B1900D Emergency Landing: Maintenance Standards & Practices

On 12 July 2016 an Air Georgian Beechcraft 1900D, C-GORF, made an emergency landing after its Nose Landing Gear (NLG) could not be lowered at the end of an Air Canada Express flight in Alberta from Lethbridge to Calgary. The resulting Transport Safety Board of Canada (TSB) safety investigation report (released on 29 May 2018) posses many questions on the management and oversight of aircraft maintenance and maintenance standards & practices.

Resting Position of Air Georgian Beech 1900D C-GORF on Runway 35R (Source: Calgary Airport Authority via TSB)

Air Georgian was formed in 1984 and operates a fleet of B1900Ds and Bombardier CRJ-100 and -200s, that carry over 500,000 passengers per annum. It is one of four carriers operating for Air Canada under the Air Canada Express brand.

History of the Flight

The TSB explain that:

When the landing gear was selected down for the approach into Calgary, the flight crew observed that there was no gear-safe indication for the NLG. The flight circled east of Calgary for about an hour while the pilots attempted to rectify the problem. An emergency was declared. The aircraft landed at 0720 Mountain Daylight Time, during daylight hours, with the nose gear in a partially extended position.

The nose gear was held off the runway with progressive aft control‑column input until the nose settled on the runway about 28 seconds after main gear contact…at approximately 52 knots indicated airspeed.

The aircraft came to a stop 6050ft from the threshold.

No fire occurred, and there were no injuries. Emergency vehicles reached the aircraft in 30 seconds, and all passengers and crew deplaned within 1 minute. Damage to the aircraft was limited to the nose landing gear components, the nose gear door and gear light, as well as 2 propeller tips on each side of the aircraft that contacted the runway.

B1900D Landing Gear Description and Lab Findings

The B1900D landing gear assemblies are retracted and lowered hydraulically. The TSB explain that:

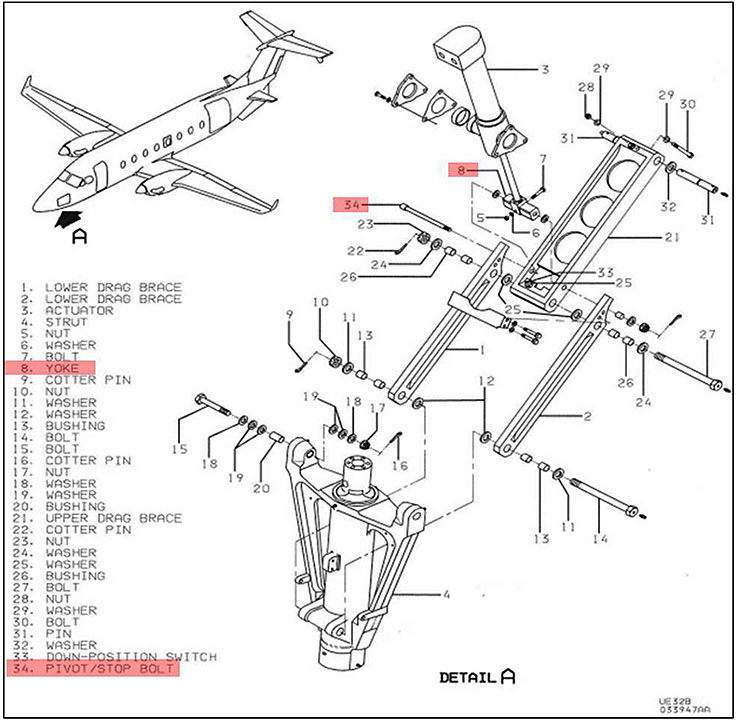

During extension and retraction, the nose gear actuator exerts pressure through an aluminum yoke fitting attached to the end of the actuator piston (see figure below). This yoke is attached to the middle of the upper and lower drag braces, and causes the drag braces, when folding or unfolding, to extend or retract the nose gear. The yoke (item 8) is attached and pivots through the braces by means of a pivot/stop bolt, part number 114-820107-1 (item 34).

The failure of the retract-and-extend mechanism of the nose landing gear was initiated by a yoke lubrication problem. The bolt with part number 114-820107-1 (item 34)…was not lubricated as required.

The yoke should turn freely around the yoke’s pivot/stop bolt; however, the occurrence yoke’s pivot/stop bolt was seized in the yoke due to deteriorated grease and corrosion for 2 reasons:

First, the deteriorated grease did not provide lubrication.

Second, insufficient lubrication allowed the penetration of moisture between the bolt and the bore surface, causing corrosion on both surfaces.

The bolt seizure resulted in abnormal loading on the yoke’s pivot/stop bolt and the actuator clevis during retraction and extension of the nose landing gear. This led to fatigue cracking and failure of the yoke’s pivot/stop bolt ends.

From 31 August to the end of September 2016, the operator examined the condition of nose landing gears in its fleet and found 5 more Beechcraft 1900D aircraft with non-airworthy nose landing gear yoke pivot/stop bolts, as well as several other nose landing gear bolts.

Air Georgian Maintenance Schedule, Process and Practices

The TSB say that Air Georgian maintenance personnel were required to lubricate and inspect the failed bolt as follows:

- Lubrication schedule: Aircraft Maintenance Manual (AMM) Chapter 12 documented the lubrication schedule to be performed at every 400-hour interval. This required personnel to “grease fittings” using specific greases.

