Hilton London Gatwick Airport, UK with the theme: How do we improve human performance in today’s aviation business?

Aerossurance is pleased to be both sponsoring and presenting at a Royal Aeronautical Society (RAeS) Human Factors Group: Engineering seminar Maintenance Error: Are we learning? to be held on 9 May 2019 at Cranfield University.

Recent Comments