Swinging Snorkel Sikorsky Smash: Structural Stress Slip-up (Brainerd Helicopters Sikorsky UH-60A Black Hawk N9FH Firefighting STC MCF)

On 25 May 2021 Sikorsky UH-60A Black Hawk N9FH of Brainerd Helicopters Inc (parent company to Firehawk Helicopters) crashed near Leesburg International Airport (LEE), Florida. This was during the post-maintenance check flight after installation of a snorkel equipped aerial firefighting system. The restricted category helicopter was destroyed and all 4 occupants died.

Wreckage of Brainerd Helicopters Sikorsky UH-60A Black Hawk N9FH, Leesburg, FL (Credit: NTSB)

The US National Transportation Safety Board (NTSB) issued their safety investigation report on 19 April 2023.

The Modification

Eight days earlier the snorkel/tank system had been installed on this ex-military restricted category helicopter in accordance with a Blackhawk Mission Equipment LLC (BME), Federal Aviation Administration (FAA) Supplemental Type Certificate (STC), number SR00933DE, approved by the by the FAA Denver ACO. BME is a subsidiary of Brainerd Helicopters.

Brainerd Helicopters Sikorsky UH-60A Black Hawk N9FH In Flight on the Day of the Accident (Credit: via NTSB)

Several days of ground testing and calibration were performed before the accident flight, which was the first flight after the 925 gallon carbon composite cabin tank and the external snorkel were installed.

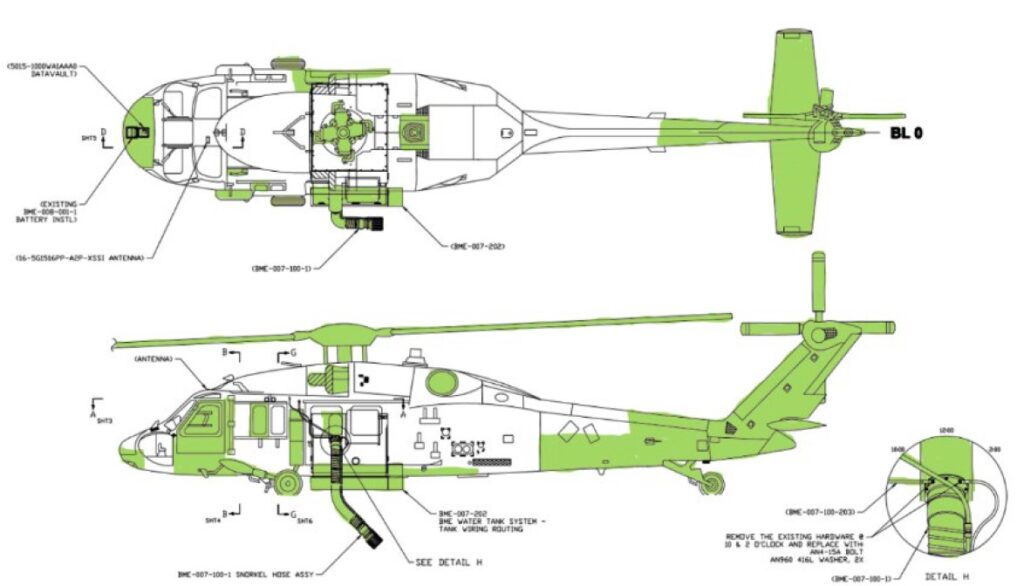

Exemplar Firehawk / Blackhawk Mission Equipment FAA Supplemental Type Certificate (STC) SR00933DE Firefighting System Installation on a Sikorsky UH-60A Black Hawk (Credit: via NTSB)

The snorkel has non-retractable 15 foot long, 6 inch diameter, flexible hose which hangs from the left side of the tank to allow water uplift in a low hover. The snorkel is outboard of a water chute, that extends out of the left cabin door, as the means to empty the tank.

