Too Rushed to Check: Misrigged Flying Controls

If you had spent 2 years rebuilding a classic 1947 Piper PA-12 you’d make the time to check the rigging of the flying controls before first flight, right? Sadly, the 25,000 hour pilot in this fatal case study was in a rush…

Accident Flight

On 8 April 2017 PA-12 N3280M was being readied at Orlando Sanford International Airport, Florida for its first flight since a restoration that included replacement of the wing and fuselage fabric, flight control cables and electrical wiring.

The US National Transportation Safety Board (NTSB) report that:

Although the mechanic who had worked on the airplane with the pilot wanted the pilot to do a high-speed taxi test before flight, the pilot wanted to “hurry up” and test fly the airplane as he had a friend visiting and wanted to take him flying in the airplane.

Multiple witnesses stated that the airplane accelerated normally, lifted off, and immediately pitched up to a near vertical attitude. One witness stated, “it was like someone took the control yoke full aft.”

The witnesses reported that the airplane reached an altitude of about 100 ft, stalled, rolled to the right, and descended in a nose-down attitude to impact on the right side of runway 27L.

A postimpact fire ensued that was extinguished by aircraft rescue and firefighting personnel on the airport.

The pilot died in the accident. The cause of death was recorded as due to “thermal and blunt force injuries”.

Safety Investigation

Examination of the wreckage revealed crush damage to the nose and the leading edges of the wings that was consistent with a nearly vertical nose-down flight path at the time of impact.

Further examination of the wreckage revealed that the airplane’s elevator control cables were misrigged, such that they were attached to the incorrect (opposite) locations on the upper and lower ends of the elevator control horn, resulting in a reversal of elevator control inputs.

The NTSB comment that:

If the pilot had checked the elevator for correct motion during the preflight inspection and before takeoff check, he likely would have discovered that it was misrigged, and the accident would have been avoided.

The NTSB disappointingly do not discuss the circumstances of the maintenance, however we note that an independent inspection of the flying controls after reconnection, which would have highlighted the error, is not required by Federal Aviation Regulations.

NTSB Probable Cause

The incorrect rigging of the elevator control cables, which resulted in a reversal of elevator control inputs applied by the pilot during the takeoff, an excessive nose-high pitch, and subsequent aerodynamic stall after takeoff.

Also causal was the inadequate post-maintenance inspection and the pilot’s inadequate preflight inspection and before takeoff check, which failed to detect the misrigging.

Safety Lessons

The NTSB observe that:

During preflight inspection of a PA-12 (before engine start), a pilot can see the elevator’s corresponding movements when the control stick is manipulated (either when standing by the open cockpit door or when seated in the front seat); likewise, a pilot standing on the ground and manipulating the elevator by hand can look forward and see the corresponding control stick movement. During a before takeoff check of the PA-12, a pilot can view the elevator from the pilot seat by turning around and looking back.

Maintenance personnel should first become familiar with the normal directional movement of the controls and surfaces before disassembling the systems. It is easier to recognize “abnormal” if you are very familiar with what “normal” looks like. Carefully follow manufacturers’ instructions to ensure that the work is completed as specified. Always refer to up-to-date instructions and manuals–including airworthiness directives, maintenance alerts, special airworthiness information bulletins, and unapproved parts notifications–when performing a task.

Be aware that some maintenance information, especially for older airplanes, may be nonspecific.

Other Safety Resources

We discussed a very similar case here Misrigged Flying Controls: Fatal Maintenance Check Flight Accident, albeit involving a more modern Piper PA-46-350P Malibu Mirage (N962DA) in 2015. Time pressures, a maintenance error rigging flying control cables and a potentially non-compliant design conspired to cause that fatal accident.

We also discuss two cases where the normal sound airmanship of pre-flight ‘full and free’ control checks would have prevented an accident:

- C-130J Control Restriction Accident, Jalalabad

- Business Aviation Compliance With Pre Take-off Flight Control Checks

In 1992 the gust locks had not been fully disengaged on a third-party DHC-4T Turbine Caribou conversion, N400NC, leading to a horrific fatal accident that killed 3.

