17 Year Old FOD and a TA-4K Ejection (Draken International Skyhawk N140EM, Las Vegas)

On 18 August 2016 an ex-RNZAF Douglas TA-4K Skyhawk of Draken International, registered N140EM, was destroyed following a loss of engine power shortly after entering the traffic pattern at Nellis Air Force Base (LSV), Las Vegas, Nevada. The pilot ejected and sustained minor injuries.

The aircraft, which impacted the ground near Las Vegas Motor Speedway, was operated as a Public Aircraft supporting the 57th Adversary Tactics Group, USAF with Dissimilar Air Combat Training (DACT). Public Aircraft are effectively the FAA equivalent of a civil ‘State Aircraft’, to use ICAO terminology. Exercise Red Flag 16-4 was under way at the time, and a pair of Draken A-4s had been exercising with 4 USAF F-16s.

The Accident Flight

The US National Transportation Safety Board (NTSB) explain in their safety investigation report (issued 28 May 2020) that:

According to the pilot, he was the lead airplane of a flight of two aggressors, returning to LSV after completion of their Weapons School support flight in the Nevada Test and Tactics Range.

Draken International Douglas TA-4K Skyhawk near Nellis AFB on 9 August 2016 (Credit: Javier Rodríguez CC BY-SA 2.0)

He led the formation to the overhead pattern, and shortly after the break to downwind, the engine lost power. The engine did not respond to throttle movements. The pilot started a turn toward the airport; however, he realized that he was unable to make the runway, so he turned left away from the runway toward a field and then successfully ejected from the airplane.

The pilot estimated that his parachute canopy fully opened approximately 100-150 feet above the ground. The pilot was a former USAF F-16 pilot and also a current Southwest B737 pilot.

Airlines

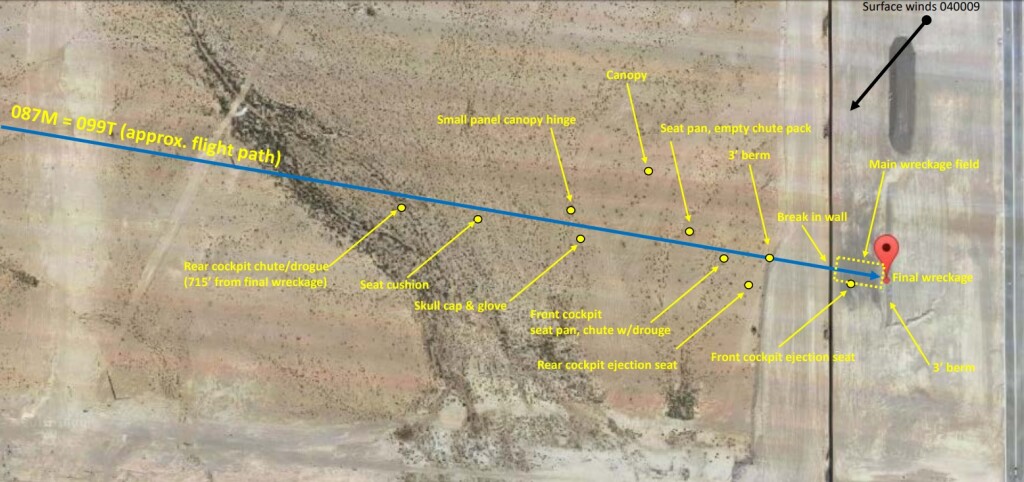

A review of surveillance video shows the airplane flying wings level at a low altitude and descending. A few seconds later, the ejection sequence was initiated and two chutes (one from the unoccupied back seat) were observed deployed. A couple of seconds later, the airplane impacts terrain…at a relatively shallow angle…

