Crashworthiness and a Fiery Frisco US HEMS Accident (Airbus Helicopters AS350B3e, N390LG of Air Methods)

Shortly after take-off from a hospital in Frisco, Colorado, on 2 July 2015, Airbus Helicopters AS350B3e helicopter, N390LG, operated by Air Methods as ‘Flight for Life’, crashed in a parking lot 120m away. This was a daytime, Visual Meteorological Condition (VMC), Part 135 flight.

The US National Transportation Safety Board (NTSB) preliminary report stated:

Multiple witnesses observed the helicopter lift off from the ground-based helipad, rotate counterclockwise, and climb simultaneously. One witness estimated that the helicopter reached an altitude of 100 feet before it started to descend. The helicopter continued to spin counterclockwise several times before it impacted a parking lot and an RV to the southwest of the Flight for Life hangar and helipad. The helicopter came to rest on its right side, was damaged by impact forces, and was charred, melted, and partially consumed by fire.

UPDATE: Ultimately the NTSB Final Report was issued 27 March 2017.

Below are a sequence of screen shots from security CCTV video shown by 9News who in an excellent piece of journalism have devoted much research to this topic:

A small fire starts, but fuel pours out an soon ignites. 28 seconds after impact one of the medical personnel is seen to kick out a door and jumps clear, on fire and suffering from 90% burns. He is still in hospital after over 30 operations. Amazingly, the other manages to egress without significant injury. A member of staff bravely approaches the helicopter with a hand held extinguisher.

A small fire starts, but fuel pours out an soon ignites. 28 seconds after impact one of the medical personnel is seen to kick out a door and jumps clear, on fire and suffering from 90% burns. He is still in hospital after over 30 operations. Amazingly, the other manages to egress without significant injury. A member of staff bravely approaches the helicopter with a hand held extinguisher.  Shortly after the pilot egresses the wreckage. He died later in hospital. The fire was brought under control by local fire departments.

Shortly after the pilot egresses the wreckage. He died later in hospital. The fire was brought under control by local fire departments.

The aircraft was positioning for display at a Boy Scouts of America event. This was Air Methods’ second fatal air accident with a post crash fire in 4 months. That accident also involved a positioning flight. Air Methods, a large player in the HEMS business founded in 1980, has had 7 air accidents in the last 5 years according to the Aviation Safety Network (looking at their HEMS business only). Five were fatal accidents with 12 fatalities.

Crash Resistant Fuel Systems

Although this particular As350 was only about a year old, as a type the AS350 was certified prior to enhance certification requirements for a crash resistant fuel system (CRFS) introduced in 1994. When those were introduced, the Federal Aviation Administration (FAA) stated:

A post-crash fire (PCF) is the number one cause of fatalities and injuries in an otherwise survivable impact resulting from a rotorcraft accident. It is estimated that annually 5 percent of the occupants in survivable rotorcraft accidents are killed or injured by a PCF. These types of fatalities and traumatic injuries would be substantially reduced by adopting the design and test criteria proposed in this notice.

Nearly all PCF’s are caused by crash-induced fuel leaks that quickly come in contact with ignition sources during or after impact. Current FAA rotorcraft airworthiness standards do not comprehensively address minimizing fuel leaks and potential fuel ignition sources in order to maximize occupant escape time in a survivable crash. The fuel containment and hazard elimination provisions contained in these proposals would, in the majority of cases, give occupants the time necessary to escape a survivable crash before a PCF could become critical.

A crash resistant fuel system, CRFS, would not be expected to prevent all fires; however, a CRFS would, in the majority of impact survivable cases, either prevent a PCF or delay the sudden massive fire, or fireball, long enough to allow the occupants to escape. These proposed standards have been validated by military safety statistics and their adoption would significantly minimize the PCF hazard and its associated fatalities and injuries.

In a study of helicopter accidents in the US in 2006 it was noted that the percentage of aircraft in the US fleet that meets this requirement remains low. The same study also noted that 9% of all US accidents in 2006 resulted in a post-crash fire. In those 13 accidents, there were 18 fatalities, which represented 44% of all US helicopter fatalities that year.