- Bolt inspection: AMM Chapter 32 documented the bolt inspection to be performed at every fifth 200-hour interval. Para C(4) required the technician to “[l]ubricate the drag brace grease fittings with grease” and then, in paragraphs C(11) to C(13), to disconnect the relevant parts of the occurrence bolt to test for “free rotation.” If the yoke did not rotate freely, “determine the cause and replace parts as necessary.”

- Detailed inspection: AMM Chapter 05 documented a detailed inspection to be performed at every fifth 200-hour interval. Subpara C(9)(b) required the technician to “inspect for proper lubrication of bolts” in accordance with the lubrication schedule. Subpara C(9)(c) required the technician to “inspect bolts for freedom of movement” in accordance with the bolt inspection.

The bolt was also required to be lubricated after each aircraft external wash:

- Airplane washing: AMM Chapter 12, Section 3F, stated that “the landing gear […] should be washed with low pressure and mild detergent as soon as is practical following operation on salty or muddy runways.” General instructions in Chapter 12, Section 3, included “use special care to avoid washing away grease from any lubricated area” and “lubricate after cleaning as necessary.” This requirement was restated below the lubrication instruction table in Chapter 12 : “After washing airplane, lubricate all lubrication points.”

The TSB don’t specifically describe how Air Georgian translated this into their own Maintenance Programme. They do say that the lubrication process at Air Georgian was the same for each of these tasks, and senior maintenance personnel described this as follows:

- Wipe away the old grease.

- Attach the tube of the grease gun to the bolt nipple and manually squeeze the grease gun handle until sufficient grease is expressed.

- Monitor for old grease seeping from all applicable seams of the bolt, indicating that the bolt is lubricated and serviceable.

- Monitor for new grease seeping from all applicable bolt seams, indicating that new grease is successfully expressed and has penetrated all relevant areas.

- Wipe away excess grease as necessary.

The TSB also say:

Some senior maintenance personnel reported that bolt lubrication deficiencies could be monitored during the lubrication task by performing step 3, above. If no old grease was seen being expelled, or if it was not possible for the new grease to enter the lubrication point in step 2, this could indicate that the bolt or part was dry and/or blocked with old, hardened grease, and therefore unserviceable. The defect would then be recorded and actioned on an additional work card.

It is therefore apparent that some personnel did have an understanding of good greasing practices.

As part of the periodic bolt inspection and detailed inspection, technicians and [licensed Aircraft Maintenance Engineers] AMEs were required to perform the lubrication. Technicians and AMEs were then required to test the pivot/stop bolt (and others) for free rotation to determine whether the bolt was sufficiently lubricated and serviceable. This required technicians and AMEs to dismantle the bolt and use their fingers to freely rotate it. If any inspection discrepancies were found, technicians and AMEs were required to “determine the cause and replace parts as necessary.” If any new parts were required, an additional work card was to be completed.

The TSB say:

If the maintenance manual is followed correctly, the occurrence bolt is required to be greased every 400 hours, at every fifth 200-hour interval, and after airplane washing, as necessary.

Documentation indicated that the occurrence aircraft received its most recent 400‑hour lubrication at the Calgary sub-base in May 2016 and its most recent detailed inspection at the Toronto main base in March 2016. There was no record of any lubrication conducted after washing.

At Air Georgian’s Toronto main base, there were pre-loaded, labelled grease guns that did not necessarily contain the grease type matching the label on the gun. This occurred so frequently that there was an informal practice whereby technicians would remove the cartridge before each use to make sure the gun contained the correct grease. This equipment issue could have contributed to errors…by increasing the probability of selecting the wrong grease. The technician or AME may not have been able to detect the error, given that many types of grease are the same colour.

Some maintenance personnel commented on the difficulty and inconvenience of the grease guns: certain grease guns required much more force than others to express the required grease. This equipment issue could have contributed to potential errors….by masking the effect of a blocked grease nipple and leading the technician to attribute the additional pressure to the typical usability issues of the grease gun.

Workload

At the time of the occurrence, Air Georgian had recently procured more CRJ-200s, increasing the number of aircraft within the fleet. It was not uncommon for a shift to experience high workload, which could include a combination of scheduled and unscheduled tasks on the Beechcraft 1900D and the CRJ‑200.

…unscheduled aircraft serviceability issues often took priority, and scheduled tasks were interrupted.

Examples taken from the Air Georgian computer-tracking program indicated multiple task-extended entries, primarily due to workload and personnel shortage.

There was no standardized practice or procedure for transitioning between a deferred task and a new task. Technicians had a varied approach to task progress tracking. Some would initial each step, some would initial each section, and some checked off each page as a whole.

If a scheduled task was interrupted and temporarily suspended, for example when a technician was halfway through lubricating the nose-wheel gear, it was not always possible to determine what had been done when the technician returned or a new technician took over the task

Supervision

It was common for a shift at the Toronto main base to be made up of a majority of junior technicians, with only 1 or 2 senior AMEs [with] [Aircraft Certification Authority] ACAs [i.e. certifying staff]. One or both of these senior AMEs with ACA status could be sick or assigned to tasks elsewhere, for example at the airport departure gates.

