Runaway Dash 8 Q400 at Aberdeen after Miscommunication Over Chocks: Collision of G-JECK into EMB-145EP G-SAJS

On 16 June 2020, during pre-departure preparation at Aberdeen Airport, former Flybe Bombardier Dash 8 Q400 G-JECK, owned by Nordic Aviation Capital, ran away while parked without chocks and struck Loganair Embraer ERJ145 G-SASJ.

Former Flybe Bombardier Dash 8 Q400 G-JECK after a Runaway Ground Collision with Parked Loganair ERJ145 G-SASJ at Aberdeen Airport (Credit: AAIB)

The Incident

The UK Air Accidents Investigation Branch (AAIB) explain in their safety investigation report (issued 8 October 2020 with creditworthy alacrity) that G-JECK had been stored at Aberdeen Airport since March 2020 when Flybe had ceasing trading.

On 16 June 2020, the aircraft was to be flown empty to Weeze Airport, Germany where it was to be placed back into storage. An organisation had been contracted by the aircraft owner to operate the aircraft for the ferry flight. This organisation provided the pilots, with ground handling services sub‑contracted to another company based at Aberdeen.

Departure was scheduled for 1600 hrs.

The commander and co-pilot for the flight had flown for the previous operator of G-JECK and were using the standard operating procedure (SOP) of that operator. The pilots had not flown since the beginning of March 2020, so they had arranged to arrive at Aberdeen earlier than normal to provide additional time to prepare for the flight without having to rush. As the aircraft had not flown for some time, they also decided to conduct two separate and independent external and internal inspections.

The pilots had been escorted to the crew lounge by a dispatcher from the ground handling company. The dispatcher returned at about 1520…

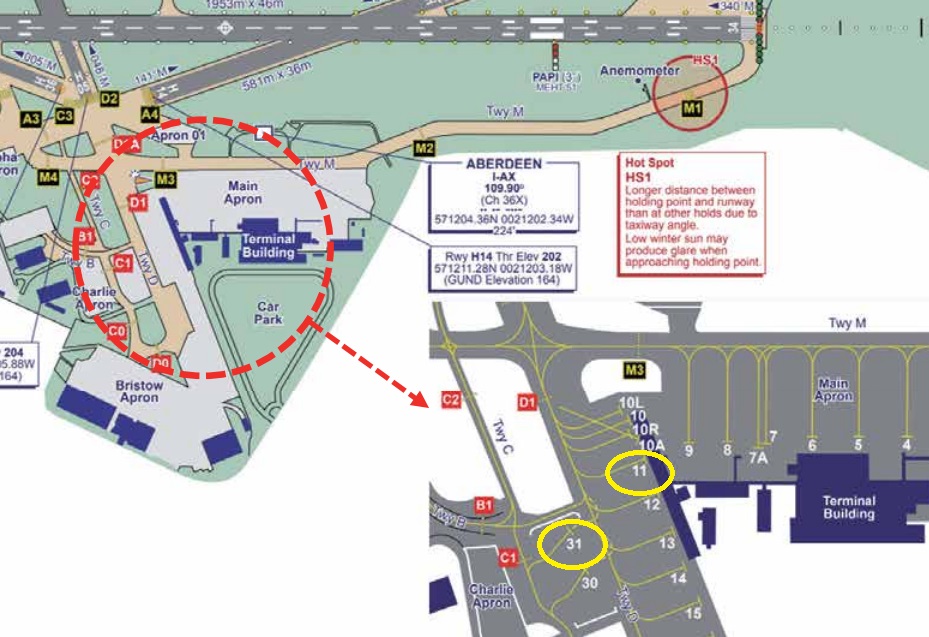

…having collected a representative of the aircraft’s owner…whose arrival at Aberdeen had been delayed. The dispatcher then drove the pilots and representative to the aircraft, arriving at 1555 hrs. G-JECK was parked on self-manoeuvring2 Stand 31 with the front of the aircraft facing Taxiway D.

