Fatal S-61N Dual Power Loss During Post Maintenance Check Flight

On 6 September 2016 Sikorsky S-61N, N805AR (MSN 61717, formerly V8-UDZ of Brunei Shell Petroleum (BSP) from 1974 to 2010), was destroyed during a post-maintenance check flight after experiencing a dual loss of engine power while in a hover near Palm Bay, Florida.

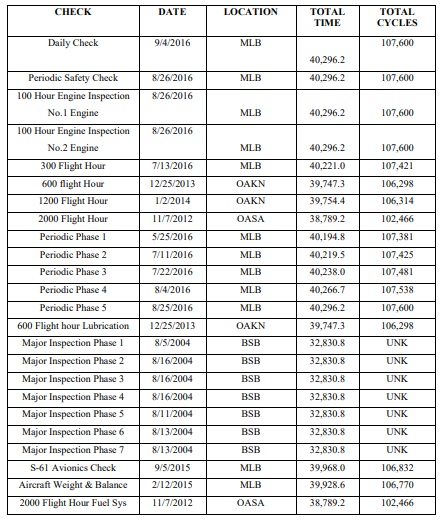

The three persons onboard were fatally injured due to “multiple blunt force injuries”. The aircraft was operated AAR, who had acquired the aviation businesses of Xe (formerly Blackwater). The aircraft had flown 40,296.2 flying hours at the time of the accident and an impressively high 107,600 cycles (consistent with the short sectors offshore Brunei).

The Accident Flight

According to the US National Transportation Safety Board (NTSB) safety investigation report:

…the helicopter’s fore/aft pitch servo had recently been removed and replaced. Subsequently, three functional check flights (FCF) were required to be completed.

Two FCFs were completed uneventfully the day of the accident, and the crewmembers were conducting the final FCF when the accident occurred.

One of the maneuvers to be performed during the final FCF was rearward flight at a computed airspeed of 20 knots.

The crew performed two of these rearward maneuvers during the accident FCF.

While the pilot was flying and recovering from the first rearward flight maneuver, unusual sounds were heard, which the flight crew identified as a compressor stall. The pilot then told the maintenance crewmember that they were returning to their home airport; however, after discussing compressor stalls and engine exhaust gas temperatures with the copilot, the pilot changed his mind and told the maintenance crewmember that they were going to try the maneuver again in a different direction relative to the wind (with the wind off the nose).

However:

While the pilot was recovering from the second rearward flight maneuver, there was a change in background noise, which the maintenance crewmember identified as a compressor stall. About 2 seconds later, there was another change in background noise, consistent with a decay in drivetrain rpm, which was followed by the helicopter descending and impacting the ground.

The helicopter came to rest upright [and a] postcrash fire consumed the cockpit and cabin. The tail boom transition section exhibited partial thermal damage, and the tail boom remained intact.

The NTSB have published a full Cockpit Voice Recorder (CVR) transcript.

Safety Investigation

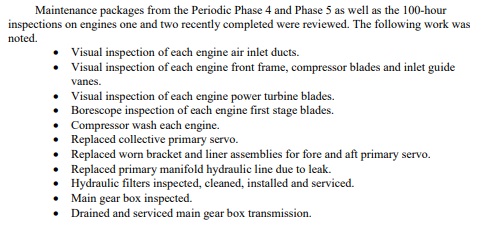

Recent maintenance on N805AR was as follows:

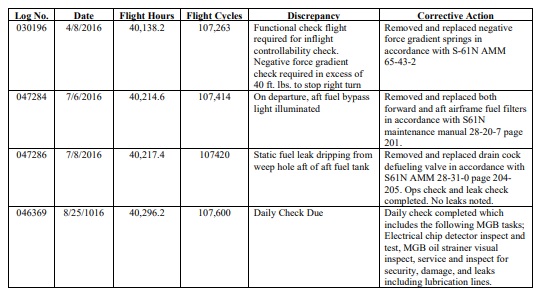

The NTSB reviewed a year of Flight Log entries. The entries before the accident were:

The aircraft was fitted with a Universal CVR-120. There is no mention of a Health and Usage Monitoring System (HUMS) or Flight Data Recorder (FDR). As the BSP S-61Ns were fitted with Meggitt IHUMS, which integrated HUMS with a CV/FDR, it appears N805AR had been demodified.