It was typical practice not to supervise tasks that were considered basic, such as lubrication, or to check the lubrication of easy-to-reach or easy-to-lubricate bolts, such as the occurrence bolt, prior to signing the maintenance release. The focus was on the more complex tasks or bolts that were harder to lubricate or reach. Depending on workload, it was common for ACAs to sign off on tasks for which they had not been present and had not inspected, or to sign off on tasks many hours after multiple tasks had been completed.

There were no standardized supervision practices.

Maintenance Personnel Training & Competence

The TSB investigation discovered a lack of standardised training and “several gaps in knowledge and training”:

…investigation interviews and observations indicated that there was a diverse standard of knowledge and performance concerning the lubrication task, and some technicians were not aware of a requirement to lubricate the aircraft following cleaning.

Aviation maintenance technician students in Canada usually attend a [Transport Canada] TC-approved training organization (ATO) to complete basic training prior to starting work at an [Approved Maintenance Organisation] AMO.

During maintenance education, [Canadian Aviation Regulations] CARs…require students to be taught about “human factors in maintenance” and the “classifications, functions, principles and properties of lubricants,” and to perform “servicing of lubrication, fuel, oil and hydraulic systems.”

The CARs do not specify the level or details for each subject taught; it is up to each individual ATO to determine how and what to teach. The investigation queried 9 ATOs to determine how lubrication tasks were taught. No standard methodology was found and the information taught varied among the ATOs. The investigation could not find any description of a training standard for a lubrication technique taught in typical student training material….or other records, other than the instruction to “grease aircraft.”

Therefore, not all technical competencies are standardized, and, as a result, it is not possible to determine a student’s technical competencies related to the lubrication and inspection tasks unless these competencies were tested and validated when the student was hired at an AMO.

Technicians then received further training on joining an AMO:

As with initial education, the CARs do not specify the level or details for each subject taught; it is up to each AMO how and what to teach in order to train employees on applicable tasks.

[The] Air Georgian maintenance documentation did not contain any grease fittings procedure, training standards, examination, or validation process.

Air Georgian’s Maintenance Policy Manual stated the following:

On the Job training shall be accomplished under the direction of a qualified individual, normally in the everyday working environment, utilizing demonstration and practice techniques.

There was no requirement or provision for [these qualified] individuals…to receive instructor‑based training related to the competency and validity of their “demonstration and practice techniques,” nor was this required by regulation.

The knowledge, rules, and skills required for teaching, demonstrating, and assessing the lubrication and inspection tasks were not detailed in any Air Georgian documentation or taught as part of any Air Georgian instructor-based training syllabus. There were also [for example] no training or supervision-related competencies listed on the ACA Occupational Standard Assessment form or the ACA Nomination form.

More generally, in Canada there is no requirement for a type rating on aircraft as large as the B1900D. The TSB found that at Air Georgian…

…in practice, for the Beechcraft 1900D fleet, an AME was required to complete on-the-job ACA training and a Beechcraft 1900D technical exam, which contained 15 randomly generated questions on the Beechcraft 1900D. When the applicant was considered ready for ACA status, an ACA Nomination form was to be completed and sent to the corporate training department. This form included a checklist of training, such as “initial training,” “6 months experience on type,” and “company training requirements current.”

Such a tick box approach might be acceptable if there were:

- Competent assessors

- Clear assessment standards

- Good records of the basis of the assessment.

As discussed above, on the first point, the ‘qualified individuals’ who oversaw OJT and assessment were not specifically developed for that role. On the second point:

There were no details in either the Maintenance Policy Manual or Maintenance Procedures Manual on what constituted an ACA’s “combination of training and experience appropriate to that aircraft” or “required competencies,” or on what was included in ACA on-the-job training.

Finally, when it comes to the third point:

Maintenance training was managed by the flight operations training department, which lacked detailed maintenance training programs and records. There were few detailed records…other than for the in-house, computer-based training. No records, except for summary sheets, were provided to the investigation to show the qualifications of maintenance personnel. The training summary sheets for the range of personnel examined in this investigation did not reflect accurate training, certifications, or signing authorities.

Additionally, human factors (HF) training was delivered online.

Each online course was followed by an exam that required a passing grade of 100% within 3 attempts.

The TSB say that if the trainee failed, senior staff would “coach and counsel” them until they achieved 100% in the exam, which of course is not the same as being able to successfully apply the techniques in the workplace. They note that:

There was no opportunity for maintenance personnel to participate in group discussion on recent maintenance errors.

This is an important learning technique if properly facilitated (and not just faux-interactivity to break up a one-way lecture). Also:

It was not possible to determine the degree of standardization of online learning outcomes…

This is because with only the immediate success rate in the on-line exam to go on, there would have been no real feedback on actual understanding or application of the key principles. Similar problems occur when classroom HF training:

- is delivered by third parties with minimal oversight and/or minimal knowledge of the local environment, and /or is

- a box-ticking exercise to present content with no verification of individual learning outcomes in the workplace, and / or

- merely highlights where the organisation itself is poor at managing HF, without any connection to a means to reliably facilitate change

We saw an advert recently that asked: “Is your Human Factors programme just a ‘tick-box’ exercise to comply with the regulations?” When we read on we realised this dubious marketing justly deserves scorn for claiming a promoted maintenance HF course would “ensure compliance with EASA Part 145.A.30.(e) “. What is more ‘tick-box’ than booking a course that allegedly “ensures compliance” with a rule that is actually written around competence?! The Acceptable Means of Compliance (AMC) for this EASA rule on maintenance personnel requirements explicitly defines competence as:

…a measurable skill or standard of performance, knowledge and understanding, taking into consideration attitude and behaviour” (AMC1 145.A.30(e) – emphasis added).

