A320 Flown on After Damaging Heavy Landing (Germania D-ASTP)

The Spanish air accident investigators, the CIAIAC (Investigación de accidentes e incidentes de aviación civil), released a preliminary report (in Spanish) on 28 June 2017 on an incident involving Germania Airbus A321-200 D-ASTP on 16 July 2016. The aircraft was performing a flight from Düsseldorf to Fuerteventura, in the Canary Islands.

Germania Airbus A321-211 D-ASTP

The crew commenced a go-around due to the approach becoming unstabilised but still touched down hard with vertical acceleration subsequently determined to have been 3.32 g. After the subsequent landing:

The crew performed an external check on the aircraft without encountering anomalies. The Commander established contact with the [operator’s] maintenance control centre (MOC) in Germany, to request confirmation and support on the on interpretation of the automatic report issued by the aircraft with respect to the hard landing.

Its not clear what response (if any) was received as the CIAIAC go on:

Due to the absence of maintenance support at the Fuerteventura airport and, in the absence of a criterion on the meaning of landing report code ‘Hard’, the crew decided to make the return flight to Dusseldorf.

The aircraft departed with the return passengers aboard 83 minutes after landing. Once in Düsseldorf the aircraft was removed from service for inspection. The left hand Main Landing Gear (MLG) was found damaged and the right hand MLG also needed replacement. The CIAIAC note the first report of an occurrence was only received by them on 30 August 2016, over 2 months after the incident. Data that confirmed the touch down had been at 3.32g was only received in mid November 2016. The CIAIAC say their investigative research is complete and the final report is due ‘shortly’.

UPDATE 22 December 2017: The CIAIAC issue their final report:

The copilot, along with the captain, who had an instructor rating, decided to make the approach with thrust and control in manual. This resulted in a go-around after making contact with the runway. Until that moment, the flight had been uneventful.

During the final approach phase, the approach unstabilized, primarily due to a drop in speed and to the airplane falling too low, and the captain executed a go-around.

CIAIAC says the carrier acknowledged that its Airbus crews were “not well trained” for manual approaches owing to a “routine practice” of using automatic systems.

The aircraft automatically generated and sent, via ACARS, an A15 hard-landing report to the company’s control center and to the manufacturer.

The A15 or LOAD<15> report is generated if

- The normal acceleration is greater than 2.6 g at touchdown. If the aircraft weight exceeds the maximum landing gross weight, the normal acceleration is reduced to 1.7 g.

- The rate of descent on the radio altimeter is greater than 9 ft/sec at touchdown. If the aircraft weight exceeds the maximum landing gross weight, the radio altimeter descent rate is reduced to 6 ft/sec.

- During a bounced landing, the normal acceleration exceeds 2.6 g.

The normal acceleration data is provided by an accelerometer mounted near the aircraft’s centre of gravity, though the sample rate means its possible the peak value may be missed. The investigators go on to say:

Due to its physical effects, the crew realized that they had had a hard landing, and the captain apologized to the passengers and explained to them what had happened as they waited to be disembarked. But the crew did not have any conclusive data on the seriousness and significance of the overload sustained by the aircraft, so the incorrect decision was made to make the return flight with passengers. …the crew did not know how to find the A15 hard landing report in the airplane, and…the detailed exterior inspection of the airplane on the ground yielded no findings. The operator did not have maintenance support in Fuerteventura, and…consulting with the Maintenance Operations Center at the operator’s main base, did not provide any assistance to the crew.

Hence:

…the interpretation of the data in the A15 report was delayed. As a result, the suitability of the airplane to remain in service could not be evaluated in time, and the less safe, though most economic, decision was made to make the return flight with passengers.

They state:

The serious incident was caused by the performance of an unstabilized final approach, resulting from a decrease in airspeed and falling below the glide slope, as well as from the late decision to execute a go-around. Contributing to the incident is the fact that the maneuver was performed without automatic systems to control the airplane’s attitude/flight path or thrust. The decision made after the event to continue to operate the airplane with passengers was risky and unsafe, and resulted from an incorrect assessment of the seriousness of the hard landing.

They recommend that Germania “improve the aptitude of its MOC personnel to ensure they provide correct support so that safe decisions are made in every aerodrome at all hours of operation”.