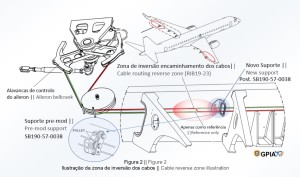

UPDATE 31 May 2019: The Portuguese accident investigation agency, GPIAAF, issued a safety investigation update on a serious in-flight loss of control incident involving Air Astana Embraer ERJ-190 P4-KCJ that occurred on 11 November 2018. The aircraft was landed safely after considerable difficulty, so much so the crew had debated ditching offshore. GPIAAF conformed that incorrect ailerons control cable system installation had occurred in both wings during a maintenance check conducted in Portugal.

GPIAFF note that: “By introducing the modification iaw Service Bulletin 190-57-0038 during the maintenance activities, there was no longer the cable routing and separation around rib 21, making it harder to understand the maintenance instructions, with recognized opportunities for improvement in the maintenance actions interpretation”. They also comment that: “The message “FLT CTRL NO DISPATCH” was generated during the maintenance activities, which in turn originated additional troubleshooting activities by the maintenance service provider, supported by the aircraft manufacturer. These activities, which lasted for 11 days, did not identify the ailerons’ cables reversal, nor was this correlated to the “FLT CTRL NO DISPATCH” message.”

GPIAFF comment “deviations to the internal procedures” occurred within the maintenance organisation that “led to the error not being detected in the various safety barriers designed” in the process. They also note that the error ” was not identified in the aircraft operational checks (flight controls check) by the operator’s crew.”

UPDATE 1 June 2019: Our analysis: ERJ-190 Flying Control Rigging Error

Aerossurance has previously written on these associated topics (including several on maintenance errors and how to combat them):

- James Reason’s 12 Principles of Error Management

- Back to the Future: Error Management

- Maintenance Human Factors: The Next Generation

- Aircraft Maintenance: Going for Gold?

- Rockets Sleds, Steamships and Human Factors: Murphy’s Law or Holt’s Law?

- Critical Maintenance Tasks: EASA Part-M & -145 Change

- Misassembled Anti-Torque Pedals Cause EC135 Accident

- Stabilised Hover Prevents Loss of Control Accidents Say FAA

- EC130B4 Accident: Incorrect TRDS Bearing Installation

- Fatal $16 Million Maintenance Errors

- Maintenance Check Flights: Safety Lessons

- Insecure Pitch Link Fatal R44 Accident

- Time Pressures and Take-Off Trim Trouble

- Crossed Wires: Online Maintenance Human Factors Training Video

- UPDATE 25 August 2018: Crossed Cables: Colgan Air B1900D N240CJ Maintenance Error On 26 August 2003 a B1900D crashed on take off after errors during flying control maintenance. We look at the maintenance human factor safety lessons from this and another B1900 accident that year.

- UPDATE 19 April 2019: FAA Rules Applied: So Misrigged Flying Controls Undetected in an accident to a Cessna 172 in Bermuda.

Also see our review of The Field Guide to Understanding Human Error by Sidney Dekker presented to the Royal Aeronautical Society (RAeS): The Field Guide to Understanding Human Error – A Review

FSF Maintenance Observation Programme (MOP)

Aerossurance worked with the Flight Safety Foundation (FSF) to create a Maintenance Observation Program (MOP) requirement for their contractible BARSOHO offshore helicopter Safety Performance Requirements to help learning about routine maintenance and then to initiate safety improvements:

Aerossurance can provide practice guidance and specialist support to successfully implement a MOP.

Aerossurance is pleased to sponsor the 9th European Society of Air Safety Investigators (ESASI) Regional Seminar in Riga, Latvia 23 and 24 May 2018.

Aerossurance is pleased to be both sponsoring and presenting at a Royal Aeronautical Society (RAeS) Human Factors Group: Engineering seminar Maintenance Error: Are we learning? to be held on 9 May 2019 at Cranfield University.

Recent Comments