Safety Lessons from a Fatal Helicopter Bird Strike: PHI Sikorsky S-76C++ N748P Contracted to Shell Oil

We look at a fatal accident that happened on 4 January 2009 that highlights a range of certification, modification, crew alerting, training and emergency response lessons. We also discuss current activity on helicopter bird strike certification requirements.

The Accident Flight

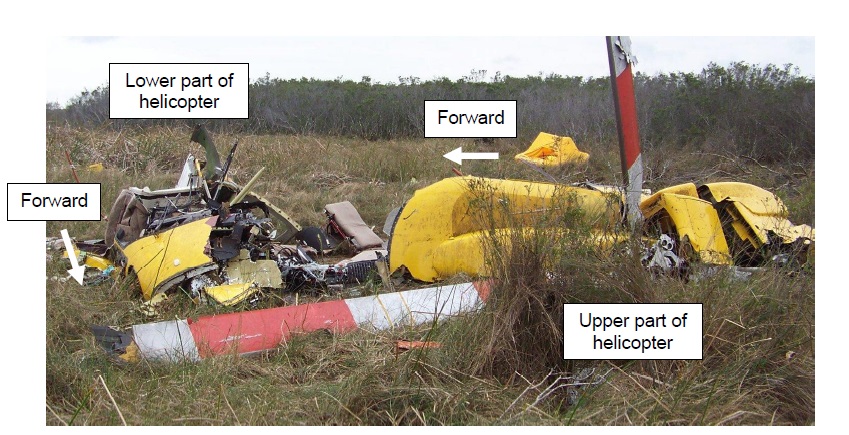

Sikorsky S-76C++ N748P of PHI took off from a heliport in Louisiana, destined for a Shell offshore installation in the Gulf of Mexico with two crew and 7 passengers aboard. The helicopter “established level cruise flight at 850 feet mean sea level and 135 knots indicated air speed” according to the US National Transportation Safety Board (NTSB) investigation report and:

About 7 minutes after departure, the cockpit voice recorder recorded a loud bang, followed by sounds consistent with rushing wind and a power reduction on both engines and a decay of main rotor revolutions per minute. Due to the sudden power loss, the helicopter departed controlled flight…

The helicopter crashed in marshland just 12 miles from the heliport.

The Caledonian Airborne Emergency Locator Transmitter (ELT) activated. While there is normally a short delay until the COSPAS/SARSAT satellite system alerts the appropriate Rescue Coordination Centre (RCC), the USAF RCC only made contact with the operator 31 minutes after impact according to their accident report form. It was not until the wreckage had been visually identified (54 minutes after impact) by another of the operator’s helicopters that a US Coast Guard helicopter was dispatched. Miraculously one passenger was found alive, albeit very seriously injured.

The NTSB N748P Accident Investigation

The NTSB identified that the helicopter had suffered a bird strike:

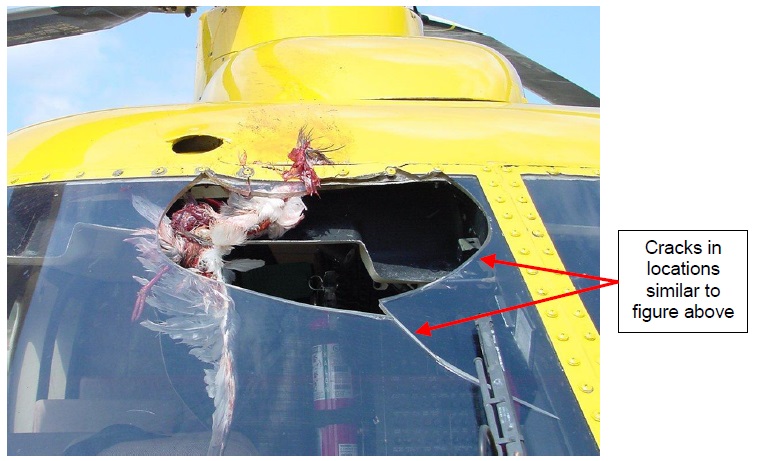

Examination of the wreckage revealed that both the left and right sections of the cast acrylic windshield were shattered.

Feathers and other bird remains were collected from the canopy and windshield at the initial point of impact and from other locations on the exterior of the helicopter. Laboratory analysis identified the remains as coming from a female red-tailed hawk;

The females of that species have an average weight of 2.4 pounds [1.1kg].

