Maintenance Issues in Fire-Fighting S-61A Accident (Croman, N1043T, Oregon)

On 19 August 2015 fire-fighting Sikorsky S-61A N1043T, operated by Croman Corp, experienced a partial loss of power to the No. 2 engine and subsequently forced landed and rolled over on a mountainside near Ironside, Oregon.

One pilot sustained minor injuries and the other was uninjured.

The Accident Flight

The aircraft was working the Eldorado Fire 8 miles SE of Unity, Oregon. According to the US National Transportation Safety Board (NTSB) safety investigation report (only released 13 April 2020), the crew:

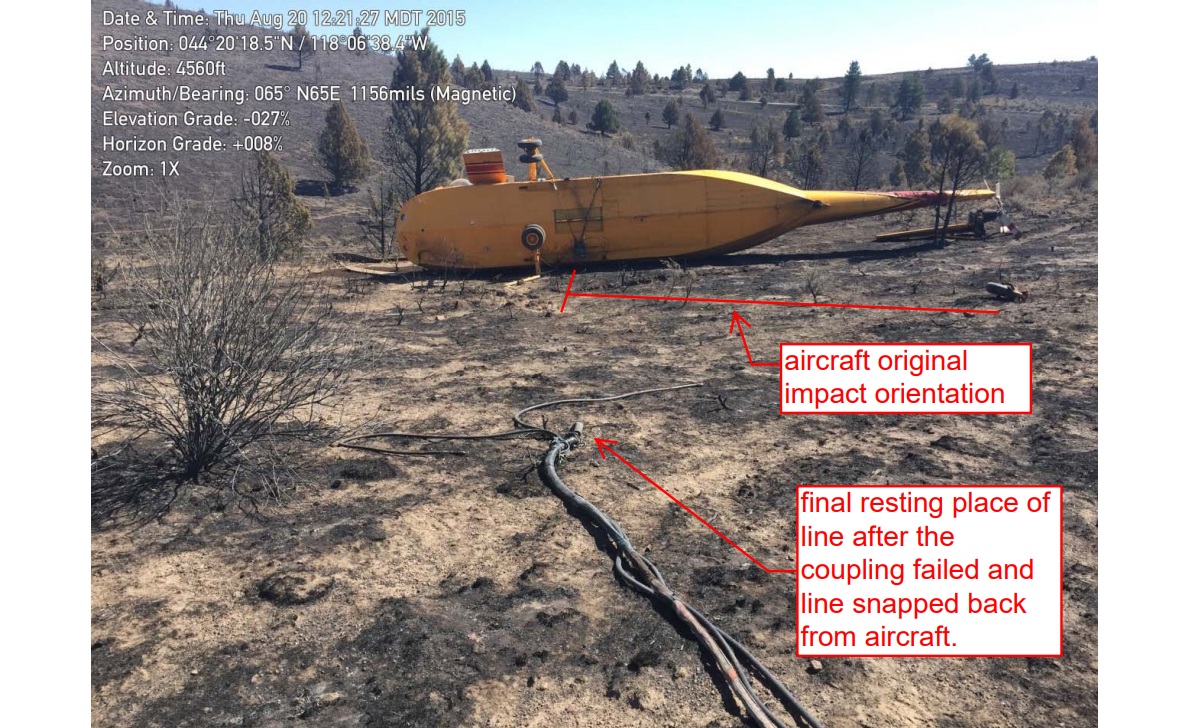

…picked up 4,000 pounds of water from a pond then made a climbing left turn to the east towards the fire. About 20 ft above the ground, there was an engine power loss and a drop in RPM. The pilot dumped the water from the bucket at the end of the longline and attempted to gain airspeed and altitude as they entered a small valley. The pilot was keeping the bucket clear of the ground and obstacles when he attempted to release the longline, but it would not fully release from the helicopter fuselage.

…they continued to lose engine RPM and rotor RPM. With the terrain rising, they found the flattest accessible spot and began to slow the helicopter.

The pilot landed the helicopter as level as possible, however, the helicopter rolled onto its right side. Before touchdown, the longline and bucket had impacted brush and trees and the bucket became entangled in a fence, which likely hindered the pilot’s ability to successfully land the helicopter.