This sort of advert, typical of training factories who are desperate to fill their classrooms to offset their high overheads, is part of the problem. It reinforces an inappropriate cultural norm of associating mere course attendance with actual competence. It can be inadvertently encouraged too by inept regulators who take the lazy route of simply counting course certificates without examining course content, competence assessment and the outcome in the workplace.

Enlightened and progressive organisations take a more sophisticated approach to learning and development: Coaching and the 70:20:10 Learning Model – Beyond Training

The US Navy has recently raised concerns about the level of competence of their maintenance personnel after a series of maintenance related incidents.

Resulting Maintenance Practices and Analysis of Potential Task Errors

The end result was variability in maintenance standards and practices, identified by TSB through interviews and observations:

For example…only some [personnel] used a flashlight, only some checked for the expression of old grease as an indicator of a dry bolt, and only some correctly checked for the expression of new grease.

The investigation observed a technician performing the lubrication task when old grease did not expel before the new grease, indicating that the bolt was dry. The technician did not consider this a reason to report it or to perform a more detailed inspection.

There were also discrepancies in what was understood if it was difficult to push new grease into the bolt and different criteria for what constituted free rotation during an inspection task.

Some technicians assumed that the aircraft was lubricated following airplane external cleaning, although they were not aware of who performed this task. Some did not know that this was a requirement.

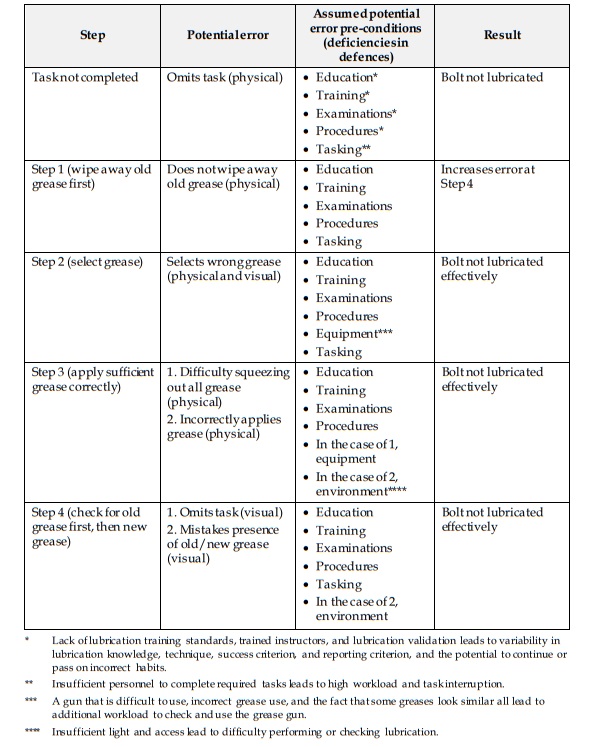

The TSB conclude that even what might be perceived as simple tasks (such as greasing) are vulnerable to knowledge-, rule- and skill-based errors.

Knowledge-based performance is largely conscious, occurring as technicians learn new situations and outcomes. As they progress, rules are learned, producing a more regulated “if/then” performance.

Knowledge- and rule‑based mistakes may occur as a result of insufficient education, training, or experience. Technicians and AMEs may not know how to deal with certain scenarios, they may apply inappropriate rules to the task, or they may not apply appropriate rules, such as following known procedures.

As technicians and AMEs gain experience and practice, they may execute more automatic skilled performance, such as in the application or inspection of grease. During this time, technicians and AMEs may make skill-based errors, such as missing deficiencies or omitting tasks, especially if they are interrupted, tired, or biased by pre-conditions such as expectation and assumptions.

They say that:

Performance errors can be mitigated by appropriate defences, such as suitable education, training, procedures, equipment, operating environment, scheduling, supervision, and safety management. These defences can reduce the likelihood of errors and detect errors should they occur.

We discuss the concept further in our perennially popular article: James Reason’s 12 Principles of Error Management

The investigators conducted an analysis of the steps that should typically be performed to ensure effective lubrication and avoid errors. The following TSB table summarises the typical errors that can occur and their pre-conditions (effectively Performance Influencing Factors [PIFs]) and consequences:

The only weakness of this table is that it reverts to inputs (‘Education’ and ‘Training’, but excluding ‘Experience’) rather than outcomes (‘Competence’).

Quality Assurance (QA) and the Safety Management System (SMS)

The Air Georgian QA programme consisted of internal audits and Corrective Action Plans (CAPs) to address items of “non-conformity”. The TSB make no comment on the efficacy of internal audits, other than they did no detect the issues highlighted by TSB. As audits are sampling exercises it can be unfair to claim that all weaknesses detectable with hindsight, were detectable beforehand. In this case, it is however reasonable to expect some of the weaknesses to have been identifiable in advance during audits.