The acrylic windshield had been fitted in place of the production windshield after delivery (discussed further below). Located about 100mm behind the windscreen of the S-76C++ are two engine fire extinguisher T-handles. These…

…are normally in the full-forward position during flight, and each is held in place by a spring-loaded pin that rests in a detent; aft pulling force is required to move the T-handles out of their detents. If the T handles are moved aft, a mechanical cam on each T-handle pushes the trigger on the associated [engine power control lever] ECL out of its wedge-shaped stop, allowing the ECL to move aft, reducing fuel to the engine that the ECL controls.

The investigators determined:

The impact of the bird on the canopy just above the windshield near the engine control quadrant likely jarred the fire extinguisher T-handles out of their detents and moved them aft, pushing both ECL triggers out of their stops and allowing them to move aft and into or near the flight-idle position, reducing fuel to both engines.

A similar incident occurred on November 13, 1999, in West Palm Beach, Florida, when a bird struck the windshield of an S-76C+ [HEMS] helicopter, N276TH, operated by Palm Beach County.

The bird did not penetrate the laminated glass windshield, but the impact force of the bird cracked the windshield and dislodged the fire extinguisher T-handles out of their detents; however, in that case, the force was not great enough to move the ECLs.

Shortly after the accident it was noted there has been wear in the engine control quadrants on some S-76C++ and Sikorsky issued an Alert Service Bulletin to address.

The NTSB Conclusions

The NTSB determined the probable causes as:

- The sudden loss of power to both engines that resulted from impact with a bird (red-tailed hawk), which fractured the windshield and interfered with engine fuel controls, and

- The subsequent disorientation of the flight crewmembers, which left them unable to recover from the loss of power.

Contributory factors were:

- The lack of Federal Aviation Administration regulations and guidance, at the time the helicopter was certificated, requiring helicopter windshields to be resistant to bird strikes;

- The lack of protections that would prevent the T handles from inadvertently dislodging out of their detents; and

- The lack of a master warning light and audible system to alert the flight crew of a low-rotor-speed condition.

The NTSB raised 12 safety recommendations to (discussed below) in November 2010. Only a few have resulted in any action to date.

Further Discussion

We will now examine ten aspects in more detail:

- Windshields: Rotorcraft Windshield Bird Strike Certification Background

- Windshields: US Army Research

- Windshields: The Retrofit Cast Acrylic Windshield

- Windshields: Safety Actions

- Bird Strike Avoidance

- Future Bird Strike Policy / Rule Making

- Low Rotor Speed Warning Systems

- Flight Crew Training for Simultaneous Dual-Engine Failure

- NTSB Safety Recommendations

- Our Observations

1. Windshields: Rotorcraft Windshield Bird Strike Certification Background

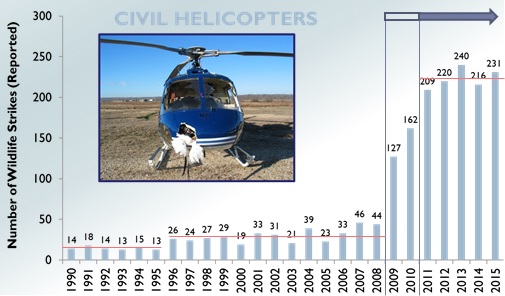

The NTSB quote a 2006 study by Dolbeer, Wright and Cleary, (“Bird Strikes to Civil Helicopters in the United States, 1990-2005“) which concluded that:

- helicopters were significantly more likely to be damaged by bird strikes than airplanes,

- windshields on helicopters were more frequently struck and damaged than windshields on airplanes, and

- helicopter bird strikes were also more likely to lead to injuries to crew or passengers.

The NTSB comment:

The authors concluded that the “high percentage of windshields damaged for helicopters, combined with the disproportionate number of human injuries, indicates that improvements are needed in windshield design and strength for these aircraft.”

However, the S-76A was certified on 21 November 1978 to a Federal Aviation Administration (FAA) Type Certification Basis (TCB) of FAR Part 29 Amendments up to 29-11 (issued 5 February 1975). There were no FAA bird-strike requirements at that time, though 29.775 Windshields and windows did require:

Nonsplintering safety glass must be used in glass windshields and windows.

In 1990 the FAA changed the 29.775 Windshields and windows requirement (in Amendment 29-31) to remove the specific reference to glass and cover all material types:

Windshields and windows must be made of material that will not break into dangerous fragments.

