Unballasted Sling Stings Speedy Squirrel (AS350B3e / H125 F-HLXO doing HESLO in France)

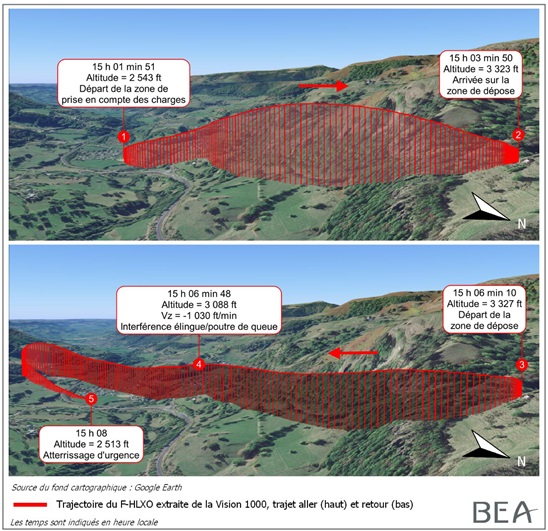

On 30 October 2020 Airbus Helicopters AS350B3e (H125) Squirrel F-HLXO of Héliberté suffered an accident during Helicopter External Sling Load Operations (HESLO) in Thiézac when after a change of plan, an underslung steel cable became tangled in the tail rotor when return from delivering a load.

The Accident

The French Bureau d’Enquêtes et d’Analyses pour la Sécurité de l’Aviation Civile (the BEA) explain in their safety investigation report issued in April 2021 (in French) that:

The pilot, holder of a commercial pilot’s license of a CPL (H), had a total of 1,340 hours of flight time and 1,675 load cyles, including 15 hours and 225 lifts in the last 30 days.

On the day…

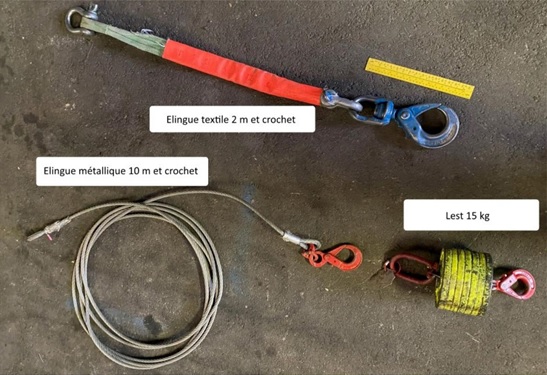

…the pilot and two ground staff prepared a sling consisting of a ten-meter wire rope and a two-meter textile extension fitted with a hook.

The tasking consists of transporting two tanks of 400 kg and ten bags…(six of about 800 kg and four of about 1,000 kg). After this phase of preparation and the briefing, the pilot takes off and presents the helicopter to hook up the tank, which is the first of the loads to be transported. The ground staff connects the hook of the metal sling to the textile extension which was already attached to the tank. The pilot lifts the load and moves towards the drop zone located 1,700 m away and approximately 230 m higher. Arriving at the drop-off area, the second ground team were unable to open the hook and release the load. After a few minutes and in the absence of an open area nearby allowing the helicopter to land, the ground personnel in consultation with the pilot decided to unhook the textile extension from the metal cable.

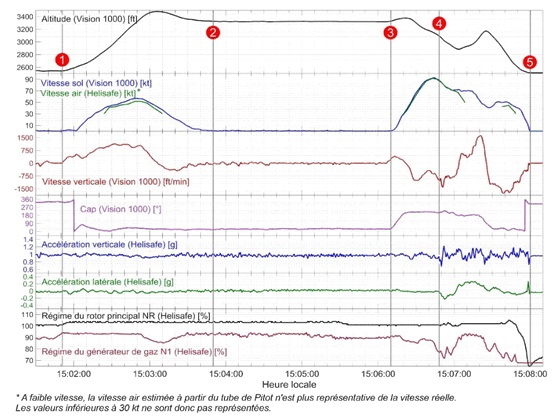

The pilot returned to the loading area, monitoring the cable via the exterior mirror. As the helicopter picks up speed the metal cable wrapped around the tail boom of the helicopter and the tail rotor. The pilot heard a ‘popping’ noise, realised the anti-torque pedals were ineffective and managed to rapidly land near the loading area. The accident was not however promptly reported to the BEA. Examining photographs the BEA note that the Tail Gear Box (TGB) was partially torn off, the tail driveshaft broken and the tailboom deformed. The BEA concluded the metal cable had wrapped around the tail rotor.

Interviews

Ground crew interviews revealed that at the loading point:

…the textile sling was already hooked onto the tank strap and that they only had to couple the metal sling and the textile strap. They did not notice any anomaly when hooking the straps of the tank to the hook of the textile sling. The second ground crew member indicated that they had had a discussion with the pilot about the need to leave the 15 kg ballast on the sling line. He stated that a joint decision with the pilot to remove the ballast was taken in view of the masses of the….bags which seemed a little high, and after having estimated that the hook of the textile sling must have a mass equivalent to the ballast.