However, TSB have more to say on the CAP process:

The CAP is required to list immediate, short‑term (30-day), and long‑term (90‑day) actions…

To evaluate the effectiveness of Air Georgian’s audit system, the investigation examined 14 of the company’s previous CAPs. The investigation determined that 12 of the CAPs did not meet the timelines specified in Air Georgian’s Maintenance Policy Manual.

Additionally, as of 30 January 2017, more than 6 months since the date of this occurrence, Air Georgian’s related internal SMS investigation report…remained at the short-term action stage (30 days). Air Georgian stated that it was waiting for the results of the TSB investigation before concluding the short‑term action of the internal SMS investigation.

Air Georgian’s campaign to inspect the rest of the fleet for the bolt that failed during this occurrence was not initiated until approximately 7 weeks following the incident.

The TSB describe the CAP process as ineffective.

The operation and maintenance of B1900Ds would nor require an SMS under Canadian regulations. However Air Georgian does have a TC approved SMS for its air operator and maintenance organisation because the company operates larger CRJs.

The company’s SMS Manual stated that “principal method for identifying both potential (proactive) and actual (reactive) hazards is the use of aviation safety reports (ASRs)”. That sort of statement is not uncommon, but can result in a simplistic and blinkered approach. That’s because it tends to imply that the organisation only reacts to reports raised by workers (reports are rarely entered by supervisors or managers in such reporting programmes) and that the reports have to be submitted in a specific way (in the case of Air Georgian this was via a web interface) even when issues are being openly discussed or fully documented in other formats. The TSB note that:

- …some maintenance employees considered only aircraft system issues or health and safety issues to be maintenance-related reportable events.

- Any maintenance event that resulted in additional work was captured using additional work cards. There was no process or practice to follow up on an additional work card with an ASR…if appropriate.

- Everyday maintenance hazards were occasionally reported to the crew chief, although they were not captured by any ASR…. For example, TSB investigators observed an instance in which incorrect grease cartridges had been loaded into grease guns, and this was [only] reported to the crew chief.

There was also not documented process or practice to follow-up hazards recorded in the crew chief handover log with an ASR. When an SMS only relies on input from limited sources, the SMS will be myopic.

There is also no mention in the TSB report of any other SMS activities prior to the occurrence (such as risk assessment / risk management, management of change or safety promotion).

TSB comment too that:

Key safety roles at Air Georgian included the [Person Responsible for Maintenance] PRM, quality assurance manager, SMS manager, and safety officer.

In the 2 years before the occurrence, there were 2 different vice presidents of maintenance holding the delegation of PRM. During transitions, there were 3 other instances in which other individuals assumed the role of PRM on an interim basis. From time to time, for short periods, the quality assurance manager held the PRM delegation and the SMS manager assumed the responsibility of the safety officer.

Air Canada / IOSA Oversight

Air Canada requires all of its Tier III operators to be compliant with the International Air Transport Association (IATA) Operational Safety Audit (IOSA) and IOSA standards and recommended practices.

To meet this requirement, Air Georgian undergoes an IOSA audit approximately every 2 years. The details of the audit are not made available to Air Canada. Through IATA, Air Canada is informed as to whether Air Georgian meets the standard.

Air Georgian passed the last 2 IOSA audits. These 2 audit reports were requested from Air Georgian but were not made available to the investigation.

This does beg the questions:

- Are IOSA audits effective in assessing actual maintenance standards and practices?

- Do airlines receive adequate assurance on their code share partners and branded regional operators from the IOSA scheme?

Transport Canada

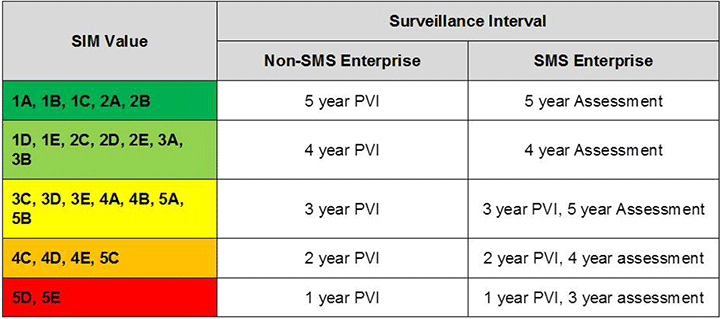

The investigation examined the last 6 years of TC’s surveillance of Air Georgian. From 2011 until the occurrence, TC conducted several surveillance activities. The activities that were relevant to the investigation included 2 program validation inspections (PVIs), 1 process inspection (PI) and 1 SMS assessment.

A PVI is TC’s “primary surveillance tool” used to determine if “all the requirements of a particular component of the SMS model or other parts of the regulations are documented, implemented, in use and effective.” Similar to a PVI, a PI is however focused on a single process only. Despite being assessed by TC as being in in the second highest (‘orange’) category of the TC Surveillance Interval Matrix, Air Georgian only required a PVI ever two years and an SMS assessment every four.

TSB comment:

While an effective SMS will help, companies vary in degrees of ability or commitment to manage risk effectively. Some are more effective than others. Less‑frequent surveillance that is solely focused on an operator’s safety management processes can be sufficient for some companies. However, the regulator must be able to vary the type, frequency, and focus of its surveillance activities to provide effective oversight to companies that are unwilling or unable to meet regulatory requirements or effectively manage risk. This could include regulatory compliance inspections. Further, the regulator must be able to take appropriate enforcement action in these cases.

