The Wrong Fuel: Three Misfuelling Accidents

Misfuelling aircraft with kerosene based Jet A-1 rather than Aviation Gasoline (AVGAS) continues to be a source of accidents. We look at three:

1) Misfuelled PA31 Accident: 15 Sept 2015 Manitoba

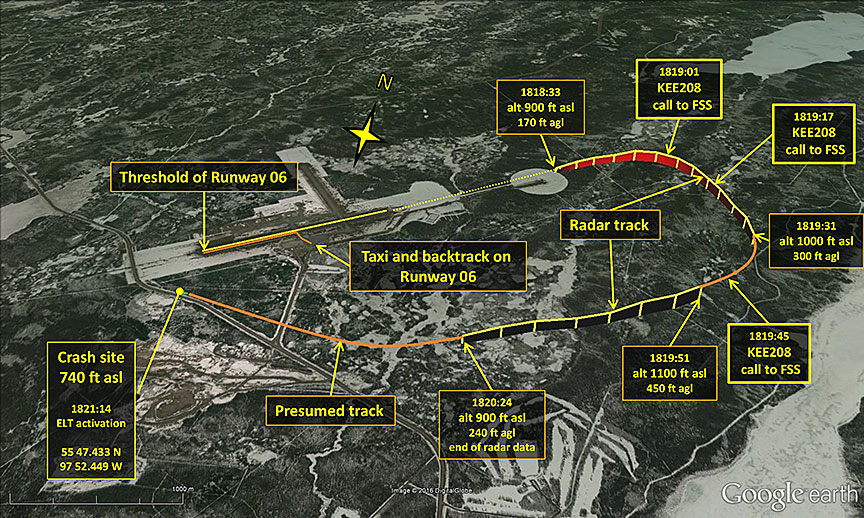

The Canadian Transportation Safety Board (TSB) has recently released their report on the 15 September 2015 accident involving twin engined Keystone Air Service Piper PA31-350 Navajo C-FXLO at Thompson, Manitoba.

The TSB say:

Shortly after rotation, both engines began to lose power. The crew attempted to return to the airport, but the aircraft was unable to maintain altitude.

The landing gear was extended in preparation for a forced landing on a highway southwest of the airport. Due to oncoming traffic, the forced landing was conducted in a forested area adjacent to the highway, approximately 700 metres south of the threshold of Runway 06.

The descent angle through the trees to the impact point of the main landing gear was about a 10° descent angle in a nose-high, wings-level attitude. From the initial impact point, the aircraft travelled another 30 m before coming to a stop. The total length of the wreckage trail from the first tree impact was approximately 76 m.

The [8] occupants sustained varying serious injuries but were able to assist each other and exit the aircraft.

Prior to Flight

The refuelling technician, who had been working for the fuelling company for a just over a month, and had no prior aviation experience, had fuelled another aircraft with Jet A1 before the Keystone aircraft arrived and drove the Jet A1 truck to where the PA-31 had parked.

The aircraft commander had intended to relay the fuel requirements to the technician, but the Co-Pilot, who was escorting passengers, had noticed that the fuel technician was having trouble with the fuel filler openings. The Co-Pilot assisted the technician and asked for required fuel quantity. The Captain overhead this conversation and so did not talk to the refueller.

Neither pilot noticed that the truck was a jet fuel truck.

The technician did not spot the aircraft placard specifying aviation gasoline.

When the technician couldn’t get the flared fuel filler nozzle to fit, he switched to a narrower nozzle, defeating a defence to prevent Jet A1 being used on a piston engined aircraft, but was sometimes required on aircraft that needed Jet A1.

Prior to departure, the Captain returned to the fuel providers office to collect the fuel slip but it was unoccupied The crew then performed an abbreviated check before taking off without the fuel slip. TSB say:

The Esso fuel dealer at Thompson Airport was Mara-Tech Aviation Fuels Ltd, which operated the Imperial Oil owned facility and equipment under an aviation dealer agreement. In addition to its day-to-day operation of the facility, Mara-Tech was responsible for staffing the facility and training the employees. Training materials were supplied by Imperial and consisted of a series of CDs or VHS tapes whose content was organized into modules. Each module was accompanied by a corresponding multiple-choice quiz.