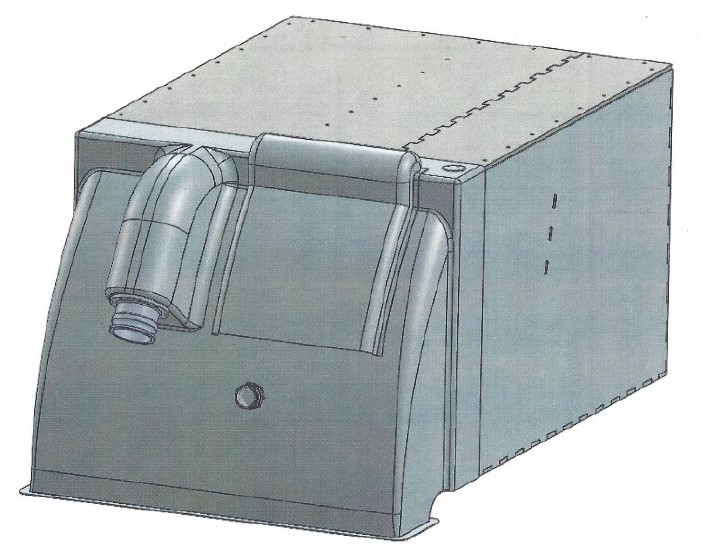

Exemplar Firehawk / Blackhawk Mission Equipment FAA Supplemental Type Certificate (STC) SR00933DE Firefighting System Tank (Credit: via NTSB)

The snorkel is attached to the tank at metal nozzle port which is secured to the tank via a by 8 AN4 bolts fastened to a backing nut plate at carbon fibre flange. The snorkel connects is attached to the nozzle port by a two lever cam-lock (the ‘coupler’). A 7.5 hp pump is mounted at the lower end of the hose.

A power cable for the pump and a lightning protection cable run down the length of the snorkel and are secured using nylon zip ties. The snorkel hose and pump assembly [mounted at the bottom] weighs 137.5 pounds.

The Fatal Accident Flight

The purpose of the local flight was to check the operation of the newly installed fire-fighting system.

The helicopter made six uneventful passes in front of the operator’s hangar at LEE and dropped water that was picked up from a lake adjacent to the airport.

Firefighting Water Drop from Brainerd Helicopters Sikorsky UH-60A Black Hawk N9FH (Credit: via NTSB)

On the seventh pass, an employee of the operator noticed that the snorkel was swinging. He called the LEE air traffic control [ATC] tower and told the controller to ask the pilot to slow down and land immediately.

Before the controller could contact the pilot, the helicopter transitioned to forward flight, gaining altitude and airspeed.

During the helicopter’s last pass another witness saw the snorkel swinging in a large circle that came “very close” to the main rotor blades.

The employee who contacted ATC said the snorkel was “violently” swinging, then heard a loud bang and…

…saw pieces of the helicopter, including the tail section, separate from the helicopter. Afterward, the helicopter started to spin and descended below the tree line. The employee then heard an explosion and saw smoke rise above the tree line.

The wreckage was contained in a 31-foot diameter vertical impact crater…in a localized swamp approximately 1,000 feet southeast from the approach end of Runway 3…and had been consumed by fire.

The vertical tail, tail rotor, stabilator, and aft portion of the empennage was located about 50 yards away on a bearing 020° magnetic from the main wreckage.

The tail section had not been exposed to fire and all tail rotor and stabilator components were present.

Tail Debris of Brainerd Helicopters Sikorsky UH-60A Black Hawk N9FH, Leesburg, FL (Credit: NTSB)

Safety Investigation

A hangar security video recording…

…showed the helicopter flying away from the camera in level flight. The helicopter yawed suddenly, started to rotate around its vertical axis, and broke apart. The helicopter then descended vertically into the wooded area beside the runway.

Unfortunately the exact behaviour of the snorkel could not be discerned in the video.

The NTSB recovered and examined those portions of the helicopter shown in green:

One main rotor blade exhibited damage consistent with striking the stainless steel ‘screen’ or ‘cage’ fitted to the snorkel’s inlet nozzle. That component was found 50 ft west of Runway 3. Nearby was the badly damaged electrical pump from the inlet nozzle.

