B767 Engine Fire – Ignition from Misrouted / Chaffed Cables

The National Transportation Safety Board (NTSB) have reported on an engine fire that occurred on 11 July 2014 when:

…Boeing B-767-332, registration number N139DL, operated by Delta Air Lines (DAL)… powered by two General Electric (GE) CF6-80A2 turbofan engines, experienced a left engine (No. 1) fire during climb at about flight level (FL) 190 (19,000 feet) from Los Angeles International Airport (LAX), Los Angles, California.

The crew performed the appropriate fire drills and made a successful overweight landing at LAX.

The Investigation

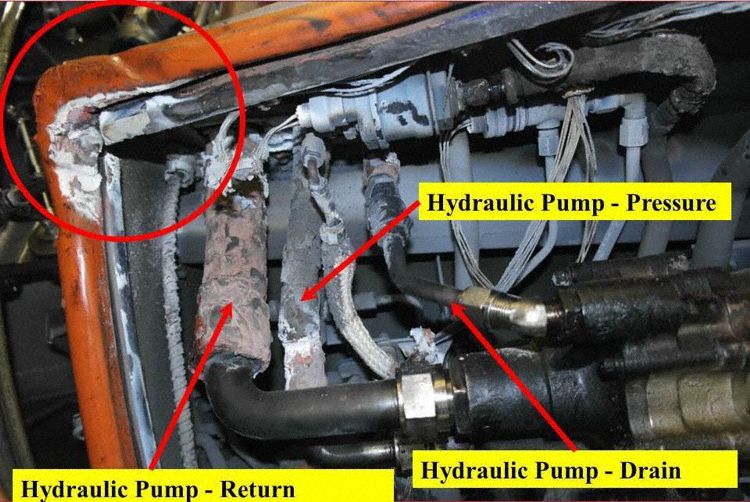

Examination of the engine revealed that the fire damage was concentrated under the engine heatshield from about the 6:00 o’clock position to the 8:30 o’clock position (aft looking forward) and forward of the accessory gearbox. The fire and thermal distress included melted and consumed electric wire insulation, melted and consumed accessory gearbox fire loop isolators, melted and consumed tubing P-clamps, exposed electric wire conductors, and soot deposits.

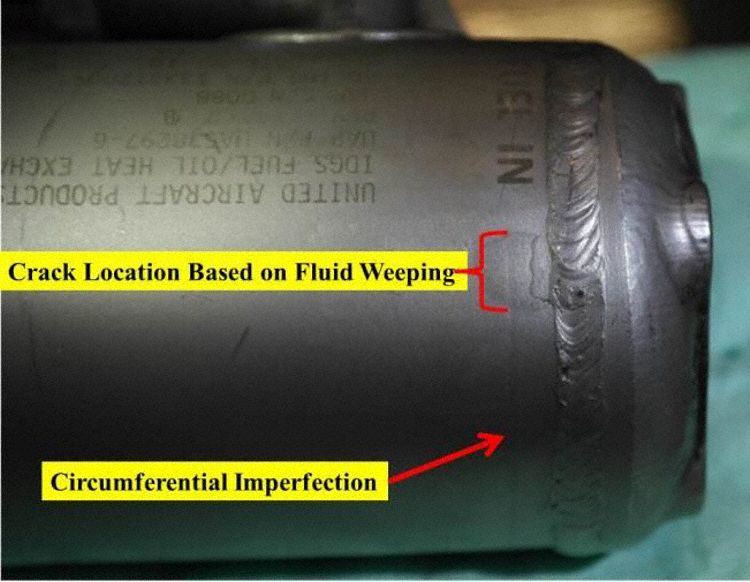

A fuel leak was detected from the integrated drive generator (IDG) fuel/oil heat exchanger main housing, which is located below the engine heatshield. Cracks were identified where the inner core was brazed to the main housing.

Additionally:

Removal of the IDG power feeder cables revealed evidence of chaffing and arc burn; this damage was not related to the fire damage that was observed overall as a result of the actual fire.