At the FAA Rotorcraft Safety Conference in April 2015 this presentation was given: Post Crash Fire and Blunt Force Fatal Injuries in U.S. Registered, Type Certificated Rotorcraft Airbus Helicopters now offers a crashworthy fuel system modification on new AS350B3e / H125 helicopters.

Encouragingly, Vector Aerospace displayed a new AS350 Primary Fuel Tank at HAI Heli-Expo 2015. Designed in cooperation with Robertson Fuel Systems LLC, the direct replacement Primary Fuel Tank features modern fuel retention technology and an increased fuel capacity (567 Litres vs 552 Litres). Once they gain a Supplemental Type Certificate (STC), they are targeting the AS350B2 retrofit market initially but new tank is also compatible with the AS350 series and EC130 aircraft. It will be interesting to see how quickly such a retrofit is taken up.

UPDATE 23 July 2015: Two days after we published this article the NTSB coincidentally published the probable cause of another HEMS accident with a post crash fire and issued a safety recommendation

The AirEvac B206 Wichita Falls Accident

On 4 October 2014 Bell 206L1+ N335AE of Air Evac EMS crashed on approach to a hospital helipad at Wichita Falls, Texas. The patient, a gunshot victim, was pronounced dead at the scene (though may have succumb to his prior injuries). The flight nurse and paramedic initially survived with severe burns, but both died within a month. The pilot was seriously injured.

The NTSB concluded the probable cause was:

The pilot’s failure to maintain yaw control when he applied power to execute a go-around at a low airspeed in dark, night conditions, which resulted in a rapid, uncommanded right yaw due to a loss of tail rotor effectiveness.

Hospital surveillance camera footage showed a large explosion about 6 seconds after impact. The NTSB note in that case:

It was also observed that the two main fuel lines that transfer fuel from the forward fuel tanks to the main tanks were separated at their rear fittings just aft of the broom closet. According to the FAA and Bell, there are no break-away fittings or mechanism (sensor) that would have sensed a separation and stopped fuel flow after the accident if power was applied. If the engine continued to run after the accident, raw fuel would have continued to be pumped into the aft cabin area from the forward tanks. Fuel may have also drained from vent lines due to the helicopter being inverted.

The New NTSB Recommendation

The NTSB issued Recommendation A15-012 on 23 July 2015 says:

Require, for all newly manufactured rotorcraft regardless of the design’s original certification date, that the fuel systems meet the crashworthiness requirements of 14 Code of Federal Regulations 27.952 or 29.952, “Fuel System Crash Resistance.”

The NTSB note that these rules were introduced in 1994 but helicopter types that are in production but certified earlier do not currently need to comply. In their recommendation letter the NTSB reinforce the point made in the accident study we reference above by noting:

Between 1994 and 2013, the NTSB has investigated at least 135 accidents in the United States involving certificated helicopters of various models that resulted in a postcrash fire. Those accidents resulted in 221 fatalities and 37 serious injuries. Only three of the accident helicopters that experienced postcrash fire had crash-resistant fuel systems and crashworthy fuel tanks.

The NTSB then state that only 15% of the US helicopter fleet are fitted with fuel systems that meet this requirement. They go on to say:

Given the significant safety benefit of crash-resistant fuel systems, the NTSB is concerned that, 20 years after needed safety improvement in the design of helicopters was mandated, such a small percentage of US-registered helicopters currently flying meet the requirement for these systems.

While ensuring that all new production helicopters meet 2x.952, this will still only have a slow improvement on the percentage of the fleet equipped unless operators start to retrofit equipment into older in-service helicopters.

UPDATE 6 August 2015: A press report says: Lawsuits renew attention on operation of dual-hydraulic AS350 helicopters

As AS350 variants became more powerful, the tail rotor blade area was increased by using larger trim tabs. The downside is that upon hydraulic pressure loss, the pedal loads would become excessive. Consequently a yaw load compensator is used as a back-up to the single hydraulic system. It uses a hydraulic accumulator is used to assist the pilot. The system is tested before flight, but if the pilot is distracted and leaves the test switch on, the pressure can drain from the accumulator.