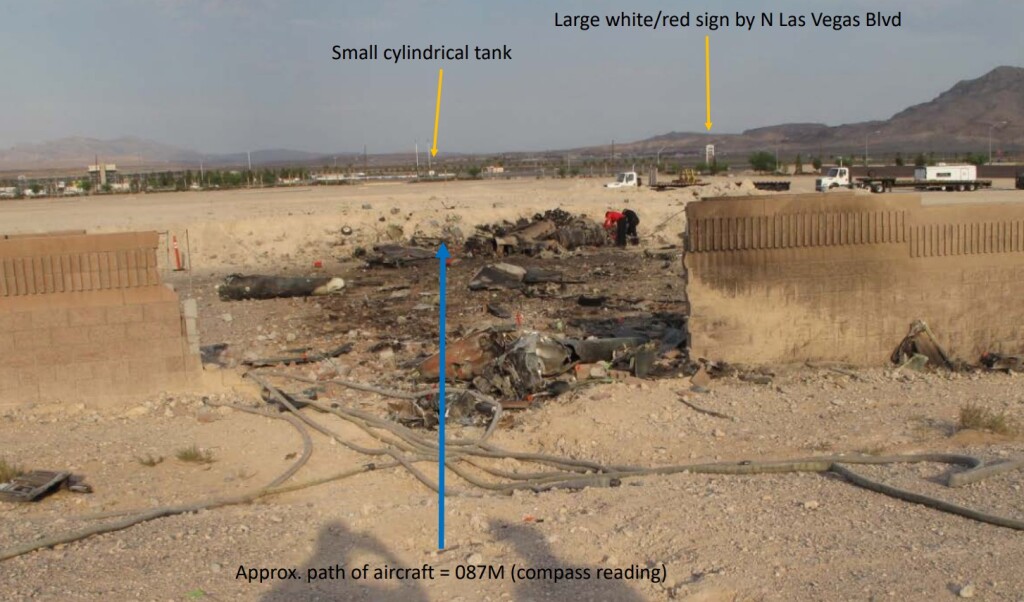

After impact, the airplane continued to slide forward on the ground for about 30 ft and then struck and breached a concrete wall.

The airplane continued to slide forward for about another 45 ft before coming to rest on its right side against a berm. A post-crash fire ensured, and the debris was mostly contained from the concrete wall to where the airplane came to rest.

Safety Investigation: Engine Shop Component Overhaul Build Debris

The TA-4K aircraft flight manual stated: ejection is mandatory “when an engine flameout occurs below 1,500 ft agl and 250 kias,” except when unusual circumstances clearly dictate otherwise.

The A-4 series was equipped with Douglas Escapac ejection seats. The TA-4K had the IG3 variant.

The ejection sequence appeared to function normally, and no anomalies were observed with the equipment. A review of the ejection seat assembly revealed that all inspections and time change requirements were current, with the exception of the separation rocket motor inspection, which were due on both ejection seats in July 2015. However, an extension of the inspections, was approved by the FAA, with the manufacturer’s assessment memorandum.

Investigating the power loss…

No anomalies were noted during the initial airframe and engine examination that would have precluded normal operation.

