Brake Failure Causes PA-31 Runway Excursion During Taxi (PR-RCS)

On 22 February 2019 privately owned Piper PA-31-325 Navajo PR-RCS suffered a runway excursion when taxiing to the end of the runway at Londrina-14 Bis Airport in Brazil for what was to be its first flight in 7 months. The aircraft suffered substantial damage. The pilot, the sole occupant, as unharmed.

The Accident

The Brazilian accident investigation agency CENIPA issued their safety investigation report in Portuguese (only) on 21 July 2021. They explain that while some inspections and engine runs had been conducted prior to the return to service, there was no evidence in the maintenance records of any storage checks having been carried out. When the aircraft taxied out for take off…

…about 300 meters from the threshold and with the aircraft at reduced speed, braking was started, which occurred normally up to 150 meters before the threshold, when the right brake began to show abnormalities. When trying to stop the aircraft, the right brake failed and the aircraft left the runway, falling into a ravine.

CENIPA Safety Investigation

In order to identify possible abnormalities in the braking system, some functional tests were carried out. Repeated movements were applied to the pedals of the pilot and co-pilot brakes of the right and left wheels of the main landing gear in order to pressurize the system and then a continuous force was applied. Seconds later, it was observed that the copilot’s right pedal began to give way, remaining a few centimeters in front of the left one ,

