Poor Painting Prevents Proper Performance: Shorts Sherpa NLG Collapse

On 13 October 2016, a Shorts C-23C SD3-60 Sherpa, N148Z, sustained minor damage following a Nose Landing Gear (NLG) collapse on landing, at the Missoula International Airport (MSO), Montana. The aircraft was operated by the US Department of Agriculture (USDA), as a public aircraft in support of the US Forest Service (USFS). The flight was a ferry flight after being re-painted in Kingman, Arizona prior to this ex-US Army 360 Sherpa conversion entering service as a smokejumper drop aircraft.

In their safety investigation report, released in November 2019, the US National Transportation Safety Board (NTSB) say:

The pilots reported that prior to landing, they had an unsafe nose gear indication. After multiple unsuccessful attempts to get the nose gear to extend and indicate that it was down and locked, they decided to come in for a landing. During the landing roll, as the airplane’s nose was lowered, the nose gear collapsed…

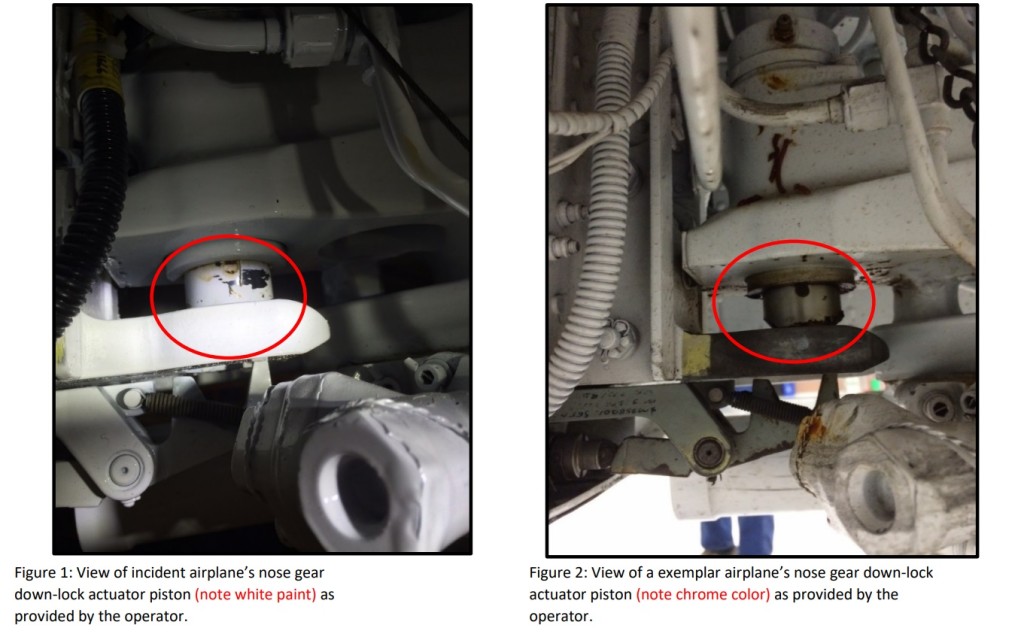

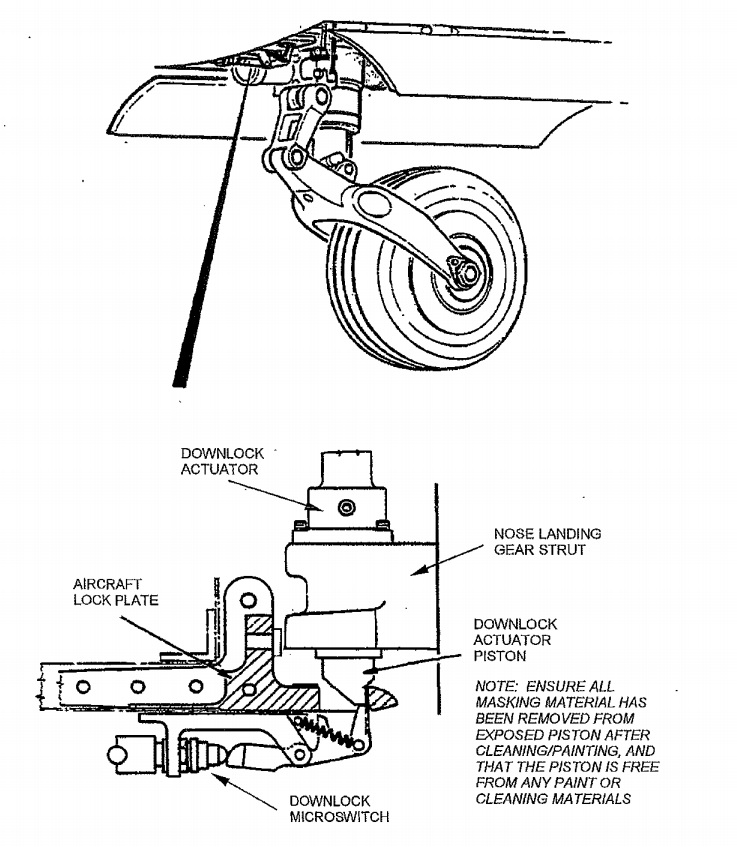

Post incident examination of the nose gear down-lock actuator piston (plunger), revealed that its chrome surface had been painted, which resulted in the locking piston not engaging, and prevented the locking of the nose gear during landing gear extension.

The painting of the nose gear down-lock actuator piston was not observed by maintenance personnel or the flight crew on their pre-flight exterior checks.

Shorts issued a SD3-60 Sherpa Service Information Letter (SIL) Sherpa L-23, in April 2007, titled: Servicing/Painting – Removal of masking material/paint from nose landing gear down-lock actuator piston after cleaning/painting operations. The SIL described a similar incident where the nose gear failed to lock in the down position, on the first flight after the airplane had been re-painted. The subsequent investigation revealed paint spray on the exposed chrome piston of the nose landing gear down-lock actuator. The SIL stated “to ensure that all masking material has been removed from the exposed piston after cleaning/painting, and that the piston is free from any paint or cleaning materials.”