Aviation dealer agreements require that fuel dealers adhere to Imperial’s operating standards and procedures. Under the aviation dealer agreement, fuel dealers have a licence to use Imperial brand trademarks, such as Esso and Esso Aviation, in marketing their businesses.

The [fuel technician’s] training consisted of reading the Imperial training material, viewing the CDs, and completing the corresponding multiple-choice quizzes. Additional certifications, such as Airside Vehicle Operator’s Permit and Transportation of Dangerous Goods, were administered by the manager at Mara-Tech’s Thompson facility.

The training was completed in 5 days and was followed by on-the-job training (riding along with the manager to gain experience fuelling aircraft). The fuel technician carried out the first unassisted fuelling on 22 August 2015.

TSB Analysis

Several factors likely allowed the fuelling error to go undetected in this occurrence. They included time pressure, the flight crew’s trust in the fuel dealer that was based on previous experience, and the direction of their attention to other work-related tasks at the time of the fuelling. These factors likely resulted in the inattentional blindness that crew members experienced toward the fuel truck signage that might have alerted them to the error in fuel type.

The flight crew had developed certain levels of trust in various aerodrome fuel dealers that extended to those dealers’ individual [technician].

The [fuel technician] was required to present a fuel order form on which the crew would specify the fuel type and amount required. However, this form was almost never used by the fuel dealer’s employees.

The fuelling operation was not adequately supervised by the flight crew. The [fuel technician] commenced the fuelling operation, having received tacit approval to do so, after the [pilots] had gone to the airport terminal.

When the fuelling was completed, the [fuel technician] printed a fuel slip, which recorded that Jet-A1 fuel had been dispensed. When the [fuel technician] left the building, the fuel slip remained inside… As a result, the fuel slip indicating that Jet-A1 fuel had been delivered was not available for scrutiny by the crew.

When the crew started the engines, the AVGAS remaining in the fuel lines and fuel filter bowls was being consumed. The expedited taxi to the runway meant that the aircraft was airborne before the fuel mixture, consisting of approximately 32% AVGAS and 68% Jet-A1, reached the engines. Given that the fuel mixture was present in all 4 fuel tanks, attempts to restore engine power by selecting another fuel tank would have been unsuccessful.

TSB Findings

Findings as to causes and contributing factors

- Delivery of the incorrect type of aircraft fuel caused loss of power from both engines, necessitating a forced landing.

- The fuelling operation was not adequately supervised by the flight crew.

- A reduced-diameter spout was installed that enabled the delivery of Jet-A1 fuel into the AVGAS fuel filler openings.

- The fuel slip indicating that Jet-A1 fuel had been delivered was not available for scrutiny by the crew.

Findings as to risk

- If administrative and physical defences against errors in aviation fuel operations are circumvented or disabled, there is a risk that the incorrect type of fuel will be delivered.

- If a reduced-diameter spout is available to accommodate non-standard fuel filler openings, there is an increased risk that Jet-A1 fuel can be dispensed into an aircraft that requires AVGAS.

Other findings

- Aircraft that were manufactured prior to the current airworthiness standards, or that have been modified by the installation of turbine engines, may have fuel filler openings that do not meet the dimension requirements.

- The airworthiness standards for rotorcraft do not specify the size of fuel filler openings.

- The use of all of the available restraint systems in the aircraft contributed to the survival of the occupants.

- There was no post-crash fire, likely due to the separation of the battery from the aircraft and to the rain-saturated crash site.

- The absence of a post-impact fire contributed to the survival of all of the aircraft’s occupants.

Safety Actions

Keystone Air Service Ltd: On 16 September 2015, an urgent memo was generated by Keystone Air Service Ltd.’s (Keystone) operations manager and circulated to all Keystone pilots. The memo reiterated the importance of crew supervision of aircraft fuelling and expectation of compliance with Keystone Company Operations Manual section 4.12.6 Supervision of Fuelling.

Transport Canada: In accordance with Transport Canada (TC) policy and procedures, a post-accident program validation inspection was conducted on 21–25 September 2015. The inspection revealed safety concerns that resulted in the suspension of Keystone’s air operator certificate. Subsequently, TC conducted an in-depth review of Keystone ‘s aviation safety record. On 29 December 2015, the Minister of Transport cancelled Keystone’s air operator certificate, citing public interest and the company’s aviation safety record.