Main Rotor Blade Damage to Brainerd Helicopters Sikorsky UH-60A Black Hawk N9FH Corresponded to the Snorkel Pump Nozzle Screen / Cage (Credit: NTSB)

There was also evidence of blue paint marks transferred to rotor blades, consistent with a strike on the tail boom.

Portions of the water tank and snorkel hose connecting port were located next to the left main landing gear within the main wreckage. A [lower] 10-ft section of the hose assembly (not including the suction pump) was located underneath the forward left side of the fuselage.

The upper hose remained attached to the tank snorkel support, and the coupler levers were in the locked position [found near the runway – see above]. Portions of the hose had torn away from the tank snorkel support, and the edges were melted [by the post crash fire].

The fire tank nozzle support structure had torn away from the aft side of the coupler assembly, revealing a ripped and deformed portion of nut plate. The nut-bolt fastener were in place but had ripped through the nut plate material.

Damage to Snorkel Hose Connection to Tank on Brainerd Helicopters Sikorsky UH-60A Black Hawk N9FH (Credit: NTSB)

Most of the moulded front section of the tank was fragmented and was largely destroyed by fire. The snorkel port that extends out of the moulded front section of the tank was recovered.

The Accident Sequence

The NTSB determined that:

Given the sudden change in behaviour of the snorkel from a consistently stable condition in normal flight to one with large and erratic oscillations, it is likely that the tank snorkel support structure was compromised and allowed the snorkel’s oscillations to increase in such a way that the pump assembly at the end of the snorkel hose contacted the main rotor blade.

The contact imparted enough energy to fracture the rotor blade at the contact point, which resulted in an imbalanced rotor system and a subsequent in-flight breakup of the helicopter.

The Design Cause

The NTSB explain that:

Blackhawk Mission Equipment LLC hired a program manager and numerous FAA Designated Engineering Representatives (DERs) to design the water tank and snorkel system, to conduct testing, and provide associated documentation to the FAA Project Team. The FAA Project Team coordinates with the STC applicant to develop a Project Specific Certification Plan (PSCP).

The STC application…had been approved by the FAA about 1 year prior to the accident.

NTSB note that:

A review of the STC application documentation revealed that the FAA had not classified the water tank and snorkel system as an external load.

This is not surprising as the snorkel is a piece of aircraft equipment, although there were potentially ambiguous references in the PSCP to operations with external loads that may have confused the NTSB.

Brainerd Helicopters Sikorsky UH-60A Black Hawk N9FH (Credit: via NTSB)

More significantly…

…the PSCP did not include the airworthiness standards for rotor blade clearances from rotorcraft structure per 14 CFR Part 29.661.

The NTSB found that:

The structural analysis of the tank used the incorrect weight of the snorkel hose and pump combination [100 lb rather than 137.5 lb].

More significantly the structural analysis did not…

…account for operational loads that would be imparted into the tank by the snorkel as called for in the certification basis in the PSCP.

Crucially:

[T]he calculations only considered a static vertical load applied to the snorkel support. The structural analysis of the snorkel support did not account for the type of dynamic loading that would be seen in operation, such as, air loads imparted by the snorkel, lateral loads imparted by the snorkel, water loads imparted by tank filling operation, water loads imparted by movement of the snorkel and pump horizontally through the water or loads imparted by the snorkel if the assembly was snagged.

The FAA ACO stated that: [Part 29] Subpart C-Strength Requirements in the PSCP, for General (29.301, 29.305(a), 29.307(a)), for flight loads (29.321–29.251, & 29.561(a)(c)) were part of the certification basis. This would have required determination of the lateral and dynamic forces on the snorkel to be used in the analysis.

Furthermore:

Testing of the snorkel and pump loads did not incorporate the water tank structure to which the snorkel was attached.

Instead a pull test had been done on the hose and pump/nozzle, with the hose mounted in a test fitting. The tank mounting was not tested at that time.

A production tank was examined by NTSB:

A manual load test was performed with the snorkel attached to the tank snorkel support structure. When the snorkel was pulled manually from the tank, the tank structure between the hose coupler and the tank face deformed between 0.03 and 0.05 inches. These manual loads represented only a small fraction of the loads that the tank snorkel support structure would experience during normal operation.

