How One Missing Washer Burnt Out a B737-800 (China Airlines B-18616)

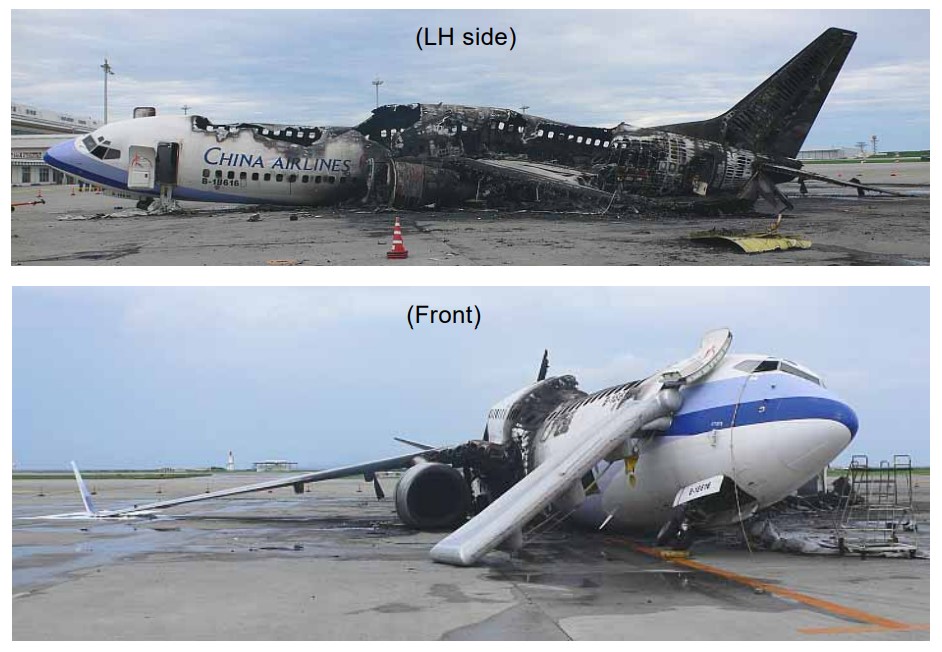

On 20 August 2007, shortly after parking on stand at Okinawa-Naha Airport, China Airlines Boeing 737-809 B-18616 suffered a massive fuel leak which ignited. After all 165 persons on board had evacuated, a large explosion occurred in the centre of the aircraft, which burned out completely. Investigators determined this occurred because one washer had fallen off before a nut was attached.

The Japan Transport Safety Board (JTSB) safety investigation report explains that it is “highly probable” that:

