Gust Lock Gaff: King Air A90 Runway Excursion

On 23 June 2016 a Beechcraft King Air A90 aerial survey aircraft suffered a runway excursion during a take off attempt at Hannover Airport.

The German Federal Bureau of Aircraft Accident Investigation (BFU) explain in their safety investigation report (dated 10 March 2020, but issued August 2020) explain that the Belgian owned aircraft, whose registration is not recorded by the BFU, was chartered to a Danish aerial survey company. Onboard that day were a pilot and a camera system operator. During taxi the pilot had noted it was “unusually difficult to control the direction of the aircraft” but not so bad as to cause concern.

At about 0828 hrs, the pilot received the clearance from the tower controller to enter runway 09L. He stated that about 1 min later he received take-off clearance and set engine takeoff power. He had paid attention to the two engines building up their take-off rotation speed uniformly.

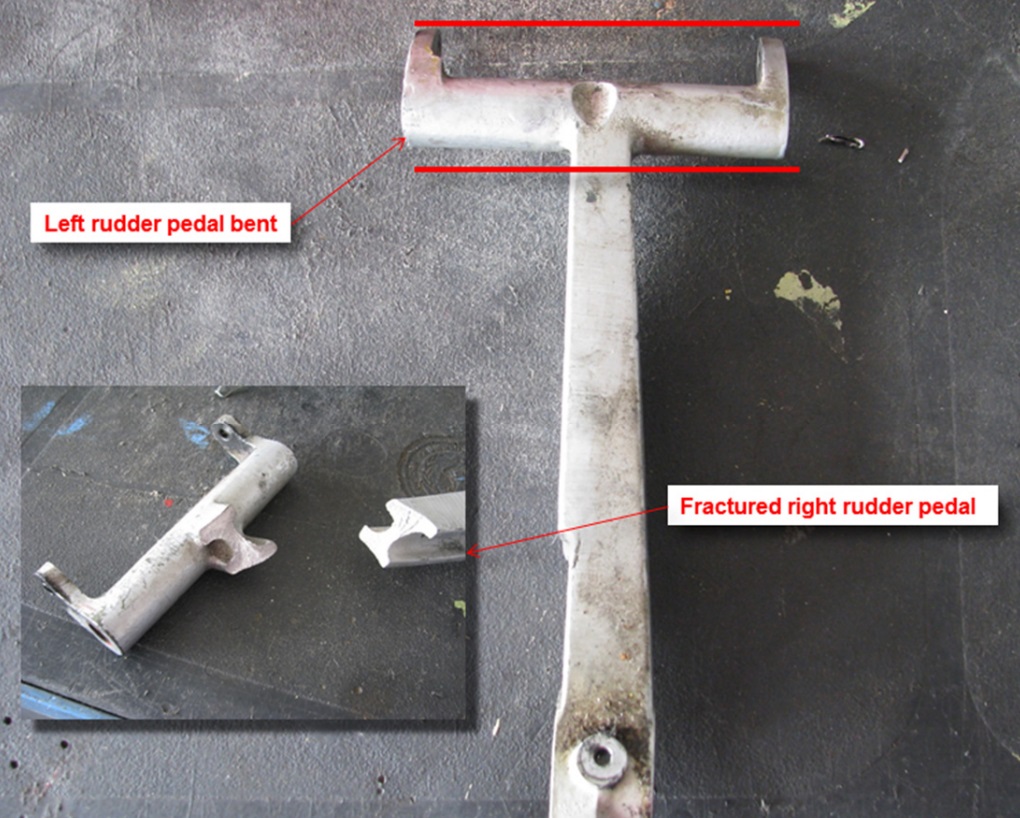

During the take-off run he had noticed a change in direction towards the left and tried to keep the aircraft on the runway centreline by using the right rudder pedal. He had pushed it up to the mechanical stop. The mounting of the right rudder pedal fractured in the process.

The aircraft could no longer be controlled.

It veered left off runway 09L with a speed of about 30 kt… It came to a stop on the grass next to the runway. [The aircraft] had yawed by approximately 70°.