The Safety Investigation

Examination of the longline revealed…

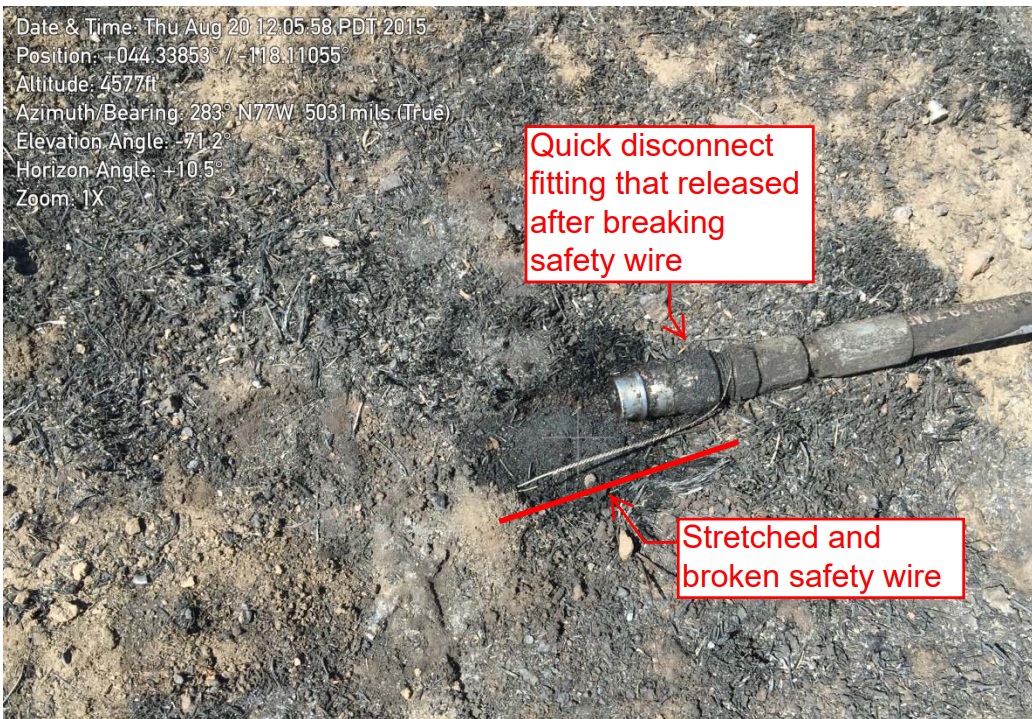

…the fuselage belly hook released the longline as intended; however, one of the two hydraulic quick-disconnect couplings failed to release the longline.

A safety wire was used to connect the fitting on the quick-disconnect mechanism to the coupling. The use of the safety wire did not allow the quick-disconnect mechanism to function as intended and release the longline.

The wire broke on impact with the ground. Examining the failed engine…

…revealed metallic debris on all four magnetic plugs.

Removal of the pinion gear assembly from the accessory gearbox revealed that the pinion gear, which mates with the bevel gear, exhibited wear on the gear teeth and some metal smearing along the tips, which is consistent with gear disengagement. Disassembly of the pinion support assembly revealed roller ball, bearing cage, and race damage to the upper support bearing and wear to the bevel gear teeth consistent with that observed on the mating pinion.

When the bevel and pinion splines disengaged, the fuel and oil pumps were no longer being driven, so fuel and lubrication to the engine were cut and the engine lost power.

Aluminum oxide particles were embedded in the cage pocket and inner races of both bearings and likely contributed to the bearing wear that eventually caused bevel and pinion gear disengagement.

According to the manufacturer, aluminum oxide is not present in any T58-GE-402 bearing or component within the oil lubrication system pathway. Historically, aluminum oxide has been inadvertently introduced into the engine during the engine overhaul/repair process. Aluminum oxide is abrasive and once it is embedded into the bearing it can cause uneven wear and accelerated failure.

The last engine light overhaul was completed about 1 year before the accident, and it is likely that the aluminum oxide was introduced at that time.

NTSB Probable Cause

A loss of power to the No. 2 engine due to the failure of the accessory gearbox drivetrain.

Also causal was the pilot’s inability to release the external longline due to the use of a safety wire across the coupling of the quick-disconnect mechanism, which interfered with his efforts to land.

Contributing to the accident was the repair facility’s failure to maintain a clean environment, which resulted in the inadvertent introduction of a contaminant during the engine overhaul/repair process.

The NTSB unhelpfully do not elaborate on the origin of either maintenance error and any associated lessons.

Safety Resources

- Load Lost Due to Misrigged Under Slung Load Control Cable

- B767 Fire and Uncommanded Evacuation After Lockwire Omitted

- Incomplete Maintenance Leads to Fatal Collective Control Loss on B407

- Micro FOD: Cessna 208B Grand Caravan Engine Failure & Forced Landing

- Coking Causes Power Loss: Australian AS350BA

- USAF Engine Shop in “Disarray” with a “Method of the Madness”: F-16CM Engine Fire

- Dash 8 Q400 Return to Base After Pitot System Contaminated By Unapproved Test Kit Lubricant