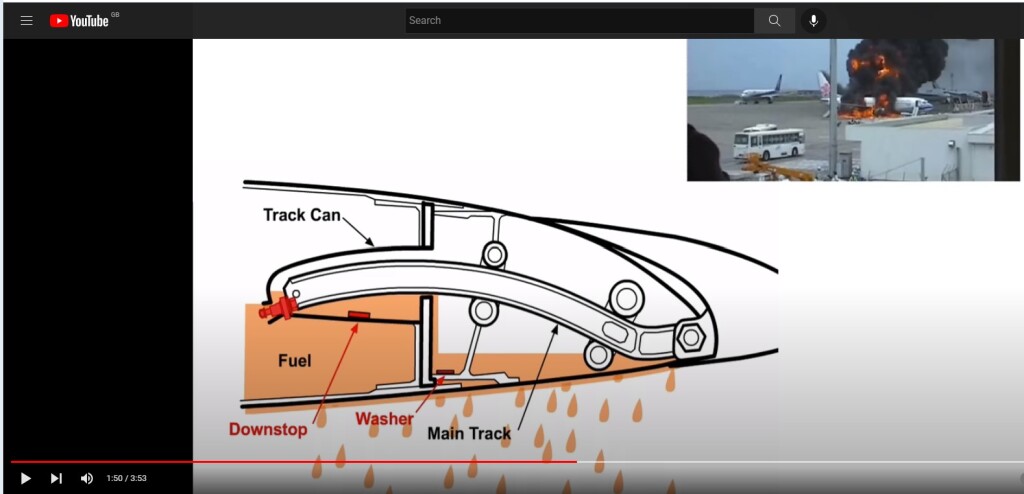

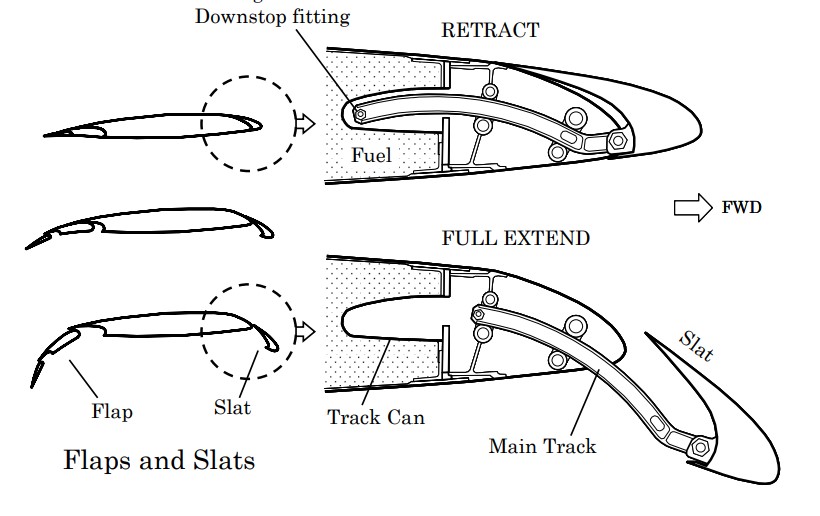

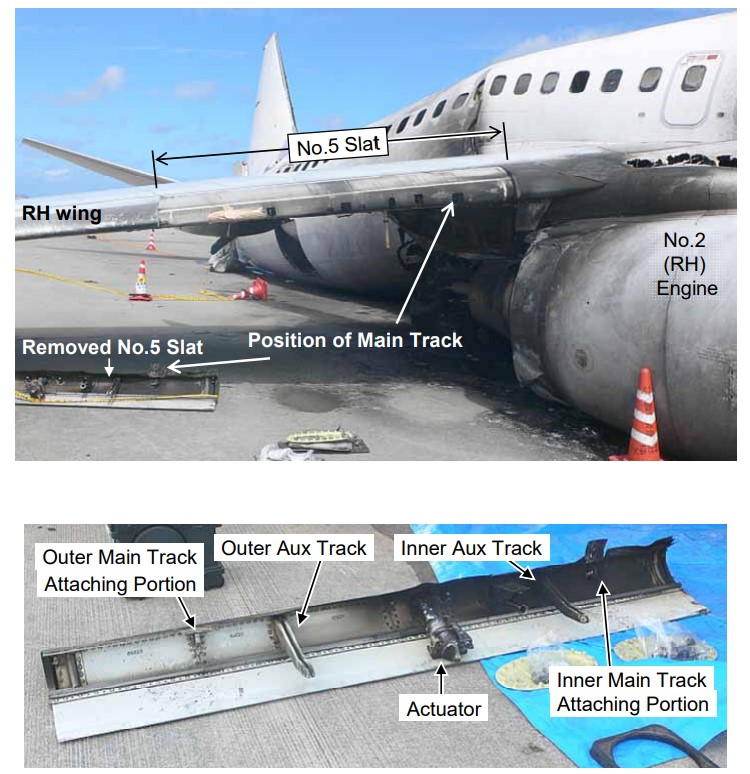

When the Aircraft retracted the slats after landing at Naha Airport, the track can that housed the inboard main track of the No. 5 slat on the right wing was punctured, creating a hole.

Fuel leaked out through the hole, reaching the outside of the wing.