The Safety Investigation

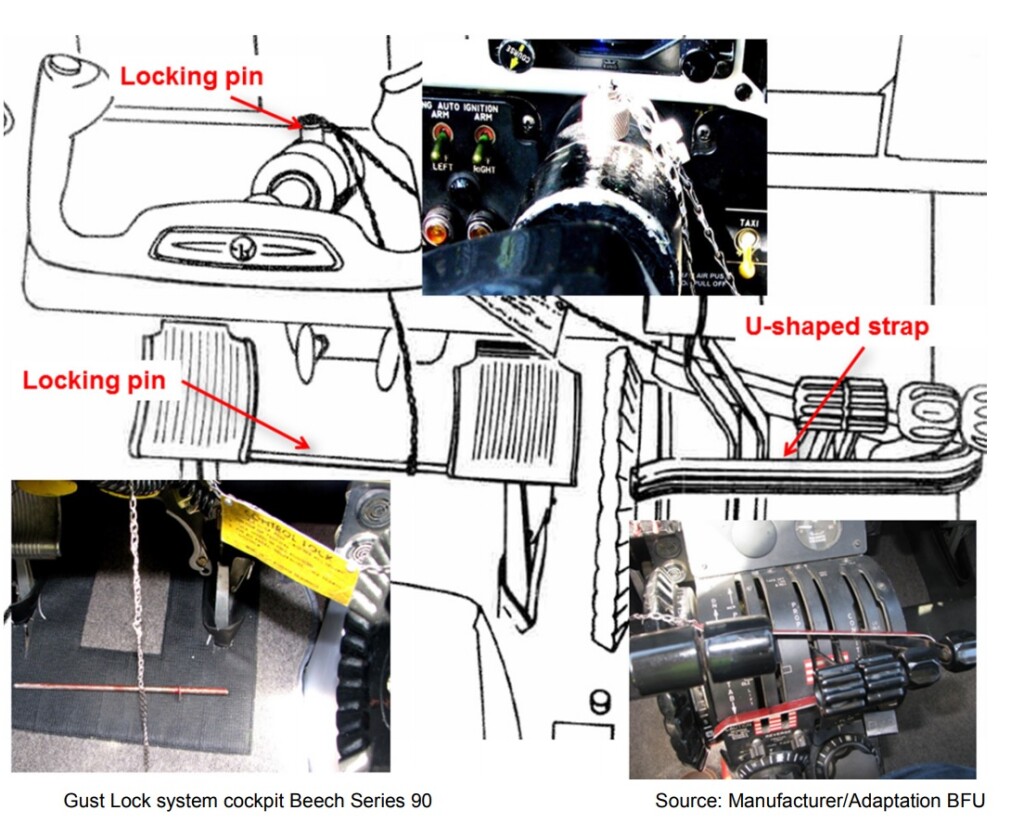

The King Air A90 has a Gust Lock System for use if the aircraft is parked for longer periods of time to prevent damage to the control surfaces due to movements caused by wind. The Pilot Operating Handbook says:

Positive locking of the rudder, elevator and aileron control surfaces, and engine controls (power levers, propeller levers, and condition levers) is provided by a removable lock assembly consisting of two pins and an elongated U-shaped strap interconnected by a chain.

Installation of the control locks is accomplished by inserting the strap over the aligned engine control levers from the copilot’s side; then the aileron-elevator locking pin is inserted through a guide hole in the top of the pilot’s control column assembly, thus locking the control wheels. The rudder pedals are held in the neutral position by the largest of the two pins, which is installed horizontally through the pilot’s rudder pedals. Removal sequence is a reverse of the installation procedure. […]

Caution Do not tow aircraft with rudder locks installed, as severe damage to the nose steering linkage can result. […]

The manufacture claim that these “…lock a combination of primary flight controls in positions that will preclude taxi…”.

The BFU note that (our emphasis added):

In the aircraft concerned the safety chain, which normally runs from the control column to the power lever to the pedals was missing. There was no warning flag on the safety pin for the rudder pedals. The original red paint was barely visible.