Parked on the opposite side of the taxiway, at Stand 11, was an Embraer EMB-145 aircraft, registration G-SAJS.

Departure was delayed to 1645 as the co-pilot’s luggage had yet to be delivered and the checks had been delayed awaiting on the owner’s representative.

However, there were no specific time constraints, and the pilots agreed to further extend the departure time if necessary.

The pilots, dispatcher and representative were met at the aircraft by three engineers from a Part-145 approved maintenance organisation (AMO) that had been maintaining the aircraft…whilst it was at Aberdeen.

Prior to boarding the aircraft, the pilots had checked that wheel chocks were fitted to the mainwheels and nosewheels. In the cockpit, the parking brake lever was confirmed as being set to the PARK position and whilst the commander reviewed the aircraft technical log, the co-pilot started the APU. The pilots checked the cockpit multi-function display (MFD) and noted that the fluid quantities of the hydraulic systems were adequate.

Neither pilot noticed what the park brake hydraulic system pressure was indicating on the MFD, but this was not required to be checked until the end of the aircraft power-on checks and prior to starting the first engine.

Shortly after the pilots had boarded the aircraft, the dispatcher and representative briefly stood near the front of the aircraft, where the representative reported that a brief conversation took place concerning the removal of the chocks.

The AAIB note that the two had differing recollections of that conversation:

The dispatcher stated that when they had initially arrived at the aircraft, the commander had referred to preparing the aircraft for departure. The dispatcher had understood this to mean that he could proceed with removing the chocks from the left and right mainwheels. He further stated that he had not instructed anyone to remove the nosewheel chocks and, had he noticed they had been removed, that he would have refitted them.

The representative stated that he had offered to assist the dispatcher in removing the chocks and asked him if he wanted the nosewheel chocks removed, which he said that the dispatcher had acknowledged. The representative further stated that he assumed that the park brake was applied because of the response he had received from the dispatcher, but that he had checked, when the last chock was removed from the mainwheels, that the aircraft did not move.

The pilots, onboard the aircraft, had not seen the chocks being removed.

The co-pilot’s luggage was then collected and loaded into the aircraft, after which the dispatcher returned to the front of the aircraft where he attached a headset to the receptacle near the nose gear in preparation for engine start.

About 15 minutes after the chocks had been removed, the commander exited the aircraft to start his walkaround inspection. This included visual checks of the nosewheel tyres and the park brake accumulator pressure gauge, which indicated about 500 psi. The commander completed his walkaround after about ten minutes, at which point two of the engineers in the nearby vehicle came across to the aircraft to answer queries from the commander.

At that time the co-pilot carried out his own walk around inspection, the pre-agreed second check.

After about ten minutes, the co-pilot completed his walkaround and returned to the cockpit. The commander returned to the cockpit shortly afterwards, whilst the two engineers went back to their vehicle. Neither pilot had authorised the removal of any wheel chocks, and neither noticed that all the wheel chocks had been removed.

The park brake accumulator pressure had been checked, but the pilots had yet to reach the part of the checklist that called for the park brake hydraulic system pressure to be checked on the MFD. As the pilots completed the load sheet, the dispatcher boarded the aircraft… and stood near the cockpit entrance. Standing on the ground near the cabin door was the representative.

About 45 minutes had elapsed since the chocks had been removed, at which point the representative noticed that the aircraft was starting to move forward and shouted to the dispatcher who alerted the pilots. Both pilots applied the toe brakes and the commander moved the park brake lever off and back to park twice, but the aircraft continued to roll forward. The commander recalled that, as the aircraft had started to move, he had noticed that the park brake hydraulic system pressure on the MFD was 0 psi. The commander also tried to steer using the tiller, but the aircraft did not respond.

The engineers and the dispatcher risked injury by trying to physically slow the aircraft while the representative ran to fetch some chocks.