A fire started when the leaked fuel came into contact with high-temperature areas on the right engine after the Aircraft stopped in its assigned spot, and the Aircraft burned out after several explosions.

The reason the slat track was punctured was…

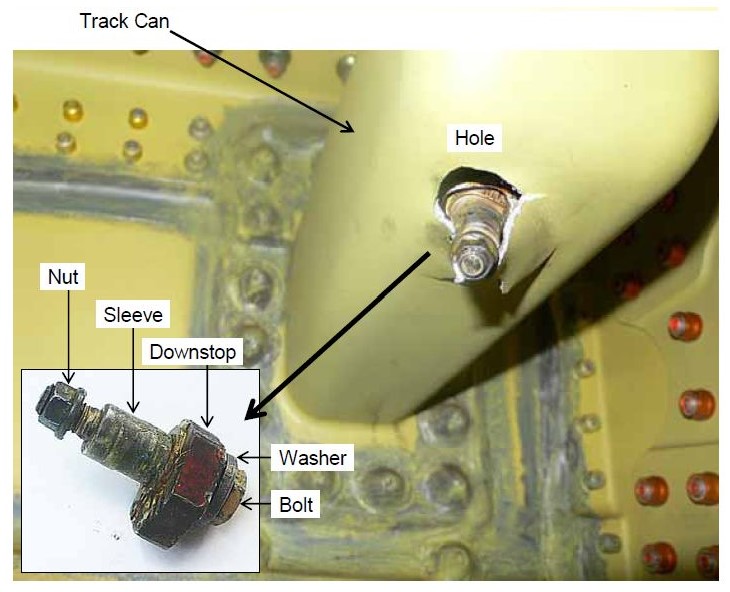

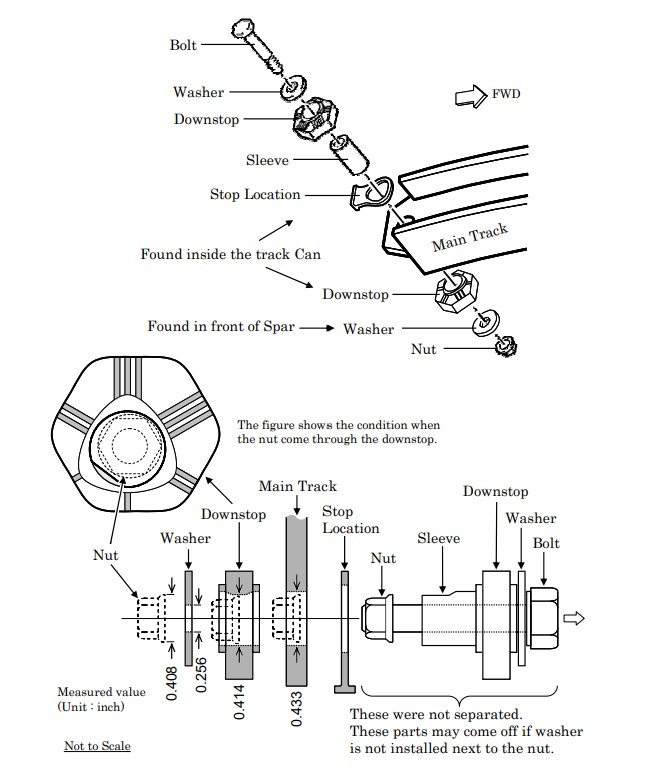

…that the downstop assembly having detached from the aft end of the above-mentioned inboard main track fell off into the track can, and when the slat was retracted, the assembly was pressed by the track against the track can and punctured it.

The downstop assembly detached because it was…

…highly probable that during the maintenance…on the downstop assembly about 1.5 months prior…the washer on the nut side of the assembly fell off, following which the downstop on the nut side of the assembly fell off and then the downstop assembly eventually fell off the track.