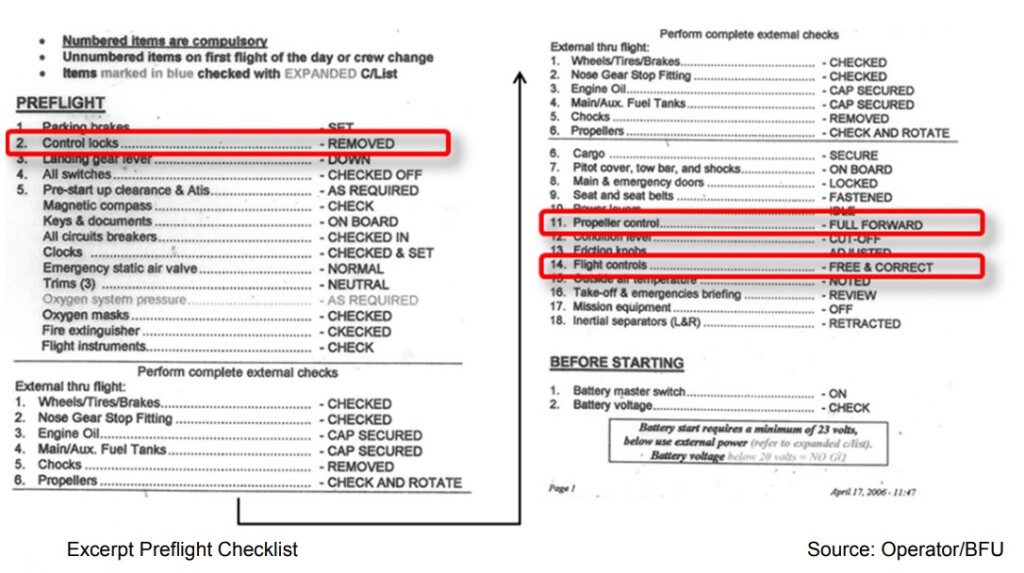

The A90 pre-flight checklist includes: (2) removal of control locks (but doesn’t specify how many), (11) checking propeller control movement and (14) the flying control ‘Free & Correct Movement’ check, verifying the control surface movement including their correct deflections. To complete (11) and (14) the locks have to been removed.

The BFU note that also:

After engine start-up, the Before Taxi Checklist listed the item Flight Controls – Checked/Free Movement, among other things. The pilot should check if control surfaces and rudder deflect correctly.

Gust locks have of course been left in place in the past. The manufacturer has issued a Safety Communiqué / Safety Reminder in March 2008 entitled “Safety reminder be sure Control Locks are removed prior Take-Off”:

Twenty-three accidents involving control locks – in planes produced by 10 different manufacturers – were reported by NTSB during the years 1964 through 1969 (only available records). So it is vital that pilots make absolutely certain they release control locks in any airplane. Although control lock removal is the pilot’s responsibility, we are always trying to find ways to improve safety. Therefore, we are doing something about the NTSB’s suggestion that all aviation manufacturers look at the type of gust control locks used to see if they can be made more fool-proof. We also feel that you, as an aircraft owner or operator, should be given the benefit of these findings and cautioned about being sure the control locks are removed.

In 1992 the gust locks had not been fully disengaged on a third-party DHC-4T Turbine Caribou conversion, N400NC, leading to a horrific fatal accident that killed 3.

The BFU reference one past gust lock accident that Aerossurance has previously examined: Gulfstream G-IV Take Off Accident & Human Factors. They mention two others:

In the case in Hannover, the BFU explain the pilot held a Commercial Transport Pilot’s Licence (CPL (A)) with ratings for Beech Aircraft BE 90/99/100/200 added on 20 January 2016. He had a total experience of 1,750 flying hours. Of which 95:35 hours were flown on the King Air 200 and just 1:15 hours on the King Air A90.

Approximately 3 weeks prior to the occurrence, the pilot received a familiarisation on the ground for this type with subsequent familiarisation flight. According to his statement, the aeroplane was pushed out of the hangar without the safety pins and prepared for the familiarisation flight. The pilot conducting the familiarisation did not point out the gust lock system. According to the PIC, on the day of the occurrence he had prepared the aeroplane for the first time alone for a flight.

For the departure from Hannover:

…when he entered the airplane, the safety pin had been in the control column and the safety element for power levers been in place.

These were removed successfully:

Due to the weak red colour and the missing safety chain he could not identify the safety pin in the rudder pedals. He had interpreted it as part of the rudder pedals. Therefore, he did not remove it and had operated the aeroplane with the safety pin in place between the rudder pedals.

