B767 Fire and Uncommanded Evacuation After Lockwire Omitted (Dynamic B767-200 N251MY at Fort Lauderdale, FL)

On 29 October 2015 Dynamic International Airways Boeing 767-200ER N251MY, powered by Pratt & Whitney JT9D-7R4E4 engines, experienced a fuel leak and fire on the ground at the Fort Lauderdale-Hollywood International Airport, Florida (FLL). One of the 100 passengers received serious injuries from jet blast, 21 minor injuries and the aircraft sustained substantial damage.

The Accident

The US National Transportation Safety Board (NTSB) explain in their safety investigation report (issued 8 June 2020):

A significant fuel leak and subsequent fire occurred in the left engine strut and nacelle during taxi…

The flight crew promptly shut down the left engine using the fire handle, and requested fire equipment.

The “A” flight attendant activated the emergency signaling system…to notify the flight deck and other crewmembers of an emergency. The chime was audible in the CVR recording, but the flight crew did not respond via interphone. There was no indication on the CVR of an evacuation checklist or communication between the cabin and flight deck.

As the airplane stopped on the taxiway, passengers saw the fire and insisted that the cabin crew initiate an evacuation. One passenger opened an overwing exit on his own, and the slide did not deploy. The cabin crew initiated the evacuation without coordination with the flight crew.

After the evacuation had already begun, the flight crew advised over the PA to evacuate out the right side of the airplane.

The flight crew did not immediately shut down the right engine and an evacuating passenger ran behind the engine [about 11 seconds after the aircraft was stopped] and was blown to the pavement resulting in serious injuries. The lack of coordination between the flight crew and cabin crew resulted in the evacuation initiating while the right engine was still running.

About 35 seconds later, the number 2 engine was shut down. About 54 seconds after the airplane stopped, an airport authority official arrived, and repositioned the 2R slide. About one minute later, airport firefighting vehicles arrived and began extinguishing the fire.

https://youtu.be/9K3HDfhgdXo

The Safety Investigation

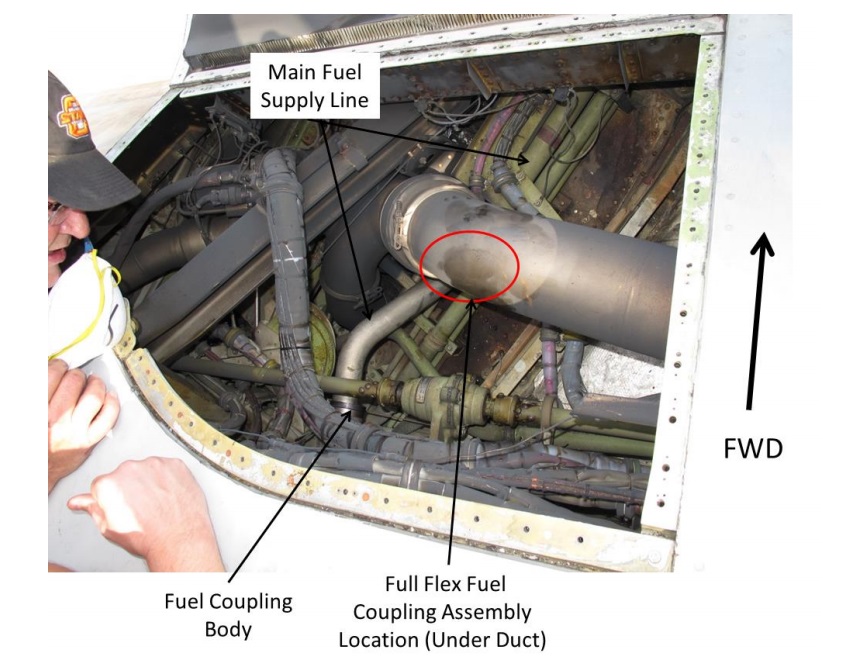

During a visual examination of the left engine and strut, a fuel coupling assembly was found separated with the coupling body pushed aft on a main fuel supply line.