UPDATE 11 January 2018: In contrast, and providing further context, the UK Air Accidents Investigation Branch (AAIB) report on another heavy landing with far better diagnosis involving Easyjet A319 G-EZAW at Munich Airport, 3 July 2017:

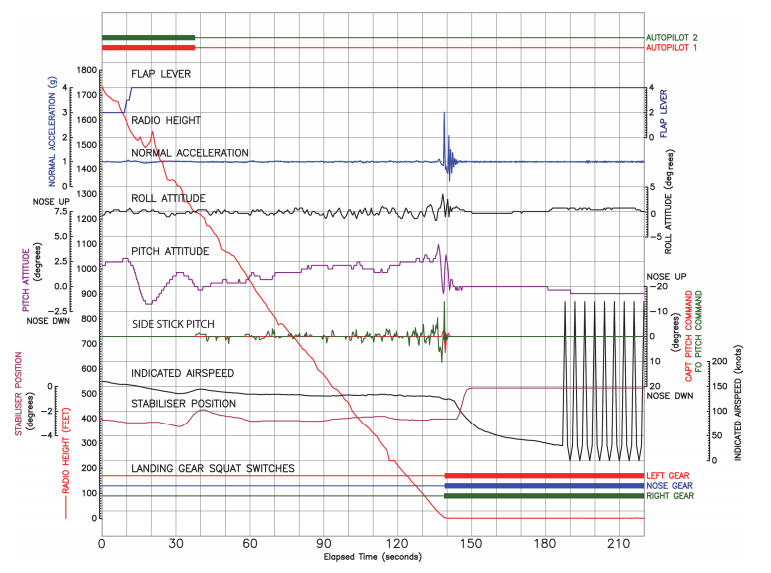

The aircraft was established on an ILS approach [but] at about 1,500 ft aal, the commander’s Flight Management Guidance Computer (FMGC)1 failed. The crew were unable to alter the target approach speed, and the engines began to spool up un-commanded. The pilot flying disconnected the autopilot and autothrust and the rest of the approach was flown manually.

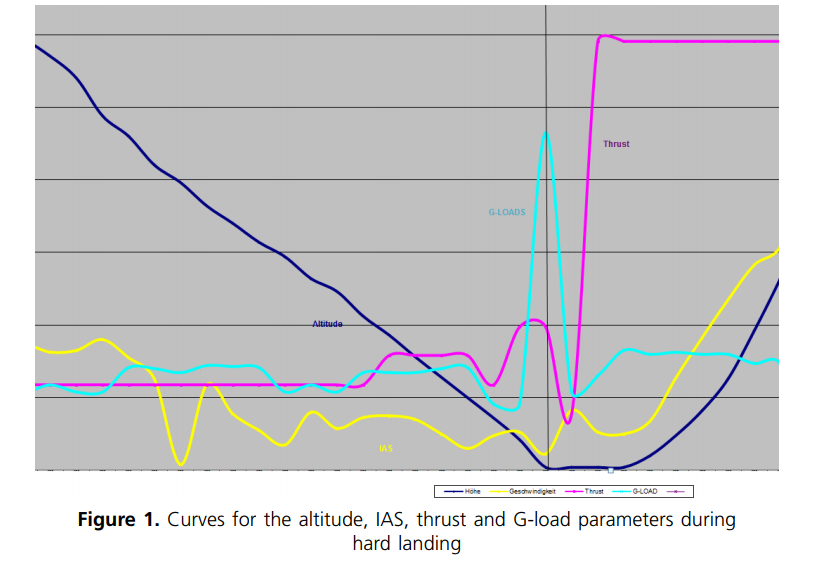

Below 50 ft the pitch attitude of the aircraft was reduced slightly just before the aircraft was flared for landing, and it touched down heavily in a relatively flat attitude. The normal acceleration recorded at touchdown was 3.01 g [and 11.9 ft/sec], which is classified as a Severe Hard Landing.

This was a slightly lower g landing than the Germania case but:

The aircraft was inspected for a Severe Hard Landing as required by the manufacturer’s Aircraft Maintenance Manual. This inspection revealed damage to the nose landing gear and the right main landing gear as well as some cracking of the paint and sealant in the nose gear bay and avionics bay.

The landing gear was sent to an overhaul shop for inspection which…

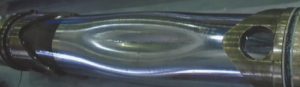

…revealed that both the nose landing gear and the right main landing gear had suffered excessive loads during the landing and could not be returned to a serviceable condition. The nose landing gear shock-absorber cylinder was found buckled (below) with the barrel and forestay lower arm pin found to be out of tolerance.

Easyjet A319 G-EZAW nose landing gear (NLG) shock absorber cylinder after heavy landing at Munich (Credit: AAIB)

The right main landing gear sliding tube and shock-absorber were also found to be outside acceptable tolerances when measured.

