King Air 200 Smoke and Fumes From Windshield Electrical Fault

Privately owned Beechcraft King Air B200 JA01EP was climbing from FL150 to FL200 en route from Gifu to Takamatsu in Japan on 6 April 2017 when smoke and a burning smell appeared in the cockpit. The whole right windshield inner pane cracked “like a spider’s web”.

The crew declared an emergency and diverted back to Gifu, making a safe landing.

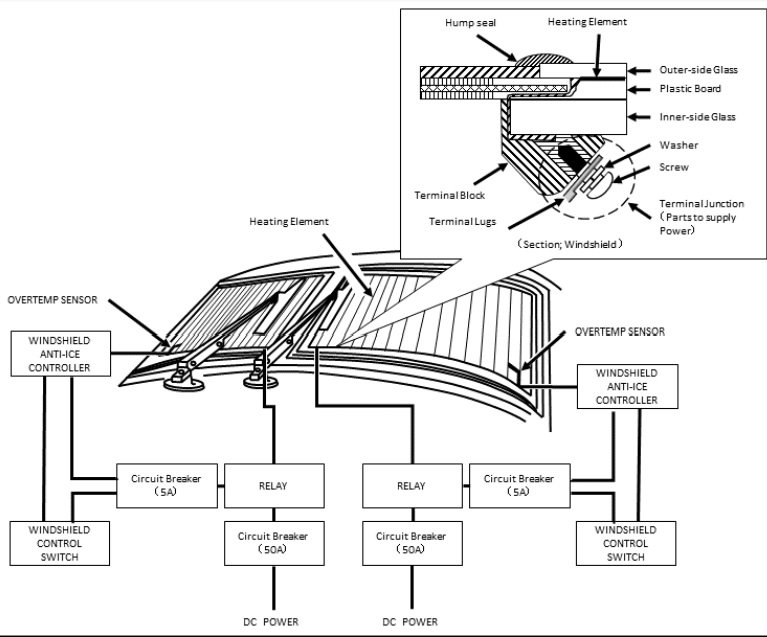

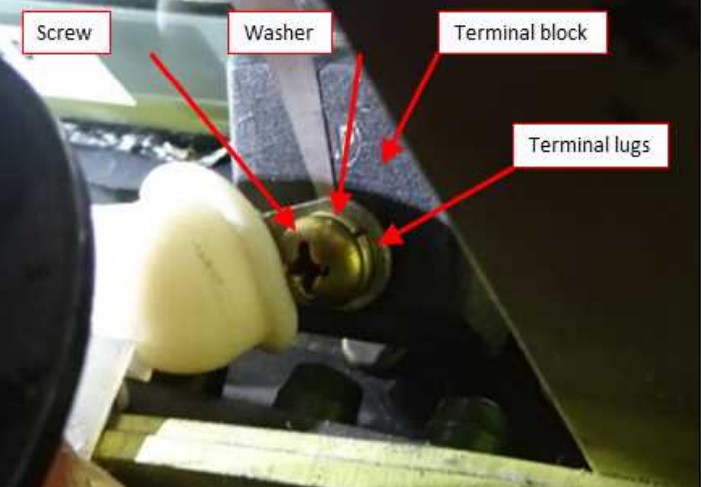

The Japan Transport Safety Board (JTSB) say in their safety investigation report that burn marks were subsequently found at and around the terminal block of the right windshield.

The JTSB say:

[The] right windshield terminal lug was loose and there was gap of 0.05mm between the screws and the terminal lugs.

…it is probable that the smoke was generated by overheating the terminal block and the surrounding parts and components were burned out, because the electrical resistance at the contact points of the terminal block junction was increased, due to the loosened screws of the terminal block.

Due to a previous partial delamination, the windshields had been replaced by a 3rd party maintenance organisation in January 2012.

The JSTB note that:

The description concerning the replacement of windshield in the maintenance manual do not include any reference to tightening torque for screws of terminal block, therefore, the screws were tightened using standard torque value (20 to 25 in-lbs).

While inspections of the windshield are required every 200 flight hours for cracks and sealant deterioration, there is no requirement to check the power connection. As no subsequent problems were reported, no further maintenance had been conducted in this area in the subsequent 5 years

The JTSB concluded that loosening of the screws likely occurred due to the vibration “because the tightening torque of the screws was not sufficient when replacing the windshield”.

Safety Resources

UPDATE 1 October 2020: JTSB have issued their report into a serious incident that occurred on 30 October 2019 to Bombardier CL-600-2C10 (CRJ100) JA11RJ of IBEX Airlines which suffered arcing and a cracked windshield.

- Professor James Reason’s 12 Principles of Error Management

- Back to the Future: Error Management

- Safety Performance Listening and Learning – AEROSPACE March 2017

- Maintenance Human Factors: The Next Generation

- Airworthiness Matters: Next Generation Maintenance Human Factors

Aerossurance worked with the Flight Safety Foundation (FSF) to create a Maintenance Observation Program (MOP) requirement for their contractible BARSOHO offshore helicopter Safety Performance Requirements to help learning about routine maintenance and then to initiate safety improvements:

Aerossurance can provide practice guidance and specialist support to successfully implement a MOP.

Aerossurance is pleased to sponsor the 9th European Society of Air Safety Investigators (ESASI) Regional Seminar in Riga, Latvia 23 and 24 May 2018

Recent Comments