.. the accessory drive lube and scavenge pump pressure (supply) line support bracket…exhibited evidence of melted material consistent with an arc burn. The location of the arc burn on the bracket was in-line with the arc burn observed in the IDG power feeder cables.

The NTSB also note:

…the IDG power feeder cables (below the engine heatshield) were not tight and straight along their support bracket but exhibited slack and dangling below the support bracket. …there should be no slack in the IDG cables; instead the cables should run straight and tight along its support bracket and gently bend upward towards the cutout hole in the engine heatshield.

…the IDG power feeder cables also exhibited a considerable amount of orange tape to bundle all the cables together. This excessive slack in the IDG power feeder cables created the situation where the cables could get pinched/wedged between the inside of the thrust reverse cowl and the accessory drive lube and scavenge pump pressure (supply) line support bracket when the thrust cowl is closed and latched creating the environment for the IDG power feeder cables to chaff against the support bracket.

They also observed that:

The excessive amount of tape used on the IDG power feeder cables suggests that maintenance personnel may have noticed this chaffing and added extra tape without realizing that the chaffing was caused from the thrust reverser pressing the IDG power feeder cables against the bracket or that the slack was contributing to the chaffing.

Conclusions

The NTSB determined the Probable Cause was:

The combination of fuel leaking from the integrated drive generator (IDG) fuel/oil heat exchanger and the coincident arcing of the IDG power feeder cables that ignited the leaking fuel.

Contributing to the ignition of the fuel was the misrouting of the IDG power feeder cables, which resulted in chaffed cables that exposed the electrical wire that contacted a metal bracket, creating an arc.

Safety Action

Based on this event, Delta:

1) updated their IDG power feeder work cards to provide additional information and guidance on the proper routing of the IDG cables both above and below the engine heatshield in order to clarify any potential confusion and to prevent future arcing events

2) conducted a once-through-the-fleet inspection for misrouted IDG power feeder cables.

The fleet inspection found 3 further misrouted IDG power feeder cables which, with both engines on N139DL, brought the total to five. Delta corrected the routing on these engines.

Maintenance Human Factors Resources

Aerossurance is proud to have sponsored a recent Royal Aeronautical Society (RAeS) seminar, Maintenance Human Factors: The Next Generation, at Cranfield University. Presentations from that seminar are available here.

Aerossurance has also previously written about a number of human factors / continuing airworthiness issues:

- Professor James Reason’s 12 Principles of Error Management

- How To Develop Your Organisation’s Safety Culture

- Critical Maintenance Tasks

- Fatal $16 Million Maintenance Errors

- Technical Records – Component Overrun

- Inadvertent Fire Bottle Discharge During Maintenance

- FOD Damages 737 Flying Controls

- Cessna Citation Excel Controls Freeze

- UPDATE 9 January 2017: S-92A Flying Control Restriction on Wiring Loom

- UPDATE 30 May 2019: PA-34 Electrical Short Melted Rudder Cable

- UPDATE 18 November 2020: Embraer ERJ-190 EWIS Production Quality a Factor in Fire

- UPDATE 27 December 2020: Fire-Fighting AS350 Hydraulics Accident: Dormant Miswiring

- UPDATE 8 February 2021: RCAF Investigate Defect on Newly Delivered CH-148 Cyclone (S-92)

Aerossurance worked with the Flight Safety Foundation (FSF) to create a Maintenance Observation Program (MOP) requirement for their contractible BARSOHO offshore helicopter Safety Performance Requirements to help learning about routine maintenance and then to initiate safety improvements:

Aerossurance can provide practice guidance and specialist support to successfully implement a MOP.

Aerossurance is also pleased to be sponsoring the Chartered Institute of Ergonomics & Human Factors‘ Human Factors in Aviation Safety conference at East Midlands Airport 9-10 November 2015 (UPDATE: and to support and present at the November 2016 event).

Aerossurance is pleased to be both sponsoring and presenting at a Royal Aeronautical Society (RAeS) Human Factors Group: Engineering seminar Maintenance Error: Are we learning? to be held on 9 May 2019 at Cranfield University.

Recent Comments