Eclipse 500 Landing Gear Production Defect

On 11 June 2015, Eclipse Aviation (now part of ONE Aviation) EA500 N508JA, operated by Memly Aviation, experienced left main landing gear (MLG) collapse while taxiing for departure at Sacramento Executive Airport, California. The three persons onboard were uninjured but there was substantial damage to the left wing. The left MLG trunnion (TSN 1,275 hours and CSN 1,492 cycles) had broken near the rear attachment point and the MLG had penetrated through the wing.

The US National Transportation Safety Board (NTSB) explain in their safety investigation report that:

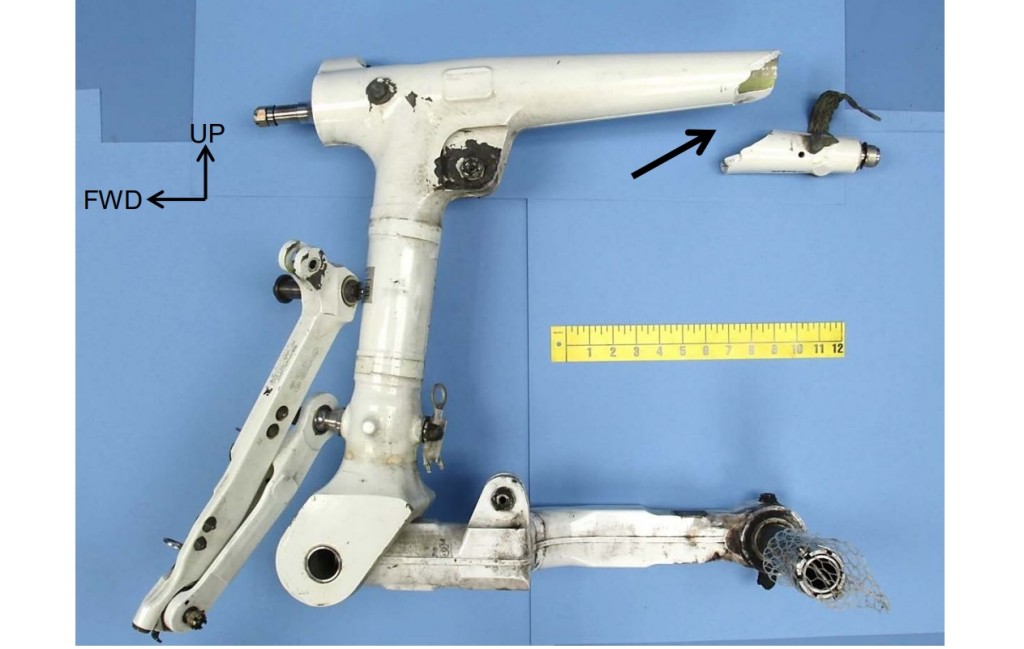

Visual examination revealed that the landing gear fractured at the trunnion portion of the landing gear.

Eclipse Aviation EA500 N508JA Failed MLG: Note the trailing arm design and side brace, with the fracture at the rear of the trunnion (Credit: NTSB)

