Fire After O-Ring Nipped on Installation

On 7 July 2016 Delta Air Lines (DAL) Pratt & Whitney PW2040 powered Boeing 757-200, N706TW, experienced a right engine fire shortly after takeoff from John F. Kennedy International Airport (JFK). The flight crew declared an emergency after receiving a right engine fire warning in the initial climb, approximately 400 feet agl. They shut down the right engine and observed the fire warning extinguish and so neither fire bottle was discharged. The flight returned to JFK and landed safely.

Thermal damage was limited to the right nacelle. The damage included a hole in the inboard core cowl consistent with a burn-through.

Safety Investigation

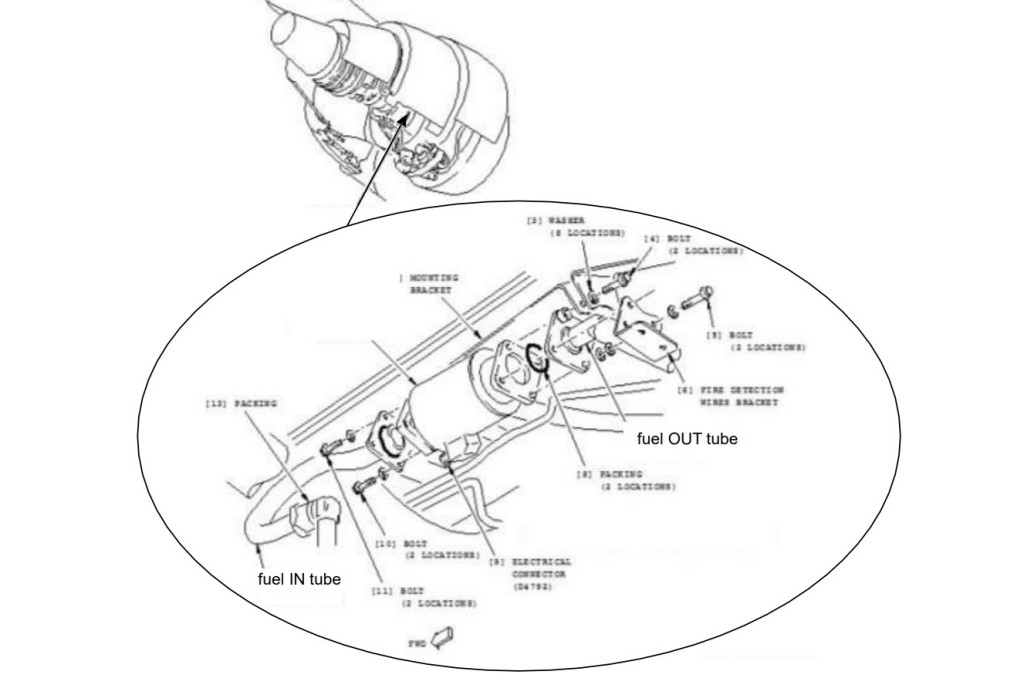

According to the US National Transportation Safety Board (NTSB) safety investigation report, the flammable fluid source was fuel leaking at the fuel flow transmitter (FFT)-to-fuel OUT tube joint. On the morning of the flight the right engine FFT had been replaced.

A rubbery blue-colored substance was found protruding from the top and left sides of FFT-to-fuel OUT tube joint.

The NTSB say that:

The FFT, fuel IN line and fuel OUT line were removed as an assembly. Pressure was applied to the assembly and leakage was observed at the suspect joint. The fuel OUT tube was removed. The tube O-ring was found eroded and with a 90° arc of material missing.

Both ends of the O-ring separation exhibited shallowly angled separations.

Parker Aerospace was asked to assess the O-ring separation. Parker reported that the similar angle/plane cuts on both ends of the O-ring is a commonly-observed damage condition that results from installation error.