Weaknesses in TC’s approach to oversight have been raised in other TSB investigations. We have looked at three previously:

- Culture + Non Compliance + Mechanical Failures = DC3 Accident TSB raise issues with the TC approach to regulation of a DC3 operator, concerned that “unsafe conditions went unidentified when the surveillance remained focused on systems”.

- HEMS Black Hole Accident: “Organisational, Regulatory and Oversight Deficiencies” The operator had insufficient resources to effectively manage safety say TSB (like this case with the warning sign of a high management turnover and difficulty producing acceptable CAPs and meeting the implementation time frames). The regulator had concerns but as TSB say: “when faced with an operator that is unable to address identified safety deficiencies, TC has difficulty adapting its approach to ensure that deficiencies are effectively identified and that they are addressed in a timely manner, or at all.”

- Performance Based Regulation and Detecting the Pathogens Devastating rail accidents in the US and Canada highlight the challenges for regulators introducing Safety Management System rules and/or PBR.

Following a 2016 TSB recommendation, the TSB has…

…acknowledged TC’s efforts to find the right balance between planned and reactive oversight activities, as well as in the use of the various types of oversight tools available. Although TC has implemented numerous improvements, it is too early to assess whether or not TC’s actions will adequately address the safety deficiency associated with this recommendation.

Safety Action Taken

TSB report that Air Georgian have taken the following safety actions (two continuing airworthiness and two maintenance training):

- In September 2016, a fleet campaign was carried out to address the greasing and bolt issue. Many bolts, including the pivot/stop bolts, were found to need replacement and servicing.

- As a result of this fleet campaign, Air Georgian advised Transport Canada that an additional inspection item has been added into the company’s maintenance tracking system, reducing the bolt inspection interval from 1200 hours to 600 hours.

- In January 2017, Air Georgian hired a manager for maintenance training.

- Human-factors training on distraction covers the need to track and document steps in the workflow. In August 2017, Air Georgian launched a communication and awareness campaign called “Flag It, Tag It and Snag It!”

The Canadian National Post newspaper reported that:

Air Georgian fired back at the safety agency itself, complaining that the investigator pre-judged the case, bullied some Georgian employees and was discriminatory toward workers whose first language was not English, according to a company memo obtained by the National Post.

[John] Lee [ the TSB’s Western regional manager] said the safety board reviewed the complaints thoroughly, but did not change any of its findings as a result.

UPDATE 22 October 2018: the TSB report on yet another incident at Air Georgian, this time involving B1900D, C-GZGA at Calgary International Airport, Alberta on 9 April 2018. This suffered a nose wheel failure:

Air Georgian B1900D C-GZGA 9 April 2018 (Credit: Calgary Airport Authority via TSB)

At 81.5 hours prior to the occurrence, the nose bearing set was serviced at the Air Georgian maintenance base at CYYC. The investigation learned that the MPM-AWR-017 form was signed off during this service, but the procedure used did not follow the instructions provided on the form. New grease was used to push out the old grease and no cleaning or detailed inspection of the bearing was carried out. The old grease was then inspected for contamination. The bearings were rotated to check for freedom of movement and then installed.

The investigation learned that although the company procedure reflects the manufacturer’s requirement, the aircraft maintenance engineer who performed the work on the occurrence aircraft adapted one of the elements of the procedure.

Air Georgian has taken the following actions in response

- The work card has been modified to provide clearer guidance and additional notes referencing the bearing-cleaning methodology.

- A general (all maintenance employees) Maintenance Technical Bulletin was published describing cleaning, inspection, and lubrication best practices. The bulletin was to be posted for 6 months and required that all maintenance employees sign off after having read it.

- The aircraft maintenance engineer who performed the work was coached on the proper procedure to follow.

Our Observations

TSB could have simply stopped their investigation after the lab analysis of the failed bolt, concluded that the bolt was inadequately lubricated and gone no further. Sadly, many investigations, even from large accident investigation agencies, rarely examine the circumstances in which the maintenance was done.

Furthermore the UK Civil Aviation Authority (CAA) report CAP1367: Aircraft Maintenance Incident Analysis, published in 2016 commented that the “industry’s commitment to error investigation has waned”. This is perhaps unsurprising when one large commercial provider of investigation training has been quoted recommending that only around 10-20% of reports actually need investigation!

Even when company investigations are initiated, many would focus on who should have greased the bolt last and gathered evidence to judge if they deserved some kind of disciplinary action. Ironically such an approach is often done in the name of a ‘ Just Culture‘ using ‘decision aids’ that are designed to determine culpability (from the Latin concept of fault or guilt, culpa). Sometimes this is semantically renamed ‘accountability’, but still unhelpfully focused exclusively on judging on the front line individual(s) and the level of reproach they should receive. One such tool is ominously marketed as “bridging the gap between the investigation and an organisation’s disciplinary processes”. We have previously discussed the corrosive misapplication of these as bureaucratic tools by managers to routinely ‘judge’…

…individuals not the system, with the potential to inadvertently reduce trust rather than enhance it. The circumstances that influenced an individual’s performance are seen as factors that mitigate culpability rather than systemic opportunities to improve. Inappropriate use of these mechanisms help normalise failure at the expense of collective improvement.