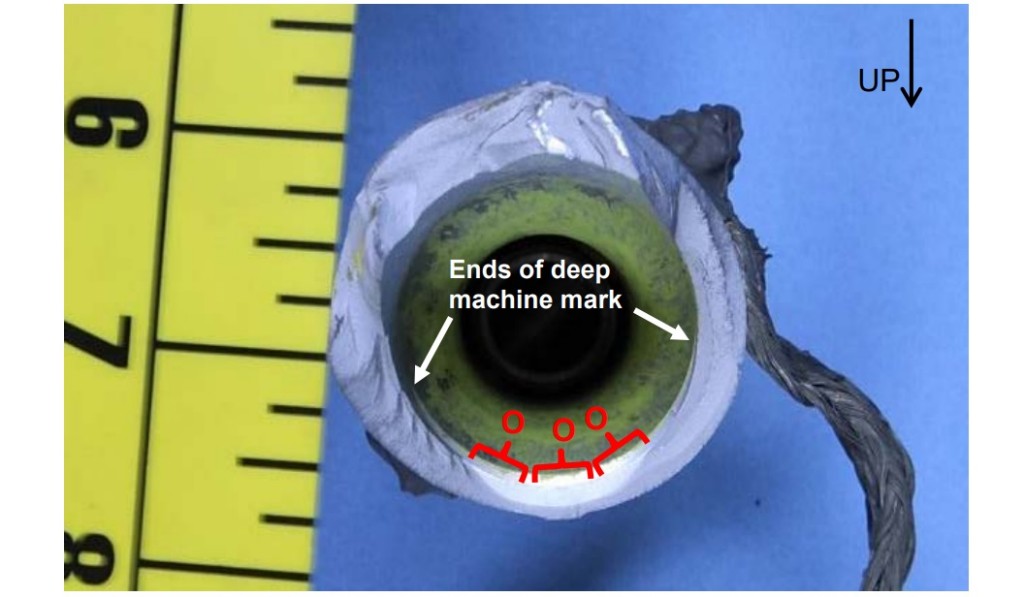

The smaller separated piece showed a fatigue crack that emanated from the inner wall. The crack itself was from a machining mark.

Eclipse Aviation EA500 N508JA Failed MLG: View looking at the aft fracture face showing a fatigue crack that emanated from multiple origins, in areas indicated by bracket “O”, at a machining mark on the inner upper surface. (Credit: NTSB)

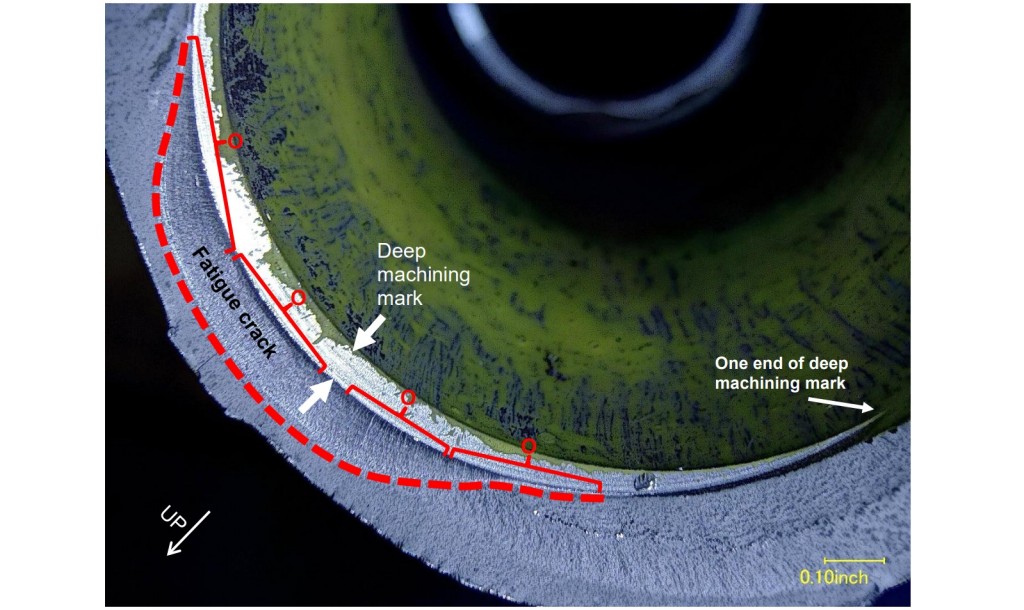

Eclipse Aviation EA500 N508JA MLG: View looking down at the aft fracture face of the trunnion showing a fatigue crack that emanated from multiple origins at a machining mark on the inner upper surface. The fatigue crack emanated from deep machining mark and terminated in the area indicated by dashed line. Origin of fatigue cracks are indicated by brackets “O”. (Credit: NTSB)

The area outside of the fracture face contained rough features consistent with an overstress separation. The deep machining mark was in a portion of the trunnion where the inner wall tapered inward, and was in a transition region where the wall thickness was increasing in thickness. The assembly contained a metal squeeze-out typical of forging/casting parts. The excess metal squeezed-out of the forged/casting products are moved by machining, which renders them a high stress area.