Former Flybe Bombardier Dash 8 Q400 G-JECK Gathering Speed as in Crosses Taxiway D as Ground Personnel Try In Vain to Slow It (Credit: Aberdeen Airport CCTV via AAIB)

The aircraft however began to gather speed on the slight 1º incline toward G-SASJ, about 70 m away.

At a ground speed of about 5 kt, G-JECK struck the underside of G-SAJS’s No 2 engine, causing its right landing gear to be lifted clear of the ground. G-JECK came to a stop with the No 2 engine of G-SAJS resting on top of its forward fuselage.

No one was injured.

A specialist recovery team using airbags separated the aircraft. The upper fuselage skin, cockpit emergency escape hatch and cockpit window of G-JECK, and the No 2 engine nacelle of G-SAJS, were damaged.

The park brake and normal braking systems of G-JECK were tested after the accident. No defects were found.

AAIB Analysis

The evidence indicates that a misunderstanding led the dispatcher to believe that clearance had been given by the commander to remove the chocks from the mainwheels. The dispatcher was aware that the nosewheels were to remain chocked until after the engines had been started. However, following the representative’s offer of assistance to the dispatcher, a miscommunication appears to have led to the nosewheel chocks being inadvertently removed.

The removal of the chocks went unnoticed by the pilots, and the dispatcher also did not realise that the chocks had been removed from the nosewheels. The dispatcher…stated that he did not expect them to be removed by anyone else, so he had no reason to focus attention on them at this point in time. The fact that 12 chocks, rather than 8, were loaded into the vehicle did not register as being at variance to these expectations.

Upon arrival at the aircraft, the pilots followed their normal procedure of checking that the wheels were chocked and, unsighted by them, the chocks were then removed. The pilots’ subsequent walkaround inspections did not require them to check the chocks and so their attention would not have been drawn to them.

The pilots had allowed themselves plenty of time to conduct duplicate checks of the inside and outside of the aircraft and to avoid missing any checklist items. Being aware of their reduced currency and that the aircraft had not flown for some time, their focus would have been predominantly on ensuring that no checklist item was omitted. This may have left less capacity to notice anything additional that they were not specifically looking for or expecting.

The park brake system had been pressurised to 3,000 psi when the engines had been operated four days before the accident. However, it was not unusual for the pressure to reduce over time whilst DHC-8-402 aircraft were parked; the AMM states that in two hours, the pressure could reduce by as much as 1,900 psi.

The evidence from the pilots’ walkarounds and photograph of the brake accumulator taken after the event, showed that the park brake hydraulic pressure could not have been more than the accumulator pre-charge pressure of about 500 psi.

Immediately after removal of the wheel chocks, it did not roll forward…

This indicates that there was residual pressure in the park brake hydraulic system at this time…About 45 minutes later, the aircraft started to roll forward, at which point the commander noticed that the park brake hydraulic system pressure on the MFD indicated 0 psi.

As neither the No 1 or No 2 hydraulic systems were pressurised, the application of the park brake and operation of the normal braking and nosewheel steering systems were ineffective in stopping or altering the path of the aircraft.

AAIB Conclusions

G-JECK rolled across Taxiway D from its parking position and struck G-SAJS because the nosewheel chocks had been inadvertently removed, and the hydraulic pressure in the park brake accumulator had depleted over several days to the point where it was unable to prevent the aircraft from moving on the 1° slope.

Safety Actions Taken

The organisation that provided the pilots for the flight and sub-contracted the ground handling services has:

- Reminded its sub-contracted ground handling companies that permission must be obtained from the aircraft commander before removing chocks.

- Reiterated that chocks are to remain fitted until either a tug had been attached to the aircraft or, when self-manoeuvring, that nosewheel chocks remain fitted until permission has been given to remove them.

- Recommended that pilots check during their walkaround that chocks had not been inadvertently removed.

The Continued Airworthiness Management Organisation (CAMO):

- Circulated a tutorial, and included it in recurrent training, to all staff within its organisation to raise awareness of the circumstances of this event.

