Bell 429 Tail Rotor Pitch Change Link Spherical Bearing Failure

On 21 August 2015, a privately operated Bell 429, N429AR, experienced an in-flight tail rotor pitch change link (PCL) failure and subsequently landed safely in Port O’Connor, Texas.

The Accident Flight

The US National Transportation Safety Board (NTSB) report that during cruise the pilot:

…felt a “slight vibration” and heard a “very faint bumping sound.” A flight control check revealed no anomalies, and the pilot continued the flight to the destination heliport.

While in a 4-ft hover, just before touching down, the helicopter began a slow, uncommanded right turn. The pilot applied full left anti-torque pedal, and the turn stopped. He then lowered the collective and landed without incident.

Examination of the Helicopter

The NTSB say in their report (and associated specialist report):

A post-flight inspection of the helicopter revealed that one of the tail rotor outboard pitch change links (PCL) was broken.

The tail rotor PCL assembly comprises a single-piece forged aluminum body with two circular ends (also known as the “banjo end”), each containing a spherical bearing (also known as a “mono-ball bearing”). One end of the tail rotor PCL is attached to the pitch change crosshead; the other PCL end is attached to its respective tail rotor blade pitch change horn. A total of four PCLs are installed on the four-bladed tail rotor of the Bell Helicopter 429: two short-length PCLs, identified as “inboard” PCLs, and two long-length PCLs, identified as the “outboard” PCLs, are used to accommodate the stacked rotor blade configuration.

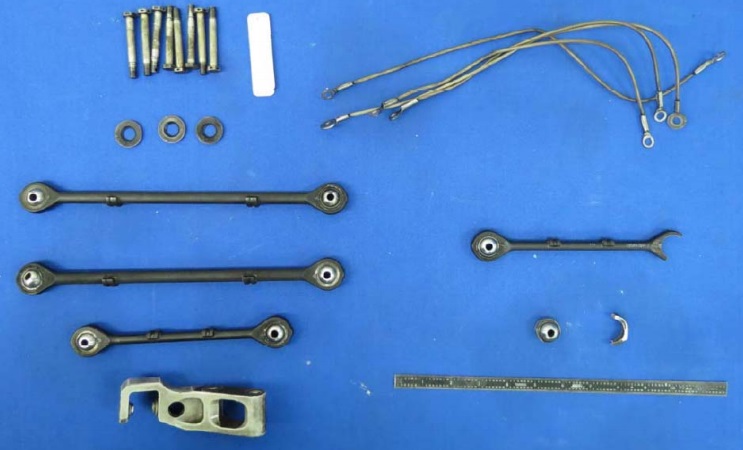

While no further damage was sustained to any helicopter components, the fractured tail rotor PCL had an adverse effect on the helicopter’s flight characteristics and required replacement, meeting the definition of substantial damage. The four tail rotor PCLs, the pitch horn associated with the fractured PCL, grounding cables, and attaching hardware were submitted by the operator for further examination.