TSB make no comment on any actions by the refuelling company.

Past History of Fuelling Accidents

In their report TSB comment:

…FAA AC 20-105B states, “Reciprocating [gasoline] engines that burn Jet A at high power settings suffer detonations, rapid loss of power, and high cylinder head temperatures, quickly followed by complete engine failure.”

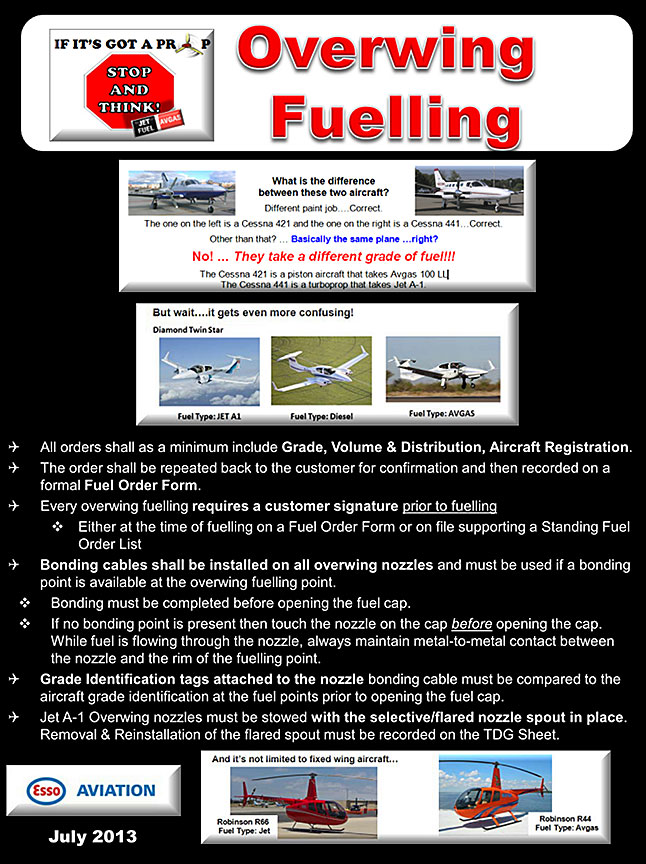

Following a series of misfuelling events in the 1980s, the aviation industry took initiatives to prevent further occurrences. Some aircraft manufacturers issued service bulletins, and made kits available, to reduce the size of fuel filler openings on aircraft that required AVGAS. The FAA and TC subsequently issued airworthiness directives that made the service bulletins mandatory.

As a result, flared spouts that would not fit into the smaller AVGAS filler openings were introduced on fuelling equipment. Fuel suppliers placed additional labelling and placarding on fuelling equipment. [Aircraft Fuel Handling Technician] training programs were introduced, and more detailed operations manuals were developed. FAA AC 20-105B and bulletins issued by some aircraft manufacturers encouraged operators to remove the words “Turbo” and “Turbo-charged” from the cowlings of turbo-charged aircraft.

In 1993, size standards for fuel filler openings were incorporated in Federal Aviation Regulations (FARs) Part 23 Airworthiness Standards: Normal, Utility, Acrobatic and Commuter Category Airplanes. The standards specified that airplanes with engines that require gasoline must have fuel filler openings no larger than 2.36 inches; airplanes with turbine engines must have fuel filler openings no smaller than 2.95 inches; and each fuel filler opening must be marked with the fuel type and minimum grade.

Certain airplanes and rotorcraft powered by turbine engines cannot be fuelled using the Jet-A1 flared spout. Some aircraft manufactured prior to the current standard have fuel filler openings that do not meet the current dimension requirements. Aircraft that have been modified by replacing the reciprocating engine with a turbine engine sometimes retain their original fuel filler openings. The angle and location of the fuel filler openings on some aircraft make the use of the Jet-A1 flared spout impractical. Consequently, many Jet-A1 fuel trucks and stationary fuelling cabinets are equipped with a reduced-diameter spout that can be temporarily installed in place of the Jet-A1 flared spout.