So we should be grateful that TSB did dig further in this case and look at the circumstances in which the maintenance was being performed and the systemic opportunities. Its noteworthy that a significant proportion of the extra insight appears to have come from a short visit to Air Georgian’s main base, in Toronto, from 30 January to 1 February 2017 for interviews and observation of maintenance. This leads to one of the opportunities discussed below.

Opportunities for Safety & Performance Improvement

If the TSB can gain insight by observing maintenance standards and practices after an accident, can organisations do something similar, without waiting for an accident, to identify improvement opportunities? We think the answer is yes.

Aerossurance worked with the Flight Safety Foundation (FSF) to create a Maintenance Observation Program (MOP) requirement for their contractible BARSOHO offshore helicopter Safety Performance Requirements to help learning about routine maintenance and then to initiate safety improvements:

Applying the MOP principles in this case could have (for example) helped:

- identify the variability in maintenance standards and practices that the TSB highlight.

- identify that senior engineers did have a clear understanding of what good looked like for greasing but that this was not something currently defined in procedures or covered in formal training.

- stimulate improvements in the grease guns arrangements by identifying the informal work-around in place.

- compare and contrast practices and resources at different lines stations.

- capture issues being discussed but not recorded as ASRs.

The very different process, that of competence assessment, both before authorising maintenance personnel and as a routine activity, is also vitally important. Whereas as MOP is systemic focused, competence assessment is person-centric and provides assurance that personnel have been equipped with the skills, knowledge and understanding necessary for their work and that they are able to demonstrate they can successfully apply these. Competence assessment however needs clear assessment standards for both technical and non-technical skills and needs to conducted systematically in a standardised way.

An excellent initiative Human Hazard Analysis (HHA) is described in Designing out human error

HeliOffshore, the global safety-focused organisation for the offshore helicopter industry, is exploring a fresh approach to reducing safety risk from aircraft maintenance. Recent trials with Airbus Helicopters and HeliOne show that this new direction has promise. The approach is based on an analysis of the aircraft design to identify where ‘error proofing’ features or other mitigations are most needed to support the maintenance engineer during critical maintenance tasks.

Other manufacturers and MROs are expanding the use of HHA during 2018.

Aerossurance and its partners can provide proven, practical expertise to successfully implement a MOP, introduce an effective competence assessment process or analyse the hazards of maintenance tasks. We can also help you ensure your learning and development programme is effective and that audits are rigorous & improvement activities robust and timely. We can also help you develop the leadership and supervisors skills within your organisation.

Other Safety Resources

Aerossurance has previously written on these associated topics:

- Airworthiness Matters: Next Generation Maintenance Human Factors Over the last 10-15 years, much attention has been focused on maintenance human factors training and reporting & investigating errors. While we could concentrate on simply doing more of these and certainly can find ways to do these things better, perhaps the next generation approach needs to include a much wider range of activities.

- Aircraft Maintenance: Going for Gold? Should we start treating maintenance personnel more like athletes who need to achieve peak performance every day?

- The Power of Safety Leadership

- Leadership and Trust

- Safety Performance Listening and Learning – AEROSPACE March 2017

- How To Develop Your Organisation’s Safety Culture

- James Reason’s 12 Principles of Error Management

- Back to the Future: Error Management

- B747 Landing Gear Failure Due to Omission of Rig Pin During Maintenance

- When Down Is Up: 747 Actuator Installation Incident

- Lost in Translation: Misrigged Main Landing Gear

- Maintenance Human Factors in Finnish F406 Landing Gear Collapse Safety investigators discuss the associated maintenance human factors and inadequacies in the type’s maintenance instructions.

- Hoist Assembly Errors: SAR Personnel Dropped Into Sea Taiwanese investigators determined that the hoist hook had been inappropriately assembled during maintenance 2 days earlier, raising questions on the technical knowledge of hoist maintenance.

- UPDATE 8 July 2018: Distracted B1900C Wheels Up Landing in the Bahamas

- UPDATE 22 July 2018: Fire After O-Ring Nipped on Installation

- UPDATE 25 August 2018: Crossed Cables: Colgan Air B1900D N240CJ Maintenance Error On 26 August 2003 a B1900D crashed on take off after errors during flying control maintenance. We look at the maintenance human factor safety lessons from this and another B1900 accident that year.

- UPDATE 3 November 2018: A Lufthansa MD-11F Nose Wheel Detached after Maintenance Error

- UPDATE 13 November 2018: Inadequate Maintenance, An Engine Failure and Mishandling: Crash of a USAF WC-130H: investigators discuss a strong cultural overtone in this accident that killed 9.

- UPDATE 18 December 2018: USAF Engine Shop in “Disarray” with a “Method of the Madness”: F-16CM Engine Fire

- UPDATE 27 December 2018: Inadequate Maintenance at a USAF Depot Featured in Fatal USMC KC-130T Accident

- UPDATE 9 February 2019: Meeting Your Waterloo: Competence Assessment and Remembering the Lessons of Past Accidents: No one was injured in this low speed derailment in London after signal maintenance errors but investigators expressed concern that the lessons about maintenance errors from the fatal triple collision at Clapham in 1988 may have been forgotten.