The organisation contracted to provide ground handling has:

- Updated its training of dispatchers to ensure that third parties undertake only those duties for which they have been explicitly briefed and trained to carry out.

Aberdeen Airport has:

- Issued an airside safety alert at Aberdeen, Glasgow and Southampton Airports highlighting the need to obtain permission before removing chocks.

- Undertaken to carry out audits of ground handling companies operating at Aberdeen to better understand chocking procedures and training.

- Requested airside operations to audit chocking procedures on the ramp area, with particular attention to self-manoeuvring stands.

- Undertaken to share safety lessons with ground handling companies via the ramp safety committee at Aberdeen.

The UK CAA:

- Published Safety Notice, SN-2020-013 – Returning Aircraft to Service from ‘Extended Parking’, which highlights threats associated with this report.

Safety Resources

Another type of end of lease miscommunication was discussed by AAIB in relation to Easyjet Boeing 737-73V, G-EZJK on 12 January 2009:

A flight control manual reversion check was being conducted as part of a post maintenance check flight. During the check, the aircraft pitched rapidly nose-down, descending approximately 9,000 ft before control was recovered.

A number of issues relating to the planning of the check flight, liaison with engineering and the involvement of multiple organisations emerged. These resulted in a flight control adjustment having been applied in the opposite sense to that intended after a prior check flight. Seven safety recommendations were made by AAIB.

Other Aerossurance articles include:

- A320 Collided with Two De-Icing Trucks Misinterpretation of communication due to a lack of standardised phraseology was a factor in this incident say the BFU, when an A320 attempted to to return to stand after a checklist error.

- Ground Collision Under Pressure: Challenger vs ATV: 1-0 Pressure, changes of plan and distractions all feature in this ground collision where a Challenger overturned an All Terrain Vehicle.

- A320 Rolls Back on Stand: Incomplete Maintenance Procedures and Ground Handling Deviations: The brakes had been set OFF during maintenance trouble shooting and the chocks removed prematurely, so the aircraft rolled when a tug with a u/s radio was being swapped out.

- Jetstar Dispatcher Forced to Run After Distracted Pushback A dispatcher was forced to run when an aircraft started to taxi while he was still connected to it after the crew became distracted, skipped procedural steps and misidentified the dispatcher.

- Jetstar Overworked Yuletide Loading Error A loading incident during a busy-pre Christmas period highlights the effect of high workload on data input errors, as well as the importance of system feedback of incorrectly entered data.

- A330 Starts to Taxi Before Tug is Clear ATSB say misunderstandings by the parties involved led to incorrect expectations and the aircraft beginning to taxi prior to the tug moving clear.

- The Passengers Who ‘Caused’ a 737 Tail Strike: Ground Handling Lessons Errors in ground handling left an aircraft out of CG range so on rotation the tail struck the runway. We analyse the lessons from the report on this incident.

- Maintenance Check Flights: Safety Lessons

- Human Factors of Dash 8 Panel Loss

- Tight Cable Tie Nose Gear Jam

- Dash 8 Q400 Return to Base After Pitot System Contaminated By Unapproved Test Kit Lubricant

- HF of the Selection of Parking Brake Instead of Speed Brake During a Hectic Approach

- UPDATE 22 October 2020: Dash 8 Q400 Control Anomalies: 1 Worn Cable and 1 Mystery

- UPDATE 26 June 2021: Pilatus PC-12 Collided with Pick-Up Truck During Dusk Take Off

- UPDATE 22 September 2021: Brake Failure Causes PA-31 Runway Excursion During Taxi

UPDATE 16 January 2021: UK CAA have issued this infographic on distraction:

Aerossurance was to have run training workshops at the EHA European Rotors VTOL Show and Safety Conference in Cologne in November 2020 on a) Safety Culture and Leadership and b) Contracting Aviation Services: An Introduction to the Basics. Sadly due to COVID-19 the show has been postponed to 2021.

Recent Comments