In 1991 the FAA certified the S-76C. Then finally, in 1996, the 29.631 Bird Strike requirement was introduced by the FAA (for new helicopter types):

The rotorcraft must be designed to ensure capability of continued safe flight and landing (for Category A) or safe landing (for Category B) after impact with a 2.2-lb (1.0 kg) bird when the velocity of the rotorcraft (relative to the bird along the flight path of the rotorcraft) is equal to VNE or VH (whichever is the lesser) at altitudes up to 8,000 feet. Compliance must be shown by tests or by analysis based on tests carried out on sufficiently representative structures of similar design.

However, while the US requirements for the S-76 were minimal until 1996, the UK Civil Aviation Authority (UKCAA) did have bird strike requirements long before FAR 29.631 was introduced. These had already been adopted in the European Joint Aviation Authorities JAR-29 certification standard. Consequently, Sikorsky developed a bird strike resistant glass laminated windshield to meet additional British Civil Airworthiness Requirements Section G (BCAR Section G) requirements when seeking to introduce the S-76A into the UK. BCAR Section G required the windshield resist penetration of a 2lb bird at 160 knots. Testing was conducted on a glass-plastic laminate windshield in 1978 and on a glass-glass laminate in 1982. Both designs passed the BCAR requirements at impact speeds of 160-173 knots. Then for the UK certification of the S-76B, six glass-glass laminate windshields were also subject to 2lb / 160 knot bird strike tests in August 1985 at a range of temperatures (20°F to 72°F). All passed. Not only did Sikorsky develop a bird strike resistant windshield designs, but to their credit they also made a bird resistant windshield the production standard:

All S-76C++ model helicopters are delivered with laminated glass heated windshields that are 0.30-inch thick with a 0.12-inch thermally tempered glass ply outboard, a 0.12-inch chemically tempered glass ply inboard, and 0.06-inch polyvinyl butyral interlayer between them.

N748P had therefore been delivered with such windshields on 25 September 2006. Although the average weight of a red tailed hawk is 2.4lbs, as N748P was operating at a lower speed that the test case, the test case approximates to being able to resist the energy of a 2.8lb bird at N748P’s cruise speed of 135 knots. However, the windshields of N748P had been replaced after delivery with lighter cast acrylic windshields that had never been bird strike tested (discussed further below).

2. Windshields: US Army Research

The NTSB say the US Army generally no longer uses cast acrylic windshield (except for example where it is necessary for an ejection seat to be able to easily break through the canopy).

One U.S. Army study (“UH-1 Ballistic and Bird Impact Test Study,” Report AMMRC CTR 75-7, April 1975) reported on bird strike tests of Bell UH-1 helicopter windshields made of different materials. The UH-1 windshield materials tested included cast acrylic, polycarbonate, and a composite constructed of a layer of polycarbonate bonded to a layer of chemically tempered glass. The report concluded, in part, that the polycarbonate and the polycarbonate bonded to glass both offer far greater bird strike protection than a standard cast acrylic windshield. The report further indicated that a cast acrylic windshield at a cruising speed of 90 knots is incapable of defeating a bird strike, and that the Plexiglas breaks into large fragments that could cause serious injury to the flight crew. Another U.S. Army report (“Design, Test and Acceptance Criteria for Helicopter Transparent Enclosures,” Report USARTL-TR-78-26, 1978) documented a study of the low-energy impact response of a number of different windshield materials. The materials tested included a tempered-glass laminate, a laminate of glass and stretched acrylic, monolithic stretched acrylic, monolithic cast acrylic, and monolithic polycarbonate. The report concluded that the cast acrylic needed to be three times as thick as the stretched acrylic or the polycarbonate to provide a similar level of protection against impact.

3. Windshields: The Retrofit Cast Acrylic Windshield

N748P had been retrofitted after delivery with a 0.312 inch monolithic cast acrylic replacement windshields supplied by a third-party manufacturer, Aeronautical Accessories Inc (AAI). The NTSB say:

Installation and use of the replacement windshields was approved by the FAA under Supplemental Type Certificate (STC) SR01340AT, which was issued to AAI on April 16, 1997. The FAA also issued a Parts Manufacturer Approval (PMA) to AAI on August 3, 1998, for the manufacture of the replacement windshields.

