Inadequate Propeller Maintenance at a USAF Depot Featured in Fatal USMC KC-130T Yanky 72 Accident

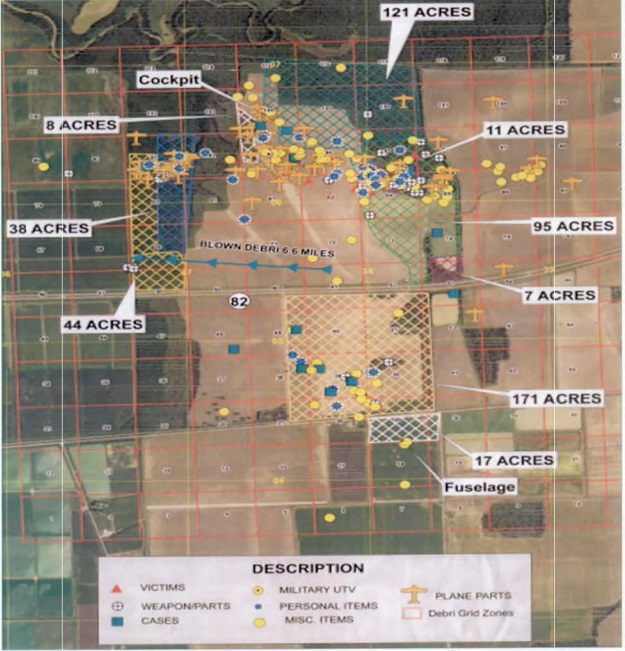

Maintenance issues at a US Air Force (USAF) depot featured in the loss of US Marine Corps (USMC) Reserve Lockheed KC-130T Hercules 165000 (callsign Yanky 72) and 16 lives when a propeller blade failed in flight over Itta Bena, Mississippi on 10 July 2017.

The USMC Command Investigation determined that the accident was due to:

…an inflight departure of the number four blade from the number two propeller. This propeller blade (P2B4) liberated while the aircraft was flying at a cruise altitude of 20,000 feet. This liberation of P2B4 is the first known occurrence of a circumferential fatigue crack initiating from a radial crack which had not grown to pass fully through to the outer diameter blade shank wall of a propeller produced by UTC Aerospace Systems (UTAS).

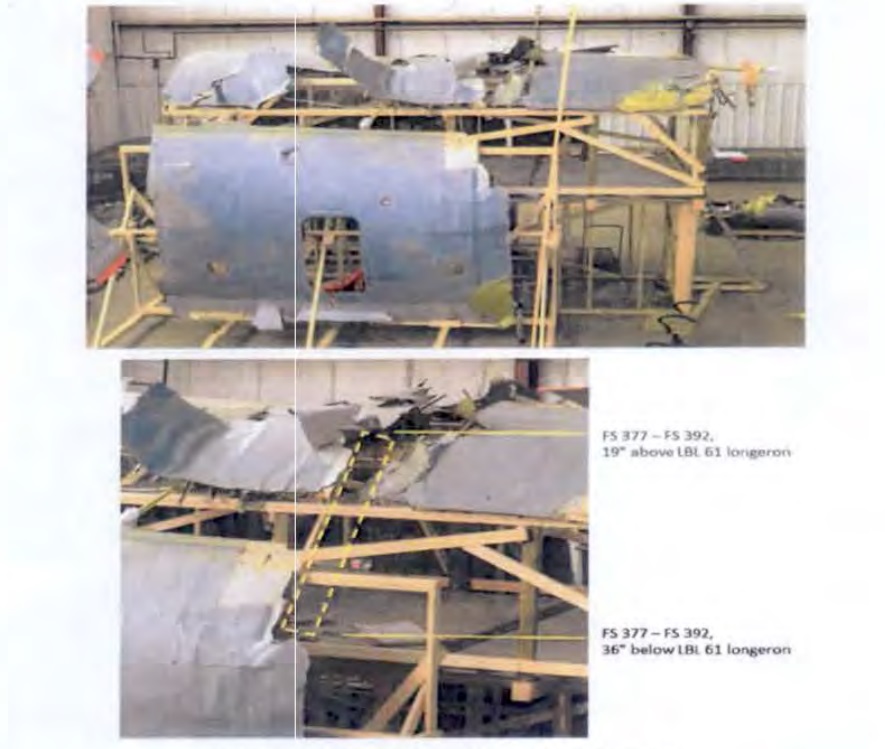

[The liberated blade] sliced through the left (port) side of the fuselage, and impacted the interior of the right (starboard) side…

This impact caused the skin of the aircraft to separate along the starboard side. The energy transferred from P2B4’s impact through the structure of the airframe also caused an overload condition of propeller three’s drive shaft. This resulted in its associated reduction gearbox assembly (RGA) failing and the separation of propeller three from the aircraft. Propeller three then momentarily embedded into the upper right section of the fuselage. After which, it continued over the aft starboard section of the fuselage and impacted the starboard horizontal stabilizer separating a significant portion of the stabilizer from the aircraft.

