Severe Propeller Vibrations on ATR 72-212A: BEA Report

The Bureau d’Enquêtes et d’Analyses (BEA), the French Safety Investigation Authority, released their report in July 2019 (in French, UPDATE 10 Sept 2019: and now also in English) on a series of propeller incidents that occurred due to a vibratory phenomena that was not uncovered in certification testing.

Caribbean In Service Event

Caribbean Airlines ATR 72-212A 9Y-TTC was operating from Tobago to Port of Spain, Trinidad and Tobago on 4 May 2014. It was at top of descent, 6000 feet and 220 KIAS, with both Hamilton Sundstrand / UTAS 568F-1 propellers at 82% Np, when the flight crew commenced a 1500 fpm descent.

The airspeed began to increase and so the crew reduced power. The airspeed did not decrease however. When the aircraft reached 246 KIAS, 4 knots below Vmo (max operating velocity), the crew reduced power to idle. The crew felt strong vibrations which was shortly followed by No 2 Propeller Electronic Control (PEC) warnings. Airspeed did now decrease, so the flight crew increased power slightly and the PEC fault indications disappeared. However, shortly after a No 2 ACW GEN fault message was displayed. After further propeller fluctuations the crew managed to balance the power, albeit at c4.5º difference in blade angles and subsequently made a safe landing.