The NTSB concluded that the design and certification data “was insufficient because it failed to consider the failure scenario that occurred during the accident”.

[A] Functional Hazard Assessment and System Safety Assessment (FHA/SSA) was submitted to document the most likely failure conditions and mitigations for the water tank and snorkel system. The FHA identified 13 discrete failure/hazard conditions and their effect on the rotorcraft or crew. All 13 were verified using the qualitative analysis method.

Three were classified as “no safety effect”, seven were classified as “minor failure condition”, and two were classified as “major failure condition.” The two that were classified as ”major” were: (1) water tank attachments become unsecure in flight, and (2) snorkel pump becomes snagged on ground obstacle or object.

It is notable that the failure condition of the snorkel hitting or getting entangled in aircraft structure (other than tail or main rotor) was classified as a minor failure condition.

Flight tests were conducted at airspeeds from 0 knots up to 193 kts IAS (1.1 times Vne), angles of bank up to 30º, climbs, normal descents, and autorotative descents. The FAA explained to the NTSB:

The FHA/SSA did not include snorkel contact to the rotor system due to required compliance to 29.251 – vibration, using flight testing. Flight test data showed that under normal operating parameters the snorkel structure would not create excessive vibrations to lead to the failure mode of the snorkel contacting the rotor system. This result satisfied 29.1309: “The equipment, system, and installations whose function is required by this subchapter must be designed and installed to ensure that they performed their intended functions under any foreseeable operating condition.”

NTSB Probable Cause

The failure of the water tank snorkel support structure, which allowed the snorkel to contact the main rotor blades.

Contributing to the accident was insufficient FAA oversight of the STC process for the water tank and snorkel.

Oddly there is no consideration of the actual design process in the probable cause nor does it appear that the NTSB interviewed the designers.

Safety Resources

The European Safety Promotion Network Rotorcraft (ESPN-R) has a helicopter safety discussion group on LinkedIn. You may also find these Aerossurance articles of interest:

- NZ Firefighting AS350 Accident: Role Equipment Design Issues

- 2009 Newfoundland S-92A C-GZCH Accident: A Failure of Design and Certification

- Fire-Fighting AS350 Hydraulics Accident: Dormant Miswiring

- HESLO EC135 LOC-I & Water Impact: Hook Confusion after Personnel Change

- Maintenance Issues in Fire-Fighting S-61A Accident

- South Korean Fire-Fighting Helicopter Tail Rotor Strike on Fuel Bowser

- Firefighting AW139 Loss of Control and Tree Impact

- Competitive Behaviour’ and a Fire-Fighting Aircraft Stall

- Short Sling Stings Speedy Squirrel: Tail Rotor Strike Fire-Fighting in Réunion

- Black Hawk Scud Running in Tennessee: IIMC & CFIT

- Usage Related Ex-Military Helicopter Accident

- Yuma Hawk Accident: Lessons on Ex-Military Aircraft Operation

- Canadian B212 Crash: A Defective Production Process

- PA-34 Electrical Short Melted Rudder Cable

- In-Flight Flying Control Failure: Indonesian Sikorsky S-76C+ PK-FUP

- Main Rotor Blade Certification Anomaly in Fatal Canadian Accident

- NTSB: Ergonomics Explain Main Rotor Loss During Flight Test

- ANSV Issue AW609 Tilt Rotor Accident Investigation Update

- Bell 525 Prototype N525TA Fatal Flight Test Accident

- SAR AW101 Roll-Over: Entry Into Service Involved “Persistently Elevated and Confusing Operational Risk”

- Second Time Unlucky: Fatal Greek Wirestrike High-Wire Illusion

- Safety Lessons from a Fatal Helicopter Bird Strike: Sikorsky S-76C++ N748P, 4 January 2009

- MC-12W Loss of Control Orbiting Over Afghanistan: Lessons in Training and Urgent Operational Requirements

- UPDATE 14 May 2023: HH-60L Hoist Cable Damage Highlights Need for Cable Guards

Recent Comments