‘Aggressive’ Grit Blasting Maintenance Leads to Engine Fire & IFSD

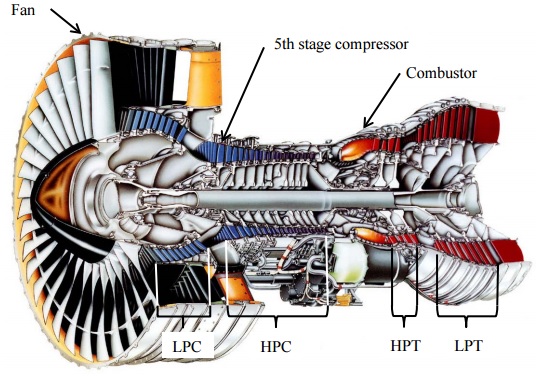

The US National Transportation Safety Board (NTSB) has issued their report on an incident that resulted in a Pratt & Whitney PW4056 engine fire and In-flight Shut Down (IFSD) on Delta Airlines Boeing 747-451 N669US on 21 September 2014. The aircraft had just taken off from Atlanta, GA (ATL):

At about 400 feet above ground level (AGL), the pilots heard a loud bang, the airplane yawed, and they noted that the No. 4 engine’s cockpit instruments indicated a loss of power. The pilot’s accomplished the quick reference handbook (QRH) engine failure checklist and shutdown the No. 4 engine.

At about 1,300 feet AGL, the No. 4 engine fire warning activated. The pilot’s accomplished the QRH engine fire checklist and discharged the A fire bottle into the No. 4 engine’s nacelle. When the fire warning did not go out after a minute, the pilots discharged the B fire bottle into the engine’s nacelle. The fire warning extinguished about 20 seconds after the B fire bottle was discharged.

The pilots dumped 280,000 pounds of fuel and returned to ATL for a three-engine landing on Runway 27 Right without further incident.

NTSB Investigation: The Damage

The disassembly of the engine revealed one 5th stage compressor blade…had separated from a high cycle fatigue fracture that had originated in the aft concave side corner of the blade neck.

The failed blade then caused extensive secondary damage across multiple stages.

The fire was caused by hydraulic fluid that leaked from a pump B-nut loosened by vibration after the blade loss.

NTSB Investigation: Prior Maintenance

The maintenance records showed that the fractured 5th stage compressor blade was among a batch of 40 blades that had been overhauled by Turbine Overhaul Services (TOS), Singapore in October 2013.

TOS is a joint venture between P&W and Singapore Technologies Aerospace, is an FAA-approved Part 145 repair station that specializes in the repair and overhaul of turbine engine compressor and turbine blades and vanes.

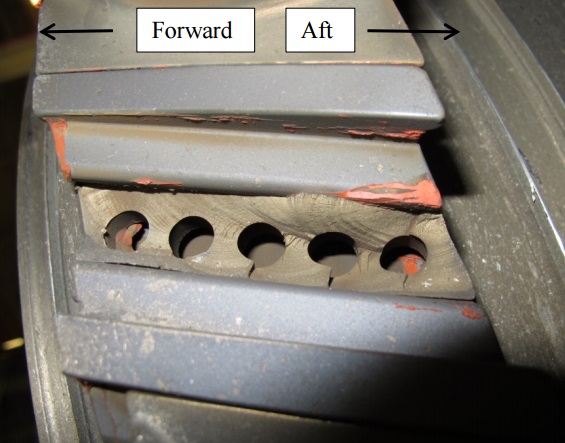

As part of the overhaul process, the plasma spray coating on the blade roots was removed and replaced. As part of the preparation for the application of the plasma spray, the surface of the blade root is grit blasted with aluminum oxide media. The blade root neck is identified in the repair procedures as a no-grit blast area.

TOS…conducted an audit of its PW4000 5th stage compressor blade overhaul and repair processes. The audit revealed TOS’s PW4000 5th stage compressor blade overhaul and repair processes conformed to the requirements except for the aluminum oxide grit blasting surface preparation prior to the application of the plasma coating. The audit revealed the operator held the grit blasting gun about 2 inches from the surface instead of the specified 4 to 6 inches.

NTSB Probable Cause

Turbine Overhaul Service’s aggressive grit blasting and incomplete masking of the blade root neck that allowed the no grit blast area being exposed during the overhaul of the blade resulting in blasting media being embedded in the blade root from which a fatigue crack developed.

The fatigue crack propagated until separation of the blade occurred that resulted in a complete loss of engine power.

The fire was caused by the B-nut on the hydraulic line from the fuel pump and pulsation damper loosening from engine vibration after the compressor blade separated spraying high pressure fluid into the engine compartment that ignited on the hot engine cases.

Safety Action

TOS took a strategy of mitigating any maintenance errors with improved tooling:

In March 2015, TOS developed a gage block that would ensure the tape was placed correctly. In addition to the masking tape, TOS uses a metal mask to preclude overspray during the grit blasting operation. TOS conducted a series of tests that showed if only the metal mask was used, some grit blasting overspray would occur. But when the metal mask was used with the masking tape, there was no overspray into the no grit blasting area.

Aerossurance has previously looked at:

- James Reason’s 12 Principles of Error Management

- Back to the Future: Error Management

- Maintenance Human Factors: The Next Generation

- Aircraft Maintenance: Going for Gold?

Aerossurance has examined a number of other engine events, including:

- Micro FOD: Cessna 208B Grand Caravan Engine Failure & Forced Landing

- Machining Defect Cause of V2500 Failure

- B787 GEnx Fan Shaft Failure

- Uncontained CFM56-7 Failure: Southwest B737-700s

- UPDATE 20 Oct 2017: Contained Failure of PW4056 on 2 October 2015

- UPDATE 19 Nov 2017 Coking Causes Power Loss: Australian AS350BA

- UPDATE 4 August: 2018: US HEMS EC135 Dual Engine Failure: 7 July 2018

- UPDATE 18 December 2018: USAF Engine Shop in “Disarray” with a “Method of the Madness”: F-16CM Engine Fire

- UPDATE 22 July 2020: NDI Process Failures Preceded B777 PW4077 Engine FBO

FSF Maintenance Observation Programme (MOP)

Aerossurance worked with the Flight Safety Foundation (FSF) to create a Maintenance Observation Program (MOP) requirement for their contractible BARSOHO offshore helicopter Safety Performance Requirements to help learning about routine maintenance and then to initiate safety improvements:

Aerossurance can provide practice guidance and specialist support to successfully implement a MOP.

Recent Comments