Flawed Post-Flight and Pre-Flight Inspections Miss Propeller Damage (Rex Saab 340 VH-ZRL)

We look at an Australian Transport Safety Bureau (ATSB) report into a regional turbprop incident and in particular why propeller damage was missed on several inspections.

The Incident Flight

On the evening of 22 February 2013, Regional Express (Rex) Saab 340B VH-ZRL, was on approach to Taree, NSW. The crew were monitoring the weather. The crosswind was reported as 50 knots when they were at about 6,000 ft, although it decreased as the aircraft descended.

At 700-800 ft above ground level (AGL), the crew became visual with the runway and committed to landing. At that point the wind was fluctuating and there was light rain. On touch down however the aircraft was subject to a gust, which made the left wing lift slightly and the aircraft to weathercock to the left, into wind. Reverse thrust had already been selected. As the aircraft veered toward the runway edge the Commander, who had been the Pilot Monitoring, took control of the aircraft. The ATSB say:

He applied right rudder, but the aircraft did not respond. As the aircraft’s airspeed decreased, the captain also applied right brake, with no effect. He then simultaneously commenced nose wheel steering using the tiller. As the captain believed that the nose wheel steering was ineffective, he elected to apply asymmetric thrust by reducing the amount of reverse thrust on the left engine and increasing reverse thrust on the right engine. The aircraft commenced moving to the right.

The crew were unable to determine how far left the aircraft had veered due to the water spray from the application of reverse thrust, but believed the aircraft had not departed the runway.

The aircraft taxied to the parking area. As the passengers disembarked there were strong winds and heavy rain.

Post Flight Actions

Using a torch, the FO then conducted a post flight inspection, which included examining the left landing gear and propellers. At the same time, refuelling of the aircraft commenced and the captain was completing paperwork. After finishing the post-flight inspection, the FO advised the captain that nil damage was found.

In preparation for the next flight to Grafton, the Captain commenced an external inspection of the aircraft using a torch…it was raining heavily. He examined the left landing gear and reported that no mud or grass was observed.

As he continued toward the left propeller, he was interrupted by the refueller. The captain then went back into the cockpit with the refueller and was further distracted by the company’s ground handling agent. As a result, the captain did not get the opportunity to inspect the left propeller blades.

The aircraft captain then conducted a runway inspection for contamination with the ground handling agent. There was “a substantial amount of standing water” and a 30 knot crosswind so the flight was cancelled. There was no evidence visible that the aircraft had earlier left the runway.

The next day the flight to Grafton was conducted. The FO made the external inspections of the aircraft.

The aircraft then returned to Sydney, at which time maintenance personnel conducted an inspection of the aircraft and observed damage to the left propeller blades.

All four blades had sustained stone damage predominantly on the back (reverse) of the blades.

Runway 04/22 at Taree consisted of a 30 m wide runway with a 3-4m wide soil and gravel shoulder either side. A subsequent runway inspection during daylight determined that the aircraft had veered onto the runway shoulder.

The blades were all removed for repair.

Crew Comments

The captain provided the following comments (those in italics relate to the inspections):

- The approach was stabilised and the aircraft landed within the touchdown zone.

- If faced with a similar situation in the future, he would likely not continue to use reverse thrust, but rather, apply forward engine power until the aircraft deviation had been corrected and then re-apply reverse thrust.

- A tactile inspection of the left propeller blades may have identified the damage, however, given the poor weather conditions on the night, the damage would not have been easy to observe.

- His additional external inspection of the aircraft had been interrupted. In hindsight, he should have asked the persons to wait until the inspection had been completed.

The FO observed:

- The apron was floodlit on the terminal side. The aircraft had been parked parallel to the terminal, with the left side parked away from the lights. The first officer was required to use a torch to conduct his external inspection. At the time, it was very dark and raining heavily.