UPDATE 1 September 2015: This topic will be discussed at the next FAA Aviation Rulemaking Advisory Committee (ARAC) meeting on 17 September 2015 where a new Rotorcraft Occupant Protection Working Group (ROPWG) is to be launched.

UPDATE 21 October 2015: The FAA has written to the NTSB to say they have asked the ARAC to draft new regulations.

UPDATE 31 October 2015: Air Methods are reported to being planning to upgrade its AS350s/H125s and EC130/H130s with crash-resistant fuel systems as soon as next year, according to Denver TV station KUSA. Air Methods sent the station a statement that it “is committed to retrofitting 100% of our Airbus AS350/EC130 (H125/H130) fleet”. The statement added that Air Methods expects “a crashworthy system to be certified in 2016” for the Airbus H125 and H130 and that the fitment was “the right thing to do”.

UPDATE 5 November 2015: The notice of a new ARAC task assignment is issued. British readers will note the irony of the date.

UPDATE 24 November 2015: In an exciting new development it is reported that the Air Medical Operators Association (AMOA) has committed:

…to the installation of Crash Resistant Fuel Systems (CRFS) in all new aircraft and equipping current aircraft with CRFS as those products become available.

They go on to say that their members are proud to partner with Bell Helicopter and Airbus Helicopters on this initiative and it is also reported that:

The focus of AMOA’s [previous] safety initiatives, including ones on increased use of night vision goggles, flight data monitoring systems and flight simulators, has been on accident prevention. The move to equip crash-resistant fuel systems “is the first commitment to address crash survivability,” said the association’s chairman, Fred Buttrell.

AMOA consists of:

- Metro Aviation

- Med-Trans Corporation

- Seven Bar Flying Service

- Air Methods Corporation

- Air Evac Lifeteam

- California Shock Trauma Rescue (CALSTAR)

- HALO Flight

- Eagle Med

- PHI Air Medical

- REACH Air Medical Services

- Trauma Hawk/ Healthcare District Palm Beach County

- Mercy Flights

It remains to see if other sectors (operators and or their customers) make similar commitments.

UPDATE 10 December 2015: Air Methods have issued this VIDEO.

UPDATE 20 December 2015: The 9News documentary is now available online: 9Wants To Know: Fueling the Fire

Buried beneath a mix of federal bureaucracy and ambivalence is a story that explains why thousands of helicopters in use today remain vulnerable to the very same problem that doomed a Flight for Life crew in Frisco, Colorado, earlier this year. For five months, 9Wants to Know analyzed hundreds of NTSB accident reports in an effort to better understand what’s “fueling the fire.” Based heavily upon a combination of interviews with victims and researchers, our conclusions have generated interest within the aviation industry and Congress and will form the basis of a national discussion that is finally underway.

UPDATE 21 December 2015: Private equity firm American Securities, is selling fuel system specialists Robertson Fuel Systems to HEICO Corporation for $255 million saying:

Tempe, Arizona-based Robertson is the world leader in the design and production of mission-extending, crashworthy, and ballistically self-sealing auxiliary fuel systems for military rotorcraft. Robertson’s products include approximately 65 different fuel systems serving over 50 different platforms across military and civil aircraft and ground vehicles. Founded in 1977 by Harry Robertson, Robertson has an installed base of over 11,000 fuel tank assemblies delivered since then and has made significant investments in developing its products over a long period of time. Robertson employs approximately 125 people at its facilities in Tempe, Arizona and Bluffdale, Utah.

Robertson are likely to benefit from any move to retrofit crashworthy fuel systems.

UPDATE 29 December 2015: Helicopter Industry Changes Course to Make Safety Improvements

UPDATE 1 March 2016: Vector Aerospace and Robertson Fuel Systems were exhibiting their soon to be certified CRFS at HAI Heli-Expo 2016 in Louisville, Kentucky.

