Freewheel Jerk on an SA330J Puma at Sea: Oil Analysis Opportunity (Erickson Helicopters Airbus SA330J N339EV)

On 26 January 2018 Airbus Helicopters SA330J N339EV, operated by Erickson Helicopters, sustained substantial damage during a fresh water engine rinse aboard the replenishment vessel USNS Wally Schirra underway in the Pacific. The helicopter was operating under Part 133 (external load) and had been shuttling supplies, known as VERTREP, to other naval vessels in the area.

The US National Transportation Safety Board (NTSB) explain in their safety investigation report (issued 3 June 2020) that…

…after landing the helicopter on the deck of the ship, power was increased on the No. 2 engine, while the No. 1 engine was reduced to ground idle in preparation for a freshwater rinse of the engines to prevent corrosion.

Once the engines were configured, the pilot saw the lead mechanic squeeze the trigger on the wand, and then there was a rumbling sound followed by a rough shudder through the airframe. He then looked back at the cockpit instruments and everything looked normal for the condition the controls were in at the time.

About that time, there was another shudder through the airframe, and he heard a change in the tone of the engine and gear box noise. He saw that the rotor speed had started to rise, and the gas generator speed of the No. 2 engine had also started to increase. He shut down the engines.

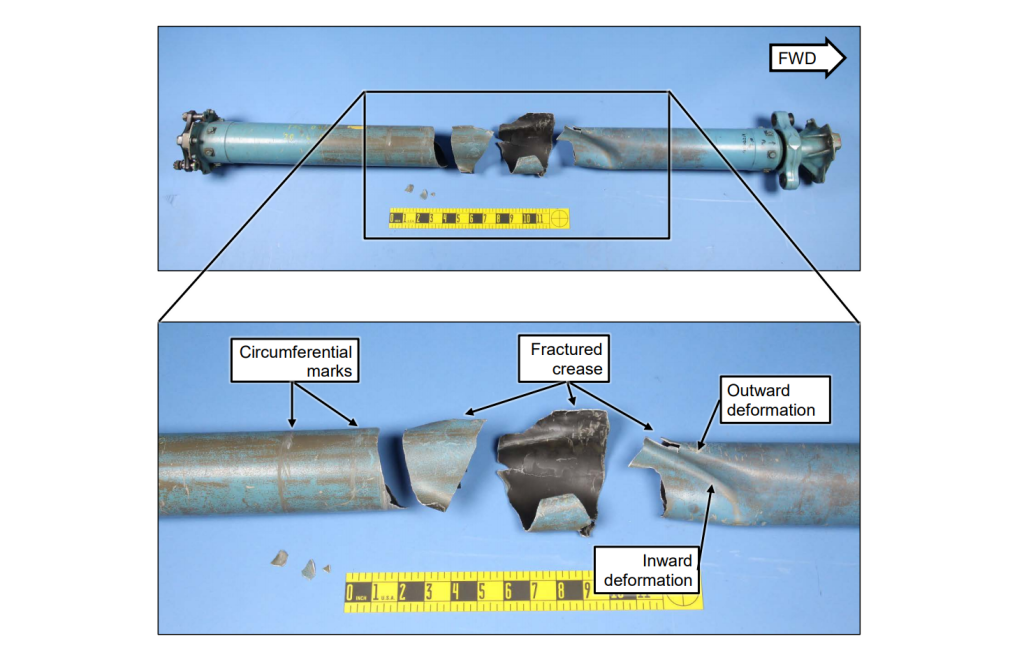

The Tail Rotor Drive Shaft (TRDS) was found to have sheared, disconnecting the Main Gear Box from the Tail Rotor.

Safety Investigation

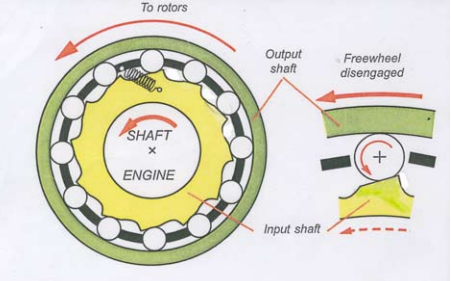

Examination of the MGB right freewheel assembly revealed that the small roller bearings were dislocated, the bearing cage was fragmented, and both tabs of the shur-lok washer showed signs of deformation with visible impact damage.