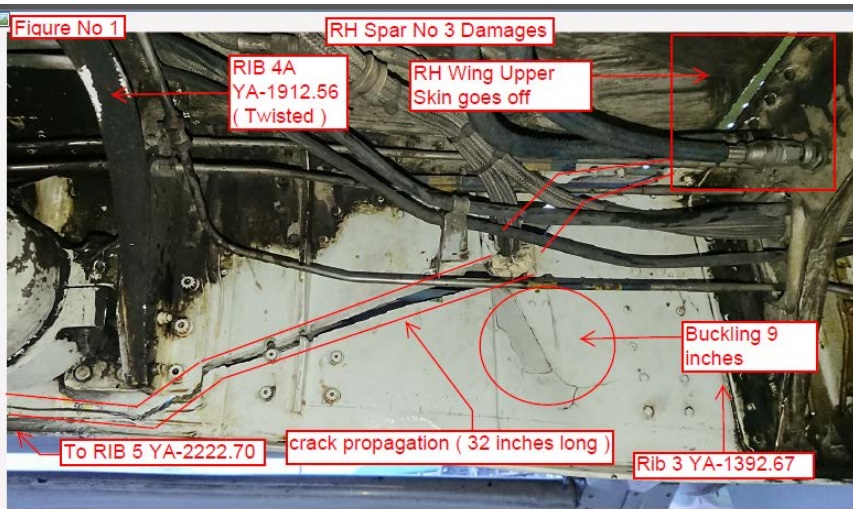

UPDATE 14 April 2018: Air Mandalay Embraer ERJ-145 XY-ALE was damaged after a heavy landing during an unstabilised approach on 18 Sept 2017. the First Officer did a walkaround but did not spot the damage so the aircraft flew 2 more sectors before an engineer found the damage, according to the Aircraft Accident Investigation Bureau (AAIB) of Myanmar report.

Air Mandalay Embraer ERJ-145 XY-ALE No 3 Wing Spar Damage (Credit: Aircraft Accident Investigation Bureau of Myanmar)

UPDATE 2 May 2018: Flight Data Services discuss the analysis of hard landing FDM data.

UPDATE 11 July 2018: The TSB of Canada has released their report on the hard landing during wind shear of Jazz Aviation Bombardier Dash 8 Q400 C-GYJZ on 9 November 2017 which substantially damaged the aircraft and generated enough load to trigger the CVR/FDR crash switch. They report that the flight crew were unsure if this 5.7g touchdown was a hard landing or not. Rather than wait for maintenance personnel to travel to the airport the pilots therefore conducted a visual inspection of the aircraft and finding nothing abnormal, decided to operate the return flight, landing uneventfully back in Montreal. Subsequent maintenance inspection found:

…buckling of the skin below the windows on the right fuselage [and] the right main landing gear during the second touchdown exceeded its ultimate design criteria, which resulted in failure of the orifice support tube during the in-stroke. Once the orifice support tube failed, shock strut damping was effectively lost, thereby generating significant bottoming loads.

TSB comment:

Neither the aircraft manufacturer nor Jazz provide the flight crew with a definition of a hard landing or criteria to determine what a hard landing is. Pilots are expected to rely on their personal experience to make such a determination. In some cases, operational pressures may influence this assessment.

The operator’s safety actions reported were:

- providing additional training on how to recognize hard landings,

- strengthening and clarifying procedures and guidance associated with suspected or actual hard landings,

- adding a warning within flight crew guidance to inform crews of the risk of a hard landing if a landing is continued following a bounce with the power levers at flight idle or disc, and

- conducting a review of flight data analysis practices and effectiveness as they relate to preventing a departure when the aircraft’s airworthiness is concerned.

UPDATE 7 July 2019: Gripen Main Landing Gear Damaged During Unstabalised Short Field Landing

UPDATE 11 August 2019: Severe Propeller Vibrations on ATR 72-212A: BEA Report: A vibratory phenomena that was not uncovered in certification testing and in one case resulted in a failure that did not get detected initially by maintenance inspections.

UPDATE 30 December 2019: White Air ATR-72-212A CS-DJG, operating for TAP Portugal, landed at Fez on 6 July 2018 after an unstabalised approach according to Portuguese accident investigators (the Gabinete de Prevenção e Investigação de Acidentes com Aeronaves [GPIAA]) but struck its tail onto the runway, touching down hard (+2.88G). The aircraft sustained abrasion damage to the aft fuselage, deformation between frames 35-38, sheared rivets and wear on the tail-skid.

The Aircraft Commander prepared for the return flight by performing a walk-round, carrying out a general inspection, looking for problems on the main landing gear and checking the tail strut (‘pogo stick’) fitted under the bumper when parked. He did not detect any anomalies and the aircraft was flown back to Lisbon before the damage was detected. GPIAA comment on:

….excessive reliance on aircraft acceptance without sharing and discussing with the operator’s technical services [and a] organizational culture with inadequate or nonexistent procedures and individual centered decision-making without effective implementation of the CRM philosophy.

UPDATE 10 August 2020: Boeing 737-800 Engine Nacelle Strike and Continued Operation

Aerossurance is pleased to be supporting the annual Chartered Institute of Ergonomics & Human Factors’ (CIEHF) Human Factors in Aviation Safety Conference for the third year running. We will be presenting for the second year running too. This year the conference takes place 13 to 14 November 2017 at the Hilton London Gatwick Airport, UK with the theme: How do we improve human performance in today’s aviation business?

Recent Comments