B747 Landing Gear Failure Due to Omission of Rig Pin During Maintenance

The UK Air Accidents Investigation Branch (AAIB) has issued their report into a serious incident involving British Airways Boeing 747-436 G-CIVX on 30 January 2016.

The Incident Flight

The aircraft was on its first flight after replacement of the Landing Gear Control Module (LGCM), in response to a reported defect, during a scheduled A Check. The AAIB say:

After retracting the landing gear following takeoff from Heathrow, the crew were unable to move the landing gear lever from the ‘UP’ to the ‘OFF’ position, as it had become jammed in the ‘UP’ detent. The crew elected to return to Heathrow and, in accordance with 747 Flight Crew Operations Manual Non-Normal Checklist procedures, the landing gear was lowered using the alternate extension system.

The aircraft landed safely, with only the nose and body landing gear deployed.

The aircraft stopped on Heathrow’s runway 27R, which was unavailable for about an hour until the aircraft was secured and towed off the runway.

The Aircraft Landing Gear Controls

The AAIB explain:

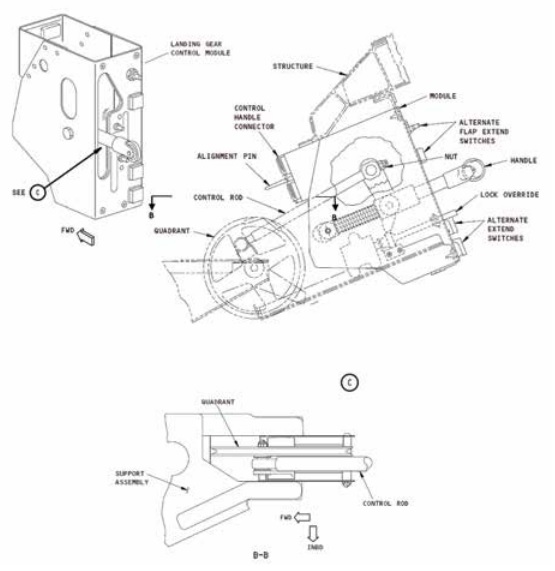

The landing gear…is mechanically commanded and hydraulically actuated. There is a three-position handle in the cockpit with the following spring-loaded detents: DN, OFF and UP. The handle must be pulled outwards against spring pressure to enable it to be moved to another position. The handle is part of the LGCM.

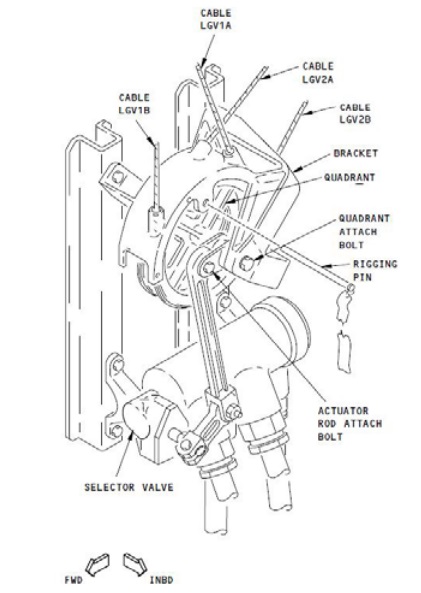

The handle is connected to a control rod, which in turn is connected to a quadrant, and attached to the quadrant is a cable that runs to the wing gear selector valve quadrant located in the right hand body gear wheel well. Another cable runs from the wing gear selector valve quadrant to the nose/body gear selector valve quadrant located in the left‑hand body gear wheel well.

The quadrant in each wheel well is connected to a selector valve by a mechanical lever. When a replacement LGCM is installed, it is a requirement in the Aircraft Maintenance Manual (AMM) to insert a rig pin in the selector valve quadrant.

This video shows typical landing gear functional checks to illustrate how the wing and body gears retract and deploy:

The Prior Maintenance

During the A Check:

The night shift had raised the task cards for the removal and re-rigging of the original LGCM; these cards included the tasks of fitting the rig pin in the selector valve quadrant, function checks and a duplicate inspection. The night shift staff removed and re-rigged the LGCM, but did not have time to compete the function checks, and the task cards were left uncertified.

The re-rigged LGCM failed the function check made by the day shift, and the day shift then fitted a replacement serviceable LGCM. The task cards raised by the day shift staff for replacing the LGCM did not contain a task for the fitment and removal of the rig pins in the selector valve quadrants. The task cards raised by the night shift were used to certify the function checks.