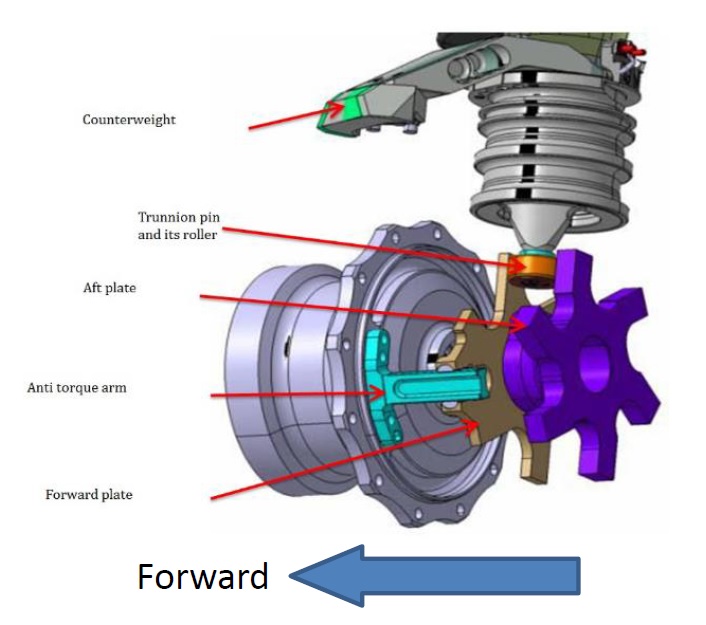

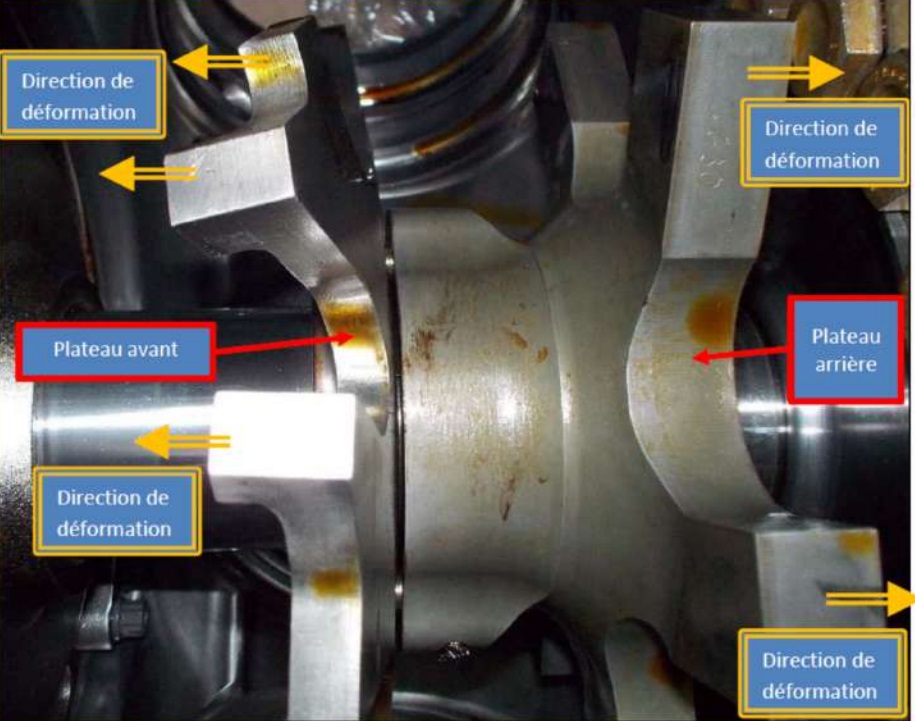

After this flight, the drive shaft of the No 2 engine’s AC generator was found broken and was replaced. Ground runs revealed no abnormalities so the aircraft was released to service. The next flight was normal until loud vibration was reported during taxi after landing when the flight crew moved the power levers from the flight idle to ground idle. Further maintenance fault finding was conducted. When the power levers were positioned in reverse thrust, vibration occurred. After shutdown, blades 1, 2, 5 and 6 of the No 2 propeller were feathered but blades 3 and 4 appeared to remain in the reverse thrust position. Upon disassembly of the No 2 propeller, the trunnion pin of blade 4 and the propeller blade actuator plate were found damaged.

The Safety Investigation

The BEA investigated this occurrence under the delegation of Trinidad and Tobago. In their report the BEA note that:

The circumstances and damage observed were similar to that which had been observed in an investigation into a serious incident on 18 September 2013 in Indonesia, involving an ATR 72-212A registered PK-WFV. An investigation was opened by the Indonesian investigation authority, the NTSC, who issued an immediate safety recommendation to the operator of the aircraft concerning the verification of the condition of the propeller blade trunnion pins and the search for crack indications on part of the fleet.

On 30 November 2014, a new similar incident occurred in Sweden to an ATR 72-212A registered SE-MDB, for which an investigation was opened by the Swedish investigation authority, SHK.

In fact there was also one other occurrence in 2007 in Spain and three more identified between 2012 and 2014 in Tanzania and Brazil. BEA comment that:

In almost all of the [7] cases, the rupture of a trunnion pin of one of the blades and damage to the propeller blade actuator forward plate were observed.

They also only involved on No 2 propellers. The BEA noted that as both propellers turn in the same direction, but are located differently relative to the fuselage, they see different aerodynamic loads. Extensive in-flight and ground vibration testing was conducted in 2014 and 2016 on a No 2 propeller to support the investigation (detailed in English in Annex 13 of the BEA report).

The BEA investigation…

….revealed the existence of alternating overloads causing damage to the plates and of a final overload in one direction [when in negative thrust] resulting in the rupture of the trunnion pin. It was not possible to determine the cause of these overloads and the precise chronology of the damage and vibrations.

The origin of the overload could not be conclusively determined, but three elements may have contributed:

- A retention force caused by a ball bunching phenomenon;

- Significant loads caused by the trunnion pin striking the ear of the plate on forward plate cyclic loading appearing when the aeroplane speed was close to VMO and the power levers in the flight idle position;

- Unplanned operation of the control loop of the propeller pitch change mechanism affected by the forward plate cyclic loading and friction phenomena.

BEA say that:

Ongoing research needs to be pursued in order to understand sequence of damage to the propeller and the origin(s) of the overloads.

The BEA comment that:

The tests carried out during the 1994-1995 propeller certification campaign did not reveal certain phenomena observed during the 2014 and 2016 flight tests: friction at the blade root bearings, the vibrations of the propeller control system when the plane is descending at a speed close to the Vmo with the power levers in idle flight position, the excitation of the front plate during the appearance of this vibratory phenomenon…

However, the certification tests had only been conducted on the No 1 propeller. They also note that:

At the time of the propeller certification, FAA Circular 20-66 did not recommend explicitly to perform descent at idle flight at different speeds.

This changed in 2001. They also note that the ATR has no propeller vibration measurement or recording system, so feedback is purely by pilot reports and subjective.

BEA comment that in relation to the fault finding 4-5 May 2014:

This incident highlighted that despite the maintenance procedures being implemented it was possible to perform a flight with significant damage of the propeller control system. It is advisable to consider together all the elements established when analyzing similar events…

Safety Actions / Recommendations

Shortly after the Swedish incident, the BEA issued four safety recommendations to EASA. These were related to:

- Informing pilots that there had been severe vibrations during descent at a speed close to Vmo with the power levers in the flight idle position and that heavy damage to the propeller pitch change mechanism and, in one case, to the engine mounting brackets, had been observed;

- Planning and carrying out of flights so that operation close to Vmo at flight idle is avoided;

- Informing maintenance personnel in the cases where pilots have felt strong vibrations during the descent at a speed close to Vmo with the power levers in the flight idle position;

- Developing an appropriate operational procedure dealing with severe propeller vibrations and including this procedure in the operators’ operational documents.

