C208B Force Landing After Inadequate Maintenance Fault Finding

On 12 May 2016 Cessna 208B Caravan N1114A of the Parachute Center was substantially damaged during a forced landing near Acampo, California, 1 minute into a skydiving flight. The aircraft ended inverted in a vineyard, the pilot suffered minor injuries, but the 17 passengers were all uninjured.

According to the US National Transportation Safety Board (NTSB) in their safety investigation report:

The pilot reported that…as the airplane passed 1,000 ft above ground level (agl), the engine lost power.

The rear door had been opened for ventilation and “one of the jumpers called out there was fuel streaming past the door“.

The pilot initiated a turn toward the airport, however, realized he was unable to make it, and landed in an open field.

During the landing roll, the airplane exited the field, crossed a road [at about 30 knots], impacted a truck [with two occupants], continued into a vineyard, and nosed over.

The accident was filmed from inside by one passenger.

Safety Investigation

Examination of the wreckage revealed:

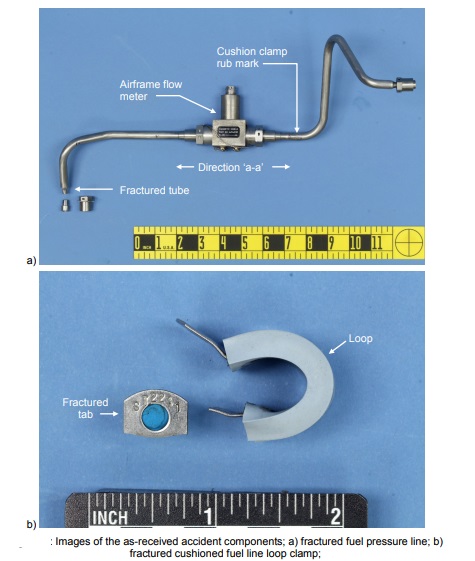

The fuel pressure line that connects the fuel control unit to the airframe fuel pressure transducer, Pratt & Whitney Canada (PWC) part number 3033981, was fractured below the fuel control unit fitting swaged seat. The supporting clamp, PWC part number 3006614, was fractured and was separated from its mating fuel pressure fuel line, PWC part number 3032010.

In addition, the airframe P3 air line that provides air to the vacuum system exhibited a hole within the tube.

The operator reported that they had replaced the fuel line, PWC part number 3033981, the night before the accident due to the original fuel line being fractured. They stated that the new fuel line had about 4 hours of operational time since the installation.

Review of the maintenance logbooks revealed that an entry regarding the replacement of the fuel line was dated April 11, 2016 [sic], with no airframe, engine, or HOBBS meter times listed. The operator…stated that the clamp was attached at the time of the fuel line replacement.

Both the new and old fuel lines and separated clamp were sent to the NTSB Materials Laboratory for further examination.

Lab analysis showed that both fractured tubes “were found to exhibit features consistent with crack initiation due to reverse bending fatigue”.

The orientation of the reverse bending fatigue cracks and the spacing of the fatigue striations on the tube fracture surfaces were consistent with high-cycle bending fatigue due to a vibration of the tube. The cushioned support clamp is designed to prevent such vibrations from occurring. However, if the clamp tab is fractured, it cannot properly clamp the tube and will be unable to prevent the vibration.

The NTSB concluded that “the clamp most likely failed first, resulting in the subsequent failure of the tubes”:

Since the clamp was likely fractured when the first fractured fuel pressure line was replaced, the clamp was either not inspected or inadequately inspected at the time of the maintenance.

Other Safety Information

It is reported that since 1999, 15 people have died jumping “from planes that took off from the parachute center”. The Parachute Centre was involved in a fatal parachute accident later in 2016. In September 2016, following that accident, 20 instructors at the centre were suspended and 120 others were told they needed to undergo more training after an investigation by the United States Parachute Association (USPA). On 31 January 2018 was subject to a raid by a the FBI and local law enforcement agents.

Previously the Federal Aviation Administration (FAA) proposed a $664,000 civil penalty against William C. Dause (doing business as The Parachute Center of Acampo) in 2010:

In all, the FAA alleges that The Parachute Center operated [de Havilland Canada (now Viking Air) DHC-6 Twin Otter] aircraft on approximately 2,121 flights between March 21, 2008 and Nov. 4, 2009 with elevator control cables that were overdue for replacement and when the plane was not in compliance with Airworthiness Directives requiring visual inspections of the wing main spar, lower spar cap extensions and wing support strut for possible corrosion.

“Putting parachutists at risk by neglecting to follow safety procedures is unacceptable,” said US Transportation Secretary Ray LaHood. “We expect aircraft operators to comply with our safety rules and will take enforcement action when they do not.”

In 2011 the FAA proposed a further $269,000 civil penalty for allegedly operating a Twin Otter on 41 flights between 2 and 15 November 2009 when it was not in compliance with a 2009 AD requiring repetitive inspections of the left and right front spar adapter assemblies.

NTSB Probable Cause

A total loss of engine power due to a fatigue fracture of the fuel pressure line that connected the fuel control unit and the fuel flow transducer due to vibration as the result of a fatigue fracture of an associated support clamp. Contributing to the accident was the mechanic’s inadequate inspection of the fuel line support clamp during the previous replacement of the fuel line.

Other Safety Resources

Past Aerossurance articles on the C208 include:

- Cessna 208 Forced Landing: Engine Failure Due To Re-Assembly Error

- Micro FOD: Cessna 208B Grand Caravan Engine Failure & Forced Landing

- NTSB Report on C208B Caravan Ditching, Molokai, Hawaii, 2013

- Canadian Mining Icing Air Accident (Cessna 208B Caravan)

- Flying Control FOD: Screwdriver Found in C208 Controls

On maintenance and safety management:

- Professor James Reason’s 12 Principles of Error Management

- Back to the Future: Error Management

- Safety Performance Listening and Learning – AEROSPACE March 2017

- Maintenance Human Factors: The Next Generation

- Airworthiness Matters: Next Generation Maintenance Human Factors

- Coking Causes Power Loss: Australian AS350BA

- Maintenance Misdiagnosis Precursor to Tail Rotor Control Failure

- UPDATE 14 February 2019: AS350B2 Accident After Vibration from Unrecorded Maintenance

- UPDATE 1 April 2019: Tree Top Autorotation for B206L1 After Loose Fuel Line B-Nut Leaks

FSF Maintenance Observation Program (MOP)

Aerossurance worked with the Flight Safety Foundation (FSF) to create a Maintenance Observation Programme (MOP) requirement for their contractible BARSOHO offshore helicopter Safety Performance Requirements to help learning about routine maintenance and then to initiate safety improvements:

Aerossurance can provide practice guidance and specialist support to successfully implement a MOP.

Aerossurance is pleased to sponsor the 9th European Society of Air Safety Investigators (ESASI) Regional Seminar in Riga, Latvia 23 and 24 May 2018.

Recent Comments