S-92A Emergency Landing: MGB Oil Checklist Recommendation

Earlier this month the Norwegian Accident Investigation Board (AIBN) issued their report into an emergency landing of Sikorsky S-92A LN-ONW, operated by Bristow Norway on 4 October 2013. The crew almost ditched due to false warnings created by a single tripped circuit breaker.

The Incident

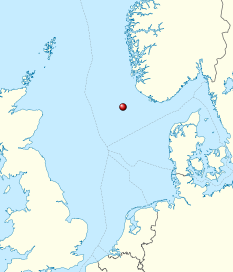

The S-92A was returning from the BP Valhall offshore installation in the North Sea to Stavanger Sola airport, after abandoning landing on the Valhall due to poor weather.

En route to Sola, the crew received MGB PUMP 1 FAIL and MGB PUMP 2 FAIL yellow cautions. According to the AIBN:

…the oil pressure had decreased from a normal value of approx. 58 psi to 49, while oil temperature was rising. This was considered a confirmation that something had happened to the main gear box. However, the emergency checklists did not provide an answer to what had happened, or what action to take. In retrospect, the commander has described this as highly frustrating.

The AIBN report that:

The crew considered that it was too risky to continue toward land, and chose to make an emergency landing at the decommissioned [production platform] Yme.

…the crew became aware of three additional yellow cautions for MGB OIL HOT, MGB OIL PRES and MGB MAN COOL. These cautions did not provide any further information to understand the situation.

The possibility that there could be a critical failure in the main gear box, also made the crew consider a possible emergency landing at sea before the helicopter reached Yme.

Wind and wave height were estimated at 40 kt and 7 to 8 m respectively [wave height being beyond the helicopter’s ditching certification].

As long as no red warning lights showed up, and oil pressure indicated above the 47 psi minimum requirement, they decided to continue towards Yme. Accordingly, they interpreted the situation as “Land as soon as possible” and not “Land immediately”.

The crew seriously considered landing on the hatch covers of a passing ship, but due to the sea state decided to continue to the Yme. The crew noted two obstructions on the closed helideck, and were surprised to find these were two 3.5m tall marine transponders.

However the crew were able to make a safe landing in the confined space.

When the helicopter landed, the first officer read that the oil temperature on the main gear box was 152 °C. There was no damages during the emergency landing. The crew and passengers were later picked up by a rescue helicopter and flown ashore.

The Safety Investigation

The next day, technicians were flown to Yme in order do trouble shooting. Early it became clear that the indications received by the crew could be related to the tripping of the M XMSN OIL WARN circuit breaker. This was confirmed. After a temperature switch (Main Transmission High Temperature Switch, P/N 92351-15808-101) was replaced, and the helicopter had been thoroughly checked by running the engine while on the ground, the helicopter was flown to Sola on Sunday 6 October.

The AIBN Comment:

The investigation showed that several of the cautions the crew received were false, and were caused by a minor fault in the indication system. The crew became seriously concerned about the indications. Despite uncertainty that arose, the crew handled the situation in a good manner and made operational decisions that reduced the risk of an potential accident occurring.

The Accident Investigation Board Norway is of the opinion that the lubrication system for the main gear box on the S-92A is very complex and that the associated emergency checklists are both insufficient and complicated. As a result, the emergency checklists may be difficult to use in a stressful emergency.

A minor fault caused a circuit breaker to trip. Several other faults in the warning and monitoring system could also have caused the circuit breaker to trip.

The Accident Investigation Board is of the opinion that Sikorsky should have predicted and described this in the emergency checklist.

It can be challenging to describe a complicated system in an orderly fashion in an emergency checklist.

The Accident Investigation Board believes that Sikorsky has not succeeded in the work on making it user-friendly while also being sufficiently exhaustive.

The emergency checklist, as at October 2013, contained a series of provisos, often in combination with the expression “and/or”. This can be difficult to understand even when the checklist is read in a calm and quiet environment.

The Accident Investigation Board also believes that the checklist is not faithful to the sectioning Indications, Confirm and ACTIONS because there are five symptoms at the end of the ACTIONS section. Another example is that the MGB OIL OUT warning is mentioned a total of six times in the checklists. Five of these mentions relate to a positive indication, whereas the latter relates to the warning not being on (not illuminated). The emergency checklist also contains an entire page devoted to supplementary information in the form of Cautions and Notes which could increase the stress of the person attempting to understand the situation.