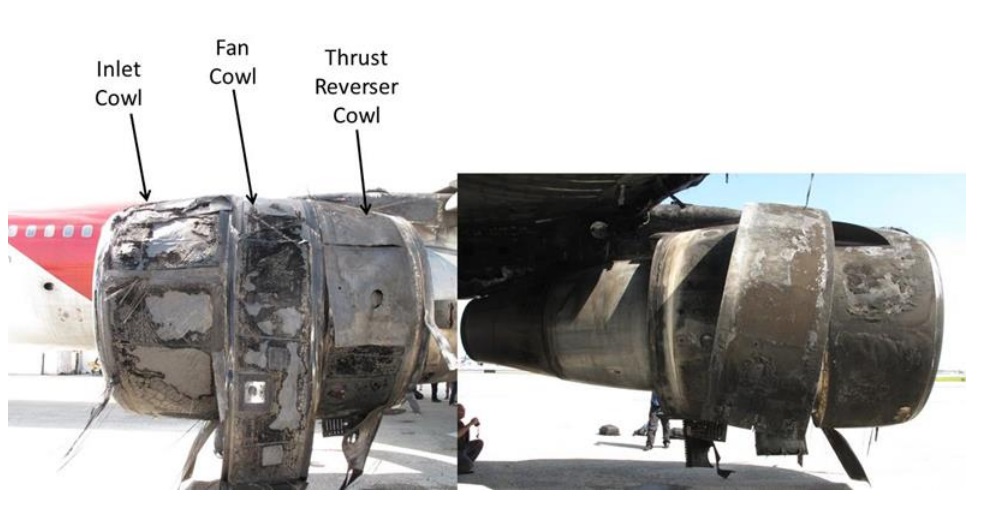

There were indications of fuel leakage at the flange interface of the fuel supply lines where the coupling had separated including discoloration from fluid pooling in the strut compartments and streaking down the left engine cowling.

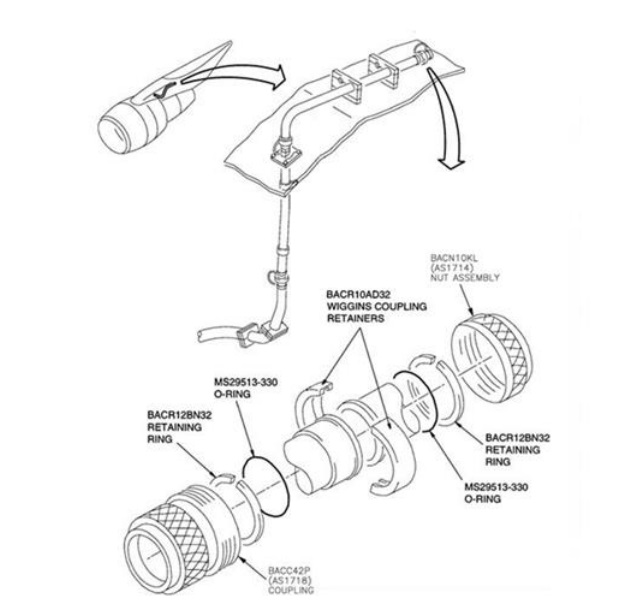

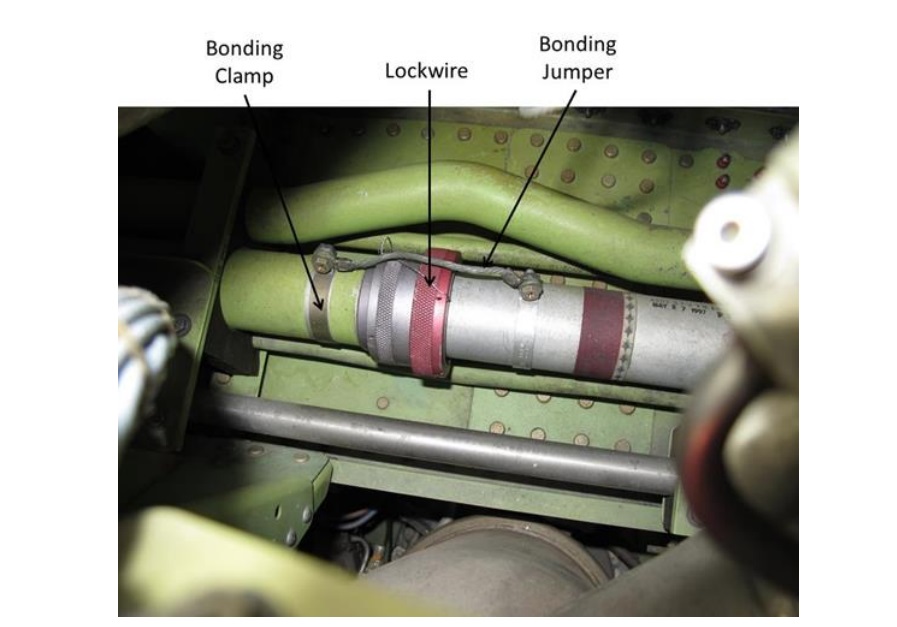

There was no safety lockwire present on either the body or nut side of the fuel coupling as required in the Boeing aircraft maintenance manual (AMM), and no broken lockwire was recovered in the surrounding strut compartments.

A material examination of the fuel supply lines and coupling components verified that the parts met dimensional drawing specifications and were free of defects or damage that would have affected normal operation.

In 2012, the airplane was placed in storage until 2015 when it was taken out of storage and prepared for leasing to Dynamic.

A Boeing Service Letter recommending replacement of fuel line flexible coupling (Wiggins coupling) retainer components was issued on March 14, 2000. Maintenance records of the accident airplane indicate the last time this service was performed was by Kalitta Air LLC on October 12, 2012 just prior to going into storage in Arizona.

Additionally, the strut fuel feed line components, while not specifically called out, could be looked at during a Zonal Inspection (General Visual) of the area during a 1C interval. The last Zonal Inspection was accomplished May 5, 2015, by Kalitta Air LLC.

About 240 flight hours were logged between the aircraft returning to service and the accident.

The right over-wing exit was opened by a passenger, but the slide did not deploy. Testing at the manufacturer revealed a misalignment in the pull-force increase mechanism created a binding in the firing cable.