As they were not certified for use in the UK there were no bird strike requirements applied. The NTSB say:

No records of the tests and analysis have been located by the NTSB or provided to the NTSB by either the FAA or the STC holder, AAI.

Starting in the late 1980s the operator had started replacing glass laminated windshields on its S-76 fleet. As the cast acrylic windshields were unheated the operator was also able to remove “the main gearbox-mounted AC generator that provides power for the windshield heaters”. The combination of the lighter windshields and generator resulted in a weight saving and a payload improvement, which would prove attractive to customers unaware of the certification background. With respect to in-service experience:

The NTSB is aware of an additional bird strike incident on April 19, 2006, involving an S-76A++ helicopter operated by PHI that was equipped with a cast acrylic windshield identical to the one in the accident helicopter.

The examination revealed a near-circular hole with radiating cracks near the top center of the right windshield. The bird [a Seagull] penetrated the windshield and pushed the right throttle to idle. The trapped remains of the bird prevented the right throttle from being re-engaged, but the pilot was able to land the helicopter safely.

4. Windshields: Safety Actions

The NTSB say:

On May 19, 2009, Sikorsky Aircraft Corporation issued a safety advisory (SSA-76-09-002) to all S-76 operators regarding the reduced safety factor of acrylic windshields (both cast and stretched) as compared to laminated glass windshields. According to the advisory, the S-76 laminated glass windshield demonstrated more tolerance to penetrating damage resulting from in-flight impacts (such as bird strikes) compared to acrylic windshields. Sikorsky expressed concern that the presence of a hole through the windshield, whether created directly by object penetration or indirectly through crack intersections, may cause additional damage to the helicopter, cause disorientation or injury to the flight crew, increase pilot workload, and create additional crew coordination challenges.

To aid operators the safety advisory also included guidance on determining the type of acrylic windshield installed by using two sheets of polarised film (stretched acrylic will still let some light through). By September 2009 the operator had fitted “OEM-type glass laminated windshields” to all their S-76Cs.

5. Bird Strike Avoidance

The Helicopter Safety Advisory Conference (HSAC) Gulf of Mexico helicopter industry association published Recommended Practice 2010-03 on Brid Strike Avoidance. A number of bird strike avoidance measures are also contained in the offshore helicopter version of the Flight Safety Foundation’s (FSF) award winning Basic Aviation Risk Standard (available to download on the FSF website) which we discussed here: FSF Launches Offshore Helicopter Standard (BARSOHO). A update of BARSOHO (Version 3), fully aligned with the HeliOffshore Safety Performance Model (SPM) (discussed here: Offshore Helicopter Safety Performance: 2016 HeliOffshore Conference Report), is due out shortly. UPDATE 1 February 2017: SPM aligned V3 is issued and available.