The Maintenance Manual is clear. NTSB don’t provide any further detail on the painting.

NTSB Probable Cause

The failure of the nose landing gear down-lock piston to engage due to paint accumulation, which resulted in a nose landing gear collapse during landing. Also causal was the failure of the facility that performed the painting to comply with manufacturer guidance regarding painting of the airplane.

Safety Resources

Human error is not itself a cause, but merely the start of a human factors investigation, as explained by Sidney Dekker in The Field Guide to Understanding Human Error – A Review (discussed in this book review The Field Guide to Understanding Human Error to the RAeS).

- Maintenance Human Factors: The Next Generation

- Airworthiness Matters: Next Generation Maintenance Human Factors

- Rockets Sleds, Steamships and Human Factors: Murphy’s Law or Holt’s Law?

- B1900D Emergency Landing: Maintenance Standards & Practices

- A Lufthansa MD-11F Nose Wheel Detached after Maintenance Error

- ATR72 VH-FVR Missed Damage: Maintenance Lessons

- B747 Landing Gear Failure Due to Omission of Rig Pin During Maintenance

- When Down Is Up: 747 Actuator Installation Incident

- Lost in Translation: Misrigged Main Landing Gear

- Maintenance Human Factors in Finnish F406 Landing Gear Collapse

- Significant Twin Otter NLG Crack

- UPDATE 28 April 2020: Beech 99A MLG Collapse

- UPDATE 3 June 2020: Beechcraft 1900C Landing Gear Collapse at San Antonio, TX

- UPDATE 16 June 2020: CRJ-200 Landing Incident Highlighted US Maintenance Competency Inadequacies

- UPDATE 28 June 2020: Maintenance Issues in Fire-Fighting S-61A Accident

Aerossurance worked with the Flight Safety Foundation (FSF) to create a Maintenance Observation Program (MOP) requirement for their contractible BARSOHO offshore helicopter Safety Performance Requirements to help learning about routine maintenance and then to initiate safety improvements:

Recent Comments