A review of the TSB database revealed [see below] that, since 1980, there have been 21 recorded instances [in Canada] in which jet fuel was delivered to an aircraft instead of AVGAS, 10 of which have occurred since 2000. Of those 21 events, 17 occurred at an aerodrome, 3 were related to refuelling from drums, and 1 occurred at a float-plane dock. These misfuelling events resulted in 8 crashes and 11 forced landings. There was 1 fatality and a number of injuries, some severe. In 2 cases, the misfuelling was detected prior to departure of the aircraft.

| TSB File # | Inv Class | Flown | Fixed-wing | Rotary-wing | |

|---|---|---|---|---|---|

| A80Q0056 | Nil | Britten-Norman Islander | YES | X | |

| A83O4077 | Nil | Piper PA-31 | YES | X | |

| A88Q0058 | C5 | Piper PA-28 | YES | X | |

| A92W0078 | C5 | Rockwell Aero Commander 685 | NO | X | |

| A93O0287 | C5 | Canadair CL215 | NO | X | |

| A97A0131 | 5 | Piper PA-31 | YES | X | |

| A97A0132 | 5 | Hughes 269C | YES | X | |

| A97C0140 | 5 | Beech 60 Duke | YES | X | |

| A98C0114 | 5 | Piper PA-31-350 | YES | X | |

| A98O0292 | 5 | Schweizer 269C (300C) | YES | X | |

| A99F0064 | 5 | Piper PA-31 | YES | X | |

| A00O0181 | 5 | Cessna 414 | YES | X | |

| A02P0089 | 5 | Piper PA23-250 | YES | X | |

| A05P0063 | 5 | De Havilland DHC-2 | YES | X | |

| A07Q0230 | 5 | Piper PA-31 | YES | X | |

| A07W0228 | 5 | Piper PA-31-350 | YES | X | |

| A10C0123 | 3 | Rockwell Aero Commander 500S | YES | X | |

| A11Q0036 | 3 | 3 Robinson R44 IIs | YES | X | |

| A15F0029 | 5 | Piper PA-46-350P | YES | X | |

| A15C0134 | 3 | Piper PA-31-350 | YES | X | |

| A16Q0059 | 5 | Piper PA-31 | YES | X |

2) PA46 22 February 2015 Washington

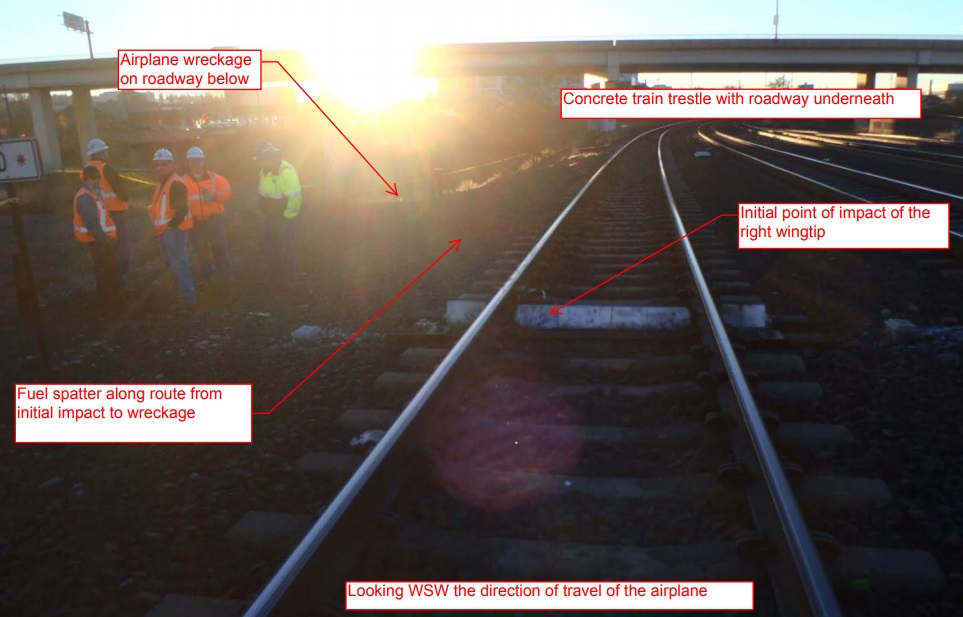

The US National Transportation Safety Board (NTSB) is investigating a 22 February 2015 fatal accident involving single engined Piper PA46-350P Malibu Mirage C-GVZW in Spokane, Washington state. The aircraft was destroyed and the pilot killed, during the attempted emergency landing when it struck a railroad track.