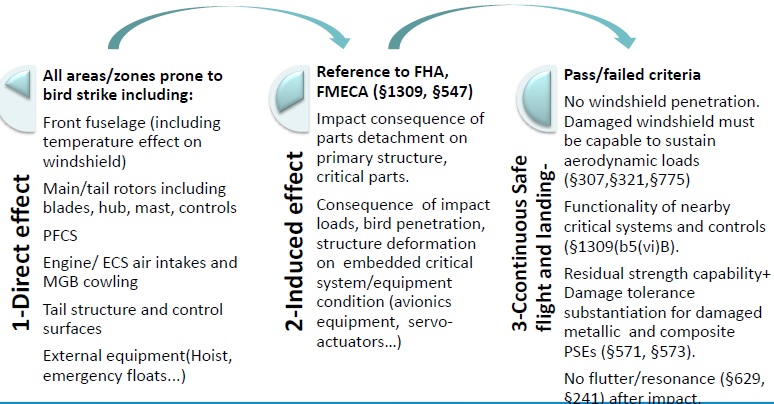

6. Future Bird Strike Policy / Rule Making

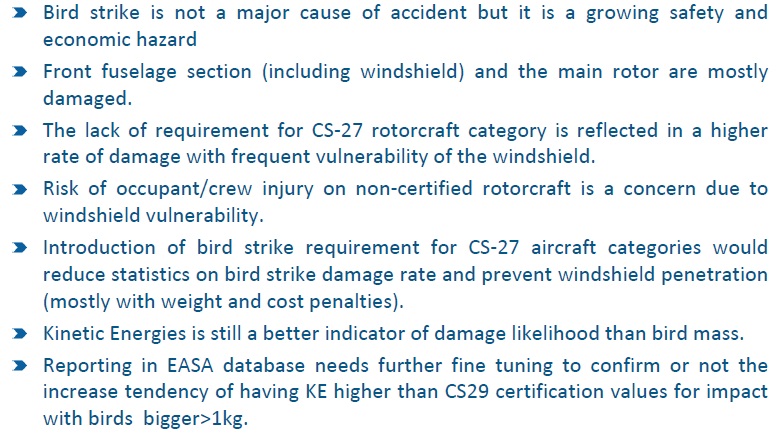

At the European Aviation Safety Agency (EASA) 10th Rotorcraft Symposium in December 2016 there was a discussion on the topic of bird strikes. EASA is a participant in the Rotorcraft Bird Strike Working Group, tasked by the FAA after this N748P accident to provide the FAA Aviation Rulemaking Advisory Committee (ARAC) with recommendations on rotorcraft bird strike protection, rulemaking, policy and guidance by October 2017. EASA is expected to release shortly a new certification memo, to clarify EASA’s expectations when showing compliance to bird strike requirement. This is expected to include the following:  EASA do comment that based on their current analysis of occurrences, bird strikes are not a major cause of accidents but are “a growing safety and economic hazard” and that:

EASA do comment that based on their current analysis of occurrences, bird strikes are not a major cause of accidents but are “a growing safety and economic hazard” and that:  They also comment of the future risk of drone/UAS/RPAS strikes. Aerossurance has previously discussed the EASA Drone Safety Risk Portfolio and Analysis.

They also comment of the future risk of drone/UAS/RPAS strikes. Aerossurance has previously discussed the EASA Drone Safety Risk Portfolio and Analysis.

7. Low Rotor Speed Warning Systems

The S-76, like most modern rotorcraft, has a relatively low rotor inertia and the NTSB say:

Based on the main rotor speed decay information provided by Sikorsky, the flight crew of N748P had about 6 seconds or less to react to the decaying [main rotor speed] Nr condition.

Some helicopter types are equipped with an audible alarm and/or warning light to alert the crew to low Main Rotor Speed (Nr).

When the S-76 was certificated in 1978, 14 CFR 29.33 did not require an audible alarm or warning system for low Nr conditions. The subsequent revision to 14 CFR 29.33 in 1978 required a low Nr warning system in single-engine helicopters and in multi-engine helicopters that did not have a device that automatically increases power on the operating engine if one engine fails. Since the S-76 has a system that automatically increases power on the operating engine in order to maintain Nr, the accident helicopter would not have required an alarm or warning system even if the latest revision did apply. The NTSB is aware that both the Sikorsky S-92A and the S-76D…have an audible low Nr warning, even though these aircraft are equipped with a system that automatically increases power in the working engine.

The NTSB specifically note that in July 2009 the FAA issued a Notice of Proposed Rulemaking (NPRM), on introducing a new Flightcrew Alerting requirement for large aeroplanes.

The NPRM proposes to incorporate redundant sensory cuing (such as aural and visual) into alerts for conditions requiring immediate flight crew awareness. The revisions are based on human factors principles [to] facilitate flight crew performance. In a letter [to the FAA]…the NTSB recognized the importance of providing salient, recognizable cues through at least two different sensory systems by a combination of aural, visual, or tactile indications.

The resulting 14 CFR 25.1322 was issued in 2011. The FAA have yet to initiate similar rule-making for rotorcraft, and 29.1322 is far more basic, something discussed at length at two recent Royal Aeronautical Society conferences on offshore helicopter automation. However , as we have discussed previously, a Special Condition has been proposed for the Bell 525 for its sophisticated Crew Alerting System:

The novel design includes the integration of audio and visual alerts, tactical sensors, and CAS message consolidation. The new technologies associated with integrated visual, aural, tactile, and alert messaging are more effective in alerting the flightcrew and aiding them in decision-making than the discrete colored lights for warning, caution, and advisory alerts prescribed in § 29.1322 alone.