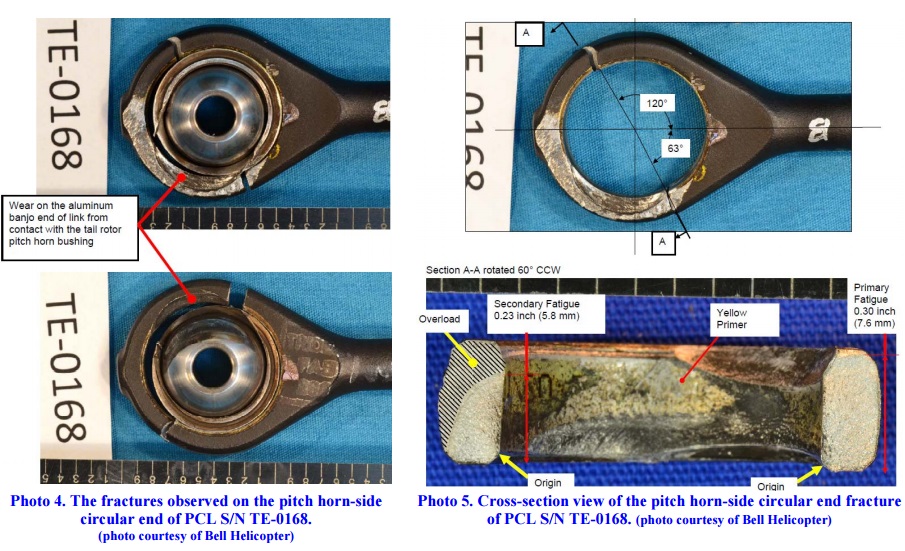

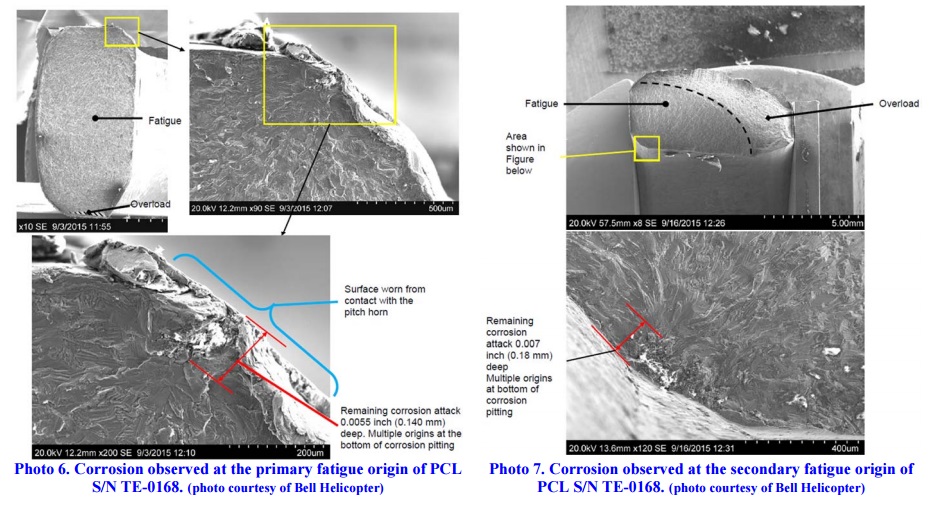

An examination of the failed PCL revealed fatigue fractures due to pitting corrosion between the spherical bearing and the bearing housing.

The fatigue fractures propagated during operation until the PCL bearing housing fractured, separating the PCL from the blade pitch horn end spherical bearing, resulting in a loss of pitch control to the affected blade.

Removal of the crosshead end spherical bearing revealed evidence of corrosion and fretting on the inner diameter surfaces of the [crosshead] circular end.

The Maintenance History

Maintenance records showed the fractured PCL was installed on the helicopter on February 6, 2015, at an aircraft total time of 1,062.9 hours. The helicopter had 1,241.9 hours total time at the time of the accident. The tail rotor PCLs had a total airtime of 179 hours…

The PCL was installed on the helicopter 12 days before the manufacturer issued an alert service bulletin (ASB) introducing a 50-hour recurrent inspection of the tail rotor PCLs for axial and radial bearing play.

Bell Helicopter ASB 429-15-16, issued on 18 February 2015 stated that:

Bell Helicopter has received reports of tail rotor pitch link assemblies 429-012-112- 101/-103 with bearings 429-312-107-103 worn beyond the published limits and bearing liner failures.

The inspection was estimated to take just 2 man hours and replacement of any degraded bearings about 3 man hours, with new bearings provided under warranty. The inspection was to be accomplished every 50 flying hours with a closing action at 200 flying hours of replacing the bearing.

Transport Canada (the aviation authority of the state of design of the B429) finally issued an Emergency Airworthiness Directive EAD CF-2015-16 on 2 July 2015 stating: “An undetected worn bearing could lead to pitch link failure, resulting in loss of controllability of the helicopter.”

The Federal Aviation Administration (FAA) only issued FAA EAD 2015-16-51 on 9 August 2015, almost 6 months after the ASB. The owner unwisely did not act on the ASB prior to the FAA EAD making accomplishment mandatory.

The tail rotor PCLs on the accident helicopter were inspected in accordance with the ASB and the EAD 9 days after the EAD was issued.

The PCL failed 6.6 flight hours after the inspection. The EAD did not require an inspection of the bearing housing portion of the PCL for corrosion, and it could not be determined if the fatigue cracks were present when the inspection was performed.

Safety Action

Following the accident, the manufacturer updated the original ASB to include inspections for bearing cracks, corrosion, and anti-corrosion sealant. The FAA also updated the airworthiness directive to reflect the additional inspections.

NTSB Probable Cause

The fatigue failure of the tail rotor pitch change link spherical bearing housing as a result of corrosion pitting.

Safety Resources

We have previously written about:

- Airbus Helicopters AS365N3 Tail Rotor Pitch Control Loss During Hoisting

- Sikorsky S-92A Loss of Tail Rotor Control Events

- UPDATE 9 May 2020: Ungreased Japanese AS332L Tail Rotor Fatally Failed

- UPDATE 13 November 2021: Bell 407 Rolls-Royce 250-C47B Uncontained Engine Failure after Bearing Failure

- UPDATE 8 January 2022: Fiery Fatal AW119 Accident in Russia After Loss of Tail Rotor Control

Both of these relate to the failure of double roller bearings of pitch change rods.

Aerossurance has extensive air safety, operations, airworthiness, human factors, aviation regulation and safety analysis experience. For practical aviation advice you can trust, contact us at: enquiries@aerossurance.com

Follow us on LinkedIn and on Twitter @Aerossurance for our latest updates.

Recent Comments