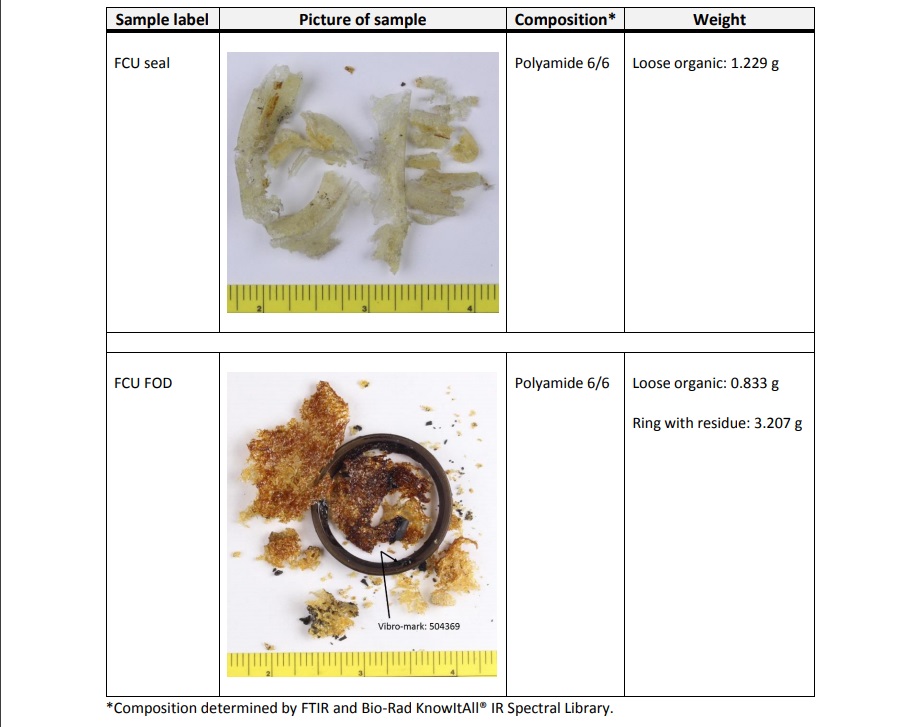

However, examination of the main fuel control (MFC) revealed foreign object debris (FOD) from a nonmetallic material inside the MFC unit. The material was identified as a nylon 6/6 material that was consistent with other seal material in the unit. However, all similar seal material inside the MFC was at its expected location.

Further, the flow path made it unlikely that any nylon 6/6 material within the MFC could have migrated from known sources during the postimpact fire to where the FOD was located. Additionally, it was unlikely the nylon material was deposited into the MFC after the accident because examination of fuel components downstream of the MFC revealed no anomalies, obstructions, or nylon material.

The MFC was rebuilt about 17 years before the accident, and the airplane had flown about 425 hours since then. It is likely that the FOD was part of an extra seal that was inadvertently installed or fell into the unit at the last maintenance overhaul. Subsequently, the FOD in the MFC eventually became positioned in such a way that restricted fuel flow and caused the loss of engine power.

NTSB Probable Cause

Foreign object debris in the engine’s main fuel control unit, which restricted fuel flow and subsequently resulted in the loss of engine power. Contributing to the accident was the installation or addition of an extra seal during the main fuel control unit rebuild.

Safety Resources

- Yuma Hawk Accident: Lessons on Ex-Military Aircraft Operation

- Jest11 is Dead: Hawker Hunter Downed by F-35A Jet Wash

- Micro FOD: Cessna 208B Grand Caravan Engine Failure & Forced Landing

- Coking Causes Power Loss: Australian AS350BA

- USAF Engine Shop in “Disarray” with a “Method of the Madness”: F-16CM Engine Fire

- Maintenance Issues in Fire-Fighting S-61A Accident

- Poor Painting Prevents Proper Performance: Shorts Sherpa NLG Collapse

- What Leaks in Vegas Stays in Vegas – A320 Hydraulic Failure

- CRJ-200 Landing Incident Highlighted US Maintenance Competency Inadequacies

- Inadequate Maintenance, An Engine Failure and Mishandling: Crash of a USAF WC-130H

- Crazy’ KC-10 Boom Loss: Informal Maintenance Shift Handovers and Skipped Tasks

- Hoist Assembly Errors: SAR Personnel Dropped Into Sea

- Contaminated Oxygen on ‘Air Force One’

- Usage Related Ex-Military Helicopter Accident

- UPDATE 22 July 2020: NDI Process Failures Preceded B777 PW4077 Engine FBO

The UK MAA commented on the regulation of such operations in 2018.

We have discussed maintenance human factors and error management more generally here:

- Professor James Reason’s 12 Principles of Error Management

- Back to the Future: Error Management

- Maintenance Human Factors: The Next Generation

- Aircraft Maintenance: Going for Gold?

- Airworthiness Matters: Next Generation Maintenance Human Factors

- Rockets Sleds, Steamships and Human Factors: Murphy’s Law or Holt’s Law?

- B1900D Emergency Landing: Maintenance Standards & Practices

Aerossurance worked with the Flight Safety Foundation (FSF) to create a Maintenance Observation Program (MOP) requirement for their contractible BARSOHO offshore helicopter Safety Performance Requirements to help learning about routine maintenance and then to initiate safety improvements:

Aerossurance can provide practice guidance and specialist support to successfully implement a MOP, which fills a gap in maintenance that in operations is filled by FDM and LOSA.

Aerossurance has extensive air safety, operations, SAR, airworthiness, human factors, aviation regulation and safety analysis experience. For practical aviation advice you can trust, contact us at: enquiries@aerossurance.com

Follow us on LinkedIn and on Twitter @Aerossurance for our latest updates.

Recent Comments