8. Flight Crew Training for Simultaneous Dual-Engine Failure

The NTSB say:

A review of the accident flight crew’s training records indicated that both pilots had fulfilled all training requirements and had completed Sikorsky S-76C++ emergency initial and recurrent training in ground school and in the simulator. The emergency procedures section of the Sikorsky S-76 flight manual describes the dual-engine failure procedure while hovering, during takeoff and initial climb, and during cruise. Upon dual-engine failure, the helicopter will yaw to the left due to the reduction in torque as engine power decreases. An immediate collective pitch reduction would be required to maintain Nr within safe limits. In most instances, if dual-engine failure occurs a safe autorotation landing could be made. According to PHI, prior to the January 4, 2009, accident, line oriented flight training (LOFT) for dual-engine failure was conducted in both ground school and in a simulator for visual and instrument flight rules conditions. Training was conducted so that one engine failed at a time, ultimately resulting in autorotation. Training for simultaneous sudden failure of both engines was part of initial training but was not part of annual recurrent training. Since the accident PHI modified LOFT to include sudden simultaneous dual-engine failure training both on the ground and in the simulator during initial and annual recurrent training. A review of NTSB data indicates that from 1982 to present [2010] the NTSB has investigated 52 accidents involving loss of engine power in dual-engine helicopters, 23 of which resulted in substantial damage. In general, the causes of the dual-engine loss of power were due to fuel exhaustion, fuel contamination, and operational errors, among other factors.

Such failures with simultaneous loss of all power are rare however (for example most fuel systems are designed so that one engine fails slightly earlier than the other in the case of fuel exhaustion).

9. NTSB Safety Recommendations

- A-10-136 to the FAA: Require that Sikorsky redesign the S-76C++ model helicopter fire extinguisher T-handles and/or engine control quadrant to ensure that the T-handles do not inadvertently dislodge out of their detents due to any external force on the canopy or windshields that could cause unintended movement of the engine power control levers. This was closed by a Sikorsky redesign of the overhead engine control lever, incorporating a damper and a positive detent for the ‘FLY’ position, made mandatory by FAA Airworthiness Directive (AD) 2012-22-13.

- A-10-137 to the FAA: Evaluate other helicopter models with engine control quadrant designs similar to the S-76C++ model helicopter and require modification, as necessary, to ensure that any external force on the canopy or windshields does not cause unintended movement of the engine power control levers. This was closed by the FAA stating they had reviewed other, unspecified, types.

- A-10-138 to the FAA: Issue a certification policy to require that operators of helicopters with windshields with demonstrated bird-strike resistance not be permitted to replace those windshields with ones that have not been demonstrated to be resistant to bird strikes. This was closed 5 years after it was ‘reconsidered’ by NTSB. No action was taken.

- A-10-139 to the FAA: Evaluate the feasibility of retrofitting helicopters manufactured before 1996 with windshields that meet the current bird-strike requirements. This was closed after the FAA started this was “neither justifiable nor economically feasible”.

- A-10-140 to the FAA: Evaluate the feasibility of requiring manufacturers to equip new helicopters, built under the old certification requirements, with windshields that meet the current bird-strike requirements. This was also closed when the FAA responded that this was potentially impractical.

- A-10-141 to the FAA: Require helicopter manufacturers to develop helicopter-specific guidance (based on the helicopter’s demonstrated capability to withstand a specific level of bird-strike impact energy) that will assist pilots in devising precautionary helicopter operational strategies for minimizing the severity of helicopter damage sustained during a bird strike, should one occur, when operating in areas of known bird activity. This remains open awaiting the Rotorcraft Bird Strike Working Group mentioned above. UPDATE 21 October 2022: This was subsequently closed ‘acceptable alternative action’ relating to publishing SAIB AIR-21-17.

- A-10-142 to the FAA: Require Sikorsky to design an audible low rotor revolutions per minute (Nr) alarm system and master warning light that will alert the flight crew of S-76 model helicopters of rapidly decaying Nr. The FAA rejected this proposed action, which the NTSB closed and classified as ‘unacceptable’.

- A-10-143 to the FAA: Once an audible low rotor revolutions per minute (Nr) alarm system and master warning light are designed as requested in Safety Recommendation A-10-142, require operators of Sikorsky S-76 model helicopters to install the audible low Nr alarm system and master warning light that will alert flight crews of rapidly decaying Nr. The FAA also rejected this proposed action, which the NTSB again closed and classified as ‘unacceptable’.

