Loose Engine B-Nut Triggers Fatal Forced Landing

On 26 September 2017 Hughes (later MD) 369D SE-JVI was being used for power line inspection on behalf of energy company Vattenfall, by the First European Aviation Company when it suffered a sudden power loss and impact with the ground that killed one occupant

History of the Accident Flight

The Swedish Accident Investigation Authority, the SHK report that:

The helicopter was equipped with a system to measure, photograph and present the status of the power line network and the surrounding terrain by means of advance data processing. The system allows for flying at a higher altitude and greater speed than in traditional power line inspection, where the operator carries out an optical inspection while flying close to the power line at low speed.

The systems operator held a CPL-H and rather unusually (for a civil aircraft) was regarded as the aircraft commander and was acting as Pilot Monitoring.

Shortly after take-off from Älvsbyn/Högheden Airport [shortly after refuelling after the first sector of the day], at a height of about 80 metres above the ground and a speed of 67 knots, they started to rapidly lose both altitude and speed. Twelve seconds later, the helicopter collided with the ground at the side of a grass field behind a building and near the edge of a forest.

The helicopter sustained substantial damage, but no fire broke out.

The systems operator was killed and the pilot was seriously injured.

Examination of the accident site showed that the helicopter “had a descent angle of approximately 70 degrees, close to zero forward speed and very low rpm in the main rotor and tail rotor, combined with an exceptionally large coning angle of the rotor disk at some point during the sequence”.

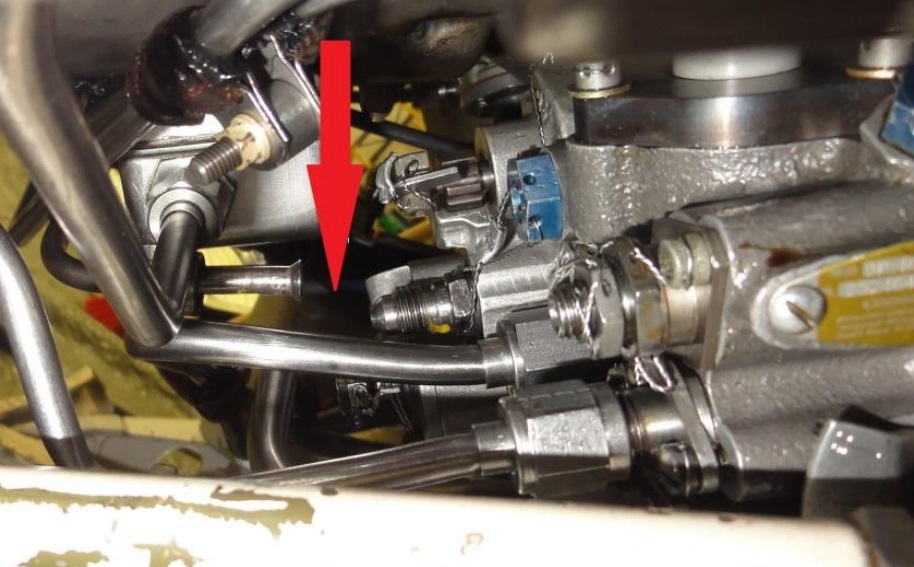

These findings indicated that the engine stopped supplying power during the flight. The technical investigation showed that a [B-nut] fitting to the gas generator fuel control unit had come loose during the flight….

The relatively low speed and altitude, in combination with a heavily loaded helicopter, meant a briefer autorotation than those practised during training. The Pilot Flying also had just 67 hours on type (though the system operator had 698 hours on type).

For this reason, the crew did not reach the landing site without utilising the available rotor rpm at an early stage, which lead to a hard collision with the ground.

The high vertical speed of some 2000–2400 feet per minute (10–12 m/s) and low or zero forward speed at the time of the collision means that the helicopter was subjected to forces which exceeded what it was designed [for].

Also of note:

…it took 1 hour and 40 minutes before the crashed helicopter was located by the rescue services and medical resources arrived at the scene, despite the helicopter’s ELT starting to transmit at the time of the accident.