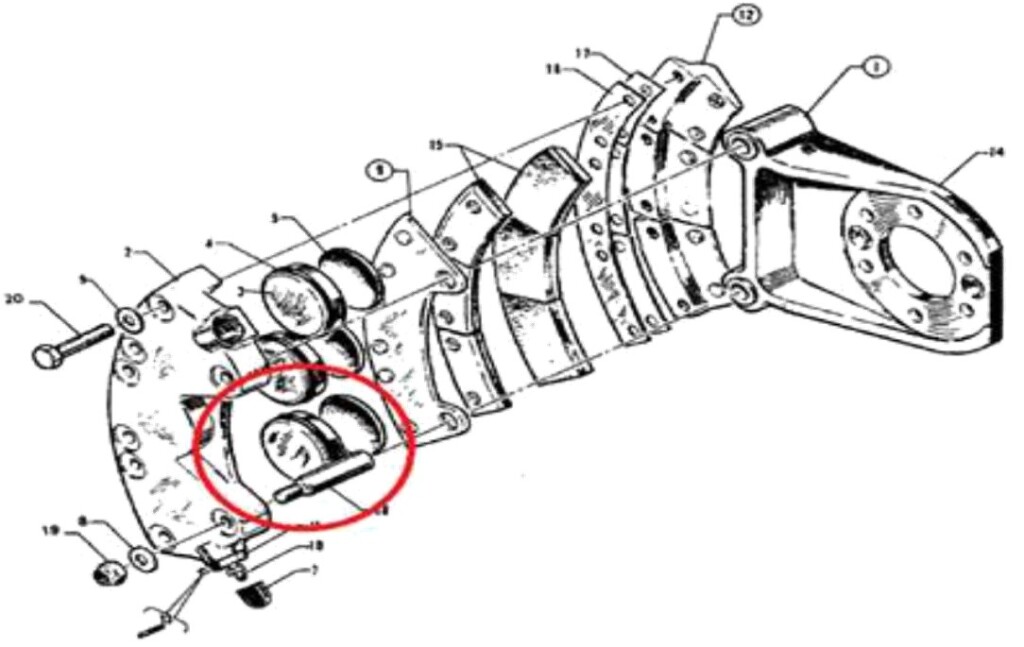

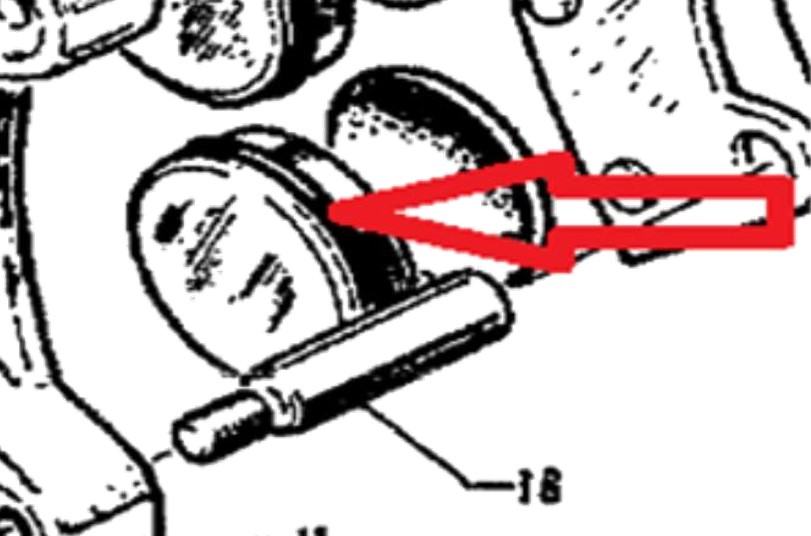

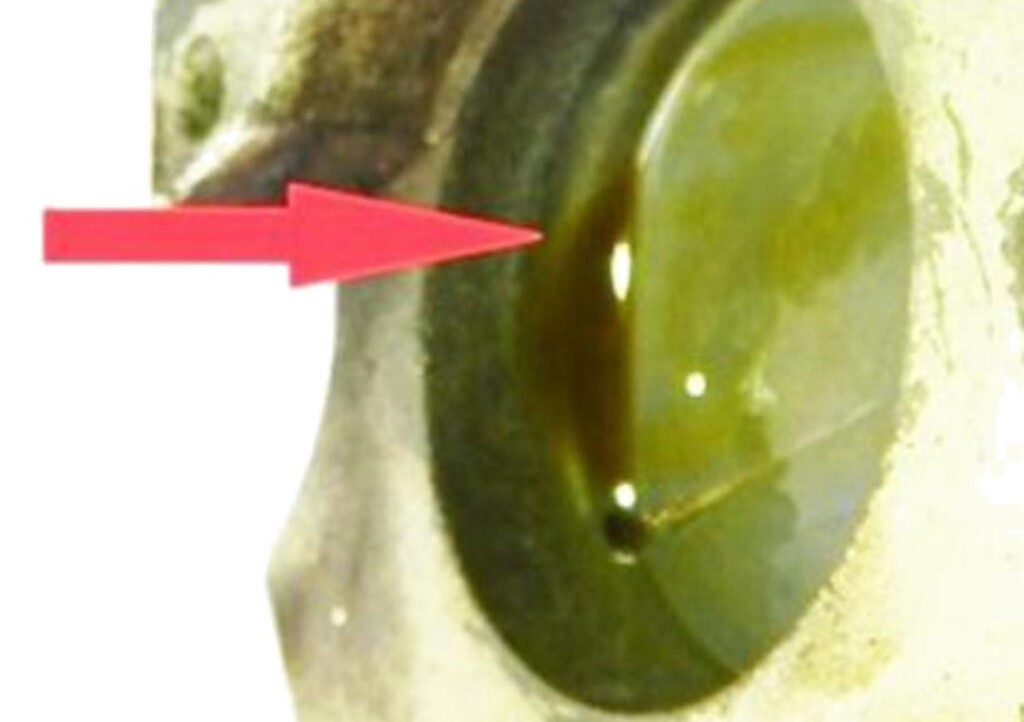

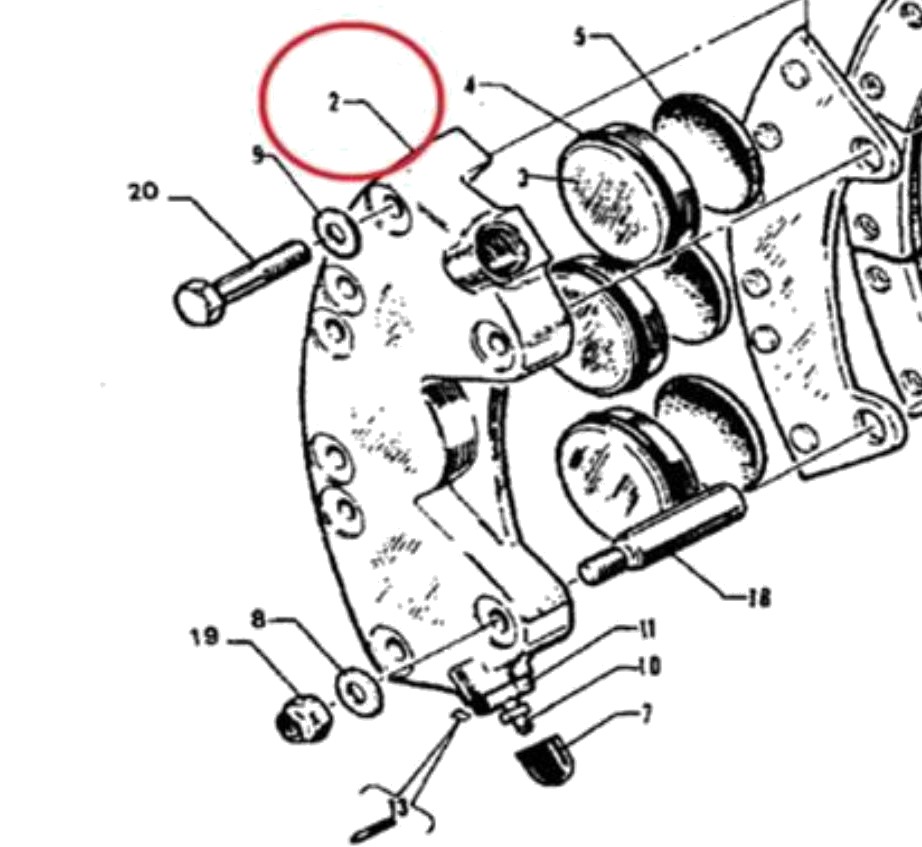

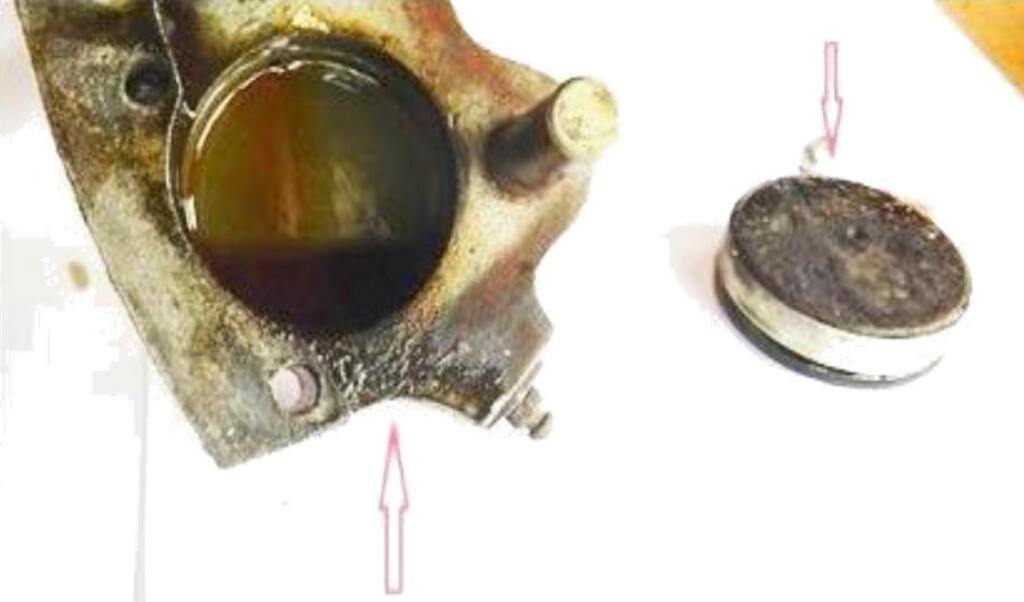

As a result, a visual inspection was carried out on the aircraft’s brake system, in order to detect possible brake fluid leaks, when a leak was found in the set of brakes on the right wheel. Thus, the right brake assembly brake piston assembly, PN 551 719 (Piper Parts Catalog, PA-31-325, Section IV, page 1J8, fig. 41, item 1) was removed [and] it was found that there was a leak in the lower piston, PN 755 838, piston (Piper Parts Catalog, PA-31-325, Section IV, page 1J8, fig. 41, item 3).