As a result, the fuselage “explosively disintegrated into multiple pieces” says the investigation.

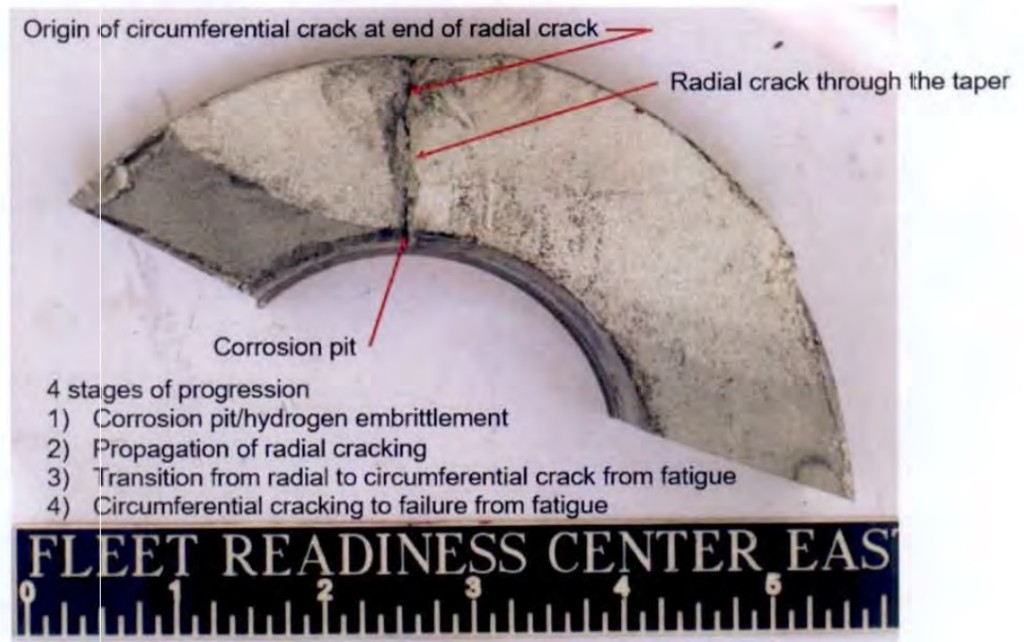

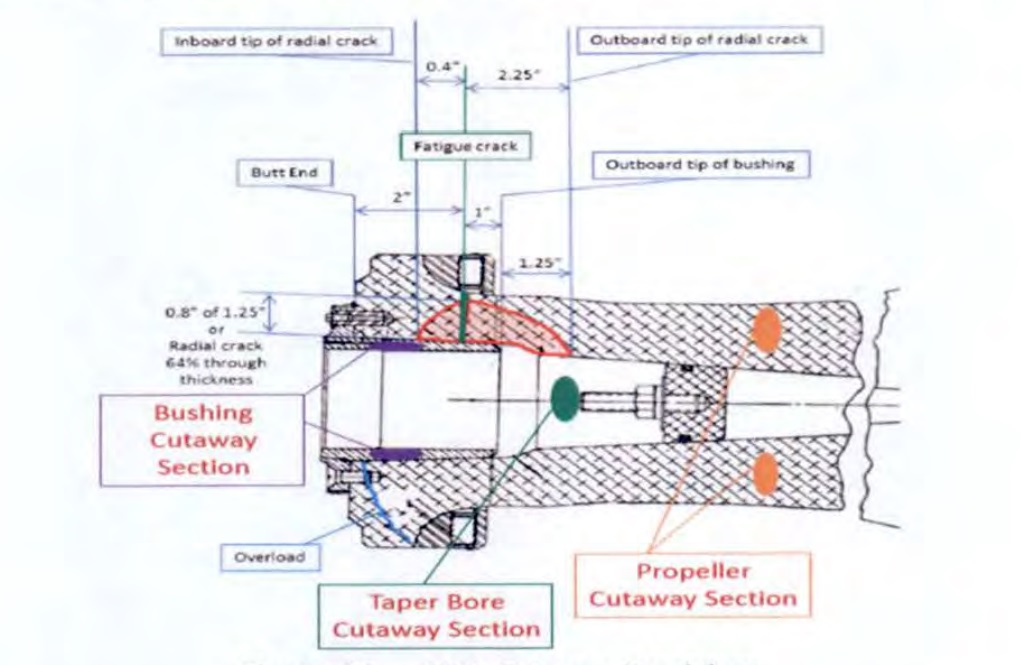

Post-mishap analysis of P2B4 revealed that a circumferential fatigue crack in the blade caused the fracture and liberation. This fatigue crack propagated from a radial crack which originated from intergranular cracking (IGC) and corrosion pitting.