Investigation

Examining the Rolls-Royce 250 engine:

…it was discovered that the pipe that supplies reference pressure (the ‘reference pipe’) from the engine compressor to the free turbine regulator and the fuel control unit had come loose from its fitting.

The threads of the pipe nut and the fitting were intact, which indicates that these had come apart prior to impact. The investigation noted that another pipe nut in the same pipe system was also loose, but it had not been completely dislodged.

The last known maintenance on the fuel control unit, when the connection unit (Filter Assembly) was fitted, was carried out on 29 September 2015 according to the identification plate on the fuel control unit. The safety wire on the connection unit was sealed with the marking H S P. The last known maintenance carried out that had an impact on the pipe nut that dislodged from the fitting was a replacement of the free turbine regulator on 18 July 2017.

During the engine investigation, it was established that another pipe nut in the same piping system had an inadequate tightening torque.

The SHK comment that:

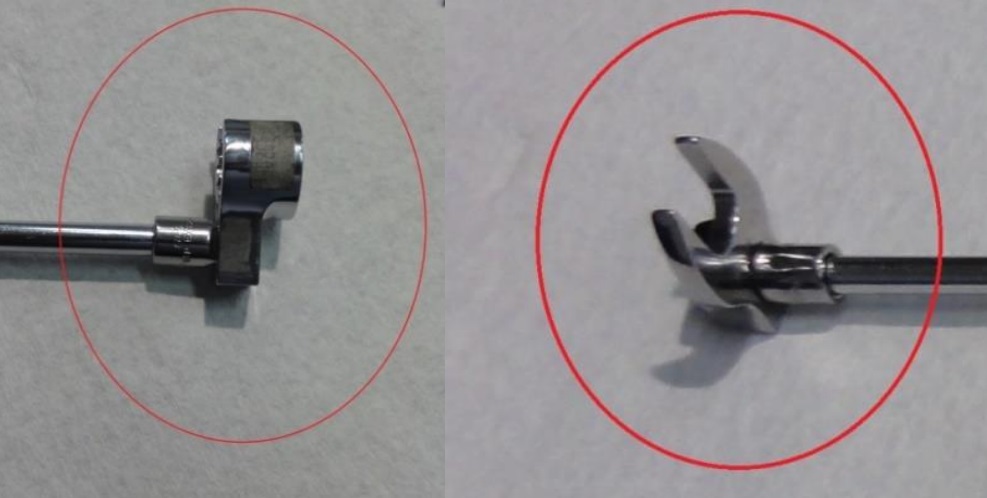

When torqueing a pipe nut, the torque wrench needs to have either an open-end or a flare-end extension. The centre of rotation for both of these adapters is offset in relation to the centre line of the torque wrench.

When working with an offset torque measuring point, the torque needs to be configured, taking into account the length of the offset as well as the point where the force impacts on the torque wrench.

At the time of SHK’s visit, the operator maintenance organisation had access to both types of adapters. However, the open-end adapter can cause an unwanted movement of the tool, meaning that the torque wrench extension is not parallel to the pipe and the nut, which in turn can lead to an incorrect torque. If the torqueing is carried out in a narrow space, there is also the risk of the adapter not turning freely, which results in the torque wrench indicating the achievement of a set torque before this is actually the case.

The SHK note there is an EASA Airworthiness Directive (AD2004-0009) for repetitive inspections of these fitting severy 100 hours. There are a total of 31 pipe nuts to be checked at each inspection.

