Tail Rotor Lightning Strip Damages AW139 Main Rotor

On 7 April 2016 Leonardo Helicopters AW139 N639NA, operated by Chevron USA as a Part 91 ‘business flight’ sustained damage to a Main Rotor Blade (MRB) tip while flying over the Gulf of Mexico. The flight was from South Lafourche (GAO), Louisiana, to an offshore installation in the Gulf of Mexico and back. The aircraft landed safely will no injury to any of the 9 persons on board.

The US National Transportation Safety Board (NTSB) classified this occurrence as an accident, primarily due to the MRB damage (we detail the legal definition below). They explain in their safety investigation report issued on 25 June 2019:

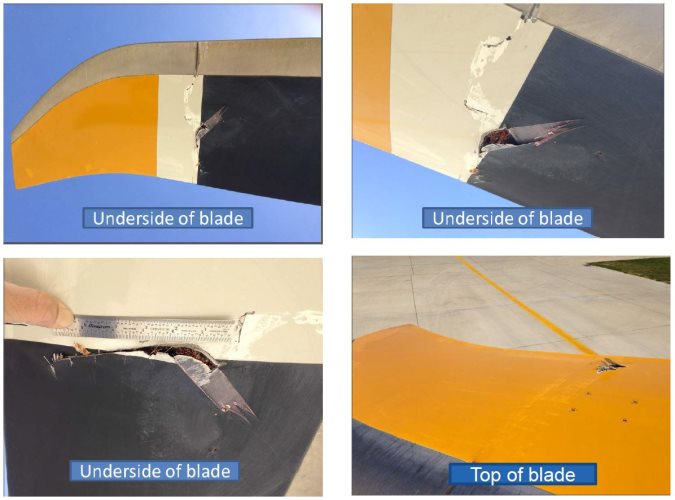

…during the flight the crew felt a slight vibration of the tail rotor. After landing at GAO during a post flight inspection, one of the tail rotor blade (TRB) erosion shield extensions, commonly known as a lightning strip (LS), was missing…

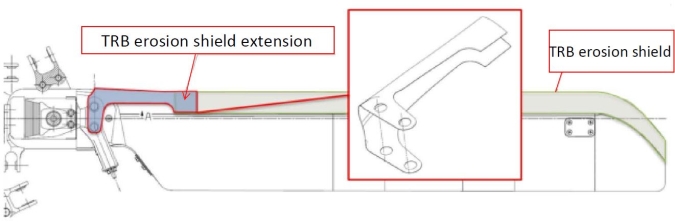

AW139 Tail Rotor Blade (TRB) erosion shield extension diagram with notations (Credit: Leonardo Helicopters via NTSB)

….and only its side tabs remained attached to the blade.

The MRB damage was also detected.

The Safety Investigation

The accident was reported to the NTSB 32 days after it occurred for reasons not detailed.

The separated LS was identified as part number (p/n) 3G6410L00152 that was manufactured in electroplated nickel.

Chevron reported that as a normal maintenance practice, an LS would be installed as a brand new part or as an “on-condition” item that had been installed at the discretion of the company maintenance personnel after the component was inspected and determined to be in airworthy condition.

The LS are unserialised and their lives are not tracked.

Chevron reported that the associated tail rotor blade (TRB) was received new from Leonardo on May 22, 2015, without an LS installed.

On January 30, 2016, the white TRB was removed and replaced due to wear on the main erosion shield from contact with the LS. The same LS [as on the previous blade] was reinstalled on the replacement white TRB.

From February 26, 2016, to April 6, 2016 the helicopter accumulated 129.1 flight hours with the new TRB installed. During that time, 34 daily serviceability checklist inspections were completed and no discrepancies applicable to the LS on the white TRB (or any other TRB) were noted.

After the occurrence Chevron completed a fleet check and added a daly 10X magnifying glass inspection of area as containment actions.

Once the TRB was returned to Leonardo, they…

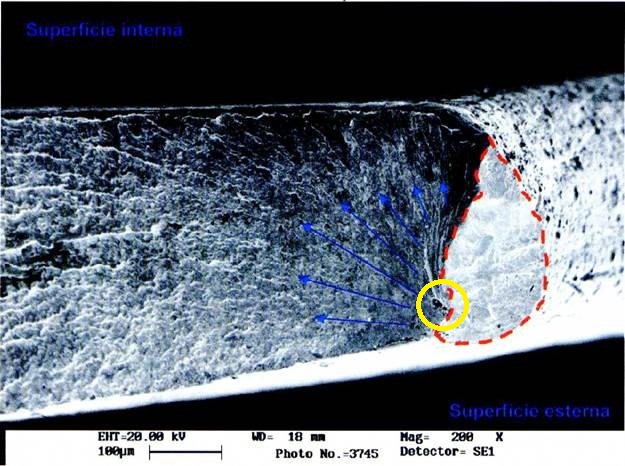

…performed a failure analysis on the remaining portion of the LS, using a scanning electron microscope (SEM), which revealed the presence of microcavity spots or porosity on the surface of the fractured section. Leonardo concluded that the microcavities were a direct result of the electroplating manufacturing process.