UPDATE 23 March 2016: The NTSB is issues three safety recommendations to the FAA and one safety recommendation to EASA however they have chosen not to recommend making the CFRS retrofit mandatory: To FAA:

- Once Airbus Helicopters completes development of a retrofit kit to incorporate a crash-resistant fuel system into AS350 B3e and similarly designed variants, prioritize its approval to accelerate its availability to operators. (A-16-8)

- Issue a special airworthiness information bulletin (SAIB) informing all owners and operators of AS350 B3e and similarly designed variants of the availability of a crash-resistant fuel system retrofit kit and urging that it be installed as soon as practicable. To encourage helicopter owners and operators to retrofit existing helicopters with a crash-resistant fuel system, the SAIB should also discuss the helicopter accidents cited in this report. (A-16-9)

- Issue a special airworthiness information bulletin that is periodically updated to inform all helicopter owners and operators about available modifications to improve fuel system crashworthiness and urge that they be installed as soon as practicable. To encourage helicopter owners and operators to retrofit existing helicopters with a crash-resistant fuel system, the SAIB should also discuss the helicopter accidents cited in this report. (A-16-10)

To EASA:

- Once Airbus Helicopters completes development of a retrofit kit to incorporate a crash-resistant fuel system into AS350 B3e and similarly designed variants, prioritize its approval to accelerate its availability to operators. (A-16-11)

UPDATE 16 May 2016: KUSA report that:

Four of the five people killed in a fiery [Bell 206] helicopter crash in Tennessee in April died not as a result of the crash, but because of burns sustained in the post-crash fire, according to an autopsy report released to the public Monday.

UPDATE 19 May 2016: Vertical Magazine publish: Crash-resistant fuel systems: determining available mods is not always easy. They point out that the NTSB have a point on the difficultly identifying available modifications as evidenced by an apparent error made by the NTSB when drafting their recommendations: It appears they assumed that all modifications appear n the FAA STC database. Of course modifications made by the Type Certificate Holder are not STCs…

…a CRFS retrofit kit for AS350 B3e/H125 helicopters is now available to order [from Airbus Helicopters], although it has not yet been certified to the provisions of Federal Aviation Regulations §27.952, which spells out specific design and testing requirements for fuel system crash resistance. According to the AHI spokesperson, “The H125 CRFS design is based on that of the H130, which already complies with §27.952. [Airbus Helicopters] is working with EASA on the methodology for certification to §27.952 on the H125.”

Vertical estimate CRFS are about $90k.

UPDATE 17 August 2016: The NTSB release the Public Docket of factual evidence (meaning a Probable Cause is relatively close). These include:

- Airworthiness Group Chairman’s Factual Report

- Performance Study

- Video Study

- Onboard Image Recorder Factual Report Note the unit was damaged by the fire

- Human Performance Factual

- Survival Factors Group Chairman’s Factual Report

- Injury Factual Report including Association for the Advancement of Automotive Medicine Abbreviated Injury Scale (AIS) severity scores

- Medical Factual Report

In total there are 43 items.

UPDATE 31 August 2016: KUSA report FAA manager would have problem flying in most of country’s helicopters