Safety Recommendations

Five safety recommendations were made:

- The FAA is recommended to: Evaluate whether the construction of the Rolls-Royce engine RR 250-C20 and other models using the same type of B-nut, without any other safety measures than the tightening torque and the prescribed nut checks, provides sufficiently secure protection against engine failure in single-engine configurations. (RL 2018:08 R1)

- The FAA is recommended to: Investigate whether there is a need to inform concerned sections of the industry that there may be deviating fittings (Filter Assembly) in circulation in international flight operations. (RL 2018:08 R2)

- EASA is recommended to: Evaluate whether the construction of the Rolls-Royce engine RR 250-C20 and other models using the same type of B-nut without any other safety measures than the tightening torque and the prescribed nut checks in accordance with EASA AD 2004-0009R3, provides sufficiently secure protection against engine failure in single-engine configurations. (RL 2018:08 R3)

- The Swedish Maritime Administration is recommended to: Review their procedures for how classification of emergency broadcasts on international emergency frequencies is applied. (RL 2018:08 R4)

- The Swedish Maritime Administration is recommended to: Evaluate and, if needed, develop their procedures to ensure a sufficiently quick dispatch of flying rescue units that are equipped, trained and have practised for search missions, including homing of emergency locator transmitters. (RL 2018:08 R5)

Safety Resources

Aerossurance has also previously written these pertinent articles:

- Professor James Reason’s 12 Principles of Error Management

- Loose B-Nut: Accident During EC130B4 Maintenance Check Flight

- B-Nuts were also involved in a $62.4mn fire on a USAF RC-135V Rivet Joint reconnaissance aircraft on 30 April 2015. We discuss that accident in our article: USAF RC-135V Rivet Joint Oxygen Fire

- Fatal H500 / 369D Low Altitude Hover Power Loss: Power Line Maintenance Project

- Tree Top Autorotation for B206L1 After Loose Fuel Line B-Nut Leaks

- AS350B2 Accident After Vibration from Unrecorded Maintenance

- UPDATE 13 July 2019: Helicopter Wirestrike During Powerline Inspection

- UPDATE 16 September 2019: Fatal Snowy Powerline Inspection Flight

- UPDATE 2 January 2020: EC130B4 Destroyed After Ice Ingestion – Engine Intake Left Uncovered

- UPDATE 21 February 2020: Fatal MD600 Collision With Powerline During Construction

- UPDATE 13 September 2020: Hawaiian Air Tour EC130T2 Hard Landing after Power Loss (Part 1)

- UPDATE 18 October 2020: Hawaiian Air Tour EC130T2 Hard Landing after Power Loss (Part 2 – Survivability)

- UPDATE 3 July 2021: EC130 Door Loss Damaged Main Rotor Blades

- UPDATE 7 August 2021: Prompt Emergency Landing Saves Powerline Survey Crew After MGB Pinion Failure

- UPDATE 13 November 2021: Bell 407 Rolls-Royce 250-C47B Uncontained Engine Failure after Bearing Failure

In 2012 the FAA Safety Team (FAASTeam) published a notice on B-Nuts:

No matter how simple this component is, it requires a specific “torque” to keep it reliable in maintaining plumbing system integrity. You may have seen a maintenance record entry where the sign-off stated, “Tightened B nut.” Does this mean it was tightened enough to stop a leak, or was it tightened to a specific torque? If you are just tightening the “B” nut, you could be setting the stage for future failure or fracture.

Just get the tools you need to get it done right!

Another “gotcha” is finger tightening then “forgetting” to torque the “B” nut. A high risk of this occurring can be distractions (like telephone calls) and interruptions (like multi-tasking) while on the job.

A good technique to follow is if you connect a “B” nut, finish the job with the proper torque. Otherwise, tag it or write it up so it is not overlooked, especially if you leave the job site or another AMT finishes the job!

According to the Rolls-Royce 250-C30 Series Operation and Maintenance Manual for example:

Proper tightening of engine tubing connections is critical to flight safety…Tubing B-nuts used in installations exposed to a high degree of vibration and pressure surges are subject to torque relaxation when improperly tightened…Old slippage marks (torque paint) shall be completely removed, using torque paint remover, and reapplied each time the B-nut is tightened.

Aerossurance has extensive air safety, operations, airworthiness, human factors, aviation regulation and safety analysis experience. For practical aviation advice you can trust, contact us at: enquiries@aerossurance.com

Follow us on LinkedIn and on Twitter @Aerossurance for our latest updates.

Recent Comments