Flying Control FOD: Screwdriver Found in C208 Controls

An Australian Cessna 208B Caravan pilot detected a control restriction during a flight control rigging check according to a Service Difficult Report (SDR) submitted to the Civil Aviation Safety Authority (CASA). The report described how the pilot:

…checked full and free movement of all flight controls. Very slight friction or binding of the elevator control was identified.

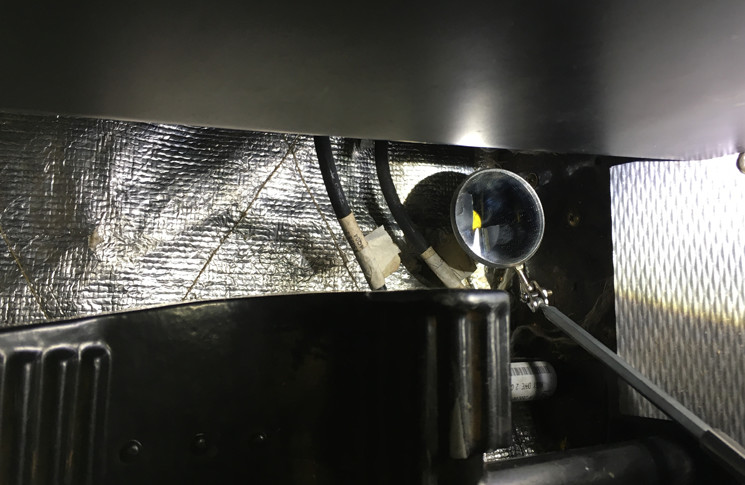

The issue was discussed with the LAME [Licenced Aircraft Maintenance Engineer] who investigated further and discovered an object wedged between the control column shroud and the control column attaching cables.

The shroud was removed and a screw driver was found.

CASA do not report any investigation results that explain the lost tool. Even when such information is available, it is very easy to fall for the fundamental attribution error that the personnel in a particular incident were ‘stupid’ or ‘unprofessional’ without considering the organisational environment and the circumstances they found themselves in.

We have previously discussed these FOD events:

- Tool Control and a Rotor Blade FOD Incident

- Micro FOD: Cessna 208B Grand Caravan Engine Failure & Forced Landing

- Misrigged Flying Controls: Fatal Maintenance Check Flight Accident

- FOD Damages 737 Flying Controls

- Crew Bag FOD Shatters Hawk Canopy

- C-130J Control Restriction Accident, Jalalabad

The UK AAIB report on the loss of Yak-52 G-YAKW, considered a fatal accident where a tool, seemingly borrowed from an unlocked tool box, jammed flying controls. Damages of £270,000 were awarded to the pilot’s family in a subsequent court case.

UPDATE 26 March 2017: Cessna 208 Forced Landing: Engine Failure Due To Re-Assembly Error

UPDATE 14 April 2017: The NTSB preliminary report on an incident on SA227 N158WA on 20 March 2017 in Boise, ID, where a lost tool appears to have come loose at rotation and caused the loss of a propeller blade tip and for debris to enter the cabin.

…about the time the airplane was rotating from Runway 10L, the pilot experienced a light vibration; he subsequently returned to BOI and landed uneventfully. During a post-landing examination of the airplane, it was revealed that a portion of the outboard section of a left propeller blade, which had fragmented into 2 pieces, was missing. Additionally, about a 4 inch by 4 inch puncture hole was observed to have gone through the left forward side of the fuselage just aft of the main air stair door; a piece of the propeller blade was found in the cabin.

It was further noted during a runway sweep for foreign objects shortly after the occurrence, that a screw driver which had been used during maintenance on the airplane earlier, and the second piece of the propeller blade tip, were both recovered from the departure runway in the same approximate location from where the airplane would have rotated.

UPDATE 12 November 2018: We analyse the outcome of this SA226 investigation: Lost Tool FODs Propeller Blade, Penetrating Turboprop’s Fuselage

Plus we have discussed maintenance human factors and error management more generally here:

- Professor James Reason’s 12 Principles of Error Management

- Back to the Future: Error Management

- Maintenance Human Factors: The Next Generation

- Aircraft Maintenance: Going for Gold?

Aerossurance worked with the Flight Safety Foundation (FSF) to create a Maintenance Observation Program (MOP) requirement for their contractible BARSOHO offshore helicopter Safety Performance Requirements to help learning about routine maintenance and then to initiate safety improvements:

Aerossurance can provide practice guidance and specialist support to successfully implement a MOP.

We have also written these other C208 articles:

- NTSB Report on C208B Caravan Ditching, Molokai, Hawaii, 2013

- Canadian Mining Icing Air Accident (Cessna 208B Caravan)

- C208B Force Landing After Inadequate Maintenance Fault Finding

Aerossurance is pleased to sponsor the 2017 European Society of Air Safety Investigators (ESASI) 8th Regional Seminar in Ljubljana, Slovenia on 19 and 20 April 2017. ESASI is the European chapter of the International Society of Air Safety Investigators (ISASI).

Aerossurance is pleased to be supporting the annual Chartered Institute of Ergonomics & Human Factors’ (CIEHF) Human Factors in Aviation Safety Conference for the third year running. This year the conference takes place 13 to 14 November 2017 at the Hilton London Gatwick Airport, UK with the theme: How do we improve human performance in today’s aviation business?

Aerossurance is pleased to be both sponsoring and presenting at a Royal Aeronautical Society (RAeS) Human Factors Group: Engineering seminar Maintenance Error: Are we learning? to be held on 9 May 2019 at Cranfield University.

Recent Comments