- Fatal S-61N Dual Power Loss During Post Maintenance Check Flight

- Misrigged Flying Controls: Fatal Maintenance Check Flight Accident

- Loose B-Nut: Accident During Helicopter Maintenance Check Flight

- Insecure Pitch Link Fatal R44 Accident

- EC135 Main Rotor Actuator Tie-Bar Failure

- S-61N Damaged During Take Off When Swashplate Seized Due to Corrosion

- Maintenance Misdiagnosis Precursor to EC135T2 Tail Rotor Control Failure

- AAR Bell 214ST Accident in Afghanistan in 2012: NTSB Report

- Fire After O-Ring Nipped on Installation

- What Leaks in Vegas Stays in Vegas – A320 Hydraulic Failure

- Poor Painting Prevents Proper Performance: Shorts Sherpa NLG Collapse

- Freewheel Jerk on an SA330J Puma at Sea: Oil Analysis Opportunity

- CRJ-200 Landing Incident Highlighted US Maintenance Competency Inadequacies

- Inadequate Maintenance, An Engine Failure and Mishandling: Crash of a USAF WC-130H

- Crazy’ KC-10 Boom Loss: Informal Maintenance Shift Handovers and Skipped Tasks

- Hoist Assembly Errors: SAR Personnel Dropped Into Sea

- Contaminated Oxygen on ‘Air Force One’

- UPDATE 30 June 2020: 17 Year Old FOD and a TA-4K Ejection

- UPDATE 22 July 2020: NDI Process Failures Preceded B777 PW4077 Engine FBO

- UPDATE 7 September 2020: Shocking Accident: Two Workers Electrocuted During HESLO

- UPDATE 31 October 2020: Loss of Control During HESLO Construction Task: BEA Highlight Wellbeing / Personal Readiness

- UPDATE 27 December 2020: Fire-Fighting AS350 Hydraulics Accident: Dormant Miswiring

- UPDATE 9 January 2021: Korean Kamov Ka-32T Fire-Fighting Water Impact and Underwater Egress Fatal Accident

- UPDATE 16 January 2021: NZ Firefighting AS350 Accident: Weaknesses in Role Equipment Design and Distribution of Key Operating Data

- UPDATE 2 April 2021: Windscreen Rain Refraction: Mountain Mine Site HESLO CFIT

- UPDATE 24 April 2021: Unballasted Sling Stings Speedy Squirrel (HESLO in France)

- UPDATE 21 May 2021: Firefighting AW139 Loss of Control and Tree Impact

- UPDATE 12 June 2021: HESLO Dynamic Rollover in Alaska

- UPDATE 26 June 2021: Engine Life Limit Exceedance Caused Logging Helicopter Fatal Accident

- UPDATE 28 August 2021: Ditching after Blade Strike During HESLO from a Ship

- UPDATE 25 September 2021: Fuel Starvation During Powerline HESLO

- UPDATE 1 January 2022: Snagged Sling Line Pulled into Main Rotor During HESLO Shutdown

See also UK CAA CAP 426 – Helicopter External Load Operations. CASA issued Airworthiness Bulletin 25-006 “to notify operators and maintainers of additional safety information and current design standards for cargo hooks installed in helicopters”. It discusses phenomena such as Dynamic Rollout (or Ring Reversal), Jammed Loads / Hooks, Uncommanded Release / Inadvertent Cargo Hook Opening etc.

We have discussed maintenance human factors and error management more generally here:

- Professor James Reason’s 12 Principles of Error Management

- Back to the Future: Error Management

- Maintenance Human Factors: The Next Generation

- Aircraft Maintenance: Going for Gold?

- Airworthiness Matters: Next Generation Maintenance Human Factors

- Rockets Sleds, Steamships and Human Factors: Murphy’s Law or Holt’s Law?

- B1900D Emergency Landing: Maintenance Standards & Practices

- Also see our review of The Field Guide to Understanding Human Error by Sidney Dekker presented to the Royal Aeronautical Society (RAeS): The Field Guide to Understanding Human Error – A Review

FSF Maintenance Observation Programme (MOP)

Aerossurance worked with the Flight Safety Foundation (FSF) to create a Maintenance Observation Program (MOP) requirement for their contractible BARSOHO offshore helicopter Safety Performance Requirements to help learning about routine maintenance and then to initiate safety improvements:

Aerossurance can provide practice guidance and specialist support to successfully implement a MOP, which fills a gap in maintenance that in operations is filled by FDM and LOSA.

Aerossurance was to have run workshops at the EHA European Rotors VTOL Show and Safety Conference in Cologne in November 2020 on a) Safety Culture and Leadership and b) Contracting Aviation Services: An Introduction to the Basics. Sadly, due to COVID-19 this has been postponed.

Aerossurance has extensive air safety, operations, HESLO, aerial fire-fighting, airworthiness, human factors, aviation regulation and safety analysis experience. For practical aviation advice you can trust, contact us at: enquiries@aerossurance.com

Follow us on LinkedIn and on Twitter @Aerossurance for our latest updates.

Recent Comments