ERJ175 NLG Uplock Spring Production Defect

On 4 December 2016 Embraer ERJ170-200LR (ERJ175) N161SY, operated by SkyWest Airlines for United Express, experienced a Nose Landing Gear (NLG) collapse during rollout when landing at the San Antonio (KSAT), Texas.

History of the Incident Flight

The US National Transportation Safety Board (NTSB) report that:

…after departure from the George Bush Intercontinental Airport (KIAH), Houston, Texas the crew heard a loud “thud/pop” just aft of the flight deck. Because no warnings or indications were displayed on the flight deck, the crew decided to proceed to [their destination, Monterrey (MMTY) Mexico]. When the landing gear was extended on approach, the crew received warning indications regarding the landing gear position and a “LDG GEAR LEVER DISAGREE” message. The crew declared a missed approach, retracted the landing gear per the quick reference handbook (QRH) procedures, and elected to divert to KSAT. Upon entering US airspace, the crew declared an emergency and performed a flyby of the control tower to verify landing gear position. The tower confirmed that the gear appeared to be in the down position. After touchdown on runway 4, during the landing rollout the nose gear retracted, without command, as the aircraft slowed to a stop. The crew and passengers evacuated the aircraft from the aft cabin doors via the evacuation slides. One minor [evacuation] injury was reported by a passenger…. The airplane sustained minor damage.

Safety Investigation

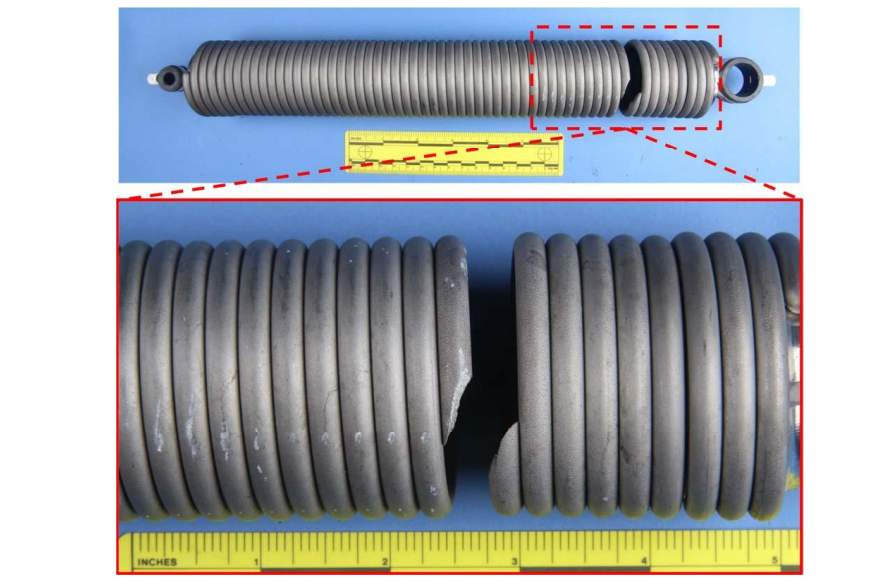

The NLG downlock springs were removed and shipped to the NTSB Materials lab…The right NLG downlock spring was received intact. The left NLG downlock spring was received in two separate pieces.

The NLG downlock spring separated in the ninth coil from the lower end due to progressive crack formation. No evidence of overstress was observed. During a visual inspection, external surfaces of the downlock spring wire had small openings, which resulted in surface roughness measurements that were above the allowable limit set by Embraer.