The second ground crew member then went to the drop-off area. He went on to explain that:

…when the tank was placed in the area, he was unable to open the hook, the straps being too short and they were still under tension. He had no other solution than to disconnect the textile sling from the metal sling.

The pilot stated he “flew slowly while monitoring the behaviour of the unweighted sling using the exterior mirror”.

Flight Data

The helicopter is equipped with a Helisafe computer, recording flight and engine parameters, as well as a Vision 1000 computer, recording flight parameters, cockpit images and ambient cockpit noise. The two systems could be synchronized. The use of the ambient noise in the cockpit made it possible to precisely determine the moment when the interference of the sling with the tail boom of the helicopter occurred.

This occurred (point 4) at an indicated airspeed of 87 kt and at a rate of descent of 1030 ft / min.

BEA Discussion

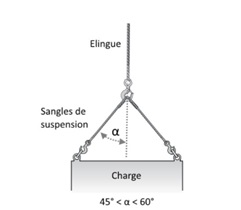

One of the principles for the sizing of load suspension straps is to have an angle in the order of 45 ° to 60 ° of the straps….

Airbus issued a newsletter in 2017 concerning the risks associated with sling transport. This letter specifies in particular the increased risk by unloaded slings which can go up and interfere with the tail boom of the helicopter and recommends the use of a ballast of at least 15 kg to decrease the risk. It specifies that in the case of a flight with an unweighted sling, it is necessary to avoid that the speed exceeds the Vy and the pilot must monitor the behavior of the sling during flight.

For the AS350 Vy is 65 knots.

Operator’s Analysis and Safety Actions

Subsequently, the operator carried out an internal investigation that identified that:

- The decision to remove the 15 kg ballast which was contrary to the procedures of the company operations manual.

- The erroneous assumption that the mass of the textile sling hook was equivalent to the ballast (the actual mass is 10 kg).

- Insufficient verification of the conformity of the load to be transported (straps too short, angle of the straps not in accordance with lifting rules) when longer straps were available.

The operator has implemented the following preventive / corrective actions:

- Systematic use of the 15 kg ballast whatever the circumstances and the flight phase.

- During slinging training, insist on respecting the angles of the straps when building up the loads to be lifted.

- For personnel who already hold the qualification, a reminder of the procedures in force.

BEA Contributory Factors

- Excessive speed gain during the descent during the return flight when the sling was not ballasted.

- The pilot’s decision not to use ballast at the end of the sling believing that the textile sling and its hook could fulfil this role.

- Insufficient checking of the load during preparation, which led to having to disconnect part of the sling during removal.

Safety Resources

The European Safety Promotion Network Rotorcraft (ESPN-R) has a helicopter safety discussion group on LinkedIn. In addition, there is a specific ESPN-R Sling Load Operations Safety Promotion discussion group. You may also find these Aerossurance articles of interest:

- Short Sling Stings Speedy Squirrel: Tail Rotor Strike Fire-Fighting in Réunion

- Korean Kamov Ka-32T Fire-Fighting Water Impact and Underwater Egress Fatal Accident

- Wayward Window: Fatal Loss of a Fire-Fighting Helicopter in NZ

- Helicopter Tail Rotor Strike from Firefighting Bucket

- Maintenance Issues in Fire-Fighting S-61A Accident

- Load Lost Due to Misrigged Under Slung Load Control Cable

- Beware Last Minute Changes in Plan

- Deadly Dusk Air Ambulance Bird Strike

- Shocking Accident: Two Workers Electrocuted During HESLO

- Loss of Control During HESLO Construction Task: BEA Highlight Wellbeing / Personal Readiness

- NZ Firefighting AS350 Accident: Weaknesses in Role Equipment Design and Distribution of Key Operating Data

- Windscreen Rain Refraction: Mountain Mine Site HESLO CFIT

- UPDATE 12 June 2021: HESLO Dynamic Rollover in Alaska

- UPDATE 28 August 2021: Ditching after Blade Strike During HESLO from a Ship

- UPDATE 4 September 2021: Dynamic Rollover During HESLO at Gusty Mountain Site

- UPDATE 25 September 2021: Fuel Starvation During Powerline HESLO

- UPDATE 16 October 2021: South Korean Fire-Fighting Helicopter Tail Rotor Strike on Fuel Bowser

- UPDATE 1 January 2022: Snagged Sling Line Pulled into Main Rotor During HESLO Shutdown

- UPDATE 3 September 2022: Garbage Pilot Becomes Electric Hooker

- UPDATE 12 November 2022: Impatience Comes Before a Fatal Fall During HESLO

- UPDATE 1 January 2023: HESLO EC135 LOC-I & Water Impact: Hook Confusion after Personnel Change

- UPDATE 18 March 2023: HESLO AS350 Fatal Accident Positioning with an Unloaded Long Line

- UPDATE 5 August 2023: A Concrete Case of Commercial Pressure: Fatal Swiss HESLO Accident

Airbus has issued several documents to warn of the risks when operating with external loads including Service Letter No 1727-25-05 of 26 March 2006 and Safety Information Note (SIN) No 3170-S-00 of 3 October 2017.

Recent Comments