The set of right brake pistons, brake assembly, PN 551 719, was removed and the pressure line to that set was plugged.

Then, the brake activation test was performed. Again, repeated movements were performed on the pilot and co-pilot pedals of the right and left wheels of the main landing gear, followed by a continuous force. However, both the pilot and co-pilot pedals remained in the same position, thus eliminating the possibility of another system leak.

Then, the set of right brake pistons, brake assembly, PN 551 719, was disassembled, when it was found that there were signs of wear (grooves) in the gasket PN 755 838, O ring (Piper Parts Catalog, PA-31-325 , Section IV, page 1J8 fig. 41, item 4).

Wear was found on the inside of the lower piston housing, PN 753 968, cylinder – brake (Piper Parts Catalog, PA-31-325, Section IV, page 1J8, fig. 41, item 2).

There was dirt accumulation on the oil at the bottom of the right brake piston assembly, brake assembly, PN 551 719 (Piper Parts Catalog, PA-31-325, Section IV, page 1J8, fig. 41, item 1).

CENIPA Conclusions

CENIPA determined that “the wear of the gasket and piston housing, and the accumulation of dirt and oil in the housing and lower piston of the right brake assembly” all “contributed to the leakage of fluid in the brake assembly of the wheel of the right landing gear”. They comment that “as the aircraft had only seven hours of flight after [its last] inspection, it is possible that the failure to actuate the right brake was due to inadequate preventive maintenance services performed on the aircraft during the said maintenance.”

Our Observation

While this event occurred pre-COVID it’s a good reminder on the importance of storage and post-storage checks.

Safety Resources

You may also find these Aerossurance articles of interest:

- Schweizer 269C Destroyed after Missed AD

- Runaway Dash 8 Q400 at Aberdeen after Miscommunication Over Chocks

- King Air 100 Uncontained TPE331-6 Failure – Inappropriate Repair Scheme

- Helicopter Throttle Bracket Left Unsecured After Maintenance

- Latent Engine Defect Downs R44: NR Dropped to Zero During Autorotation

- R44 Force Lands After Improper Repair

- Robinson R44 Power Loss: Excessive Lubricant

- Helicopter Engine Unapproved Repair Leads to Forced Landing Damage

- Maintenance Misdiagnosis Precursor to Tail Rotor Control Failure

- Inappropriate Autorotation Training: Police AS350

- Tree Top Autorotation for B206L1 After Loose Fuel Line B-Nut Leaks

- Fatal R44 Loss of Control Accident: Overweight and Out of Balance

- FAA Rules Applied: So Misrigged Flying Controls Undetected

- NDI Process Failures Preceded B777 PW4077 Engine FBO

- Japanese Jetstar Boeing 787 GEnx-1B Engine Biocide Serious Incident

- CFM56-7 HPC Titanium Fire Due to VSV Maintenance Assembly Error (United Boeing 737-924)

- Uncontained CF6-80 Failure: American B767-300 28 Oct 2016

- USAF Engine Shop in “Disarray” with a “Method of the Madness”: F-16CM Engine Fire

- Inadequate Maintenance, An Engine Failure and Mishandling: Crash of a USAF WC-130H

- Engine Failure after Inadvertently Being Put Back into Service Incomplete

- NTSB Confirms United Airlines Maintenance Error After 12 Years

- Fire After O-Ring Nipped on Installation

- 17 Year Old FOD and a TA-4K Ejection

- Machining Defect Cause of V2500 Failure

- ‘Aggressive’ Grit Blasting Maintenance Leads to Engine Fire & IFSD

- Micro FOD: Cessna 208B Grand Caravan Engine Failure & Forced Landing

- Cessna 208 Forced Landing: Engine Failure Due To Re-Assembly Error

- B767 Fire and Uncommanded Evacuation After Lockwire Omitted

- Forced Landing after CAMO Underestimated Operation in Dusty Environments

And

Aerossurance‘s Andy Evans will be running two training sessions at European Rotors in November 2021. One will be on safety leadership and the other on how to procure and assure aviation services. He discussed these in a recent European Rotors Digital Series interview:

Recent Comments