Safety Action

Dynamic International Airways issued a Fleet Campaign Directive to inspect the remainder of their fleet. No other instances of improper installation were found.

NTSB Probable Cause

The separation of the flexible fuel line coupling and subsequent fuel leak due to the failure of maintenance personnel to install the required safety lockwire. Contributing to the severity of the accident was the initiation of the evacuation before the right engine was shut down which led to the passenger’s injury.

Safety Resources

We have previously written about another premature evacuation Premature A319 Evacuation With Engines Running and a significantly delayed evacuation: Delta MD-88 Accident at La Guardia 5 March 2015

Also see the RAeS Specialist Paper: Emergency Evacuation of Commercial Passenger Plane UPDATE 7 July 2020: Updated RAeS Passenger Evacuation Paper now available

UPDATE 2 September 2020: Transportation Safety Board of Canada (TSB) releases its investigation into the 10 May 2019 collision between a fuel truck and Jazz DHC-8-300 C-FJXZ at Toronto/Lester B. Pearson International Airport, Ontario.

Following the collision, because the fuel tanker was not visible from the flight deck or from the flight attendant’s position in the cabin, both the flight crew and the flight attendant needed a few moments to assess what had occurred and decide on the best course of action regarding a rapid deplanement or evacuation. In addition, the flight crew required some time to shut down the engines and allow for the propellers to stop turning before passengers could safely exit the aircraft.

After the flight crew shut down the engines, the captain called the flight attendant via the interphone and instructed her to initiate a rapid deplanement. The flight attendant answered the call, but had difficulty hearing the captain over the noise of the passengers. At that time, the smell of fuel and/or engine exhaust reached the cockpit, and the captain gave the order over the passenger address system to evacuate.

However, nobody on the aircraft reported hearing the captain’s evacuation order, possibly due to the passenger address system being damaged by the impact, and/or passenger noise in the cabin. Due in part to increasing pressure from the passengers, including verbal threats from one of them, the flight attendant opened the main door (exit L1) slowly. When the flight attendant smelled fuel, she decided to initiate an emergency evacuation.

The hazards that existed were all closer to the rear of the aircraft, which made the use of the front exits an appropriate choice; however, the decision to block the right-hand front emergency exit door (exit R1) because of the risk of injury to passengers increased the evacuation time.

Some passengers seated along the left side of the aircraft had seen the oncoming fuel tanker and were aware that a collision was imminent. Approximately 30 seconds after impact, while the propellers were still turning, some passengers near the rear of the aircraft decided to act on their own by opening the rear emergency window exits without waiting for directions from the flight crew or flight attendant.

When the rear emergency window exits were opened, the smell of exhaust and noise of the engines entered the cabin and may have been interpreted by the passengers as a significant risk of fire and/or explosion, which resulted in an increase in panic.

Also see:

- James Reason’s 12 Principles of Error Management

- Back to the Future: Error Management

- Airworthiness Matters: Next Generation Maintenance Human Factors

- B1900D Emergency Landing: Maintenance Standards & Practices

- Fire After O-Ring Nipped on Installation

- What Leaks in Vegas Stays in Vegas – A320 Hydraulic Failure

- A319 Double Cowling Loss and Fire – AAIB Report

- CFM56-7 HPC Titanium Fire Due to VSV Maintenance Assembly Error (United Boeing 737-924)

- Emirates B777 Runway Impact During Attempted Go-Around, 3 August 2016, Dubai: Accident Report

- Uncontained CF6-80 Failure: American B767-300 28 Oct 2016

- Incomplete Maintenance Leads to Fatal Collective Control Loss on B407

- UPDATE 16 June 2020: CRJ-200 Landing Incident Highlighted US Maintenance Competency Inadequacies

- UPDATE 28 June 2020: Maintenance Issues in Fire-Fighting S-61A Accident

- UPDATE 30 June 2020: 17 Year Old FOD and a TA-4K Ejection

- UPDATE 22 July 2020: NDI Process Failures Preceded B777 PW4077 Engine FBO

- UPDATE 22 September 2021: Brake Failure Causes PA-31 Runway Excursion During Taxi

- UPDATE 7 August 2022: Fuel Tube Installation Trouble

UPDATE 7 January 2021: Airbus publishes Attention Crew at Stations with advice on evacuation best practice.

Plus our review of The Field Guide to Understanding Human Error by Sidney Dekker presented to the Royal Aeronautical Society (RAeS): The Field Guide to Understanding Human Error – A Review

Aerossurance worked with the Flight Safety Foundation (FSF) to create a Maintenance Observation Program (MOP) requirement for their contractible BARSOHO offshore helicopter Safety Performance Requirements to help learning about routine maintenance and then to initiate safety improvements:

Aerossurance can provide practice guidance and specialist support to successfully implement a MOP.

Aerossurance has extensive air safety, operations, SAR, airworthiness, human factors, aviation regulation and safety analysis experience. For practical aviation advice you can trust, contact us at: enquiries@aerossurance.com

Follow us on LinkedIn and on Twitter @Aerossurance for our latest updates.

Recent Comments