UPDATE 6 September 2017: In their report the NTSB say:

The pilot was conducting a cross-country flight from Canada to California and had landed to clear customs into the United States and to refuel his airplane.

During the initial climb after takeoff, the engine experienced a total loss of power, and the pilot attempted to make an off-airport forced landing. The right wing struck railroad tracks at the top of a hill, and the airplane continued down an embankment, where it came to rest adjacent to the bottom of a railroad bridge.

Postaccident interviews revealed that, when requesting fuel from the fixed-base operator (FBO), the pilot did not specify a grade of fuel to be used to service the airplane. The refueler mistakenly identified the airplane as requiring Jet A fuel, even though the fuel filler ports were placarded “AVGAS (aviation gasoline) ONLY.”

The fueler subsequently fueled the airplane with Jet A instead of aviation gasoline. Additionally, the fueling nozzle installed on the fuel truck at the time of the refueling was not the proper type of nozzle. Jet A and AvGas fueling nozzles are different designs in order to prevent fueling an airplane with the wrong type of fuel.

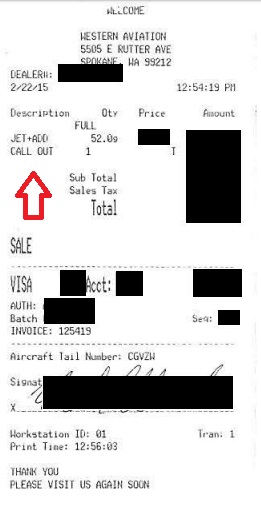

Following the fueling, the pilot returned to the FBO and signed a receipt, which indicated that the airplane had been serviced with Jet A.

However it is not in itself a strong indicator (red arrow added).

There were no witnesses to the pilot’s preflight activities, and it is unknown if the pilot visually inspected or obtained a fuel sample before takeoff; however, had the pilot done this, it would have been apparent that the airplane had been improperly fueled.

The NTSB determined the probable cause as:

A total loss of engine power due to the refueler’s incorrect refueling of the airplane.

Contributing to the accident was the fixed-base operator’s improper fueling nozzle, which facilitated the use of an incorrect fuel, and the pilot’s inadequate preflight inspection

3) C421 27 August 2014 New Mexico

The NTSB is also investigating a 27 August 2014 fatal accident involving twin engined Elite Medical Transport / Amigos Aviation Cessna 421C Golden Eagle N51RX at Las Cruces (LRU), New Mexico when it impacted the ground shortly after takeoff. All four people on board the air ambulance flight died.

UPDATE 3 May 2017: According to the NTSB:

The airplane arrived LRU about 1834 to pickup a patient for a flight to PHX.

According to the line service technician who worked for the fixed-base operator (FBO), before taking off for the air ambulance flight with two medical crewmembers and one patient onboard, the pilot verbally asked him to add 40 gallons of fuel to the airplane, but the pilot did not specify the type of fuel. The line service technician drove a fuel truck to the front of the airplane and added 20 gallons of fuel to each of the multiengine airplane’s wing tanks. The pilot was present during the refueling and helped the line service technician replace both fuel caps.

Shortly after takeoff, a medical crewmember called the company medical dispatcher and reported that they were returning to the airport because smoke was coming from the right engine.

The aircraft subsequently impacted the ground.

A postimpact fire immediately ensued and consumed most of the airplane. Investigators who arrived at the scene the day following the accident reported clearly detecting the smell of jet fuel.

The airplane, which was equipped with two reciprocating engines, should have been serviced with aviation gasoline, and this was noted on labels near the fuel filler ports, which stated “AVGAS ONLY.”