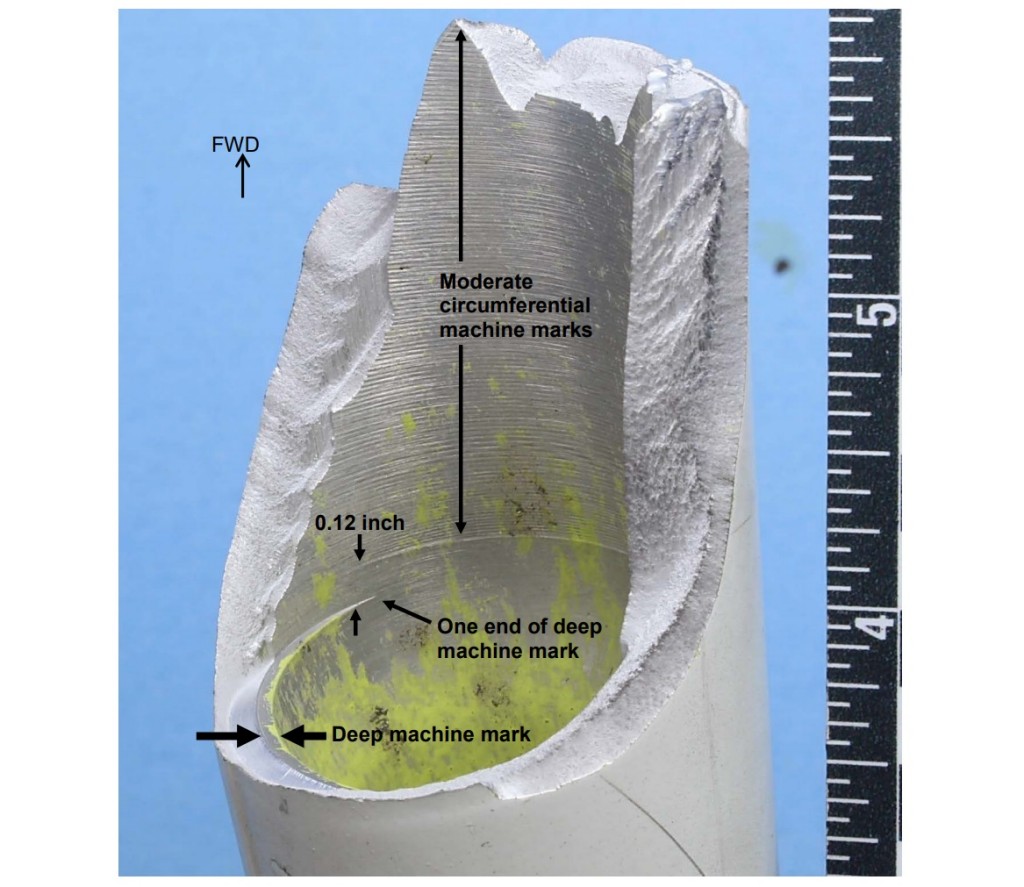

Eclipse Aviation EA500 N508JA MLG: Side view of the trunnion showing the aft fracture face. The fatigue crack emanated from multiple origins at a deep machining mark on the inner upper surface (Credit: NTSB)

According to the manufacturer, the initiation of the fatigue crack from a step machined inner wall of the trunnion was outside of the design requirements. Eclipse Aerospace, and the landing gear manufacturer, Mecaer Aviation Group, inspected for the presence of the machined steps.

The manufacturer indicated that they had a systemic manufacturing defect that potentially effected the entire fleet of EA500 aircraft. Eclipse Aerospace and Mecaer, issued a mandatory [sic] Service Bulletin to address the issue.

Mecaer also communicated with the machine shop responsible for the defect and process changes were put in place to prevent the issue…

Other Safety Resources

- Production Errors on a SAR Helicopter Full Ice Protection System

- Machining Defect Cause of V2500 Failure

- Micro FOD: Cessna 208B Grand Caravan Engine Failure & Forced Landing

- Metro 23 MLG Corrosion Causes Runway Excursion

- UPDATE 18 November 2020: Embraer ERJ-190 EWIS Production Quality a Factor in Fire

- UPDATE 17 September 2022: Canadian B212 Crash: A Defective Production Process

Recent Comments