UPDATE 5 October 2016: EASA Consult on Proposed AD on AS350B3 /H125 Hydraulics

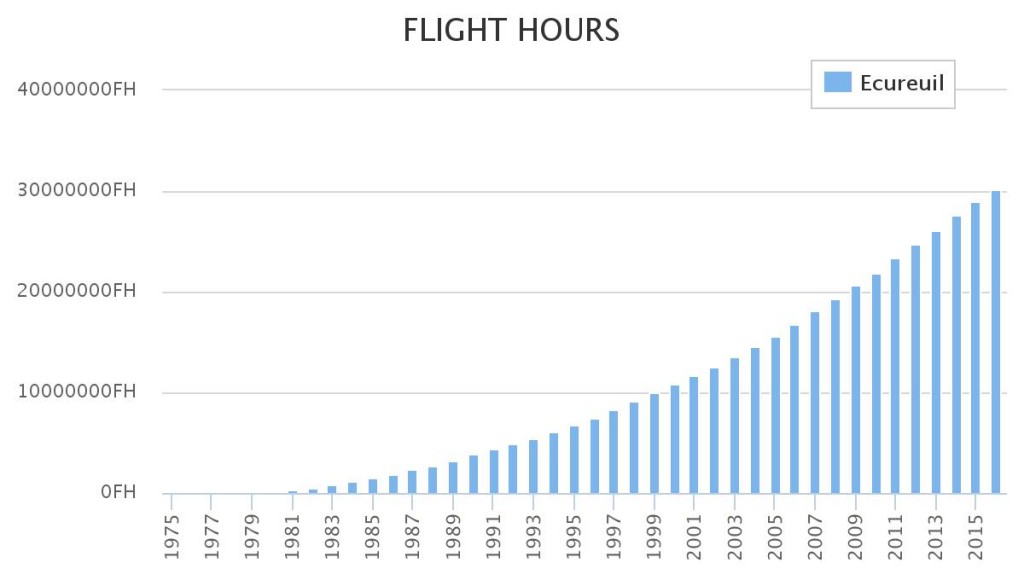

UPDATE 13 October 2016: It is worth noting that the AS350 family has now achieved an incredible 30 million flying hours:

UPDATE 20 December 2016: Report estimates costs, benefits of improved helicopter crash resistance: A cost-benefit analysis report submitted to the FAA ARAC by the ROPWG. But the estimates must be treated with caution:

…working group member Krista Haugen pointed to the Frisco Flight For Life crash as an example of how the absence of detailed injury data can lead to underestimating the value of safety improvements. In the group’s analysis, the flight nurse who suffered serious injuries in that crash represented a net benefit valuation of $2.4 million, yet his medical expenses alone are likely to be much higher than that — and that’s without taking into account his lost earnings, the impact on his quality of life, or the burdens placed on family members. “The thermally injured survivor of this crash sustained full-thickness burns to 90 percent of his body because of the post-crash fire. He was hospitalized in the burn intensive care unit for 11 months, with total hospitalization time just over 12 months,” Haugen stated.

UPDATE 25 March 2017: The NTSB Board will meet at 09:30 EST 28 March 2017 to determine the probable cause of this accident. A link to the webcast will be available online shortly before the start of the meeting.

UPDATE 28 March 2017: Below is the draft report abstract and the associated presentations and statements from the Board meeting:

Presentations:

- Opening Statement – Acting Chairman T. Bella Dinh-Zarr, PhD, MPH

- IIC presentation– Dr. Jennifer Rodi

- Airworthiness presentation– Chihoon Shin

- Crashworthiness presentation– Dr. Kristin Poland

- Flight recorders presentation– Sean Payne

- Closing Statement – Acting Chairman T. Bella Dinh-Zarr, PhD, MPH

The draft probable cause after the meeting (see the abstract) was:

…Airbus Helicopters’ dual hydraulic AS350 B3e helicopter’s (1) preflight hydraulic check, which depleted hydraulic pressure in the tail rotor hydraulic circuit, and (2) lack of salient alerting to the pilot that hydraulic pressure was not restored before takeoff. Such alerting might have cued the pilot to his failure to reset the yaw servo hydraulic switch to its correct position during the preflight hydraulic check, which resulted in a lack of hydraulic boost to the pedal controls, high pedal forces, and a subsequent loss of control after takeoff.

Contributing to the accident were (1) the lack of salient alerting to the pilot of the absence of hydraulic boost to the pedal controls and the resulting high pedal loads and (2) the pilot’s failure to perform a hover check after liftoff, which would have alerted him to the pedal control anomaly at an altitude that could have allowed him to safely land the helicopter. Contributing to the severity of the injuries was the helicopter’s fuel system, which was not crash resistant and facilitated a fuel-fed postcrash fire.

Six new recommendations are raised (see the abstract). The NTSB staff had originally proposed a probable cause of “the pilot’s failure to reset the yaw servo hydraulic switch to its correct position during the pre-flight hydraulic check”. Board member Robert Sumwalt objected saying:

“This pilot did not do what he was supposed to do,” Sumwalt said. “But if we dig deeper — and that’s what really bothers me about the original probable cause is that it is saying that the pilot screwed up. Well, we do believe that the pilot did not restore the switch. However, I think it was a trap. To put the pilot as the primary factor of the probable cause is just wrong, because it points to the last person who made the last mistake. I think we need to dig deeper to get to the root cause of this.”

After debate the compromise above was produced. However, it should be noted the operator had not embodied an available warning system modification.