- He had conducted a thorough visual inspection of the left landing gear and top surface of the left propeller blades. When conducting his inspection, he stood facing the propellers and turned the blades in an anti-clockwise direction. This was suitable for sighting the front surface of the blades, but not the reverse side. He had also conducted a tactile inspection of the leading edge of the blades. He had got out of the habit of inspecting the surface of the reverse side of the blades and consequently did not see the damage.

- When looking at the blades afterwards with the engineers, he could not recall observing damage that he would have considered a huge amount of damage.

- If he had sighted the damage on the night, he would have sought the captain’s advice.

- The propeller damage had no effect on the aircraft’s performance; with no vibrations, sounds or abnormal indications noted.

The FO also opined that…

…when conducting a considerable number of flights within a short period of time, it was easy to become complacent when having to conduct a pre-flight and post-flight inspection for each flight.

ATSB Safety Message

Complacency, the feeling of satisfaction or contentment with what is happening, may occur from a pilot’s overconfidence in performing a task that has been previously conducted numerous times, without incident. This may result in a pilot inadvertently overlooking important information or responding to a situation inappropriately.

The best defence against complacency is for pilots to remain vigilant and alert, and be mindful that even the most routine tasks must be conducted with care and concentration.

We have previously discussed complacency: Complacency: A Useful Concept in Safety Investigations?

An interruption/distraction can cause the crew to feel rushed and be confronted with competing tasks. The crew must then complete one task before performing another, which may result in poor results in one or more of the completed tasks. This may leave uncertainties unresolved, the omission of actions, and failing to detect and correct resulting abnormal conditions.

Acknowledging that some distractions cannot be avoided, but others can be minimised or eliminated is the first step in developing preventative strategies and lines-of-defence.

The ATSB highlight Flight Safety Foundation (FSF) guidance that after interruptions/distractions have been recognised and identified, the next priority is to re-establish situation awareness as follows:

- Identify: What was I doing?

- Ask: Where was I distracted?

- Decide/act: What decision or action shall I take to get ‘back on track’?

We also note the FO, to his credit, discussed getting into a (bad) habit of only looking at the front of the blades while the aircraft commander seems to have complacently accepted that visual inspection in poor light would not identify such damage.

Safety Resources

See also our articles:

- Dispatcher Forced to Run After Distracted Pushback

- ATR 72 In-Flight Pitch Disconnect and Structural Failure

- Time Pressures and Take-Off Trim Trouble

- Troublesome Tiedowns

- When Habits Kill – Canadian Hughes 500 Helicopter Accident

- UPDATE 10 August 2020: Boeing 737-800 Engine Nacelle Strike and Continued Operation

UPDATE 23 February 2018: Another ATSB report is published featuring distraction (plus high workload): Flight path management and descent toward the lower limit of controlled airspace involving Airbus A320, VH-VND, on approach to Melbourne Airport, Victoria, on 11 February 2015.

UPDATE 11 March 2018: EC120 Forgotten Walkaround

UPDATE 14 April 2018: Air Mandalay Embraer ERJ-145 XY-ALE was damaged after a heavy landing during an unstabilised approach on 18 Sept 2017. the First Officer did a walkaround but did not spot the damage so the aircraft flew 2 more sectors before an engineer found the damage, according to the Aircraft Accident Investigation Bureau (AAIB) of Myanmar report.