This intergranular radial crack in P2B4 had grown to a total of 2.7 inches in length along the interior taper bore of the blade, extending 1.25 inches beyond the bushing. The radial crack had grown outward through 64 percent of the shank wall section until it was 0.45 inches from the outer diameter at the time P2B4 liberated on 10 July 2017. When the circumferential fatigue crack reached critical length the remainder of the blade shank structure failed in overload…

The analysis also revealed the presence of anodize coating within the band of corrosion pitting and intergranular cracking on the blade near the origin of the crack.

This finding proves that the band of corrosion pitting and intergranular cracking was present and not removed during the last overhaul of P2B4 at Warner Robins Air Logistics Complex (WR-ALC) in the fall of 2011. The investigation concluded that the failure to remediate the corrosion pitting and intergranular cracking was due to deficiencies in the propeller blade overhaul process at WR-ALC which existed in 2011 and continued up until the shutdown of the WR-ALC propeller blade overhaul process in the fall of 2017.

In fact 12 of the 16 propeller blades on the accident aircraft “were determined to have: corrosion that existed at the time of their last overhaul at WR-ALC”.

A US Navy (USN) engineering team conducted a ‘process audit’ of the WR-ALC propeller blade repair facility in August 2017. Their report concluded the US Navy requirements for propeller overhaul are different from the USAF requirements. The team found deficiencies in the compliance with the technical publication requirements, preservation/storage, borescope inspection, Fluorescent Penetrant Inspection (FPI), Quality Assurance checks and standardization of USAF/USN repair processes.

The USAF formed its own Independent Review Team (IRT) in September 2017 to “assess and improve the propeller blade overhaul process at WR-ALC” and “create a uniform approach to overhaul procedures of both Air Force and Navy C-130T blades”

WR-ALC plans to upgrade and improve their borescope process and equipment to incorporate robotic capture and inspection of the taper bore on all blades overhauled. This borescope process will require a technician to verify and inspect the robotically captured images, which are designed to provide higher definition and resolution in order to assist in identifying corrosion and other defects. Gas bead blast of the taper bore will be conducted on all blades in order to clean the taper bore prior to capturing the image with the borescope camera. The eddy current inspection will be upgraded to automate, improve the sensitivity, and increase the area that the inspection can cover on the blade which will allow the technician the ability to inspect the whole blade. The FPI process will be upgraded to utilize robotics to completely submerge the blades into the chemical substance and increase the submersion time to four hours before the technician reviews the blade for corrosion and cracks. WR-ALC plans to update their process mapping to incorporate all the various work control documents into one consolidated electronic document identifying all defects and corrective actions conducted on the blade. This document will follow the blade through the process and be included into the blade’s historical logbook for life cycle preservation. The USAF plans to adopt the USN process of wet bushing install with primer instead of dry bushing installation. The USAF plans to adopt the USN process of using permatreat to assist with protecting a propeller blade from corrosion.

The investigation did NOT however identify WHY these shortcomings had come to exist.

The USMC investigators also identified that Navy personnel intended to provide technical oversight of work contracted to the USAF were actually unqualified for that role and were simply providing administrative support.

UPDATE 15 March 2019: Propeller cracking fears led Air Force to ground 60 C-130Hs, replace pre-1971 blades after investigations that followed the Mississippi USMC KC-130T accident. This affected 1/3 of the USAF C-130H fleet (mostly from Air National Guard units). A review of 23 cases of intergranular cracking had found 22 were on blades from before 1971, when the manufacturing process was changed.

UPDATE 25 April 2020: Hydraulic failure caused F-16 to crash near March base last year, Air Force says

…improper installation of two hydraulic check valves…resulted in the loss of sufficient hydraulic pressure to control the [F-16]. …an inadequate [flight-control system] overhaul process that lacked an effective procedure to identify improper installation of ISA check valves was a substantially contributing factor.

UPDATE 15 June 2020: An FAA AD is issued in response.