Damage to these tabs is consistent with a sudden engagement of the bearing, resulting in an instantaneous spike in torque, known as freewheel jerk.

During the transition of the No. 2 engine from the idle position to the flight position, the condition of the freewheel small roller bearings likely prevented the freewheel cage from maintaining the large freewheel rollers on the ramp due to the effect of the freewheel spring. This situation is unstable until an “imbalance” modifies it and suddenly causes the cage and the freewheel rollers to rise on the ramp, imparting a torque spike into the rotor drive system.

Another SA330J Undertaking VERTREP from USNS Alan Shepard (T-AKE 3) in the Gulf of Aden in 2011 (Credit: US Navy / Mass Communication Specialist 3rd Class Trevor Welsh)

NTSB say that oil analysis had the potential for early detection of the freewheel unit failure mode:

The maintenance manual for the SA330 helicopter requires the oil analysis be performed every 150 hours for the main gear box and every 50 hours for the intermediate gear box. Laboratory results were obtained from the two prior oil samples. The two samples taken were 88.4 hours and 2 years apart [indicating very low utilisation or a period of storage].

The first, dated February 13, 2016 listed Fe at 3.3 parts per million. The second sample, taken in November of 2017 [albeit prior to the 150 hour interval] was misplaced by the operator and not found until after the accident. When it was sent for analysis on February 4, 2018, Fe was detected at 14.7 parts per million.

…had both of these samples been analyzed at the time of the inspection, it is likely the operator would have been able to detect the increase in metal before the bearing wear became severe enough to cause the jerk.

Oddly while the NTSB laboratory documented an examination of the TRDS, the FWU wasn’t examined.

Safety Action

After the accident, the operator implemented an internal requirement for oil sample analysis in shorter intervals.

Observation

This accident does demonstrate the current Achilles heel of this oil analysis technique in that it is invariably tied to remote laboratories. Many helicopter operations either have logistical challenges returning regular samples or, especially in oil and gas offshore helicopter operations, have flying rates that mean challenging turnaround times for analytical feedback. There are however some portable testing kits that may make this more practical.

Lewis and Clark-class dry cargo and ammunition ship USNS Wally Schirra (T-AKE 8) in the Pacific in 2017 with a MH-60S Sea Hawk under taking VERTREP (Credit: US Navy / Mass Communication Specialist 2nd Class Sean M. Castellano)

Safety Resources

- Ungreased Japanese AS332L Tail Rotor Fatally Failed

- For Rotors Grease is the Word

- Maintenance Misdiagnosis Precursor to EC135T2 Tail Rotor Control Failure

- Misassembled Anti-Torque Pedals Cause EC135 Accident

- EC130B4 Accident: Incorrect TRDS Bearing Installation

- Fatal S-61N Dual Power Loss During Post Maintenance Check Flight

- AAIB Report on the Ditchings of EC225 G-REDW 10 May 2012 & G-CHCN 22 Oct 2012

- EC225 LN-OJF Accident Norway (29 April 2016) Investigation Timeline

- AAR Bell 214ST Accident in Afghanistan in 2012: NTSB Report

- Fatal S-61N Dual Power Loss During Post Maintenance Check Flight

- Loss of AS332L1 LN-OPG off Brønnøysund, Norway, 8 September 1997

- Insecure Pitch Link Fatal R44 Accident

- EC135 Main Rotor Actuator Tie-Bar Failure

- Bell 429 TR Pitch Change Link Bearing Failure

- S-61N Damaged During Take Off When Swashplate Seized Due to Corrosion

- Tail Rotor Pitch Control Loss During Hoisting

- Sikorsky S-92A Loss of Tail Rotor Control Events

- NTSB Reveal Lax Maintenance Standards in Honolulu Tour Helicopter Accident

- Aerossurance Wins MAA HUMS Maintenance Credit Contract

- EASA HUMS Research Developments

- EASA & FAA HUMS / VHM Developments

- HeliOffshore Launch HUMS Best Practice Guide

- Helicopter HUMS Maintenance Credit: New Initiatives

- UPDATE 28 June 2020: Maintenance Issues in Fire-Fighting S-61A Accident

Recent Comments