BFU Conclusions

The serious incident, veering off the runway, was a result of loss of control during take-off run.

Directly Contributing Causes:

- The Gust Locks of the rudders were not removed prior to the take-off run.

- The Pedal Gust Lock pin was not sufficiently marked and the safety chain missing.

Indirectly Contributing Causes:

- The Preflight Checklist does not list the number of Gust Control Locks to be removed.

- The training of the Gust Lock system including the different rudder and power lever locks of the different aircraft types was insufficient.

Safety Advice

NTSB Safety Alert SA-048 Flight Control Locks: Overlooking the Obvious offered the following advice:

Errors of omission are frequently associated with interruptions, distractions, time pressures, divided attention, and complacency about standard operating procedures (SOPs).

So NTSB advise:

- Pilots of all experience levels should follow SOPs and use checklists, which serve as a memory aid to help counteract human performance vulnerabilities. Do not rely on memory alone.

- Recognize that procedural omissions are also common in many other types of accidents, including those involving gear-up landings, fuel starvation, incorrect fuel pump settings, and flap misconfigurations.

- Be prepared to abort the takeoff if something does not seem right. When a pilot is confronted with a sudden, abnormal event, responses are more likely to be delayed or inappropriate. Having a plan will help reduce reaction time and can result in a safer response.

- When flying alone, read the checklist aloud and touch the applicable switch or control. Research has shown that touching an object while verbally communicating enhances the probability that an activity has been accomplished.

- Avoid using improvised control lock devices that may be inconspicuous and easily overlooked during preflight checks.

And clearly too: Inspect your gust locks, record and rectify defects and degradations.

Safety Resources

We have discussed human factors and error management more generally here:

- Professor James Reason’s 12 Principles of Error Management

- Back to the Future: Error Management

- Rockets Sleds, Steamships and Human Factors: Murphy’s Law or Holt’s Law?

- Complacency: A Useful Concept in Safety Investigations?

- Also see our review of The Field Guide to Understanding Human Error by Sidney Dekker presented to the Royal Aeronautical Society (RAeS): The Field Guide to Understanding Human Error – A Review

Also see:

- C-130J Control Restriction Accident, Jalalabad

- Business Aviation Compliance With Pre Take-off Flight Control Checks

- Gulfstream G-IV Take Off Accident & Human Factors

- Fatal US G-IV Runway Excursion Accident in France – Lessons

- Execuflight Hawker 700 N237WR Akron Accident: Casual Compliance

- Unstabilised Approach Accident at Aspen

- Disorientated Dive into Lake Erie

- G-III Attempted Takeoff Using Runway Edge Lights as Centerline

- Wait to Weight & Balance – Lessons from a Loss of Control

- Business Jet Collides With ‘Uncharted’ Obstacle During Go-Around

- G200 Leaves Runway in Abuja Due to “Improper” Handling

- Cockpit Tensions and an Automated CFIT Accident

- Aborted Take Off with Brakes Partially On Results in Runway Excursion

- Global 6000 Crosswind Landing Accident – UK AAIB Report

- Luftwaffe VVIP Global 5000 Written Off After Flying Control Assembly Error

- Visual Illusions, a Non Standard Approach and Cockpit Gradient: Business Jet Accident at Aarhus

- ERJ-190 Flying Control Rigging Error

- Misassembled Anti-Torque Pedals Cause EC135 Accident

- Glider Controls Fail After Non Compliant Maintenance Embodying an AD

- Misrigged Flying Controls: Fatal Maintenance Check Flight Accident

- Too Rushed to Check: Misrigged Flying Controls

- FAA Rules Applied: So Misrigged Flying Controls Undetected

- UPDATE 4 October 2020: Investigators Suggest Cultural Indifference to Checklist Use a Factor in TAROM ATR42 Runway Excursion

- UPDATE 4 April 2021: Fatal 2019 DC-3 Turbo Prop Accident, Positioning for FAA Flight Test: Power Loss Plus Failure to Feather

Aerossurance was to have run two training workshops at the EHA European Rotors VTOL Show and Safety Conference in Cologne in November 2020 on a) Safety Culture and Leadership and b) Contracting Aviation Services: An Introduction to the Basics. Unfortunately these have been postponed due to COVID-19.

Recent Comments