- A-10-144 to the FAA: Revise 14 Code of Federal Regulations 27.33 and 29.33 to require an audible low rotor revolutions per minute alarm system and master warning light for all dual-engine helicopters, even those that are equipped with a device that automatically increases power on the operating engine when the other engine fails. This remains open awaiting progress on wider changes to FAR27 and FAR29, although an update promised by the FAA for February 2016 has not been recorded in the NTSB database. UPDATE 16 February 2017: This was subsequently closed ‘unacceptable action’.

- A-10-145 to the FAA: Require operators to include simultaneous dual-engine power loss scenarios in both initial and recurrent ground and simulator training for pilots of dual-engine helicopters. In 2012 FAA stated that they believe “that there is a very small likelihood that an accident scenario leading to dual-engine power loss will occur again. Therefore, we do not plan on requiring this training”. The FAA later changed their minds and this remains listed as open by the NTSB awaiting a promised change FAA Order 8900.1 to include this training. UPDATE 23 February 2024: This was closed ‘unacceptable action’ after the FAA again changed their mind and confirmed they would take no further action.

- A-10-146 to the FAA: Update the 14 Code of Federal Regulations Part 29 transport-category helicopter bird-strike standards so that they are consistent with the latest military and civilian bird-strike database information and trends in bird populations. This remains open awaiting the Rotorcraft Bird Strike Working Group mentioned above. UPDATE 21 October 2022: This was subsequently closed ‘unacceptable action’.

- A-10-147 to the FAA: Update the 14 Code of Federal Regulations Part 27 transport-category helicopter bird-strike standards so that they are consistent with the latest military and civilian bird-strike database information and trends in bird populations. This remains open awaiting the Rotorcraft Bird Strike Working Group mentioned above. UPDATE 21 October 2022: This was subsequently closed ‘unacceptable action’.

Overall the response to these recommendations was deeply uninspiring.

10. Our Observations

The fatal N748P S-76C++ accident highlights some of the complexity of interpreting TCBs and the equivalent level of safety by both air operators and their customers as the State of Design’s certification requirements may not be the most stringent applied. We are aware of oil & gas industry safety studies, crucially conducted without the benefit of any rotorcraft certification expertise, that have been significantly flawed by ignoring this point.

Fortunately an analysis, which is now a requirement of the FSF’s BARSOHO standard, is likely to become easier with greater harmonisation of regulations and their application, however actual designs may still exceed the applicable certification requirements (as in the case of Sikorsky’s production windshield). This also shows the importance of careful consideration of modifications and comparison of bids from different operators so that payload/range and cost are not inadvertently prioritised without due regard to safety.

The importance of sharing and monitoring in-service experience is demonstrated as there were both a previous 1999 S-76 incident when a bird strike on the stronger glass laminate windshield resulted in a throttle movements and one in 2006 that involved a penetration on an STC acrylic windshield that retarded one throttle to idle (both discussed above). We are aware of at least one similar incident that had occurred on another medium helicopter type in Nigeria. Despite 12 NTSB recommendations, only a few have resulted in any action to date.

It is also surprising that the NTSB did not examine in more detail the effectiveness of the accident alerting or the search and rescue.

Other Safety Resources

UPDATE 15 January 2017: Power of Prediction: Foresight and Flocking Birds looks at how a double engine loss due to striking Canada Geese had been predicted 8 years before the US Airways Flight 1549 ditching in the Hudson (which was just days after the Louisiana helicopter accident).

UPDATE 2 April 2017: NTSB Recommendations on JT15D Failure to Meet Certification Bird Strike Requirements

UPDATE 14 June 2017: This accident features in the first FAA Rotorcraft Lessons Learnt report.

UPDATE 6 December 2017: In a presentation on behalf of the RBSWG to the 11th EASA Rotorcraft Symposium it was revealed that in the US 94% of the current helicopter fleet is made up of types that never needed to meet a bird strike requirement. This accident and the Hudson A320 ditching, both in January 2009, were likely causes of a big increase in all wildlife strikes reporting across the US helicopter fleet.  While fixed wing aircraft predominantly strike birds during take-off and landing, two thirds of rotorcraft strikes occurred during the en route phase (where kinetic energy is highest). Only 8-9% occurred during approach and 9-10% during climb. The presentation went on:

While fixed wing aircraft predominantly strike birds during take-off and landing, two thirds of rotorcraft strikes occurred during the en route phase (where kinetic energy is highest). Only 8-9% occurred during approach and 9-10% during climb. The presentation went on:

The largest single component struck by birds is the windshield with 47% on Part 27 and 40% on Part 29. 84-85% of all bird strikes occurred on components forward of the main rotor mast. This includes the main rotor which experienced 30%-33% of the strikes reported. Not one single record exists for windshield penetration on Part 29 rotorcraft certified to the FAA bird strike airworthiness standard established over 21 years ago. This is statistically significant. For newly manufactured and existing rotorcraft, the RBSWG proposed to use a Risk-Based Safety-Tiered approach that scales the bird strike regulation based on the maximum number of occupants onboard. As the number of occupants increases, so does the risk exposure.