It is considered highly probable that a factor contributing to the detachment…was the design of the downstop assembly, which was unable to prevent the assembly from falling off if the washer is not installed.

Unusually the nut was smaller diameter than the hole the bolt passed through.

Despite the fact that the nut was in a location difficult to access during the maintenance works, neither Boeing nor China Airlines had paid sufficient attention to this when preparing the Service Letter and Engineering Order job card, respectively. Also, neither the maintenance operator nor the job supervisor reported the difficulty of the job…

There is an excellent short video that illustrates this accident:

Flight Safety Australia: It was almost all over: the destruction of China Airlines flight 120

Safety Resources

You may also find these Aerossurance articles of interest:

- B1900D Emergency Landing: Maintenance Standards & Practices

- Fuel Tube Installation Trouble

- Fire After O-Ring Nipped on Installation

- Uncontained CFM56-7 Failures: Southwest B737-700s

- Uncontained PW1524G Failure During CS100 Certification Testing

- Machining Defect Cause of V2500 Failure

- B787 GEnx Fan Shaft Failure

- USAF Engine Shop in “Disarray” with a “Method of the Madness”: F-16CM Engine Fire

- Bell 407 Rolls-Royce 250-C47B Uncontained Engine Failure after Bearing Failure

- NTSB Confirms United Airlines Maintenance Error After 12 Years

- Machining Defect Cause of V2500 Failure

- ‘Aggressive’ Grit Blasting Maintenance Leads to Engine Fire & IFSD

- Micro FOD: Cessna 208B Grand Caravan Engine Failure & Forced Landing

- Cessna 208 Forced Landing: Engine Failure Due To Re-Assembly Error

- NDI Process Failures Preceded B777 PW4077 Engine FBO

- King Air 100 Uncontained TPE331-6 Failure – Inappropriate Repair Scheme

- B767 Fire and Uncommanded Evacuation After Lockwire Omitted

- Engine Life Limit Exceedance Caused Logging Helicopter Fatal Accident

- Engine Failure after Inadvertently Being Put Back into Service Incomplete

- Coking Causes Power Loss: Australian AS350BA

- Schiebel Camcopter S-100 Engine Failure Results in Baltic Crash

- Maintenance Misdiagnosis Precursor to Tail Rotor Control Failure

- Contaminated Oxygen on ‘Air Force One’

- B747 Landing Gear Failure Due to Omission of Rig Pin During Maintenance

- When Down Is Up: 747 Actuator Installation Incident

- Lost in Translation: Misrigged Main Landing Gear

- Maintenance Human Factors in Finnish F406 Landing Gear Collapse

- Hoist Assembly Errors: SAR Personnel Dropped Into Sea

- ERJ-190 Flying Control Rigging Error

- ATR 72 Rudder Travel Limitation Unit Incident: Latent Potential for Misassembly Meets Commercial Pressure

- UPDATE 29 July 2023: Missing Cotter Pin Causes Fatal S-61N Accident

Aerossurance’s Andy Evans was recently interviewed about safety investigations, the perils of WYLFIWYF (What-You-Look-For-Is-What-You-Find) and some other ‘stuff’ by with Sam Lee of Integra Aerospace:

Aerossurance has previously written on these associated topics:

- Airworthiness Matters: Next Generation Maintenance Human Factors Over the last 10-15 years, much attention has been focused on maintenance human factors training and reporting & investigating errors. While we could concentrate on simply doing more of these and certainly can find ways to do these things better, perhaps the next generation approach needs to include a much wider range of activities.

- Aircraft Maintenance: Going for Gold? Should we start treating maintenance personnel more like athletes who need to achieve peak performance every day?

- James Reason’s 12 Principles of Error Management

- Back to the Future: Error Management

Aerossurance worked with the Flight Safety Foundation (FSF) to create a Maintenance Observation Program (MOP) requirement for their contractible BARSOHO offshore helicopter Safety Performance Requirements to help learning about routine maintenance and then to initiate safety improvements.

Recent Comments