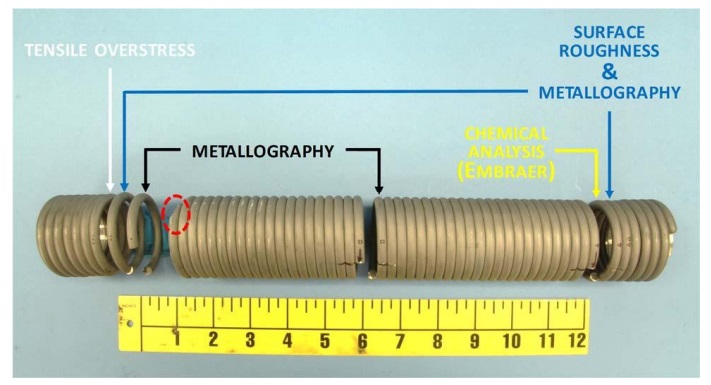

Macro photo showing how the spring was sectioned and which coils were used

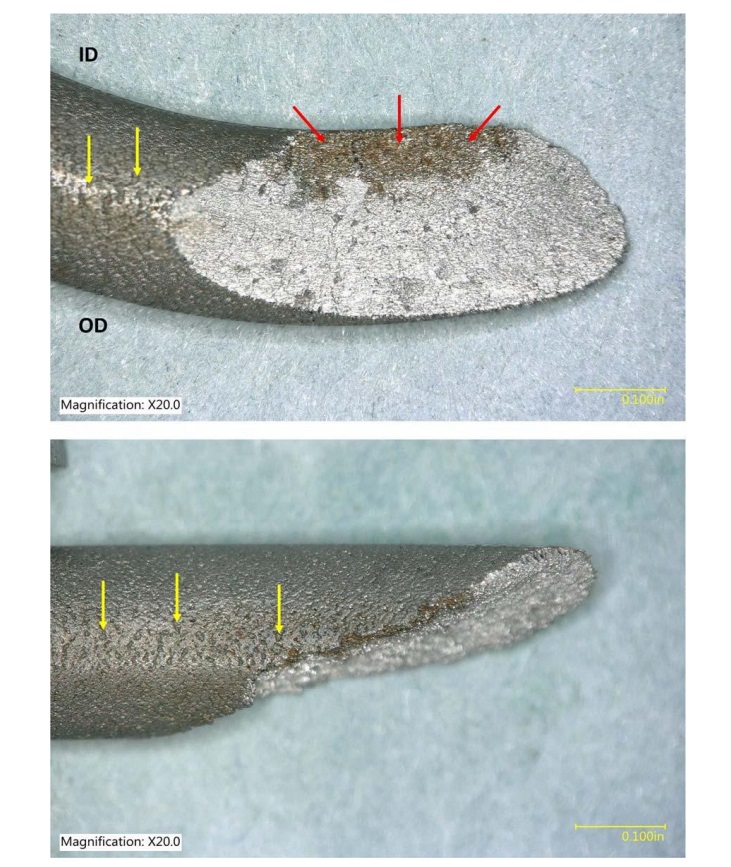

for each type of testing performed. (Credit: NTSB)Cross-sections prepared through multiple downlock spring coils along the length of the spring showed intergranular cracking at the openings. The openings and cracking were associated with white etching microstructure of the wire that was consistent with retained austenite, while the base material of the coils had microstructure consistent with martensite, as specified. The amount of retained austenite in a circumferential surface layer of the downlock spring coils was above the allowable limit specified by Embraer per AMS 5678.

Digital microscope images of the wire fracture surface as viewed looking down on the top of the coil (top) and from the ID of the coil (bottom). The red arrows point to a thumbnail shaped stain on the fracture surface. The yellow arrows point to openings on the spring wire surface. (Credit: NTSB)

Two spring pieces (an end segment and a ring segment) were documented using radiographic images. The computed tomography (CT) slice images were examined, processed, and analyzed by the NTSB to evaluate the components. The results of the CT imaging were inconclusive in locating crack location in the spring segments. The manufacturer provided information to the NTSB regarding additional NLG and MLG downlock springs that failed during operations. The spring from this incident was the only one which resulted in an uncommanded gear retraction on landing. Manufacturing records for the incident spring were reviewed and compared with other events. The manufacturer identified a suspect batch of raw material for the springs, common to multiple events and springs with higher than allowable amounts of retained austenite. The aircraft manufacturer performed multiple quality audits throughout the supply chain for the spring manufacturing process and shared the results with the investigative team.

NTSB Probable Cause

A failure of the nose landing gear down lock spring which precluded normal downlock operation of the nose landing gear. The spring failure was due to the presence of too much retained austenite which led to the formation of progressive cracking and subsequent failure of the spring.

Safety Action

On 1 March 2017, Embraer released a letter accompanying Service Bulletins for both the E170/175 and E190/195 fleets:

The letter addressed an inspection and possible replacement of the NLG downlock springs manufactured from certain material batches.

Other Safety Resources

- Eclipse 500 Landing Gear Production Defect

- Production Errors on a SAR Helicopter Full Ice Protection System

- Machining Defect Cause of V2500 Failure

- Micro FOD: Cessna 208B Grand Caravan Engine Failure & Forced Landing

- UPDATE 28 June 2019: Tail Rotor Lightning Strip Damages AW139 Main Rotor

- UPDATE 28 April 2020: Beech 99A MLG Collapse

- UPDATE 18 November 2020: Embraer ERJ-190 EWIS Production Quality a Factor in Fire

- UPDATE 17 September 2022: Canadian B212 Crash: A Defective Production Process

Recent Comments