Three day shift engineers were involved in the fitting of the LGCM. They had the relevant sections of the AMM and the applicable Temporary Revision (TR) to the AMM, generated by the operator to provide additional information on the task. The engineers became focused on achieving the correct adjustment and hence were using the TR (which did not specify the need to fit the rig pins).

A consequence of omitting to use the rig pin was the need to use five shims to enable the LGCM to be fitted to the instrument panel; three shims are more typical for a correctly rigged system.

One of the engineers, who was positioned near the quadrant in the right-hand wheel well, noticed that the rig pin was not fitted and that the quadrant was moving (by inputs from another engineer in the cockpit). He was concerned that he might be injured, and took a planned break that was overdue.

It’s not clear in the AAIB report if the engineer had intended to query / report the omission or how long the break was overdue.

Analysis and Conclusions

It was concluded that jamming was due to the rig pin not being inserted during maintenance, which led to “additional and unnecessary shims being used to rig the landing gear lever”.

The operator’s internal investigation identified the following causal factors:

- The distraction of the engineer when he saw the quadrant move, and he took his break

- Deficiencies in the operator’s task card system

- The omission of the need to fit the rig pin in the operator’s TR for this task

- An inadequate handover between the night shift and the day shift

Safety Actions

BA has taken a number of actions according to the AAIB including:

- Updating the TR so that technical management are consulted if more than three rigging shims are used for this task and to include a requirement to fit rig pins and to check that the rig pins can be inserted freely once function checks are completed

- Holding staff briefings to reinforce the requirements to adhere to handover procedures

- Publishing a bulletin to highlight this incident, including the distraction aspect

- Introduction of additional skills training in task card generation.

Other Resources

Aerossurance has previously looked at these associated topics:

- First Eleven: Guidance for Designers on Maintenance Human Performance

- James Reason’s 12 Principles of Error Management

- Back to the Future: Error Management

- Maintenance Human Factors: The Next Generation

- Aircraft Maintenance: Going for Gold?

- Rockets Sleds, Steamships and Human Factors: Murphy’s Law or Holt’s Law?

- Critical Maintenance Tasks: EASA Part-M & -145 Change

- When Down Is Up: 747 Actuator Installation Incident

- UK AAIB: Boeing Safety Responses ‘Not Adequate’

- Misassembled Anti-Torque Pedals Cause EC135 Accident

- EC130B4 Accident: Incorrect TRDS Bearing Installation

- Fatal $16 Million Maintenance Errors

- C-130J Control Restriction Accident, Jalalabad

- Misrigged Flying Controls: Fatal Maintenance Check Flight Accident

- BA Changes Briefings, Simulator Training and Chart Provider After B747 Accident

- BA A319 Double Cowling Loss and Fire – AAIB Report

- When Down Is Up: 747 Actuator Installation Incident

- Maintenance Human Factors in Finnish F406 Landing Gear Collapse Safety investigators discuss the associated maintenance human factors and inadequacies in the type’s maintenance instructions.

Also see our review of The Field Guide to Understanding Human Error by Sidney Dekker presented to the Royal Aeronautical Society (RAeS): The Field Guide to Understanding Human Error – A Review

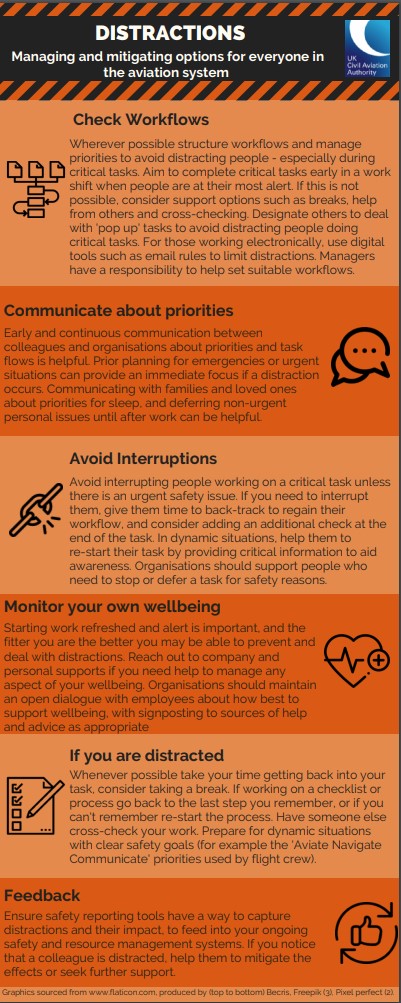

UK CAA has issued this infographic on distraction:

UPDATE 11 February 2018: Lost in Translation: Misrigged Main Landing Gear

UPDATE 24 June 2018: B1900D Emergency Landing: Maintenance Standards & Practices The TSB report posses many questions on the management and oversight of aircraft maintenance, competency and maintenance standards & practices after this serious incident. We look at opportunities for forward thinking MROs to improve their maintenance standards and practices.