At the end of their investigation into the incident, the SHK issued a safety recommendation to EASA that it:

Consider introducing temporary limitations in the manoeuvring envelope, or limitations of the power ranges within the latter, until the problem is resolved and rectified.

EASA issued a Safety Information Bulletin. The BEA note that:

Since October 2014, ATR has published a specific maintenance procedure, for use after an abnormal vibratory event that occurred during flight, to avoid re-flying an aircraft whose propeller control system is damaged in a significant way. This procedure is based on a published bulletin service by UTAS on 2 October 2014 (SB 568F-61-67) describing an inspection procedure which provides operators with instructions for measuring angular clearance of the six propeller blades in the event that a vibration was felt, combined with the occurrence of fault codes 67 and 68 of the PEC (blade angle error angle). The instructions require performing a dimensional and visual inspection of the cylinder plates of the control system if the maximum allowed value is exceeded on a blade.

- EASA ensures that ATR and UTAS continue to analyse the phenomenon of cyclic efforts on the front plateau highlighted in slow motion flight and to a speed slightly higher than the Vmo in order to confirm that he flight envelope of the ATR72-212A provides sufficient margins for avoiding this phenomenon causing damage. [Recommendation FRAN-2019-016]

- EASA shall ensure that research is pursued with the aim of understand the sequence of damage to the propeller and the origin(s) of the damage and, while waiting for the result of this research, the operating procedures recommended by ATR for descent be reviewed to prevent any evolution between 240 and 250 kts in idle. [Recommendation FRAN-2019-017]

- EASA assesses the value of requiring level indicators vibration dampers for each propeller-motor assembly are installed in cockpits of commercial transport aircraft equipped with turboprops. [Recommendation FRAN-2019-018]

- a) EASA and b) FAA require initial certification of propellers includes analysis of a thorough study of vibratory behaviour of each propeller at idle flight at speeds around Vmo. [EASA: Recommendation FRAN-2019-019] and [FAA: Recommendation FRAN-2019-034]

Other Safety Resources

- A Failure in Propeller Design and Certification Resulted in the Loss of an EMB-120 in 1991

- Inadequate Maintenance at a USAF Depot Featured in Fatal USMC KC-130T Accident

- Flawed Post-Flight and Pre-Flight Inspections Miss Propeller Damage

- ATR72 In-Flight Pitch Disconnect and Structural Failure

- A320 Flown on After Damaging Heavy Landing

- UPDATE 12 October 2019: ATR72 VH-FVR Missed Damage: Maintenance Lessons Unclear communications, shift handover & roles and responsibilities, complacency about fatigue and failure to use access equipment all feature in this serious incident.

UPDATE 12 August 2019: Russia’s Interstate Aviation Committee (IAC/MAK), which led the investigation into the fatal loss of Aircraft Industries L410UVP-E20 RA-67047 stated in their investigation report that the pitch setting of the blades of the No 2 Avia AV-725 propeller dropped to minus 1.8° while the Khabarovsk Airlines aircraft was just 170m above ground, resulting in a loss of control and fatal accident on 15 November 2017. Analysis had indicated that the probability of such an event was “10E14” and, so this “was the reason why [no] instructions for flightcrew for this event were introduced into [the flight manual]”.

UPDATE 16 August 2019: A new AD is proposed by EASA for an improved GE engine push-pull control which reduces further the risk of uncommanded in-flight reversal of the AV-725 propeller on the L410 UVP-E20/ NG.

UPDATE 30 December 2019: White Air ATR-72-212A CS-DJG, operating for TAP Portugal, landed at Fez on 6 July 2018 after an unstabalised approach according to Portuguese accident investigators (the Gabinete de Prevenção e Investigação de Acidentes com Aeronaves [GPIAA]) but struck its tail onto the runway, touching down hard (+2.88G). The aircraft sustained abrasion damage to the aft fuselage, deformation between frames 35-38, sheared rivets and wear on the tail-skid.

The Aircraft Commander prepared for the return flight by performing a walk-round, carrying out a general inspection, looking for problems on the main landing gear and checking the tail strut (‘pogo stick’) fitted under the bumper when parked. He did not detect any anomalies and the aircraft was flown back to Lisbon before the damage was detected. GPIAA comment on:

….excessive reliance on aircraft acceptance without sharing and discussing with the operator’s technical services [and a] organizational culture with inadequate or nonexistent procedures and individual centered decision-making without effective implementation of the CRM philosophy.

Recent Comments