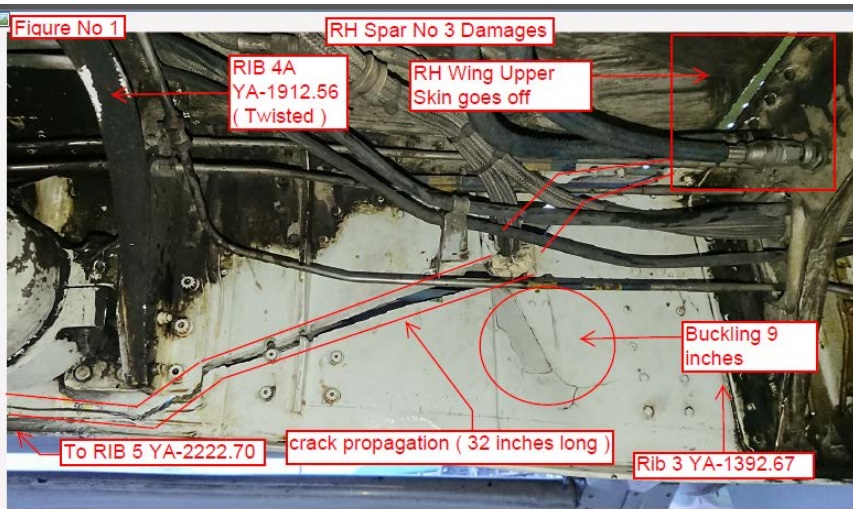

Air Mandalay Embraer ERJ-145 XY-ALE No 3 wing Spar Damage (Credit: Aircraft Accident Investigation Bureau of Myanmar)

UPDATE 11 July 2018: The TSB of Canada has released their report on the hard landing during wind shear of Jazz Aviation Bombardier Dash 8 Q400 C-GYJZ on 9 November 2017 which substantially damaged the aircraft and generated enough load to trigger the CVR/FDR crash switch. They report that the flight crew were unsure if this 5.7g touchdown was a hard landing or not. Rather than wait for maintenance personnel to travel to the airport the pilots therefore conducted a visual inspection of the aircraft and finding nothing abnormal, decided to operate the return flight, landing uneventfully back in Montreal. Subsequent maintenance inspection found:

…buckling of the skin below the windows on the right fuselage [and] the right main landing gear during the second touchdown exceeded its ultimate design criteria, which resulted in failure of the orifice support tube during the in-stroke. Once the orifice support tube failed, shock strut damping was effectively lost, thereby generating significant bottoming loads.

TSB comment:

Neither the aircraft manufacturer nor Jazz provide the flight crew with a definition of a hard landing or criteria to determine what a hard landing is. Pilots are expected to rely on their personal experience to make such a determination. In some cases, operational pressures may influence this assessment.

The operator’s safety actions reported were:

- providing additional training on how to recognize hard landings,

- strengthening and clarifying procedures and guidance associated with suspected or actual hard landings,

- adding a warning within flight crew guidance to inform crews of the risk of a hard landing if a landing is continued following a bounce with the power levers at flight idle or disc, and

- conducting a review of flight data analysis practices and effectiveness as they relate to preventing a departure when the aircraft’s airworthiness is concerned.

UPDATE 10 June 2019: Troublesome Tiedowns: The Sequel A Robinson R22 suddenly fails to respond to control inputs and descends and impacts the sea. Investigators find a tie-down wrapped around the main rotor head.

UPDATE 11 August 2019: Severe Propeller Vibrations on ATR 72-212A: BEA Report: A vibratory phenomena that was not uncovered in certification testing and in one case resulted in a failure that did not get detected initially by maintenance inspections.

UPDATE 30 December 2019: White Air ATR-72-212A CS-DJG, operating for TAP Portugal, landed at Fez on 6 July 2018 after an unstabalised approach according to Portuguese accident investigators (the Gabinete de Prevenção e Investigação de Acidentes com Aeronaves [GPIAA]) but struck its tail onto the runway, touching down hard (+2.88G). The aircraft sustained abrasion damage to the aft fuselage, deformation between frames 35-38, sheared rivets and wear on the tail-skid.

The Aircraft Commander prepared for the return flight by performing a walk-round, carrying out a general inspection, looking for problems on the main landing gear and checking the tail strut (‘pogo stick’) fitted under the bumper when parked. He did not detect any anomalies and the aircraft was flown back to Lisbon before the damage was detected. GPIAA comment on:

….excessive reliance on aircraft acceptance without sharing and discussing with the operator’s technical services [and a] organizational culture with inadequate or nonexistent procedures and individual centered decision-making without effective implementation of the CRM philosophy.

Aerossurance is pleased to sponsor the 9th European Society of Air Safety Investigators (ESASI) Regional Seminar in Riga, Latvia 23 and 24 May 2018.

Recent Comments