UPDATE 25 August 2018: Crossed Cables: Colgan Air B1900D N240CJ Maintenance Error On 26 August 2003 a B1900D crashed on take off after errors during flying control maintenance. We look at the maintenance human factor safety lessons from this and another B1900 accident that year.

UPDATE 3 November 2018: A Lufthansa MD-11F Nose Wheel Detached after Maintenance Error

UPDATE 29 January 2019: We’ve also published these USAF maintenance case studies:

- USAF Engine Shop in “Disarray” with a “Method of the Madness”: F-16CM Engine Fire

- Inadequate Maintenance, An Engine Failure and Mishandling: Crash of a USAF WC-130H

- Inadequate Maintenance at a USAF Depot Featured in Fatal USMC KC-130T Accident

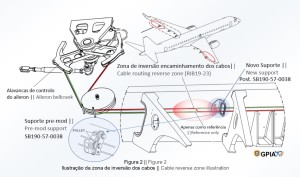

UPDATE 31 May 2019: The Portuguese accident investigation agency, GPIAAF, issued a safety investigation update on a serious in-flight loss of control incident involving Air Astana Embraer ERJ-190 P4-KCJ that occurred on 11 November 2018. The aircraft was landed safely after considerable difficulty, so much so the crew had debated ditching offshore. GPIAAF conformed that incorrect ailerons control cable system installation had occurred in both wings during a maintenance check conducted in Portugal.

GPIAFF note that: “By introducing the modification iaw Service Bulletin 190-57-0038 during the maintenance activities, there was no longer the cable routing and separation around rib 21, making it harder to understand the maintenance instructions, with recognized opportunities for improvement in the maintenance actions interpretation”. They also comment that: “The message “FLT CTRL NO DISPATCH” was generated during the maintenance activities, which in turn originated additional troubleshooting activities by the maintenance service provider, supported by the aircraft manufacturer. These activities, which lasted for 11 days, did not identify the ailerons’ cables reversal, nor was this correlated to the “FLT CTRL NO DISPATCH” message.”

GPIAFF comment “deviations to the internal procedures” occurred within the maintenance organisation that “led to the error not being detected in the various safety barriers designed” in the process. They also note that the error ” was not identified in the aircraft operational checks (flight controls check) by the operator’s crew.”

UPDATE 1 June 2019: Our analysis: ERJ-190 Flying Control Rigging Error

UPDATE 12 October 2020: Frozen Dash 8-100 Landing Gear After ‘Improper Maintenance Practices’ Say NTSB

UPDATE 15 March 2021: ATR 72 Rudder Travel Limitation Unit Incident: Latent Potential for Misassembly Meets Commercial Pressure

FSF Maintenance Observation Programme (MOP)

Aerossurance worked with the Flight Safety Foundation (FSF) to create a Maintenance Observation Program (MOP) requirement for their contractible BARSOHO offshore helicopter Safety Performance Requirements to help learning about routine maintenance and then to initiate safety improvements:

Aerossurance can provide practice guidance and specialist support to successfully implement a MOP.

Aerossurance is pleased to again be supporting and presenting at the annual Chartered Institute of Ergonomics & Human Factors’ (CIEHF) Human Factors in Aviation Safety Conference. The conference takes place at the Radison Blu Hotel, East Midlands Airport, 7-8 November 2016.

We will also be presenting at the Flight Safety Foundation (FSF) International Air Safety Summit (IASS) in Dubai, 14-16 November 2016.

Aerossurance is delighted to be sponsoring an RAeS HFG:E conference at Cranfield University on 9 May 2017, on the topic of Staying Alert: Managing Fatigue in Maintenance. This event will feature presentations and interactive workshop sessions.

Aerossurance is pleased to be supporting the annual Chartered Institute of Ergonomics & Human Factors’ (CIEHF) Human Factors in Aviation Safety Conference for the third year running. This year the conference takes place 13 to 14 November 2017 at the Hilton London Gatwick Airport, UK with the theme: How do we improve human performance in today’s aviation business?

Aerossurance is pleased to be both sponsoring and presenting at a Royal Aeronautical Society (RAeS) Human Factors Group: Engineering seminar Maintenance Error: Are we learning? to be held on 9 May 2019 at Cranfield University.

Recent Comments