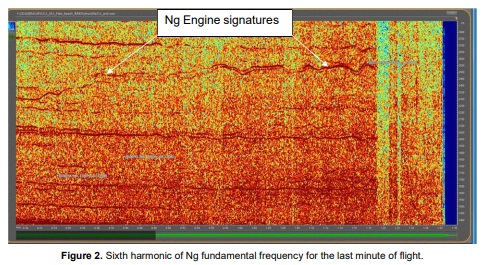

Although the crew identified the sounds and loss of power as compressor stalls, a sound spectrum study could not characterize the gas generator speed (Ng) behavior, due to overdriven audio on the CVR, to determine the engine anomaly the crew identified as a compressor stall. It is likely that the cause of the overdriven audio is related to an engine anomaly. At the same time the engine anomaly occurred, the sound spectrum revealed Nr quickly decayed due to a dual loss of engine power coupled with a high collective setting.

Because main rotor speed (Nr) decayed at the same time the overdriven audio occurred, it is likely both engines lost power nearly simultaneously. No anomalous damage to the engines was found that would have explained the dual loss of engine power and the main rotor drive system did not exhibit evidence of preimpact mechanical malfunction.

Due to the calculated fuel load and post crash fire, fuel exhaustion is considered unlikely.

During postaccident examination, the left (No. 1) freewheeling unit (FWU) was found to rotate freely in both directions of rotation instead of rotating freely in only one direction as it was designed to do. Had the left FWU failed in flight resulting in a loss of drive between the No. 1 engine and the main gearbox, the No. 1 engine power turbine would have experienced an overspeed due to the sudden loss of load.

There was however no indication in acoustic data that would support this.

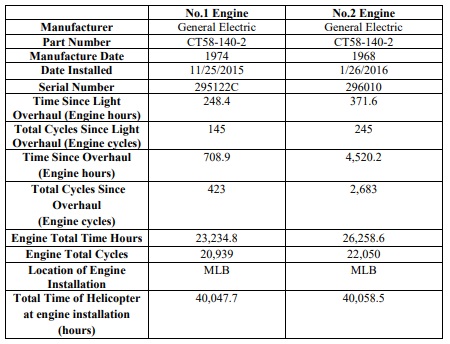

The engine history was as follows:

The NTSB highlight that:

Review of the rotorcraft flight manual (RFM) emergency procedures revealed, “2. If an abnormal engine conditions occurs such as engine stall, flame-out, or overtemperature, transition to single engine flight or landing….”

NTSB Probable Cause

A dual loss of engine power for undetermined reasons after the pilot’s improper decision to attempt another maneuver after recovering from a perceived compressor stall, rather than returning to the airport.

UPDATE 7 June 2019: FAA Enforcement Action

The U.S. Department of Transportation’s Federal Aviation Administration (FAA) proposes a $742,677 civil penalty against AAR Airlift Group…

The FAA alleges that between February 16, 2016 and January 27, 2017, AAR Airlift failed to properly document the replacement of components on 13 Sikorsky S-61N helicopters.

AAR Airlift allegedly documented in its maintenance records that it followed required maintenance procedures. However, the FAA alleges AAR did not at the time use or possess the special equipment necessary to properly replace the components. The components are hydraulic pistons [sic i.e. servos] that change the angle of the helicopters’ rotor blades….

The FAA further alleges that AAR Airlift operated the helicopters in violation of its operations specifications after it failed to use the required special equipment to replace the components. The flights occurred in Afghanistan, the Central African Republic, the Democratic Republic of the Congo, Niger and Uganda.