They also recommend:

- Reduce airspeed when practical

- Increase altitude as quickly as possible and practical

- Use taxi and landing lights

They also say:

The location of bird concentrations during seasonal migrations and the local bird nesting and roosting habitats, should be made available to the rotorcraft operator/pilot for preflight planning to minimize the potential for bird strikes. Air carriers and general aviation operators working with the Flight Safety Programs and Flight Service Briefing should identify and publish the known locations and probability of bird concentrations. This information on bird concentrations should be incorporated into alert bulletins, flight service notice to airmen (NOTAM) and other systems presently used to inform flight crews of flight hazards.

The RBSWG submitted its final report to the ARAC on 10 November 2017. The ARAC was due to meet on 14 December 2017 to review the report. It is expected to be made public in 2018.

UPDATE 2 March 2018: Swedish Military NOE Helicopter Bird Strike

UPDATE 15 April 2018: Wildlife strikes add to US Air Force and Navy’s mishap count

UPDATE 5 October 2018: FAA: 665 helicopter bird strikes over the last 3 years

Of the eight injuries reported, four were to pilots, and four were passengers. The incidents typically involved medium to large birds, with some penetrating into the aircraft. The more minor injuries were typically the result of flying debris caused by the strike — particularly broken glass.

In terms of the impact on the aircraft, 79 strikes (12 percent) resulted in at least some damage. Of these, 41 (six percent) produced “substantial damage” — defined as damage to an aircraft’s structural integrity, performance, or flight characteristics, normally requiring major repairs or the replacement of the entire affected component.

In all, 28 incidents resulted in over $10,000 in damage/repair costs, four of which exceeded $100,000. For the three-year period, bird/wildlife strikes to helicopters resulted in a total of over $3.7 million in repair and damage costs — not including the revenue lost to an aircraft being out of service while in repair.

UPDATE 9 November 2018: The NTSB report that Air Methods HEMS Bell 407 N620PA suffered an in-flight loss of control due to multiple bird strikes from a skien of snow geese (typically 4lb+) on 19 November 2017 while cruising at 1240ft AGL (all3 POB died).

UPDATE 28 December 2018: Final Report Issued on 2008 B737 Bird Strike Accident in Rome

UPDATE 3 January 2019: USAF HH-60G Downed by Geese in Norfolk, 7 January 2014

UPDATE 13 June 2019: UK AAIB report on a Bell 429 birdstrike.

UPDATE 7 November 2020: Deadly Dusk Air Ambulance Bird Strike

UPDATE 30 December 2020: AS350B3/H125 Bird Strike with Red Kite

UPDATE 19 April 2021: EASA have issued Safety Information Bulletin SIB 2021-07 on Bird Strike Risk Mitigation in Rotorcraft Operations and accompanying safety promotion material.

UPDATE 23 March 2022: Big Bustard Busts Blade: Propeller Blade Failure After Bird Strike

UPDATE 8 May 2022: HeliOffshore 2022 Conference Review

UPDATE 14 May 2022: Review of “The impact of human factors on pilots’ safety behavior in offshore aviation – Brazil”

UPDATE 28 May 2022 AW169 Birdstrike with a Turkey Vulture

UPDATE 17 February 2023: Dusk Duck: Birdstrike During Air Ambulance Flight

UPDATE 22 April 2023: Swinging Snorkel Sikorsky Smash: Structural Stress Slip-up

UPDATE 8 February 2025: S-76D Loss of Control on Approach to an Indian Drilling Rig

Aerossurance is pleased to sponsor the 2017 European Society of Air Safety Investigators (ESASI) 8th Regional Seminar in Ljubljana, Slovenia on 19 and 20 April 2017. Registration is just €100 per delegate. To register for the seminar please follow this link. ESASI is the European chapter of the International Society of Air Safety Investigators (ISASI).

Recent Comments