The AIBN commend the crew:

They made operative decisions that reduced the risk of an accident and they kept the air traffic control up-to-date insofar as possible.

Another indication of the vital need for prompt exchange of safety information is illustrated by the AIBN too:

On 28 August 2013, there was an incident in the Gulf of Mexico that was similar to the incident with LN-ONW. An S-92A with serial number 920015 and registration N392PH received the same five yellow cautions on the MFD because circuit breaker M XMSN OIL WARN had tripped. Sikorsky had not yet alerted other operators of S-92A regarding this when the incident with LN-ONW took place. However, knowledge concerning the incident with N392PH helped Sikorsky to give Bristow Norway good guidance during the trouble shooting and work on understanding what happened to LN-ONW.

The Safety Recommendation – SL No. 2015/11T

The Accident Investigation Board is of the opinion that the emergency checklist for the main gearbox on the S-92A was complicated and difficult to understand, particularly in a stressful emergency situation. This view is supported by the operating company Bristow Norway AS.

After this incident, Sikorsky has revised the relevant parts of the emergency checklist, and started a redesign process to improve the warning/caution system on the main gearbox.

The Accident Investigation Board Norway is however of the opinion that further improvements is needed, and therefore recommends that Sikorsky revise the emergency checklist with the aim of further simplification and increased user-friendliness.

Additionally the operator was proactive with their internal investigation. The AIBN report:

In accordance with its own routines, Bristow Norway AS commenced an internal investigation of the incident. Among other things, the report published on 26 November 2013 contained four safety recommendations. One of these related to a dialogue with Sikorsky with regard to improving the main gearbox’s oil system. The remaining three related to information and training own personnel in order to be better prepared to handle similar situations.

Observations

This incident shows:

- The criticality of a single circuit breaker which almost resulted in a ditching in a hazardous sea state

- The importance of clear and comprehensible check lists

- The importance of communicating about safety occurrences

S-92A MGB Background

The S-92A MGB has been controversial. As the AIBN report:

In 2002, Sikorsky carried out a test of the main gear box, where the oil was drained… A catastrophic failure occurred after 11 minutes. Accordingly, the requirement for 30 minutes’ safe operation was not met. With reference to AC 29-2C, Sikorsky decided to install a bypass valve in the external oil cooler circuit. By closing the valve, any external oil leaks could be stopped. It was considered extremely remote that other leaks in the oil system could prevent a safe landing within 30 minutes. This was accepted by the certification authority, the Federal Aviation Administration (FAA).

In service two leaks occurred outside of the oil cooler, destroying the myth that such failures were extremely remote. One was the S-92A fatal accident offshore Canada in 2009 in which 17 people died, although miraculously one passenger survived. This has triggered both further work on helicopter ditching but also on transmission loss of lubrication rule making.

See also: Helicopter MGB oil system failure analysis using influence diagrams and random failure probabilities

UPDATE 13 June 2016: As a reminder that consulting the MGB emergency procedures is not rare, a CHC Helikopter Service S-92A was forced to make an emergency landing on an installation in the Norwegian sector on 10 June 2016.

The aircraft departed from a drilling rig operated by Total and made the unscheduled landing 26.7 miles away, on BP’s Ula platform, with 16 people on board….

“A CHC operated Sikorsky S92 helicopter departing at 0921 from the drilling rig Maersk Gallant to Stavanger/Sola got alarm indicating low oil pressure in the gearbox shortly after takeoff”, Total Norge said…“the helicopter requested prioritised landing on the Ula platform operated by BP, as a precautionary unplanned landing in accordance with procedures for such alarms.

Now we know that his “false alarm” had to do with technical/electronic error. Such alarms can occur from time to time and need to be handled as real alarms”.

UPDATE 31 May 2017: NPA 2017-07 Rotorcraft gearbox loss of lubrication is issued for consultation (until 31 July 2017) which includes:.

… CS 29.1521 has also been amended to include an additional power plant limitation that describes how the RFM emergency procedures should reflect the test evidence relating to a loss of lubrication.

UPDATE 28 June 2018: The outcome of NPA 2017-07 entered Part-29 Amendment 5.