It was the joint responsibility of the line technician and pilot to ensure that the airplane was filled with aviation fuel instead of jet fuel and their failure to do so led to the detonation in the engine and the subsequent loss of power during initial climb.

In accordance with voluntary industry standards, the FBO’s jet fuel truck should have been equipped with an oversized fuel nozzle; instead, it was equipped with a smaller diameter nozzle, which allowed the nozzle to be inserted into the smaller fuel filler ports on airplanes that used aviation gasoline. The FBO’s use of a small nozzle allowed it to be inserted in the accident airplane’s filler port and for jet fuel to be inadvertently added to the airplane.

The NTSB determined the probable cause as:

The misfueling of the airplane with jet fuel instead of the required aviation fuel, and the resultant detonation and a total loss of engine power during initial climb.

Contributing to the accident were the line service technician’s inadvertent misfueling of the airplane, the pilot’s inadequate supervision of the fuel servicing, and the fixed-base operator’s use of a small fuel nozzle on its jet fuel truck.

Other Guidance

Total have issued a useful guide on avoiding errors in fuelling. It includes a number of deliberate steps to trap any human errors or misunderstandings consistent with our past article: Professor James Reason’s 12 Principles of Error Management

The NTSB have issued safety alerts on fuelling, one for pilots and the other for refuellers.

Footnote

According to one refuelling company there are globally around 250,000 aircraft refuellings every day (100,000 commercial aircraft and 250.000 GA aircraft). This accident illustrates that the controls, while highly effective, can be breached, especially if there is a degree of confirmation bias.

UPDATE 12 October 2019: Plane filled with wrong fuel before crash that killed Tampa plastic surgeon, says NTSB (Piper PA-60-602P Aerostar, N326CW).

UPDATE 25 June 2020: Japanese Jetstar Boeing 787 GEnx-1B Engine Biocide Serious Incident

UPDATE 19 July 2020: Wrong fuel added before crash of Alaska forestry plane that injured pilot and 3 firefighters, NTSB says. According to the NTSB the fuel truck driver…

…was unfamiliar with the airplane, so he queried the pilot as to where he should attach the grounding strap and the location of the fuel filler port. Before starting to refuel the airplane, he asked the pilot “do you want Prist with your Jet” to which the pilot responded that he did not. After completing the refueling process, he returned to his truck, wrote “Jet A” in the meter readings section of the prepared receipt, and presented it to the pilot for his signature. The pilot signed the receipt and was provided a copy. The fueler stated that he later added “no Prist” to his copy of the receipt.

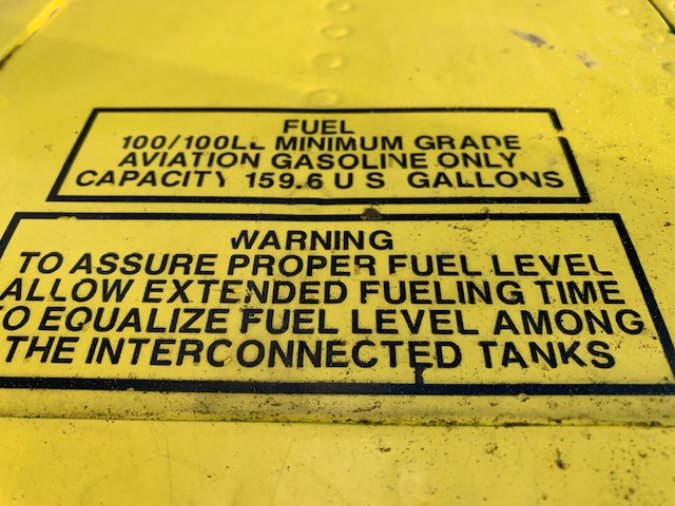

Unfortunately the aircraft, Aero Commander 500S N909AK is powered by piston engines and should have been filled with AVGAS. A slightly degraded placard near the fuel port on the top of the wing stated, in part: “FUEL 100/100LL MINIMUM GRADE AVIATION GASOLINE ONLY CAPACITY 159.6 US GALLONS”.

All four occupants were injured when it ditched in a flood gravel pit shortly after take off.

- UPDATE 15 November 2025: AS350 HESLO Fuel Incident (Superabsorbent Polymer Contamination)

Recent Comments