Safety Analysis

It therefore was concluded the O-ring had been ‘nipped’ during installation that morning. During the takeoff, high-pressure fuel had therefore flowed past the damaged seal and sprayed into the engine compartment, contacting hot surfaces and igniting.

NTSB Probable Cause

Maintenance personnel’s failure to ensure proper installation of a fuel tube O-ring, which resulted in an undercowl engine fire during initial climb.

Maintenance Instruction Review and the Fallacies of Compliance and Reporting

The NTSB go on to note that a review of the B757 Aircraft Maintenance Manual (AMM) FFT installation procedure found the following:

- AMM Task 73-31-01-404-018-P00 did not include an instruction to lubricate the tube O-rings prior to installation: Note that: Parker Hannifin Publication ORD5700, Parker O-Ring Handbook pg. 3-4, paragraph 3.1.5 states that “use of a suitable grease or oil during assembly helps protect the O-ring from damage by abrasion, pinching, or cutting” and “helps the O-ring to seat properly”.

- AMM Task 73-31-01-404-018-P00 incorrectly directs that the fuel IN and fuel OUT tube O-rings to be installed on the FFT rather than into the fuel tube O-ring glands.

- AMM Task 73-31-01-404-018-P00 did not specify a torque value for the tube attachment bolts.

Boeing has since revised these instructions to correct these errors.

The NTSB note that:

The FFT installation task used by the DAL technician to install the FFT directly aligned with the Boeing AMM and so included these omissions/errors.

So a focus purely on maintenance compliance monitoring would likely not have detected this prior to the incident, although the documentation anomalies probably should have attracted attention and been reported previously.

While the NTSB do not discuss if any reports had been raised previously, its not uncommon for personnel to not report such issues because they assume that someone else already must have spotted the problem.

Obviously, not damaging an O ring during installation is a fundamental expectation too. The NTSB report does not examine the conduct of the maintenance task further, so there is no other insight into how the task was conducted

Safety Resources

Aerossurance worked with the Flight Safety Foundation (FSF) to create a Maintenance Observation Program (MOP) requirement for their contractible BARSOHO offshore helicopter Safety Performance Requirements to help learning about routine maintenance and then to initiate safety improvements:

Applying the MOP principles could, for example, have helped identify any variability in maintenance standards and practices and captured documentation issues not otherwise formally reported.

See also:

- B1900D Emergency Landing: Maintenance Standards & Practices

- When Down Is Up: 747 Actuator Installation Incident

- Airworthiness Matters: Next Generation Maintenance Human Factors Over the last 10-15 years, much attention has been focused on maintenance human factors training and reporting & investigating errors. While we could concentrate on simply doing more of these and certainly can find ways to do these things better, perhaps the next generation approach needs to include a much wider range of activities.

- Aircraft Maintenance: Going for Gold? Should we start treating maintenance personnel more like athletes who need to achieve peak performance every day?

- James Reason’s 12 Principles of Error Management

- Back to the Future: Error Management

- The Power of Safety Leadership

- Leadership and Trust

- Safety Performance Listening and Learning – AEROSPACE March 2017

- How To Develop Your Organisation’s Safety Culture

- Complacency: A Useful Concept in Safety Investigations?

- What Leaks in Vegas Stays in Vegas – A320 Hydraulic Failure

- UPDATE 25 August 2018: Crossed Cables: Colgan Air B1900D N240CJ Maintenance Error On 26 August 2003 a B1900D crashed on take off after errors during flying control maintenance. We look at the maintenance human factor safety lessons from this and another B1900 accident that year.

- UPDATE 10 June 2020: B767 Fire and Uncommanded Evacuation After Lockwire Omitted

- UPDATE 7 August 2022: Fuel Tube Installation Trouble

Aerossurance is pleased to be both sponsoring and presenting at a Royal Aeronautical Society (RAeS) Human Factors Group: Engineering seminar Maintenance Error: Are we learning? to be held on 9 May 2019 at Cranfield University.

Recent Comments