Engine Maintenance Introduced FOD that Caused an EC120 Power Loss (N421PB)

On 9 April 2021, a private Airbus EC120B, N421PB, was substantially damaged in heavy landing after a loss of engine power near LeRoy, Kansas.

Private Airbus EC120B N421PB (Credit: Coffey County Sherriff)

The pilot and passenger were were uninjured.

The Accident Flight

The US National Transportation Safety Board (NTSB) reported in their safety investigation report, issued 16 August 2023 that the pilot (a CPT with 561 hours total and 164 in type) stated that:

…while in cruise flight at 2,000 ft, he heard the low rotor speed warning horn but no cockpit caution/warning lights illuminated.

The…engine’s free turbine speed and the main rotor speed were “drooped”, and he reduced collective and moved the cyclic control aft to stabilize the main rotor speed. He was able to maintain main rotor speed with about “70%” collective input as indicated on the first limit indicator (FLI).

The helicopter decelerated from 100 knots to 85 knots while the pilot maintained the helicopter’s altitude. The pilot and the passenger [also a qualified pilot] began looking for suitable fields to land in, but about 2-3 minutes after the initial main rotor low speed warning horn, the horn resumed a sustained tone for the remainder of the flight.

The pilot stated that the main rotor speed continued to decrease as he flew toward an open field for a landing, but he eventually entered an autorotation before reaching the intended field because of the decreasing main rotor speed.

[T]he pilot entered a right turn and made an immediate landing in a residential backyard.

The helicopter had a high descent rate when it touched down. The landing gear skids were deformed outward and the tail boom and fenestron exhibited buckling/crushing consistent with the tailboom impacting the ground.

Private Airbus EC120B N421PB Tailboom / Fenestron Damage (Credit: Airbus Helicopters)

Safety Investigation

Testing confirmed the pilot’s report of the engine being unable to maintain free turbine speed at 100% while under increased loads.

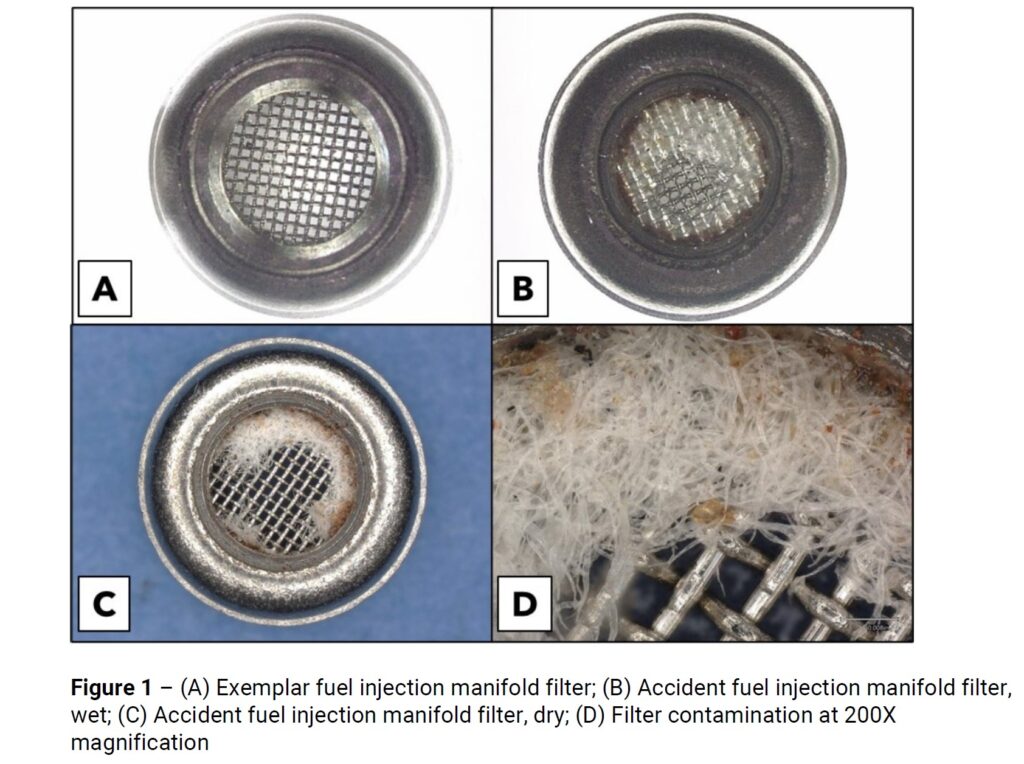

Further examination and testing revealed a contaminated fuel injection manifold fuel filter, which restricted the amount of fuel that could be delivered to the engine’s gas generator. A laboratory examination determined the contamination was consistent with a cellulose material.

Cellulose is found in natural plant fibers. The spectra of known samples of white paper and white cotton were…compared to the unknown sample and exhibited strong matches.

Similar contamination was found in engine’s main fuel filter and fuel control unit (FCU) during disassembly.

NTSB concluded that:

Based on the known information, the cellulose contamination found in the fuel injector manifold filter was likely introduced during associated fuel system maintenance at an undetermined date.

Our Observation

While the contamination source was not determined by NTSB it distinct possibility the cellulose was from some form of cleaning cloth or paper towel. This material is often not controlled with the same rigour as tools. for example, yet can also cause damage an in-flight emergencies.

A similar previous Aerossurance FOD case study was: FOD Damages 737 Flying Controls

Safety Resources

The European Safety Promotion Network Rotorcraft (ESPN-R) has a helicopter safety discussion group on LinkedIn. You may also find these Aerossurance articles of interest:

- Maintenance Human Factors: The Next Generation

- Aircraft Maintenance: Going for Gold?

- Rotor Blade Tool Control FOD Incident

- Maintenance Issues in Fire-Fighting S-61A Accident

- FOD and an AS350B3 Accident Landing on a Yacht in Bergen

- Air Ambulance Helicopter Downed by Fencing FOD

- Tool Bag Takes Out Tail Rotor: Fatal AS350B2 Accident, Tweed, ON

- Loose Clothing Downs Marijuana Survey Helicopter

- Flying Control FOD: Screwdriver Found in C208 Controls

- Lost Tool FODs Propeller Blade, Penetrating Turboprop’s Fuselage

- Dash 8 Q400 Return to Base After Pitot System Contaminated By Unapproved Test Kit Lubricant

- Dash 8 Q400 Control Anomalies: 1 Worn Cable and 1 Mystery

Recent Comments