Mind the Handrail! – Walk-to-Work Helideck Hazard

A recent offshore helicopter incident has highlighted a new hazard as offshore industry practices change.

A medium helicopter carried a team to a Normally Unattended Installation (NUI). After an uneventful landing, the disembarking team noticed that the folding handrail for the access steps behind the helicopter was in the up position. It was just 300mm from the tail rotor. A pitch angle of nine degrees during the landing would have been sufficient for a tail rotor strike.

When a NUI is temporarily manned the Helicopter Landing Officer (HLO) must ensure these hand rails are folded down when an aircraft in on approach. When de-manning the NUI, the HLO will fold the handrail in use down as the passenger embark.

So what went wrong when the last helicopter departed?

Nothing!

On investigation the last visit to the installation had been by a walk-to-work (or W2W) vessel, where workers transfer by stabilised gantry (VIDEO).

The investigation found there was no helideck inspection as part of the W2W NUI de-manning checks.

To prevent a reoccurrence Installation, Maintenance and Safety Managers need to ensure that NUI down-manning procedures include verification that the helideck is being left in a safe condition.

The helicopter crew did not see the relatively small erect handrail. The UK Civil Aviation Authority (CAA) Standards for Offshore Helicopter Landing Areas (CAP437) says:

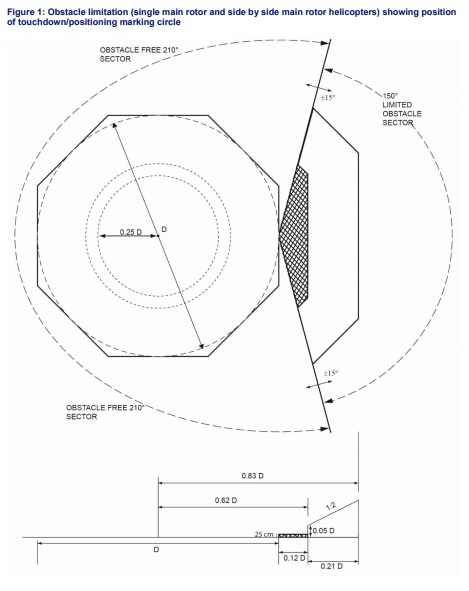

Where handrails associated with helideck access/escape points exceed the height limitations given at paragraph 3.23 [shown graphically in an illustration below] they should be retractable, collapsible or removable. When retracted, collapsed or removed the rails should not impede access/egress or lead to gaps which could result in a potential fall from height. Handrails which are retractable, collapsible and removable should be painted in a contrasting colour scheme. Procedures should be in place to retract, collapse or remove them prior to helicopter arrival. Once the helicopter has landed, and the crew have indicated that passenger movement may commence…, the handrails may be raised and locked in position. The handrails should be retracted, collapsed or removed again prior to the helicopter taking off.

The handrail in question appears to have been marked with faded yellow and blacks stripes, which may have been difficult to see against their background with adjacent black and dark coloured structure.

There are high contrast GRP handrail options available:

CAP437 chapter 3 paragraph 3.23 defines the clearance, based on the D value, required on a helideck as shown below:

Note: More detailed information on this incident was shared in a safety alert by an industry association Aerossurance is a member of.

Other Helideck Safety Resources

- Helideck Safety Alerts: Refuelling Hoses and Obstructions

- NTSB Recommendations on Offshore Gas Venting

- Passive Fire-Retarding Helideck Designs

- US BSEE Helideck A-NPR / Bell 430 Tail Strike

- Troublesome Tiedowns

- Helideck and Helicopter Egress Training Facilities

- Wrong Deck Landings

- FOD and an AS350B3 Accident Landing on a Yacht in Bergen

- UPDATE 16 April 2022: Helideck Heave Ho!

Aerossurance regularly assists oil and gas companies and vessel operators review and update their helideck procedures and adverse weather policies, examine helideck structural integrity issues and provide independent assurance of helideck readiness.

Aerossurance is pleased to be supporting the annual Chartered Institute of Ergonomics & Human Factors’ (CIEHF) Human Factors in Aviation Safety Conference for the third year running. We will be presenting for the second year running too. This year the conference takes place 13 to 14 November 2017 at the Hilton London Gatwick Airport, UK with the theme: How do we improve human performance in today’s aviation business?

Recent Comments