AAR Airlift has asked to meet with the FAA to discuss the case.

UPDATE 8 July 2021: AAR Corp. Settles False Claims Act Investigation by DOJ for $11 Million relating to “AAR’s maintenance of nine Sikorsky [LMT] S-61 helicopters used by U.S. Transportation Command (TRANSCOM) for moving troops and supplies in Afghanistan and U.S. African Command”.

AAR’s settlement with DOJ “resolves allegations that Airlift knowingly failed to maintain nine aircraft in accordance with contract requirements, and that because of this failure, the helicopters were not airworthy and should not have been certified by Airlift as ‘fully mission capable [FMC],’” DOJ said on July 7. Under some contracts, aircraft were to be FMC for at least 24 days a month with six days allotted for maintenance.

The DOJ investigation into AAR Corp. arose after a 2015 “qui tam” whistleblower lawsuit brought by Christopher Harvey, AAR Airlift’s former lead conformity specialist…

[The] Continuous Airworthiness Maintenance Program (CAMP) for S-61s “was incomplete and woefully out of date,” the lawsuit said. “For example, the S-61 manufacturer maintenance program requires a ‘debonding check’ to be conducted on the helicopter’s tail rotor blades every 12 months. This requires the maintenance crew to ensure that the blades on the tail rotor are not in danger of falling apart (a particular concern in sandy or salt-water environments).” Harvey’s team “discovered that there was no debonding check in the CAMP,” the lawsuit said. “When [Harvey] inquired about this he was shocked to learn that management of the maintenance department had no idea such a check was necessary, let alone whether it had been conducted. The problems with the S-61 CAMPs were only the tip of the iceberg. There were parts on the S-61s that could not be confirmed as valid for that aircraft. There were life-limited parts that were not being tracked such that there was no way to ensure that they would be inspected and replaced as required.”

As part of the agreement, AAR Corp. agreed to pay more than $429,000 to resolve faulty helicopter maintenance claims brought by the FAA in 2019.

Safety Resources

The European Safety Promotion Network Rotorcraft (ESPN-R) has a helicopter safety discussion group on LinkedIn. You may also find these Aerossurance articles of interest:

- Maintenance Human Factors: The Next Generation

- Critical Maintenance Tasks: EASA Part-M & -145 Change

- Maintenance Check Flights: Safety Lessons

- Misrigged Flying Controls: Fatal Maintenance Check Flight Accident

- Loose B-Nut: Accident During Helicopter Maintenance Check Flight

- Insecure Pitch Link Fatal R44 Accident

- UPDATE 1 April 2019: Tree Top Autorotation for B206L1 After Loose Fuel Line B-Nut Leaks

- UPDATE 24 October 2019: EC135P2+ Loss of NR Control During N2 Adjustment Flight

- UPDATE 15 January 2020: AAR Bell 214ST Accident in Afghanistan in 2012: NTSB Report

- UPDATE 7 February 2020: S-61N Damaged During Take Off When Swashplate Seized Due to Corrosion

- UPDATE 8 April 2020: NTSB Confirms United Airlines Maintenance Error After 12 Years

- UPDATE 9 May 2020: Ungreased Japanese AS332L Tail Rotor Fatally Failed

- UPDATE 10 December 2022: Main Rotor Blade Certification Anomaly in Fatal Canadian Accident

- UPDATE 24 December 2022: S-61N Accident in Afghanistan: Investigators Focus on Auxiliary Servocylinder

- UPDATE 29 July 2023: Missing Cotter Pin Causes Fatal S-61N Accident

Aerossurance is pleased to be both sponsoring and presenting at a Royal Aeronautical Society (RAeS) Human Factors Group: Engineering seminar Maintenance Error: Are we learning? to be held on 9 May 2019 at Cranfield University.

Recent Comments