UPDATE 4 July 2024: “Engineer charged with obstructing a criminal investigation into the cause of the Yanky 72 plane crash“

Safety Resources

You may also be interested in these Aerossurance articles:

- How To Develop Your Organisation’s Safety Culture positive advice on the value of safety leadership and an aviation example of safety leadership development.

- How To Destroy Your Organisation’s Safety Culture a cautionary tale of how poor leadership and communications can undermine safety.

- James Reason’s 12 Principles of Error Management

- Back to the Future: Error Management

- NTSB Probable Causes and Bad Apples

- B1900D Emergency Landing: Maintenance Standards & Practices The TSB report posses many questions on the management and oversight of aircraft maintenance, competency and maintenance standards & practices after this serious incident. We look at opportunities for forward thinking MROs to improve their maintenance standards and practices.

- Safety Intelligence & Safety Wisdom

- HROs and Safety Mindfulness

- Consultants & Culture: The Good, the Bad and the Ugly

- USMC CH-53E Readiness Crisis and Mid Air Collision Catastrophe

- Loss of RAF Nimrod MR2 XV230 and the Haddon-Cave Review

- Culture + Non Compliance + Mechanical Failures = DC3 Accident

- RCAF Production Pressures Compromised Culture

- Investigators Criticise Cargo Carrier’s Culture & FAA Regulation After Fatal Somatogravic LOC-I

- AC-130J Prototype Written-Off After Flight Test LOC-I Overstress

- C-130 Fireball Due to Modification Error

- C-130J Control Restriction Accident, Jalalabad

- Crossed Cables: Colgan Air B1900D N240CJ Maintenance Error

- Korean T-50 Accident at Singapore Airshow

- ‘Procedural Drift’: Lynx CFIT in Afghanistan

- Investigation into F-22A Take Off Accident Highlights a Cultural Issue

- USAF Engine Shop in “Disarray” with a “Method of the Madness”: F-16CM Engine Fire

- Inadequate Maintenance, An Engine Failure and Mishandling: Crash of a USAF WC-130H: On 2 May 2018, a WC-130H, 65-0968, of the Puerto Rico Air National Guard‘s 156th Airlift Wing (156 AW), crashed shortly after take off from Savannah/Hilton Head International Airport (KSAV), Georgia. All nine persons on board were killed.

- UPDATE 26 January 2019: MC-12W Loss of Control Orbiting Over Afghanistan: Lessons in Training and Urgent Operational Requirements

- UPDATE 9 February 2019: Meeting Your Waterloo: Competence Assessment and Remembering the Lessons of Past Accidents: No one was injured in this low speed derailment in London after signal maintenance errors but investigators expressed concern that the lessons about maintenance errors from the fatal triple collision at Clapham in 1988 may have been forgotten.

- UPDATE 30 March 2019: Contaminated Oxygen on ‘Air Force One’ Poor standards at a Boeing maintenance facility resulted in contamination of two oxygen systems on a USAF Presidential VC-25 (B747).

- UPDATE 3 April 2019: A Failure in Propeller Design and Certification Resulted in the Loss of an EMB-120 in 1991

- UPDATE 11 August 2019: Severe Propeller Vibrations on ATR 72-212A: BEA Report: A vibratory phenomena that was not uncovered in certification testing and in one case resulted in a failure that did not get detected initially by maintenance inspections.

- UPDATE 12 October 2019: ATR72 VH-FVR Missed Damage: Maintenance Lessons Unclear communications, shift handover & roles and responsibilities, complacency about fatigue and failure to use access equipment all feature in this serious incident.

- UPDATE 30 October 2019: ‘Crazy’ KC-10 Boom Loss: Informal Maintenance Shift Handovers and Skipped Tasks

- UPDATE 9 May 2020: Ungreased Japanese AS332L Tail Rotor Fatally Failed

Aerossurance worked with the Flight Safety Foundation (FSF) to create a Maintenance Observation Program (MOP) requirement for their contractible BARSOHO offshore helicopter Safety Performance Requirements to help learning about routine maintenance and then to initiate safety improvements: Aerossurance can provide practice guidance and specialist support to successfully implement a MOP.

Aerossurance can provide practice guidance and specialist support to successfully implement a MOP.

As one article, Retired Air Force Four-Star: How to Solve Aviation Crisis has discussed:

…the best solution is for senior officials to keep the door open and have ongoing conversations on potential problems. “It’s not as much oversight as much as it is … going out and talking with [individuals] … just seeing what’s going on…”

Recent Comments