SEM image of the N639NA TRB LS fatigue propagation from a micro-cavity, yellow circle (Credit: Leonardo via NTSB)

In [the image above] the area circled in yellow is the microcavity, the red dashes indicate the crack initiation, and the blue arrows indicate the direction of the fatigue crack propagation.

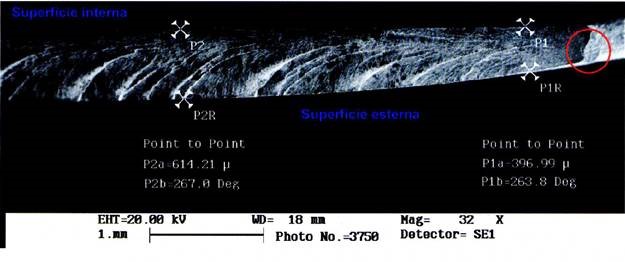

It then propagated further from its origin (circled in red).

Finite element modelling (FEM) of an exemplar LS was completed to determine the expected inflight stress values, to include the influence of the centrifugal force and the bending moment due to the deformation of the TRB under beam bending loads. The simulation showed that the maximum stress values in the crack initiation area were considerably lower than the fatigue limit specified for the electroplated nickel material.

The FEM model considered the geometric and fitting stress concentrations without the presence of a material flaw (such as a microcavity). Although the microcavity observed on the accident LS could not be replicated by the FEM model, Leonardo concluded that the presence of a microcavity could adversely influence the in-flight stresses and reduce the overall strength of the LS.

A flight test was performed to evaluate the load conditions of the LS during flight. Strain measurement instrumentation was installed on a Leonardo [AW139, but] did not reveal any particular load condition that could lead to similar LS failures experienced during the accident flight.

Leonardo identified 6 additional events involving the same LS part number. All…resulted in an uneventful landing.

- LS crack identified during scheduled inspections (3 events)

- LS fractured and separated in flight (2 events)

- LS fractured and separated inflight, which resulted in damage to MRB tip (2 events, including the accident flight)

NTSB Probable Cause

Despite 38 months to reach a probable cause determination, the NTSB settled on a fairly simplistic probable cause that:

The fatigue failure of a tail rotor blade erosion shield extension, which resulted in in-flight damage to a main rotor blade.

Leonardo concluded more precisely that the fatigue originated from microcavities created during the electroplating manufacturing process.

Safety Action

In response to the reports of similar LS failures, Leonardo changed the specification from electroplated nickel to a higher strength steel.

As of July 31, 2017, for all newly built helicopters, the TRB installation drawing was updated to prescribe the installation of a steel LS, p/n 3G6410A03053 [with a revised design].

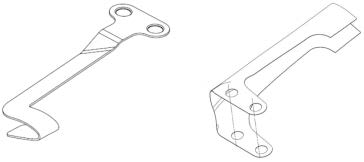

Diagram of the updated AW139 TRB steel LS (left) and electroplated nickel LS (right) (Credit Leonardo via NTSB)

Additionally, Leonardo will issue an optional service bulletin to provide the steel LS upon customer request.

No comment is made on the reuse of the unserialised TRB of leading edge Lightning Strips.

Taxonomies of Flight Safety

The NTSB classified this occurrence as an accident as per the following US legal definitions:

830.2 Definitions. As used in this part the following words or phrases are defined as follows:

Aircraft accident means an occurrence associated with the operation of an aircraft which takes place between the time any person boards the aircraft with the intention of flight and all such persons have disembarked, and in which any person suffers death or serious injury, or in which the aircraft receives substantial damage. For purposes of this part, the definition of ‘‘aircraft accident’’ includes ‘‘unmanned aircraft accident,’’ as defined herein.

Substantial damage means damage or failure which adversely affects the structural strength, performance, or flight characteristics of the aircraft, and which would normally require major repair or replacement of the affected component. Engine failure or damage limited to an engine if only one engine fails or is damaged, bent fairings or cowling, dented skin, small punctured holes in the skin or fabric, ground damage to rotor or propeller blades, and damage to landing gear, wheels, tires, flaps, engine accessories, brakes, or wingtips are not considered ‘‘substantial damage’’ for the purpose of this part.

It is a feature of the ICAO Annex 13 classification system that minor blade damage does not equate to an accident. That wording is not in the US regulation.

The official classification of this occurrence as an accident 3 years after the event undermines a number of industry safety statistics such as here: Helicopter Ops and Safety – Gulf Of Mexico 2016 Update

Other Safety Resources

- Eclipse 500 Landing Gear Production Defect

- Production Errors on a SAR Helicopter Full Ice Protection System

- Machining Defect Cause of V2500 Failure

- Micro FOD: Cessna 208B Grand Caravan Engine Failure & Forced Landing

- ERJ175 NLG Uplock Spring Production Defect

- S-76C+ MLG Collapsed Due to Pothole

- UPDATE 3 July 2021: EC130 Door Loss Damaged Main Rotor Blades

- UPDATE 7 November 2021: Italian Alps AW139 Mountain Rescue Hoisting Blade Strike

Recent Comments