UPDATE 30 March 2017: Vertical magazine look at this accident in detail too: Flight For Life: Anatomy of an Accident. They discuss previous incidents and what Air Methods claims to have known and done:

Air Methods has long touted the fact that it was the first air medical operator to enter the FAA’s Safety Management System (SMS) voluntary implementation program — an initiative that is intended to help operators proactively identify and address risks before they result in accidents. Yet, despite Air Methods having attained the highest level of that program in 2013, NTSB transcripts suggest that its high-level operations managers were only vaguely aware of an incident within their company that prompted a manufacturer’s safety notice.

…in October 2015, the director of safety’s acting replacement confirmed, “There has been a review, certainly, of how information flows since this accident, and that process broadened… Safety notices now go to the training department as well as maintenance.”

Since May 2016 a new Technical Publications Procedures ensures that safety information notices and special airworthiness information bulletins are forwarded to the chief pilot, director of operations, and aviation compliance evaluator.

Air Methods’ systemic difficulties in distributing safety notices are suggestive of the challenges associated with managing an organization of 1,300 pilots spread across 300 bases, each base with its own local operational challenges and practices.

Air Methods’ former safety director described the company’s culture as “fragmented and distributive . . . There was a disconnect, I think, between the corporate expectation and what was talked about at [headquarters in Englewood, Colorado] and how it translated to the individual base employee.”

Additionally:

But any helicopter pilot who has seen video of the crash knows there’s one other thing that might have prevented it: a slow, careful lift-off to the hover…

Air Methods pilots interviewed by the NTSB agreed this was best practice.

That makes [the pilot] Mahany’s takeoff perplexing, because this 13,000-hour pilot was by all accounts a consummate professional, dedicated to his job and committed to safety.

Air Methods’ former director of safety commented in an NTSB interview that some pilots at the Frisco base were in the habit of performing maximum-performance takeoffs.

The base had only recently upgraded from an older AS350 model to the more powerful H125, and “so their takeoff profile — because the pad was around 9,000 feet, 9,100 feet, I think it was — with the older aircraft, a little less power, they would just take off: bring max power in, do a max performance takeoff,” he said.

This was not a technique that was endorsed by Air Methods, and the company’s training materials explicitly call for pilots to perform a hover power check prior to departure.

UPDATE 13 April 2017: NTSB issue the final report.

UPDATE 30 June 2017: It is reported that:

Rep. Jared Polis and Rep. Ed Perlmutter introduced what they’re calling the “Helicopter Fuel System Safety Act.” The legislation, an extension of previously proposed legislation, would require helicopter manufacturers to place crashworthy fuel systems onboard every newly built helicopter starting a year after the bill’s passage.

UPDATE 25 July 2017: RFS begins flight testing on AS350 CRFT after successfully completing drop test

Following the successful completion of a 50-foot drop test that demonstrated the tank’s ability to withstand impact without any leakage, thereby helping to prevent post-crash fires, flight testing of the AS350 CRFT is now underway at Vector’s Langley, British Columbia, facility.

UPDATE 5 December 2017: Larry Kelly of the FAA confirms the ROPWG will go to the ARAC in Jan 2018.

UPDATE 7 December 2017: Robertson Fuel Systems and StandardAero (who have acquired Vector) announce they have gained an FAA STC for their CRFS for the Airbus AS350 and EC130 family of light single helicopters. It is reported that:

Production deliveries to launch partners, Air Methods Corporation (AMC) and WeatherTech Aviation LLC, are already underway with additional orders now being taken from operators worldwide.

European Aviation Safety Agency (EASA) certification of the CRFT is expected to follow shortly.

UPDATE 1 February 2018: Flight nurse receives $100 million settlement from Flight For Life crash “Repsher sustained burns over 90 percent of his body” and was “hospitalized for more than a year following the accident, and faces lifelong complications as a result of his injuries”.

UPDATE 10 February 2018: A question of priorities: Protecting helicopter occupants

In many ways, the fatal Flight For Life accident that occurred in Frisco, Colorado, in July 2015 was not unique. [But] was dramatically captured on surveillance video.