UPDATE 27 April 2020: Sikorsky Signs Cougar for S-92A+ Helicopter Upgrades, with an order for four upgrade kits which Sikosrky The company anticipate will be delivered in: 2023

The kit features the new Phase IV main gearbox that uses a supplemental oil pump and additional oil lines to reuse main gearbox oil that is accumulated in a lower sump in the event of primary lubrication failure on the helicopter twin.

In their A+ brochure Sikosrky say the “Phase IV Main Gear Box – Eliminates Lubrication “Land Immediately” Hazards”.

…the new gearbox fits into the existing space for the legacy component and provides for increased time between overhaul interval of up to 25 percent. Though the new gearbox is heavier than then the original one, it is offset with weight savings elsewhere on the aircraft.

The upgrade can be fitted to existing helicopters as part of the current 1,500-hour inspection and is just one of several menu items that can be selected for the A+ twin. Other options include an increased gross weight kit to 27,700 pounds and uprated engines, GE Aviation CT7-8A6s, that offer better payload capability and hot-and-high performance. The new engine, which was certified in June 2019, allows customers to operate with both full seats and full fuel under most conditions.

UPDATE 29 September 2020: The Norwegian Safety Investigation Authority (NSIA) announce the start of an investigation into a serious incident to Bristow S-92A LN-ONQ SW of Stavanger Airport on 25 September 2020.

During descent from 7 000 ft. towards 1 000 ft….the crew received a caution that the oil pressure on the main gearbox had dropped below 45 psi. Shortly afterwards, the caution “INPUT / ACC # 1 HOT” came on. According to the emergency checklist, the crew pulled the left engine back to idle. When the oil pressure dropped further to below 35 psi, the oil cooler was automatically switched off. During the further flight towards Sola, the oil temperature rose and the caution “INPUT / ACC # 2 HOT” came on. The highest recorded oil temperature before landing was 214 degrees C. The crew declared mayday, and continued the descent to a height of 200 ft. They were preparing to land on the sea if the oil pressure were to disappear completely. The landing at Sola was undramatic…

Among their early observations were that:

There was some oil spill on the left engine and the left side of the main gearbox. Oil was observed on the outside of the helicopter, especially on the left side of the fuselage. The oil appeared to come from the left engine input to the main gearbox area. There were no signs of leakage in the oil cooler or its hose connections. Approximately 4 liters..of oil was lacking from main gearbox. The indicator that warns of a high pressure difference across the oil filter had come out.

UPDATE 23 September 2022: Report on Aviation incident offshore by Ekofisk Lima in the North Sea on 25 September 2021 involving Sikorsky S-92A, LN-ONH operated by Bristow Norway AS:

The helicopter experienced a sudden loss of oil pressure in the main gear box with related aural and visual warnings. The crew turned immediately towards Ekofisk Lima for a short final and landing. The landing was performed without problems and no persons were injured.

The investigation has found that the loss of oil pressure was due to the Vespel spline adapter driving one of the oil pumps was completely worn down.

The Norwegian Safety Investigation Authority sees it as likely that a combination of factors casued the excessive wear of the Vespel spline adapter. A higher service life on the component than logged, natural variation in production and materials of the Vespel spline adapter, and the individual torque load on the pump are all contributing factors.

The loss of oil pressure did not lead to immediate risk of failure of the main gearbox.

Sikorsky has after the incident adjusted the service life of the Vespel spline adapter to prevent reoccurence.

Extra Resources on Checklist Design

The European Helicopter Safety Team (EHEST), part of the European Aviation Safety Agency (EASA) European Strategic Safety Initiative (ESSI) will shortly publish: EHEST Leaflet HE 11 – Training and Testing of Emergency and Abnormal Procedures in Helicopters

A 2006 NASA paper covers: Design Guidance for Emergency and Abnormal Checklists in Aviation

UK CAA has published CAP676 Guidelines for the Design and Presentation of Emergency and Abnormal Checklist, last revised in 2006 (parts of the CAP are out of date due with the coming into force of EASA Air Ops Regulations: see IN-2014/113 for further details).

Aerossurance is pleased to be supporting the annual Chartered Institute of Ergonomics & Human Factors’ (CIEHF) Human Factors in Aviation Safety Conference for the third year running. We will be presenting for the second year running too. This year the conference takes place 13 to 14 November 2017 at the Hilton London Gatwick Airport, UK with the theme: How do we improve human performance in today’s aviation business?

Recent Comments