- UPDATE 14 February 2019: AS350B2 Accident After Vibration from Unrecorded Maintenance

- UPDATE 23 March 2019: Maintenance Misdiagnosis Precursor to Tail Rotor Control Failure

- UPDATE 30 March 2019: Contaminated Oxygen on ‘Air Force One’ Poor standards at a Boeing maintenance facility resulted in contamination of two oxygen systems on a USAF Presidential VC-25 (B747).

- UPDATE 1 April 2019: Tree Top Autorotation for B206L1 After Loose Fuel Line B-Nut Leaks

- UPDATE 19 April 2019: FAA Rules Applied: So Misrigged Flying Controls Undetected in an accident to a Cessna 172 in Bermuda.

- UPDATE 24 May 2019: Loose Engine B-Nut Triggers Fatal Forced Landing

- UPDATE 6 October 2019: Glider Controls Fail After Non Compliant Maintenance Embodying an AD

- UPDATE 12 October 2019: ATR72 VH-FVR Missed Damage: Maintenance Lessons Unclear communications, shift handover & roles and responsibilities, complacency about fatigue and failure to use access equipment all feature in this serious incident.

- UPDATE 30 October 2019: ‘Crazy’ KC-10 Boom Loss: Informal Maintenance Shift Handovers and Skipped Tasks

- UPDATE 6 December 2019: Dash 8 Q400 Return to Base After Pitot System Contaminated By Unapproved Test Kit Lubricant

- UPDATE 7 December 2019: Luftwaffe VVIP Global 5000 Written Off After Flying Control Assembly Error

- UPDATE 8 April 2020: NTSB Confirms United Airlines Maintenance Error After 12 Years

- UPDATE 23 April 2020: Poor Painting Prevents Proper Performance: Shorts Sherpa NLG Collapse

- UPDATE 9 May 2020: Ungreased Japanese AS332L Tail Rotor Fatally Failed

- UPDATE 3 June 2020: Beechcraft 1900C Landing Gear Collapse at San Antonio, TX

- UPDATE 10 June 2020: B767 Fire and Uncommanded Evacuation After Lockwire Omitted

- UPDATE 16 June 2020: CRJ-200 Landing Incident Highlighted US Maintenance Competency Inadequacies

- UPDATE 12 October 2020: Frozen Dash 8-100 Landing Gear After ‘Improper Maintenance Practices’ Say NTSB

- UPDATE 27 December 2020: Fire-Fighting AS350 Hydraulics Accident: Dormant Miswiring

- UPDATE 15 March 2021: ATR 72 Rudder Travel Limitation Unit Incident: Latent Potential for Misassembly Meets Commercial Pressure

- UPDATE 7 August 2022: Fuel Tube Installation Trouble

- UPDATE 20 August 2022: How One Missing Washer Burnt Out a Boeing 737

- UPDATE 29 July 2023: Missing Cotter Pin Causes Fatal S-61N Accident

Aerossurance’s Andy Evans was recently interviewed about safety investigations, the perils of WYLFIWYF (What-You-Look-For-Is-What-You-Find) and some other ‘stuff’ by with Sam Lee of Integra Aerospace:

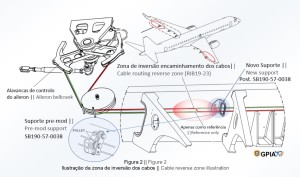

UPDATE 31 May 2019: The Portuguese accident investigation agency, GPIAAF, issued a safety investigation update on a serious in-flight loss of control incident involving Air Astana Embraer ERJ-190 P4-KCJ that occurred on 11 November 2018. The aircraft was landed safely after considerable difficulty, so much so the crew had debated ditching offshore. GPIAAF conformed that incorrect ailerons control cable system installation had occurred in both wings during a maintenance check conducted in Portugal.

GPIAFF note that: “By introducing the modification iaw Service Bulletin 190-57-0038 during the maintenance activities, there was no longer the cable routing and separation around rib 21, making it harder to understand the maintenance instructions, with recognized opportunities for improvement in the maintenance actions interpretation”. They also comment that: “The message “FLT CTRL NO DISPATCH” was generated during the maintenance activities, which in turn originated additional troubleshooting activities by the maintenance service provider, supported by the aircraft manufacturer. These activities, which lasted for 11 days, did not identify the ailerons’ cables reversal, nor was this correlated to the “FLT CTRL NO DISPATCH” message.”

GPIAFF comment “deviations to the internal procedures” occurred within the maintenance organisation that “led to the error not being detected in the various safety barriers designed” in the process. They also note that the error ” was not identified in the aircraft operational checks (flight controls check) by the operator’s crew.”

UPDATE 1 June 2019: Our analysis: ERJ-190 Flying Control Rigging Error

Aerossurance is pleased to be both sponsoring and presenting at a Royal Aeronautical Society (RAeS) Human Factors Group: Engineering seminar Maintenance Error: Are we learning? to be held on 9 May 2019 at Cranfield University.

UPDATE 24 October 2022: The Royal Aeronautical Society (RAeS) has launched the Development of a Strategy to Enhance Human-Centred Design for Maintenance. Aerossurance‘s Andy Evans is pleased to have had the chance to participate in this initiative.

Recent Comments