UPDATE 27 February 2018: StandardAero has signed a Memorandum of Understanding (MOU) for 40 retrofittable CRFTs in support of Papillon Grand Canyon Helicopters’ fleet of AS350B3 and EC130B4 tour aircraft. Installation of the first CRFT will take place in April 2018. The operator had suffered 5 fatalities after the 10 February 2018 accident to EC130B4 N155GC which suffered a post crash fire.

UPDATE 26 May 2018: US Fatal Night HEMS Accident: Self-Induced Pressure & Inadequate Oversight Four died when Metro Aviation Airbus Helicopter AS350B2 N911GF suffered a loss of control due to spatial disorientation after taking off into night instrument meteorological conditions from a remote site. In that case there was no fire.

UPDATE 10 June 2018: Italian HEMS AW139 Inadvertent IMC Accident We look at the ANSV report on a HEMS helicopter Inadvertent IMC event that ended with an AW139 colliding with a mountain in poor visibility.

UPDATE 18 June 2018: EASA published further responses in their Annual Safety Recommendations Review 2017.

UPDATE 26 June 2018: StandardAero announce EASA certification for its retrofittable CRFT system for AS350 and EC130. Since FAA certification 40 CRFT kits have been delivered.

UPDATE 8 September 2018: Torched Tennessee Tour Trip (B206L N16760) An ungreased fuel pump spline failed, the aircraft crashed and suffered a fatal post crash fire.

UPDATE 29 September 2018: HEMS A109S Night Loss of Control Inflight

UPDATE 5 October 2018: Helicopter industry leaders applaud passage of FAA Reauthorization Act 2018, which includes…

…mandating crash resistant fuel systems (CRFS) in newly-manufactured helicopters; improved oversight for the air ambulance industry and clarity over its billing practices; an attempt to address a perceived shortage of pilots and other aviation professionals; and the introduction of new guidelines for incorporating unmanned aircraft systems (UAS) into U.S. airspace.

The CRFS provision flows, in large part, from the legacy of the 2015 crash of a Flight for Life Airbus H125 (previously known as the AS350 B3e) AStar in Frisco, Colorado. Pilot Patrick Mahany lost his life in the post-crash fire that consumed the aircraft, and flight nurses Dave Repsher and Matt Bowe were severely injured. The effort to improve post-crash survivability was originally spearheaded by Mahany’s widow, Karen, and then led through Congress by two of the state’s legislators in the House of Representatives, Jared Polis (D-Colo.) and Ed Perlmutter (D-Colo.).

A CRFS has only been available as an option for the H125 since 2014, but it has been standard on H125s manufactured in the U.S. since 2016. However, a system wasn’t available for legacy AS350 models until December 2017, when a retrofit kit developed by Robertson Fuel Systems and StandardAero was certified.

With the bill’s passage, all newly-manufactured helicopters to be operated in the U.S. must have a CRFS installed.

UPDATE 6 March 2019: From 2020, all H125s built at Marignane in France will be fitted with a CRFS as standard, matching the US production line in Columbus, Mississippi. The H130 is also fitted with a CRFS as standard. Airbus will extend its existing CRFS STC to the AS350B3 and EC130B4. Retro-fits will be done at cost (about €35,000 / US$39,600).

UPDATE 12 June 2019: AStar fuel tanks differ in cost, but also safety features “…complying fully with 27/29.952 is neither easy nor cheap”. Airbus have yet to certify a tank compatible with the cargo swing installation, Standard Aero have but it is typically sold for between US$100,000 and US$120,000 (2-4 times the price of the Airbus CRFS).

UPDATE 26 September 2020: Fatal Fatigue: US Night Air Ambulance Helicopter LOC-I Accident

UPDATE 18 October 2020: Hawaiian Air Tour EC130T2 Hard Landing after Power Loss (Part 2 – Survivability)

UPDATE 17 January 2021: Grand Canyon Air Tour Tragic Tailwind Landing Accident

Aerossurance is pleased to be supporting the annual Chartered Institute of Ergonomics & Human Factors’ (CIEHF) Human Factors in Aviation Safety Conference for the third year running. We will be presenting for the second year running too. This year the conference takes place 13 to 14 November 2017 at the Hilton London Gatwick Airport, UK with the theme: How do we improve human performance in today’s aviation business?

Recent Comments